Airflow powder grinding system and powder treatment process

A treatment process and airflow technology, which is applied in the field of jet mill pulverization system and powder treatment process, can solve the problems of sticky particles clogging the nozzle, high powder crushing cost, and imprecise particle powder, so as to reduce the crushing cost and improve the screening efficiency And cleaning efficiency, improve the effect of crushing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

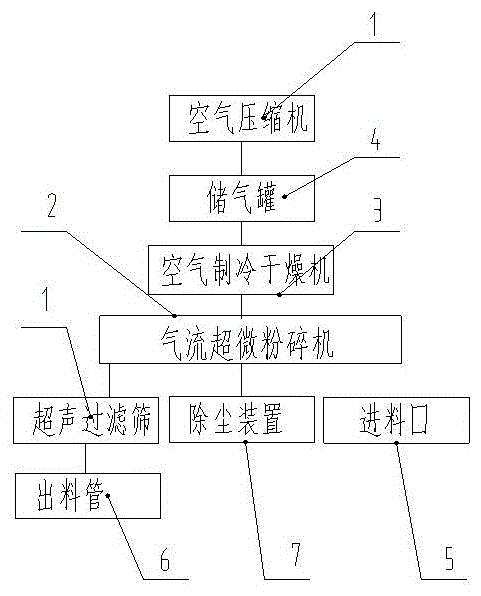

[0021] like figure 1 As shown, a jet mill powder system includes an air compressor 1 and a jet pulverizer 2 connected in sequence, an air refrigerator 3 is connected between the air compressor 1 and the jet pulverizer 2, and the air refrigerator The air inlet of 3 is connected to the air compressor 1, and the air outlet of the air refrigerator 3 is connected to the airflow ultrafine pulverizer 3; an air storage tank 4 is connected between the air compressor 1 and the air refrigerator 3, and the airflow ultrafine The pulverizer 3 is connected with a dust removal device 7;

[0022] The dust removal device 7 includes a gas outlet, which is used to purify the separated medium gas, and discharge the medium gas through the gas outlet to the gas intake port for recycling and continue to carry the sticky powder particles for pulverization .

[0023] The airflow ultrafine pulverizer 2 includes a crushing area and a classification area. The pulverization area is located at the bottom ...

Embodiment 2

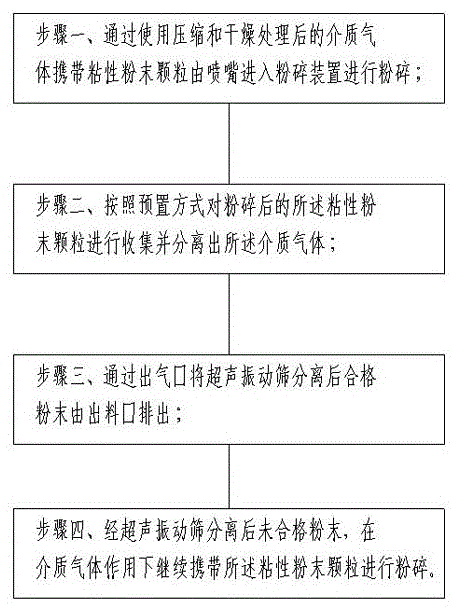

[0026] like figure 2 Shown, a kind of powder processing technology is characterized in that, comprises:

[0027] Step 1, using compressed and dried medium gas to carry cohesive powder particles from the nozzle into the crushing device for crushing;

[0028] Step 2, collecting the pulverized sticky powder particles according to a preset method and separating the medium gas;

[0029] Step 3. After the qualified powder is separated by the ultrasonic vibrating screen through the air outlet, the qualified powder is discharged from the outlet;

[0030] Step 4: After the unqualified powder is separated by the ultrasonic vibrating sieve, the viscous powder particles are continued to be crushed under the action of the medium gas.

[0031] Using the compressed and dried medium gas to carry sticky powder particles from the nozzle into the crushing device for crushing specifically includes: obtaining the medium gas in the space through the air intake port; compressing and drying the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com