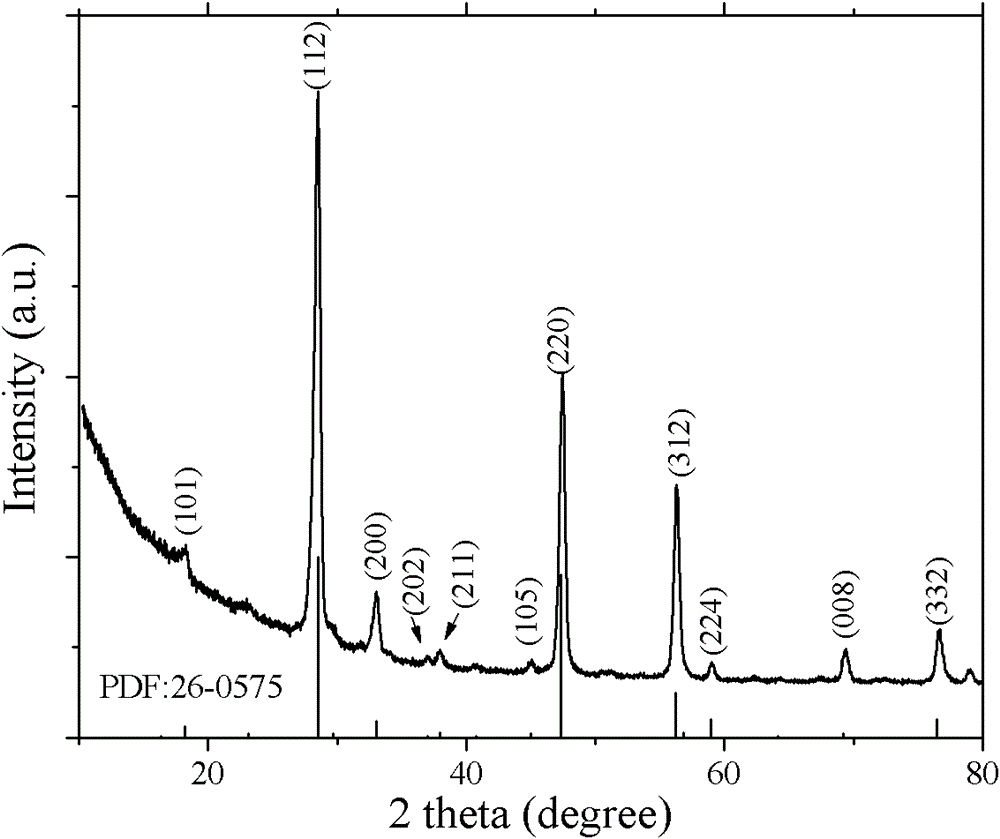

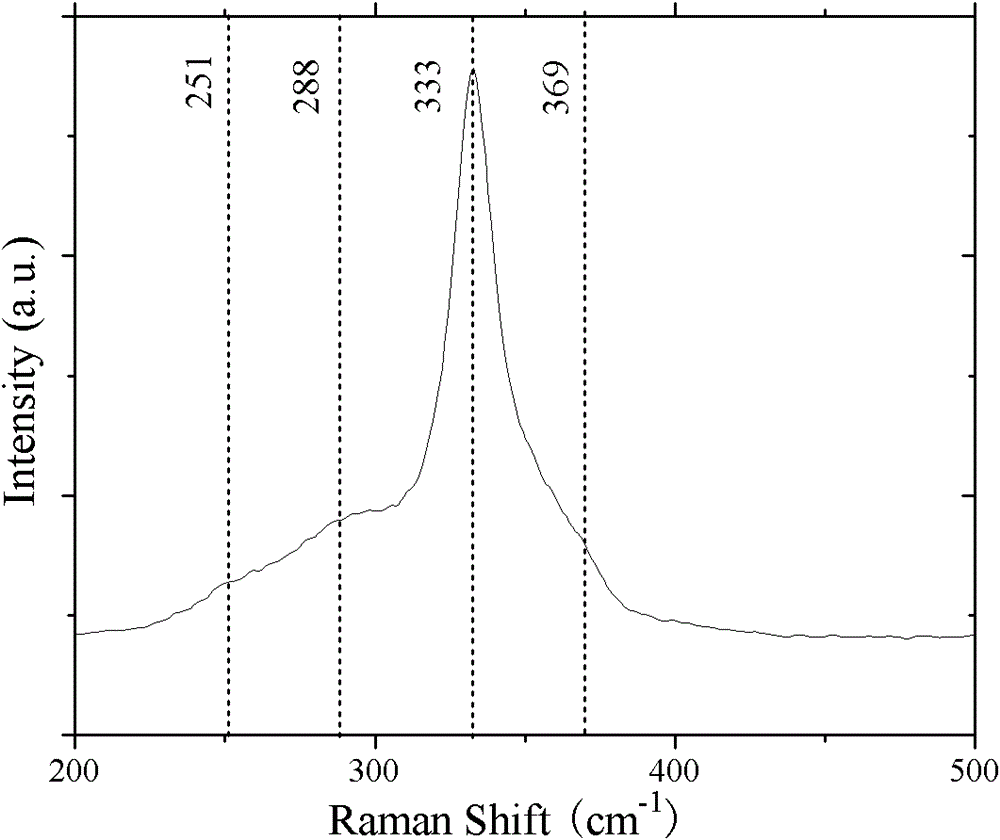

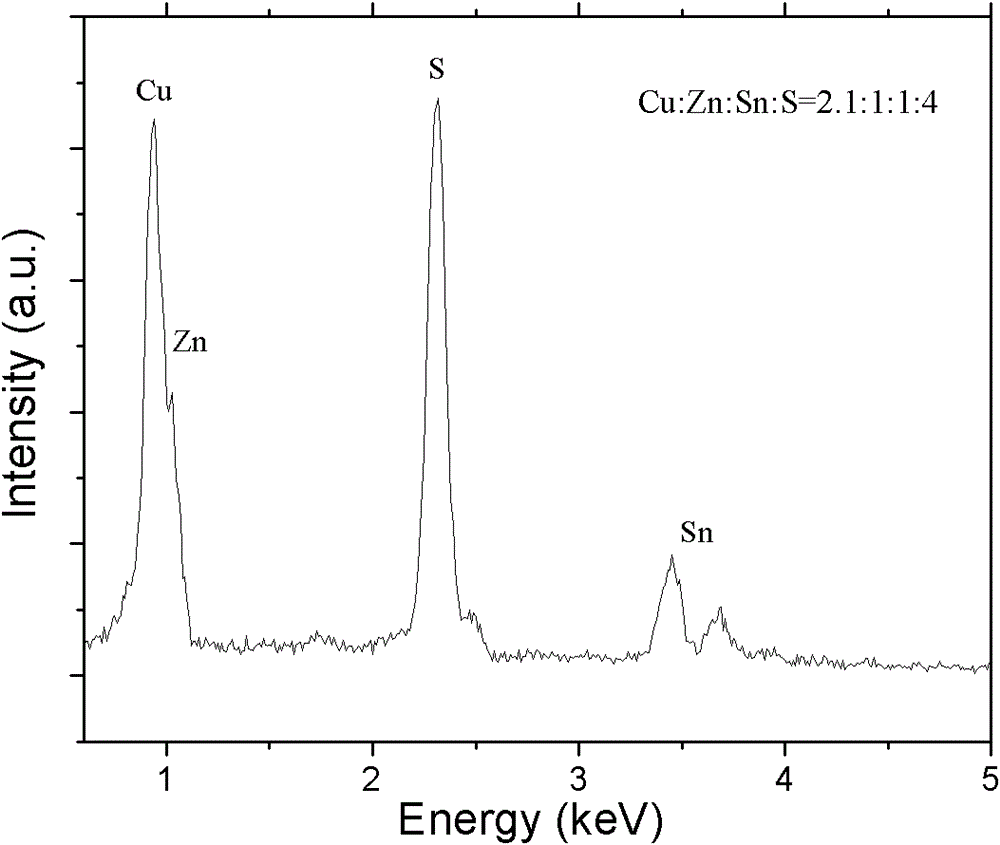

Low cost solution method for preparing solar cell absorption layer material Cu2ZnSnS4

A solar cell, absorber layer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1). First, the surface of the substrate is cleaned. The molybdenum-coated glass substrate is ultrasonically cleaned with acetone, alcohol and deionized water for 10 minutes in sequence. The cleaned substrate can be used directly without drying. Subsequently, a copper-tin-containing binary or ternary sulfide mixed film is prepared on the substrate by adsorption deposition of continuous ion layers. Analytical pure stannous chloride (SnCl 2 2H 2 O) and copper chloride (CuCl 2 2H 2 (0) is configured into a cation mixed solution with a concentration of 0.025 M and 0.05 M, and its pH value is 5; then use analytically pure sodium sulfide (Na 2 S·9H 2 O) It is configured as a 0.05 M anion solution with a pH value of 14. Place 4 beakers in a row, inside which are respectively placed a cation mixed solution containing copper chloride and stannous chloride, deionized water, an anion solution containing sodium sulfide, and deionized water. Each cup corresponds to the continuo...

Embodiment 2

[0045] (1). By the method described in embodiment 1, the purity of all raw materials used is all the same, and here substrate is conductive glass. Among them, continuous ion layer adsorption deposition is used to prepare binary or ternary sulfide mixed films containing copper and tin on the substrate. Wherein the cationic solution is a mixed solution of copper sulfate and