A kind of preparation method of high-efficiency ZNO-based dye-sensitized solar cell photoanode and the photoanode it makes

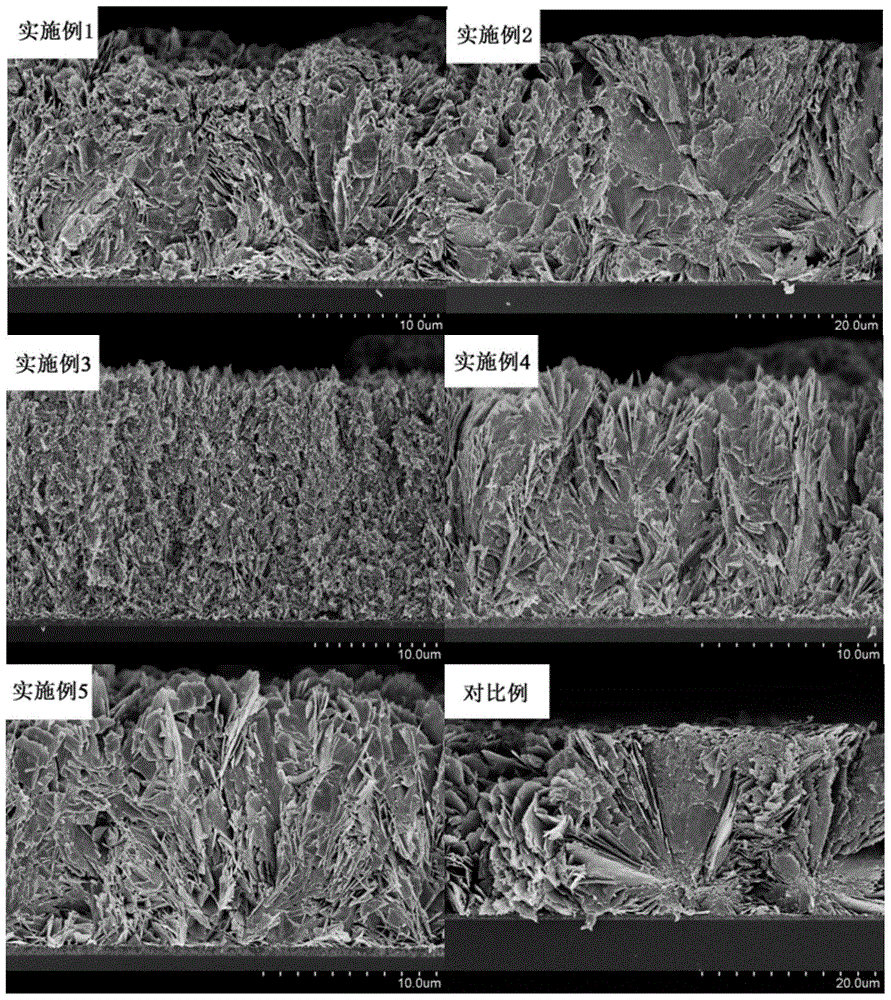

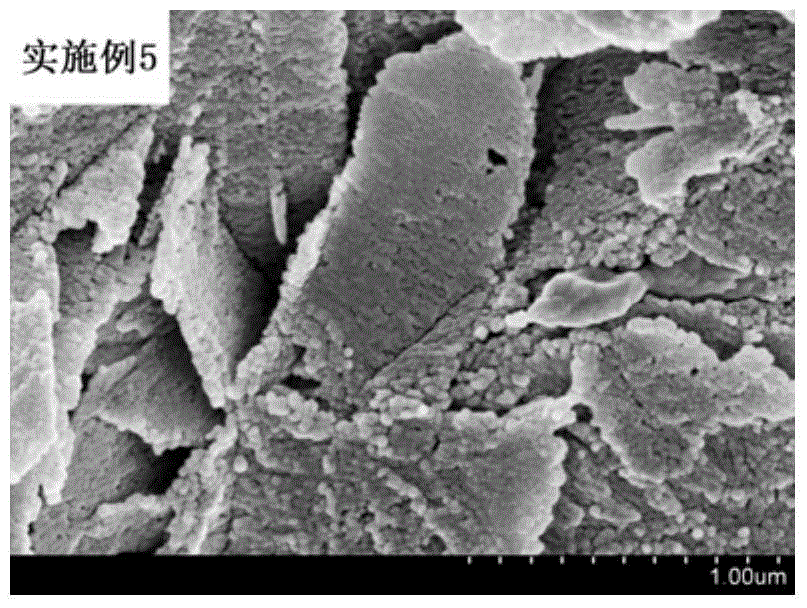

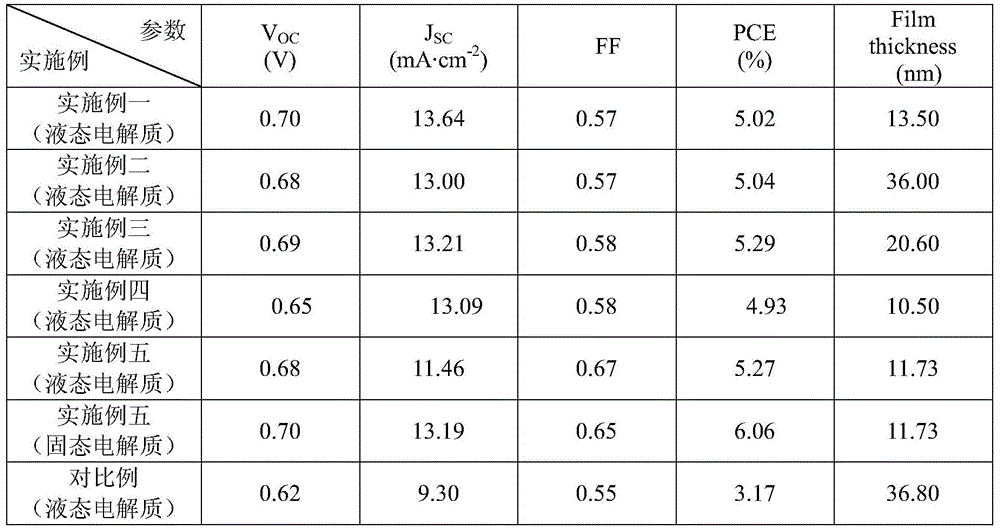

A technology for solar cells and dye sensitization, applied in the field of photoanode, dye-sensitized solar cell ZnO-based photoanode preparation, can solve the problems of uneven film, sparse arrangement of nanosheets, unsatisfactory photoelectric conversion efficiency, etc. The effect of film inhomogeneity, reduction of roughness, and tight arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the high-efficiency ZnO-based dye-sensitized solar cell photoanode in this embodiment, the steps are as follows:

[0037] (1) Preparation of ZnO sol

[0038] Put 50ml of ethylene glycol methyl ether solution on a magnetic stirrer and stir, and add 4.39g of zinc acetate dihydrate and 1.20ml of monoethanolamine while stirring, and stir at 25°C for 10h to obtain a transparent ZnO sol ; The concentration of zinc acetate dihydrate and monoethanolamine in ethylene glycol methyl ether solution is 0.4M;

[0039] (2) Preparation of ZnO dense barrier layer

[0040] Using the impregnation method, the cleaned conductive substrate was immersed in the above-mentioned ZnO sol, and the conductive substrate was taken out at a uniform speed after 4s; Calcined in a muffle furnace, the calcination temperature is 450°C, and the holding time is 30min, so that the ZnO dense barrier layer is coated on the conductive substrate; the heating rate of drying and calcinatio...

Embodiment 2

[0047] The preparation method of the high-efficiency ZnO-based dye-sensitized solar cell photoanode in this embodiment, the steps are as follows:

[0048] (1) Preparation of ZnO sol

