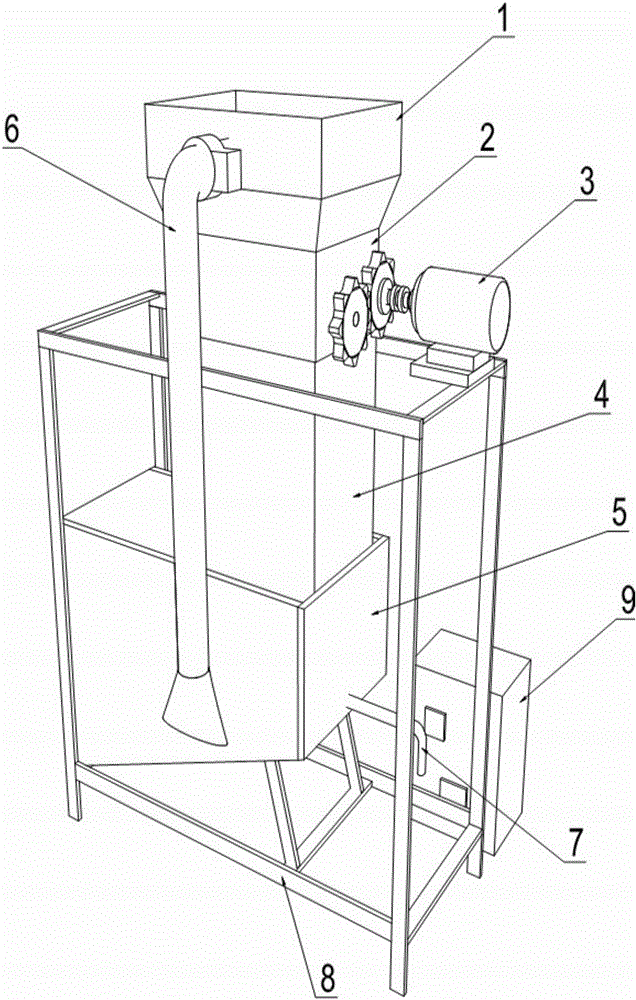

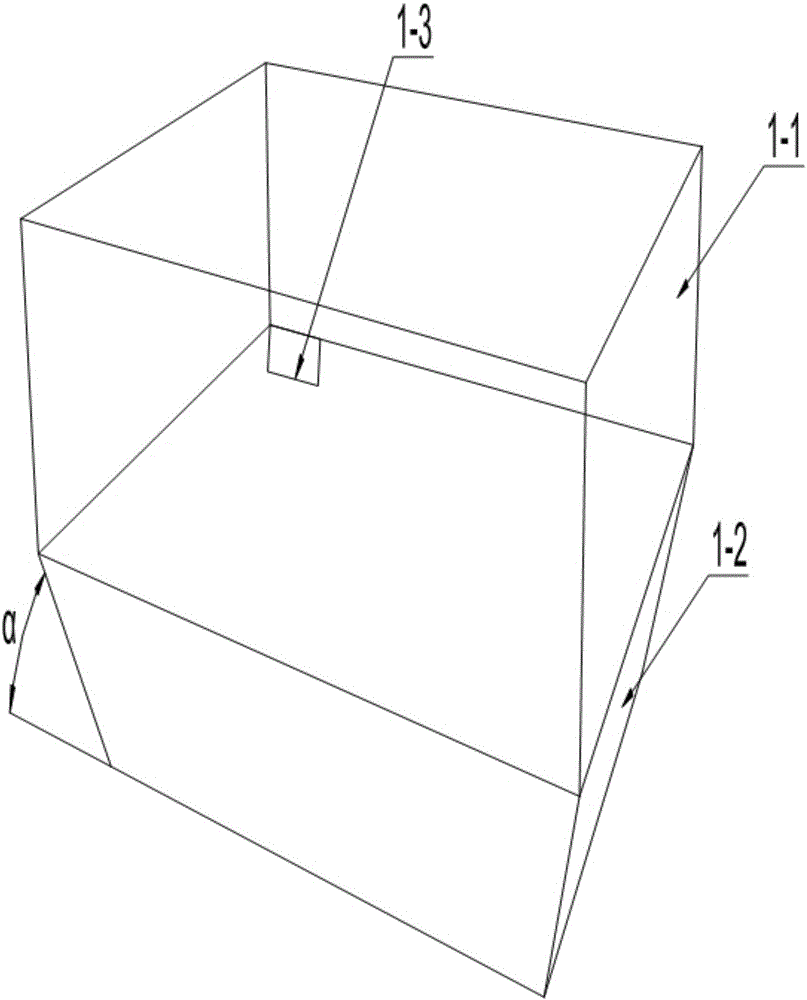

Crushing, compression and dehydration integrated device and working method thereof

A pulverizing device and pulverizing bin technology are used in drying solid materials, drying solid materials without heating, grain processing, etc., which can solve the problems of large space, time-consuming and labor-intensive for scrap materials, and achieve a simple, practical and applicable compression mechanism. Wide range, novel and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

