Gallium-nitride-based film on graphene-modified patterned metal substrate and preparation method

A graphene modification, metal substrate technology, applied in metal material coating process, gaseous chemical plating, plating of superimposed layers, etc., can solve problems such as low dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

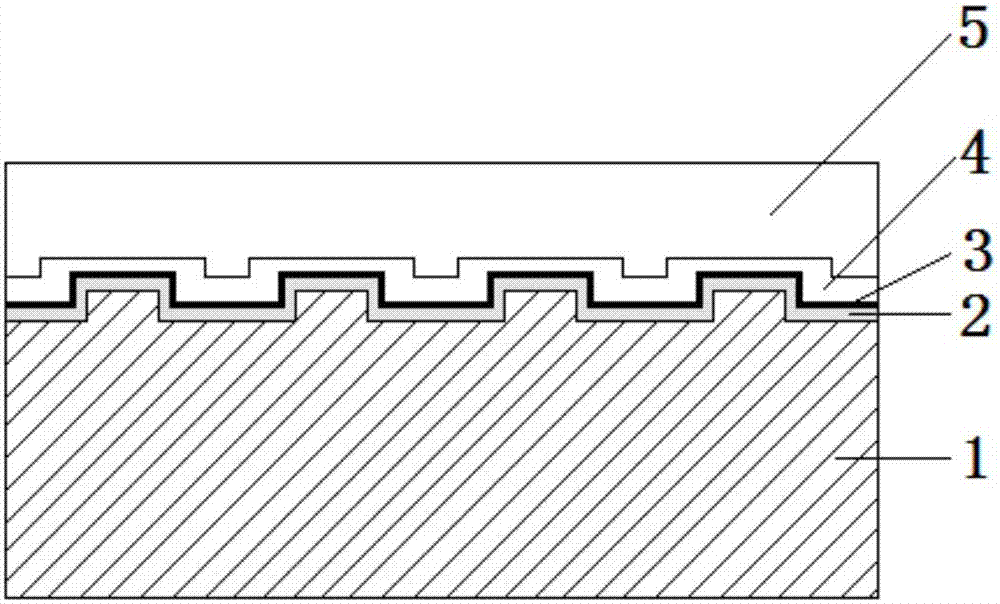

[0045] One of the embodiments, as attached figure 1 , as shown in 2, 3.

[0046] The substrate is a patterned Ti substrate 1. The periodic pattern on the patterned Ti substrate 1 is prepared by photolithography and plasma dry etching on one side of the 1mm thick Ti plate. The periodic pattern is formed by Constructed of raised cylinders arranged in a hexagonal lattice, the diameter of each cylinder is 2 μm, the height of the cylinder is 0.5 μm, and the axial distance between the nearest adjacent cylinders is 4 μm.

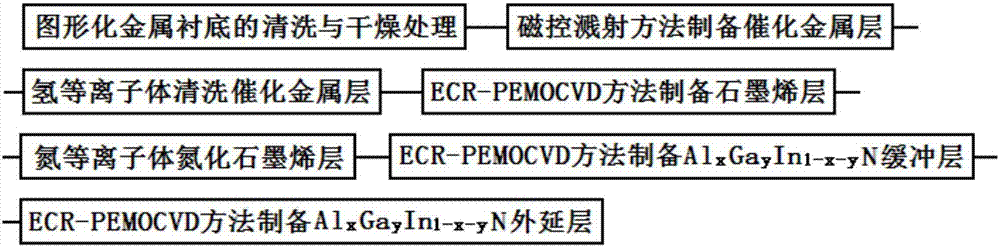

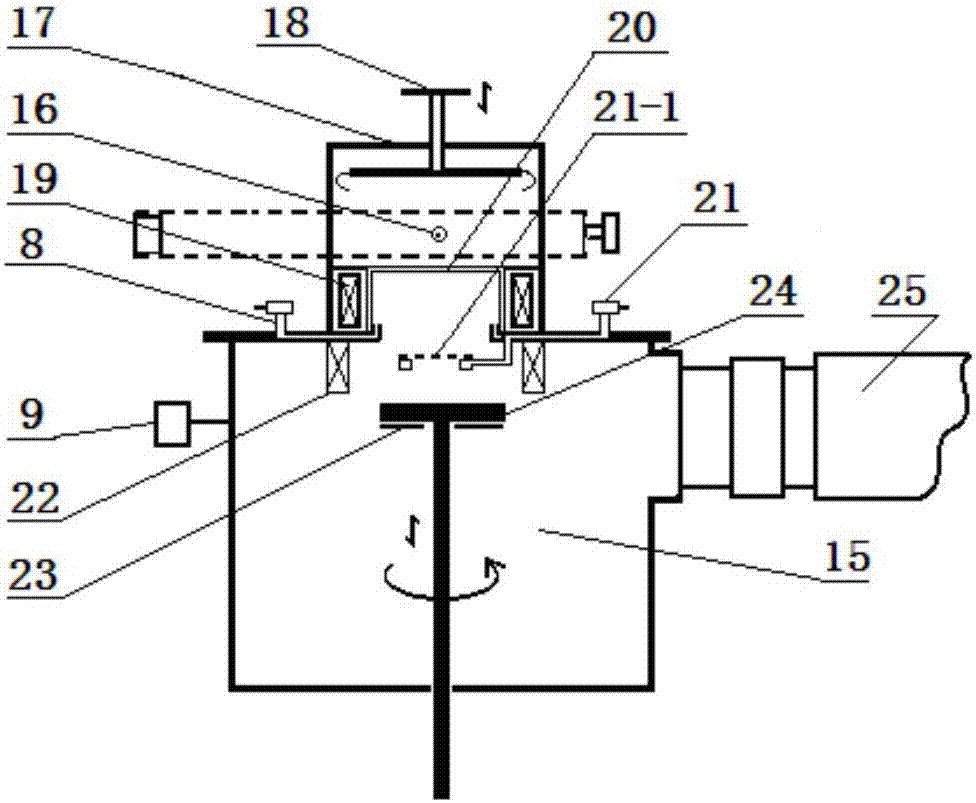

[0047] A method using magnetron sputtering equipment and ECR-PEMOCVD equipment (invention patent: ZL201210247144.8), prepared at low temperature on the above-mentioned patterned Ti substrate 1 as attached figure 1 Al shown 0.40 Ga 0.50 In 0.10 The continuous process steps of N thin film are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com