Preparation method of spherical microcrystalline graphite

A technology of microcrystalline graphite and spherical graphite, which is applied in graphite and grain processing, etc., can solve the problems of incomplete pulverization, low sphericity and low purity of spherical graphite, and achieve increased tap density, increased purity, and reduced specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

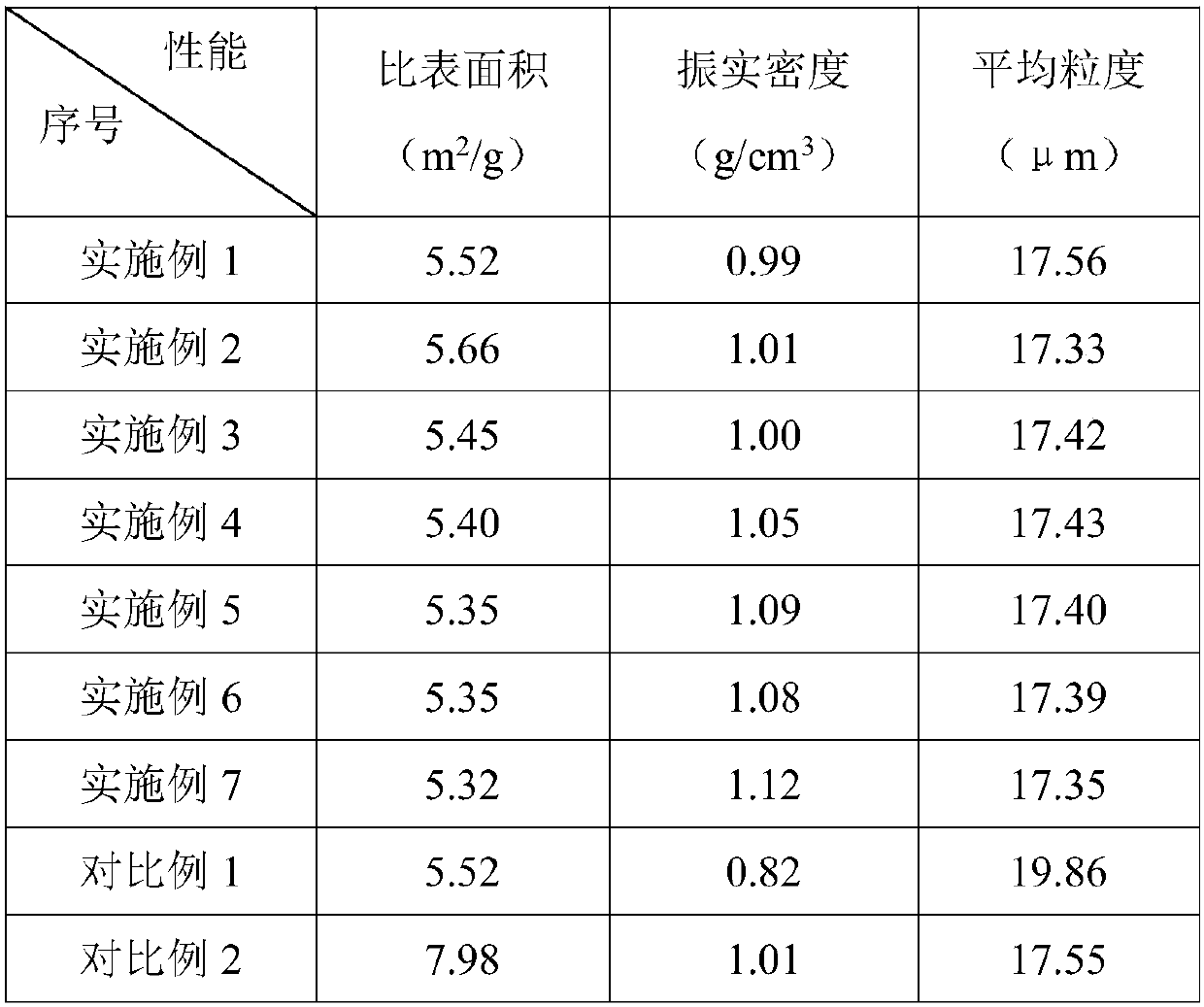

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of spherical microcrystalline graphite, comprises the following steps:

[0032] S1. Pretreatment: use microcrystalline graphite as raw material, obtain its dry concentrate after flotation, and then use a shearing machine for pretreatment with a power of 5KW and a rotating speed of 2500r / min to obtain coarsely crushed microcrystalline graphite;

[0033] S2. Shaping: the coarsely crushed microcrystalline graphite obtained in step S1 is finely crushed in the first pulverizer, the rotating speed of the first pulverizer is 2000r / min, and then the first classification, magnetic separation and second classification are carried out, The rotating speeds of the first classifier and the second classifier are respectively 1800r / min and 2000r / min to obtain the initial product of spheroidized graphite;

[0034] S3. Purification: the spherical graphite initial product obtained in step S2, after dedusting treatment, adopts 30...

Embodiment 2

[0038] This embodiment provides a method for preparing spherical microcrystalline graphite. The difference from Embodiment 1 is that in step S1, the power of the shearing machine is 8KW, and the rotation speed is 1500r / min.

Embodiment 3

[0040] This embodiment provides a method for preparing spherical microcrystalline graphite. The difference from Embodiment 1 is that in step S1, the power of the shearing machine is 6KW, and the rotation speed is 2000r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com