A system for producing spherical microcrystalline graphite

A technology of microcrystalline graphite and production system, applied in the fields of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of low purity of spherical graphite and complicated production process of spherical graphite, so as to improve the purity, speed up the purification reaction, reduce the The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

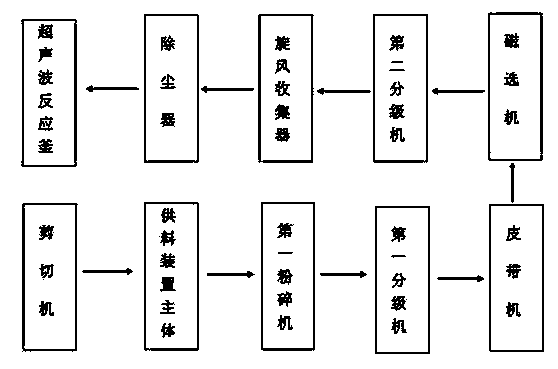

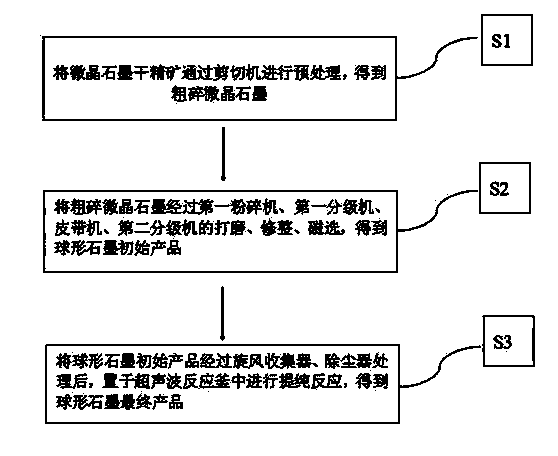

[0047] Such as Figure 1~4 As shown, the spheroidized microcrystalline graphite production system provided in this embodiment includes a pretreatment unit, a shaping unit and a purification unit in sequence of production;

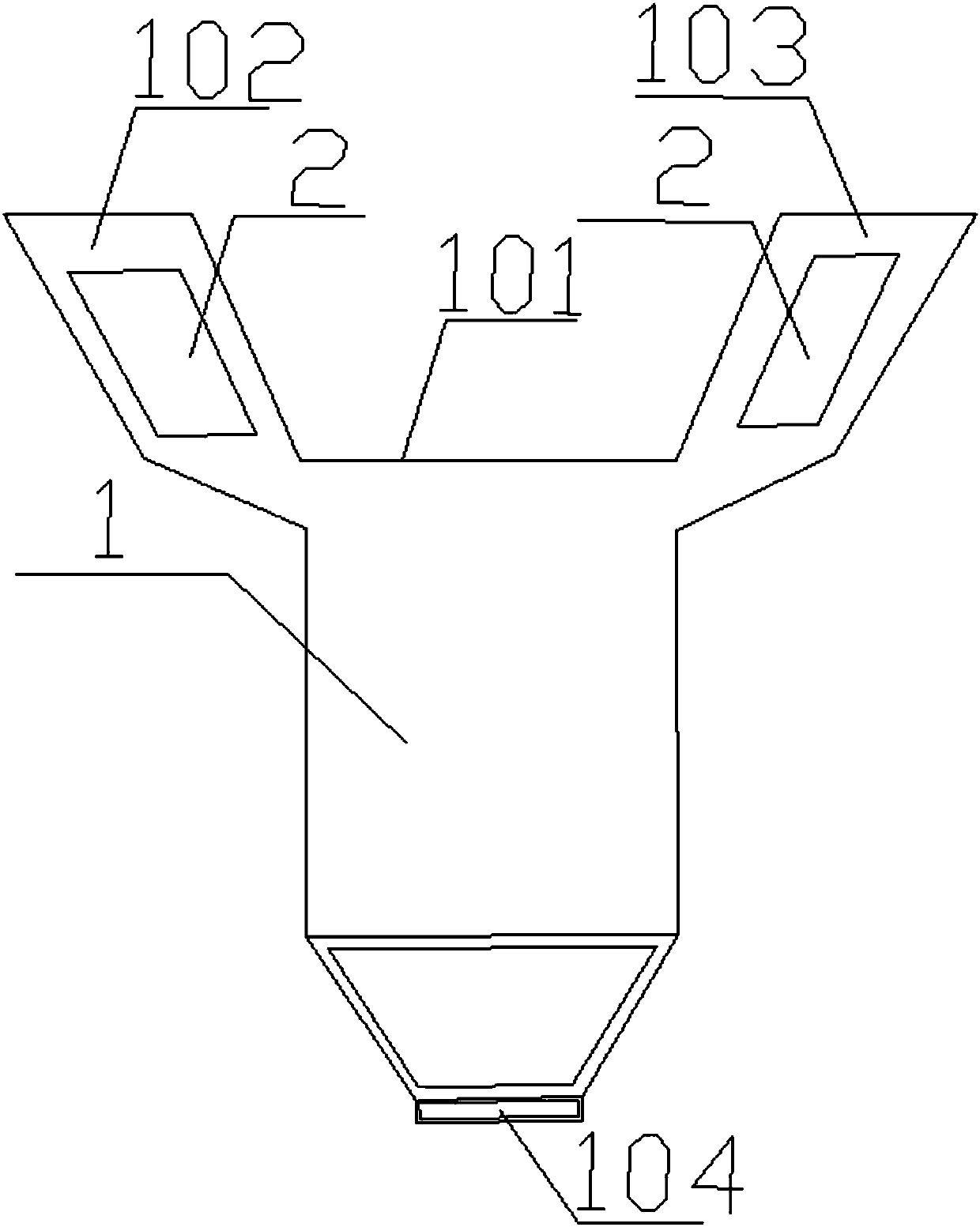

[0048] Such as image 3 As shown, the pretreatment unit includes a feeding device 1, and the feeding device 1 includes a feeding device main body 101 and a first feeding port 102 and a second feeding port 103 arranged at both ends of the feeding device 1 main body. The inclination angle of the feed port 102 and the second feed port 103 is 40°~60°, the first feed port 102 and the second feed port 103 are also provided with a shearer 2, and the feeding device 1 also includes The discharge port 104 arranged at the lower end of the main body 101 of the feeding device;

[0049] The shaping unit includes a secondary spheroidizing device. The secondary spheroidizing device includes a first pulverizer, a first classifier, a belt conveyor, and a second classifier ...

Embodiment 2

[0061] The spheroidized microcrystalline graphite production system provided by this embodiment is different from that of Example 1 in that in step S3, the equipment parameters of the ultrasonic reactor are as follows: the frequency is 20KHz, the power is 2000W, the time is 30min, and the acidic aqueous solution is Hydrofluoric acid, the volume content of the hydrofluoric acid is 50%, the liquid-solid ratio of the hydrofluoric acid and the material is 2:1, the temperature of the purification reaction is 60°C, and the reaction time is 2h.

Embodiment 3

[0063] The spheroidized microcrystalline graphite production system provided in this embodiment is different from that of Example 1 in that in step S3, the equipment parameters of the ultrasonic reactor are as follows: the frequency is 50KHz, the power is 1800W, the time is 20min, and the acidic aqueous solution is Hydrofluoric acid, the volume content of the hydrofluoric acid is 40%, the liquid-solid ratio of the hydrofluoric acid and the material is 3:1, the temperature of the purification reaction is 50°C, and the reaction time is 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com