stannous sulfate. The concentrations of copper sulfate and stannous sulfate were 0.04 M and 0.08 M, respectively. Potassium sulfide solution was used as anion solution with a concentration of 0.1 M. The pH values of the cation solution and the anion solution are 3 and 14 respectively, and the adsorption, washing, reaction and washing times in one cycle of continuous ion layer adsorption deposition are 60s, 120s, 60s, 120s respectively, and the deposition cycle is 40 cycles.

[0046] (2). Use a chemical bath to deposit a layer of ZnS film on the surface of the film. The deposition solution used a mixed so...

Embodiment 3

[0049] (1). According to the method described in Example 1, the purity of all raw materials used is the same, and the substrate here is metal foil. Subsequently, a copper-tin-containing binary or ternary sulfide mixed film is prepared on the substrate by adsorption deposition of continuous ion layers. Wherein the cation solution uses a mixed solution of copper acetate and tin protochloride. The concentrations of copper acetate and stannous chloride were 0.02 M and 0.04 M, respectively. The anion solution uses ammonium sulfide solution with a concentration of 0.02 M. The pH values of the cation solution and the anion solution were 5 and 14 respectively, and the adsorption, washing, reaction and washing times in one cycle of continuous ion layer adsorption deposition were 60s, 120s, 60s, 120s, respectively, and the deposition cycle was 80 cycles.

[0050] (2). Use a chemical bath to deposit a layer of ZnS film on the surface of the film. As the deposition solution, a mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com