[0049] Put 50ml of ethylene glycol methyl ether solution on a magnetic stirrer and stir, and add 4.39g of zinc acetate dihydrate and 1.20ml of monoethanolamine while stirring, and stir at 25°C for 10h to obtain a transparent ZnO sol The concentration of zinc acetate dihydrate and monoethanolamine in ethylene glycol methyl ether solution is 0.4M;

[0050] (2) Preparation of ZnO dense barrier layer

[0051] Using the impregnation method, the cleaned conductive substrate was immersed in the above-mentioned ZnO sol, and the conductive substrate was taken out at a uniform speed after 4s; Calcined in a muffle furnace, the calcination temperature is 450°C, and the holding time is 30min, so that the ZnO dense barrier layer is coated on the conductive substrate; the heating rate of drying and calcinatio...

Embodiment 3

[0058] (1) Preparation of ZnO sol

[0059] Put 50ml of ethylene glycol methyl ether solution on a magnetic stirrer and stir, and add 4.39g of zinc acetate dihydrate and 1.20ml of monoethanolamine while stirring, and stir at 25°C for 10h to obtain a transparent ZnO sol ; The concentration of zinc acetate dihydrate and monoethanolamine in ethylene glycol methyl ether solution is 0.4M;

[0060] (2) Preparation of ZnO dense barrier layer

[0061] Using the impregnation method, the cleaned conductive substrate was immersed in the above-mentioned ZnO sol, and the conductive substrate was taken out at a uniform speed after 4s; Calcined in a muffle furnace, the calcination temperature is 450°C, and the holding time is 30min, so that the ZnO dense barrier layer is coated on the conductive substrate; the heating rate of drying and calcination is 8°C / min;

[0062] (3) Preparation of ZnO nanosheet films on vertical conductive substrates

[0063] (3-1) Preparation of Growth Solution

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com