Ceramic raw material crushing equipment with iron removal function

A technology of ceramic raw materials and crushing equipment, which is applied in the field of ceramic processing, can solve problems such as low crushing efficiency, insufficient crushing fineness, and no iron removal function, and achieve the effect of improving crushing efficiency and crushing effect, and improving crushing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

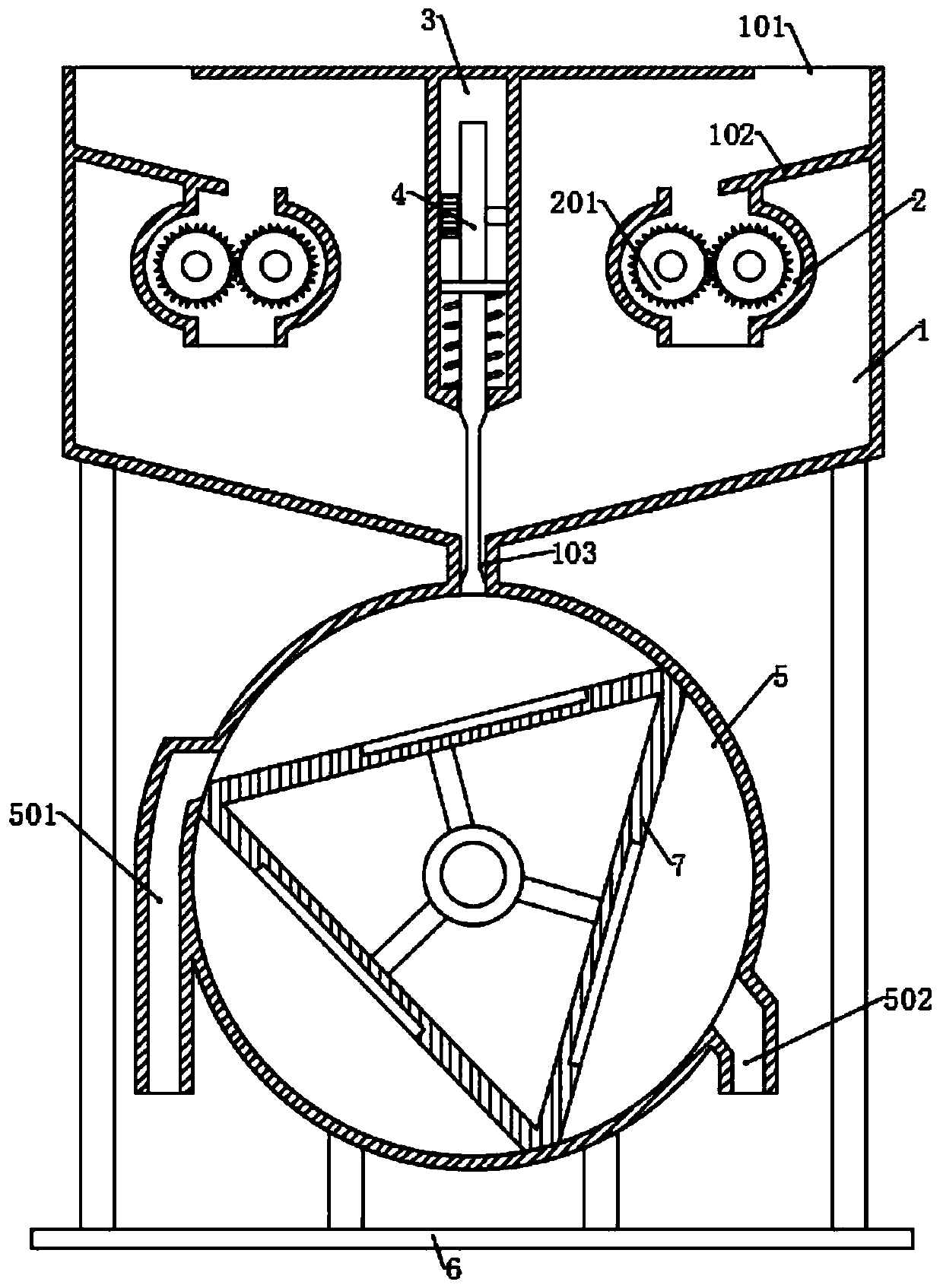

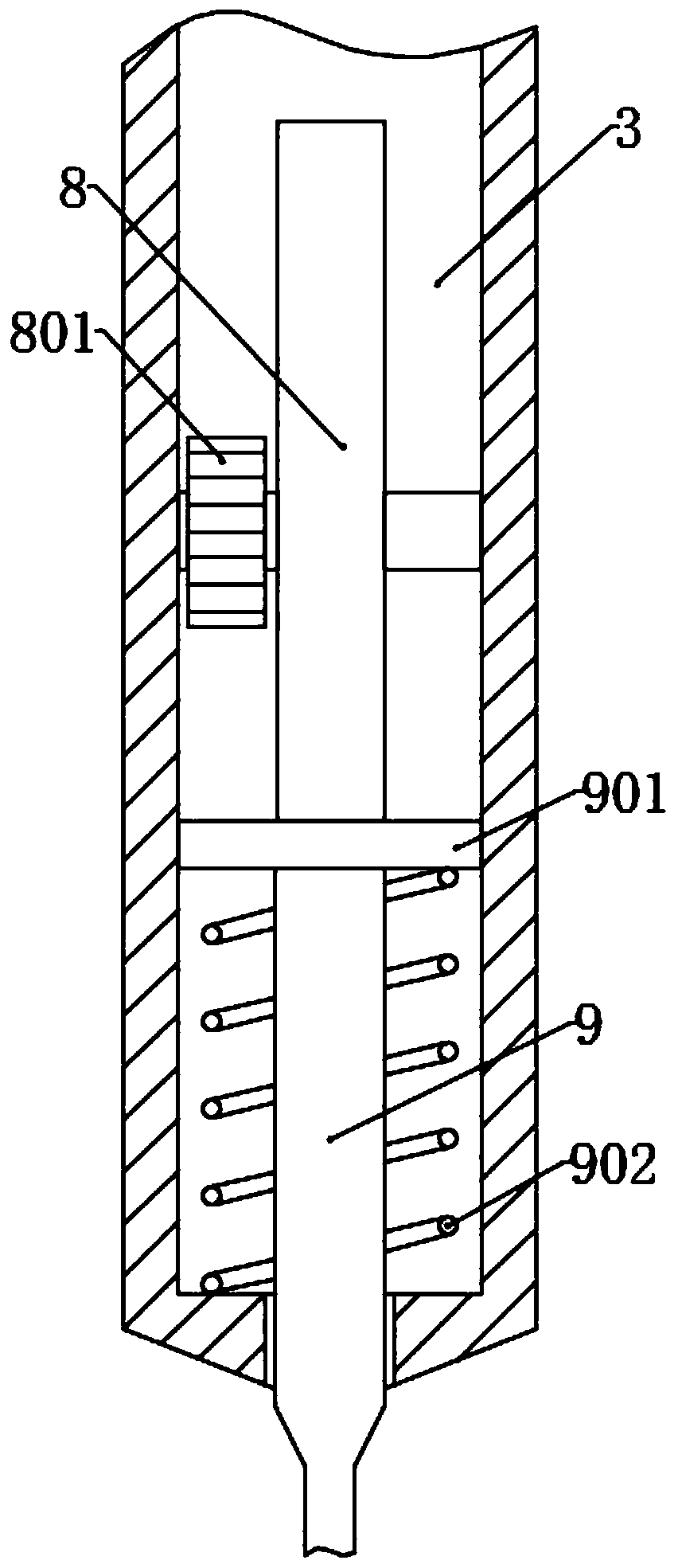

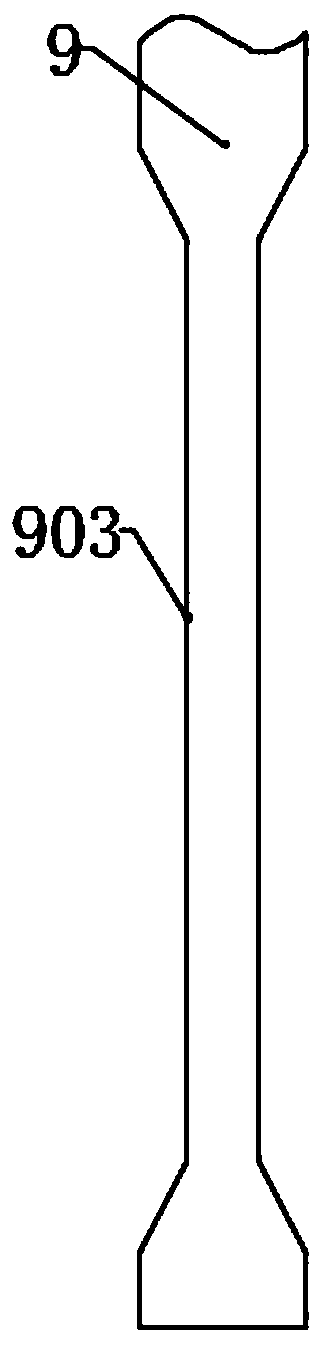

[0033] Please refer to the accompanying drawings, the present invention provides a technical solution: a ceramic raw material crushing equipment with iron removal function, including a base 6 fixedly arranged in sequence from bottom to top, iron removal box 5 and material storage box 1, material storage box 1 The upper part of the feed port 101 is provided with an inclined material guide plate 102 below the feed port 101. The first crushing chamber 2 is provided under the inner side of the material guide plate 102, and a crushing assembly is arranged in the first crushing chamber 2. 