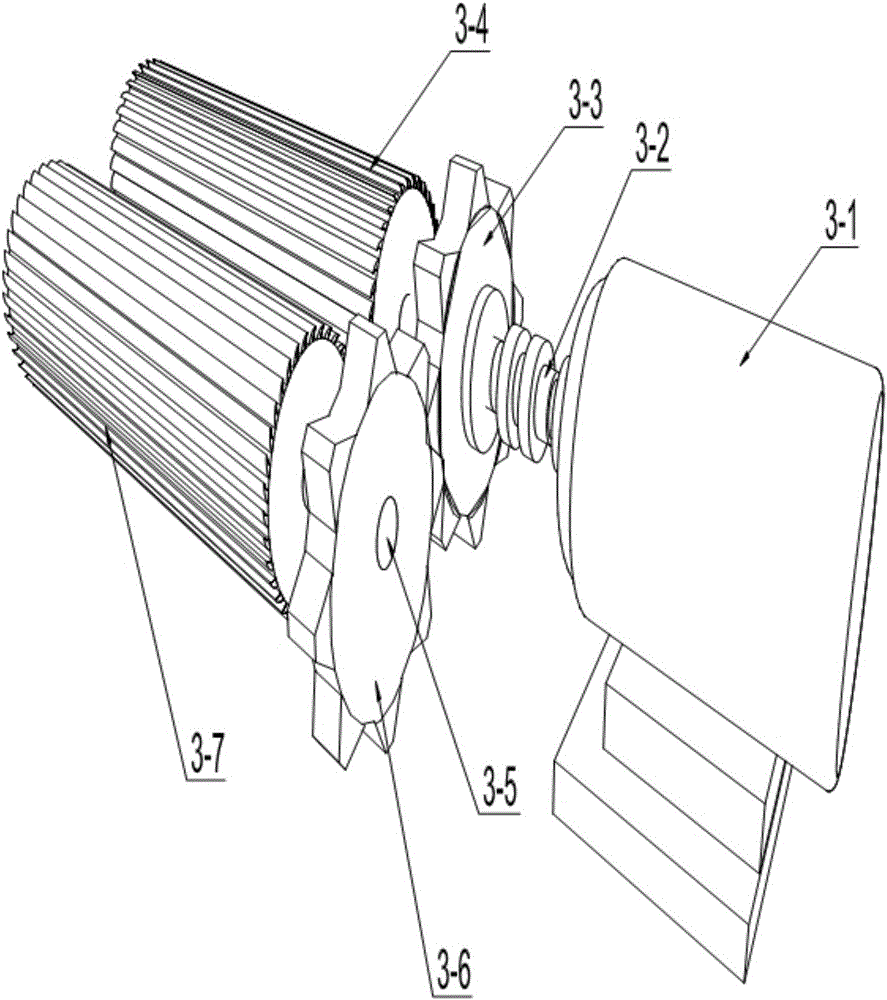

[0059] Follow the steps below to manufacture the crushing teeth 3-4-2 of the present invention in parts by weight:

[0060] Step 1. Add 500 parts of ultrapure water with a conductivity of 0.0005μS / cm into the reactor, start the agitator in the reactor at a speed of 135rpm, and start the heating pump to raise the temperature in the reactor to 45°C; add in sequence 2 parts of homeopathic dichloroethylene, 1 part of propylene oxide, 7 parts of o-nitrophenol, stirred until completely dissolved, adjusted the pH value to 3.0, adjusted the speed of the stirrer to 65 rpm, and the temperature was 40 ° C, and the esterification reaction was carried out for 2 hours;

[0061] Step 2, take 6 parts of o-toluic anhydride, 3 parts of p-aminophenol hydrochloride and pulverize, the powder particle size is 380 mesh; add 15 parts of o-nitrochlorobenzene and mix evenly, spread in the tray, the thickness of the tile is 18mm, irradiated with alpha rays with a dose of 1.55kGy and an energy of 1.55MeV...

Embodiment 2

[0066] Follow the steps below to manufacture the crushing teeth 3-4-2 of the present invention in parts by weight:

[0067] Step 1. Add 1000 parts of ultrapure water with a conductivity of 0.03μS / cm into the reactor, start the stirrer in the reactor at a speed of 180rpm, and start the heating pump to raise the temperature in the reactor to 70°C; 13 parts of homeopathic dichloroethylene, 15 parts of propylene oxide, and 19 parts of o-nitrophenol were stirred until completely dissolved, and the pH value was adjusted to 7.0. The speed of the stirrer was adjusted to 95 rpm, the temperature was 60 ° C, and the esterification reaction was carried out for 10 hours;

[0068] Step 2, take 20 parts of o-toluic anhydride, 15 parts of p-aminophenol hydrochloride and pulverize, the powder particle size is 650 mesh; add 30 parts of o-nitrochlorobenzene and mix evenly, spread it in the tray, the thickness of the laying is 45mm, irradiated with α-rays with a dose of 4.15kGy and an energy of 9...

Embodiment 3

[0073] Follow the steps below to manufacture the crushing teeth 3-4-2 of the present invention in parts by weight:

[0074] Step 1. Add 508 parts of ultrapure water with a conductivity of 0.00056μS / cm into the reactor, start the stirrer in the reactor at a speed of 138rpm, and start the heating pump to raise the temperature in the reactor to 49°C; add in sequence 9 parts of homeopathic dichloroethylene, 9 parts of propylene oxide, and 9 parts of o-nitrophenol were stirred until completely dissolved, and the pH value was adjusted to 3.9. The speed of the agitator was adjusted to 69 rpm, the temperature was 49 ° C, and the esterification reaction was carried out for 9 hours;

[0075] Step 2, take 9 parts of o-toluic anhydride, 9 parts of p-aminophenol hydrochloride and pulverize, the particle size of the powder is 389 mesh; add 19 parts of o-nitrochlorobenzene and mix evenly, spread it in the tray, the thickness of the laying is 19mm, irradiated with α-rays with a dose of 1.59kG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com