Fluorocarbon film rubber plug

A technology of rubber stopper and fluorocarbon film, which is applied in the types of packaging items, special packaging items, packaging, etc., can solve the problems of complex production process, difficult to uniform film formation on the surface of rubber stopper, and film peeling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The fluorocarbon film rubber plug in this embodiment includes a rubber plug body, the surface of the rubber plug body is completely covered with a fluorocarbon polymer film, and the rubber plug body and the fluorocarbon polymer film are integrated by physical and / or chemical bonding In one piece, there is no adhesive in between.

[0025] The carbon atom content in the fluorocarbon polymer film is 30-50%, and the fluorine atom content is 50-70%.

[0026] The thickness of the fluorocarbon polymer film is about 1 μm.

[0027] Manufacturing method of fluorocarbon film rubber stopper:

[0028] Clean and dry the surface of the ordinary rubber plug body, and then place it in the deposition chamber of the plasma-enhanced chemical vapor deposition (PECVD) equipment and vacuumize it to 1??10 -1 Below Pa. When the deposition chamber temperature rises rapidly to 100 o After C, feed C with a flow rate of 50~100sccm 4 f 8 Gas; adjust the air pressure in the deposition chamber ...

Embodiment 2

[0030] The fluorocarbon film rubber plug in this embodiment includes a rubber plug body, the surface of the rubber plug body is completely covered with a fluorocarbon polymer film, and the rubber plug body and the fluorocarbon polymer film are integrated by physical and / or chemical bonding In one piece, there is no adhesive in between.

[0031] The carbon atom content in the fluorocarbon polymer film is 20-35%, the fluorine atom content is 35-55%, the hydrogen atom content is 10-15%, and the silicon atom content is 1-3%.

[0032] The thickness of the fluorocarbon polymer film is about 1 μm.

[0033] Method for manufacturing fluorocarbon polymer stoppers

[0034]Clean and dry the surface of ordinary rubber stoppers, and then place them in the deposition chamber of plasma enhanced chemical vapor deposition (PECVD) equipment and vacuumize to 1??10 -1 Below Pa. When the deposition chamber temperature rises rapidly to 170 o After C, first feed a certain proportion of CF 4 an...

Embodiment 3

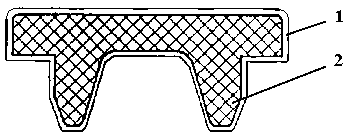

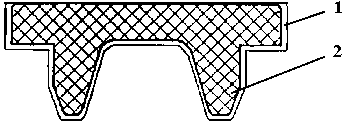

[0036] Fluorocarbon membrane rubber stopper in the present embodiment is as figure 1 As shown, including the rubber plug body, the surface of the rubber plug body is covered with a fluorocarbon polymer film, and the rubber plug body and the fluorocarbon polymer film are integrated into one body by physical and / or chemical bonding, and there is no glue in between agent.

[0037] The content of carbon atoms in the fluorocarbon polymer film is 25-45%, the content of fluorine atoms is 45-60%, the content of oxygen atoms is 4-6%, and the content of nitrogen atoms is 1-3%.

[0038] The thickness of the fluorocarbon polymer film is about 0.5 μm.

[0039] Manufacturing method of fluorocarbon film rubber stopper:

[0040] Place the ordinary rubber stopper in the deposition chamber of the inductively coupled plasma chemical vapor deposition (ICP-CVD) equipment and evacuate to 1??10 -2 Below Pa, C with a flow rate of 50~65sccm 4 f 8 Gas and 5~15sccm N 2 O gas; adjust the air pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com