201, the middle upper part of the material storage box 1 is provided with a drive chamber 3, and the bottom is provided with a discharge port 103, the drive chamber 3 is provided with a blanking assembly 4, the blanking assembly 4 is correspondingly connected with the discharge port 103, and the iron removal box 5 It is a circular box, the top of which communicates with the discharge port 103, and t...

Embodiment 2

[0036] A ceramic raw material crushing device with the function of removing iron, comprising a base 6 fixedly arranged sequentially from bottom to top, an iron removal box 5 and a material storage box 1, the upper part of the material storage box 1 is provided with a feed port 101, and the feed port 101 The lower part of the material guide plate 102 is provided with an inclined material guide plate 102, the first crushing chamber 2 is provided under the inner end of the material guide plate 102, the crushing assembly 201 is provided in the first crushing chamber 2, and the middle upper part of the material storage box 1 is provided with a drive chamber 3. There is a discharge port 103 at the bottom, and a blanking assembly 4 is provided in the drive chamber 3. The blanking assembly 4 is connected to the discharge port 103 correspondingly. The iron removal box 5 is a circular box, and its top is connected to the discharge port 103 Connected, its center of circle is rotatably con...

Embodiment 3

[0043] A ceramic raw material crushing device with the function of removing iron, comprising a base 6 fixedly arranged sequentially from bottom to top, an iron removal box 5 and a material storage box 1, the upper part of the material storage box 1 is provided with a feed port 101, and the feed port 101 The lower part of the material guide plate 102 is provided with an inclined material guide plate 102, the first crushing chamber 2 is provided under the inner end of the material guide plate 102, the crushing assembly 201 is provided in the first crushing chamber 2, and the middle upper part of the material storage box 1 is provided with a drive chamber 3. There is a discharge port 103 at the bottom, and a blanking assembly 4 is provided in the drive chamber 3. The blanking assembly 4 is connected to the discharge port 103 correspondingly. The iron removal box 5 is a circular box, and its top is connected to the discharge port 103 Connected, its center of circle is rotatably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com