A Plasma Flow Control Device for Drag Reduction of Airships in Near Space

A technology of flow control and plasma, applied in the direction of rigid spacecraft, etc., can solve the problems of large surface area of the hull, drag reduction, plasma intensity, limited area, etc., and achieve reduced airship resistance, high density, and large plane area uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

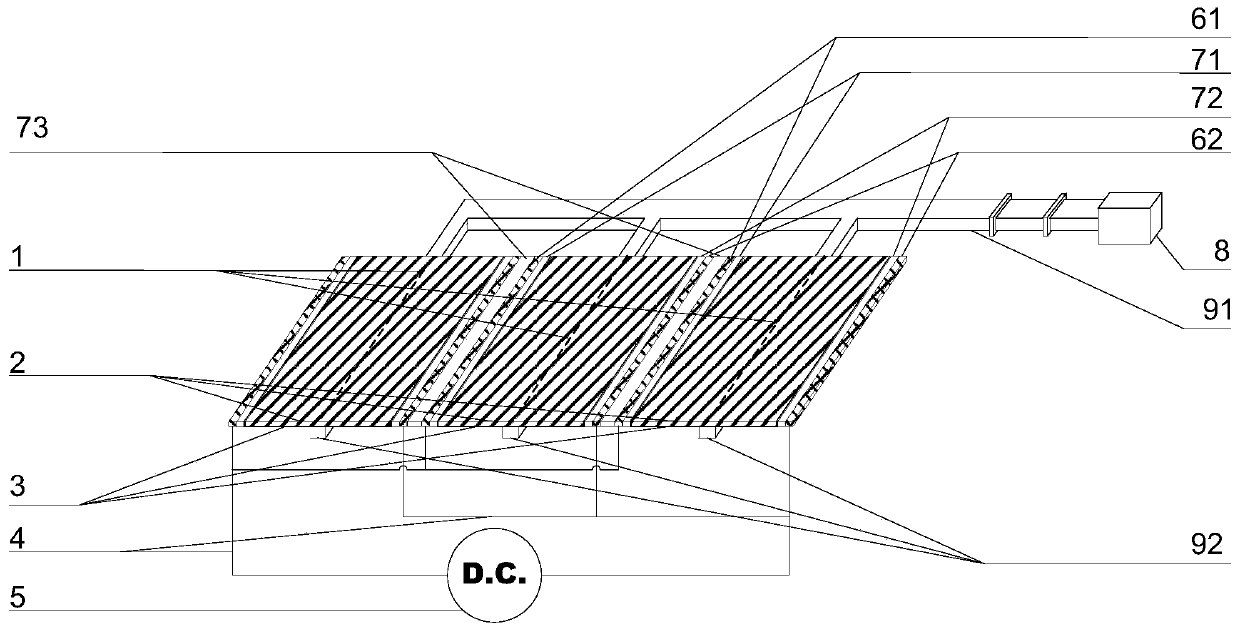

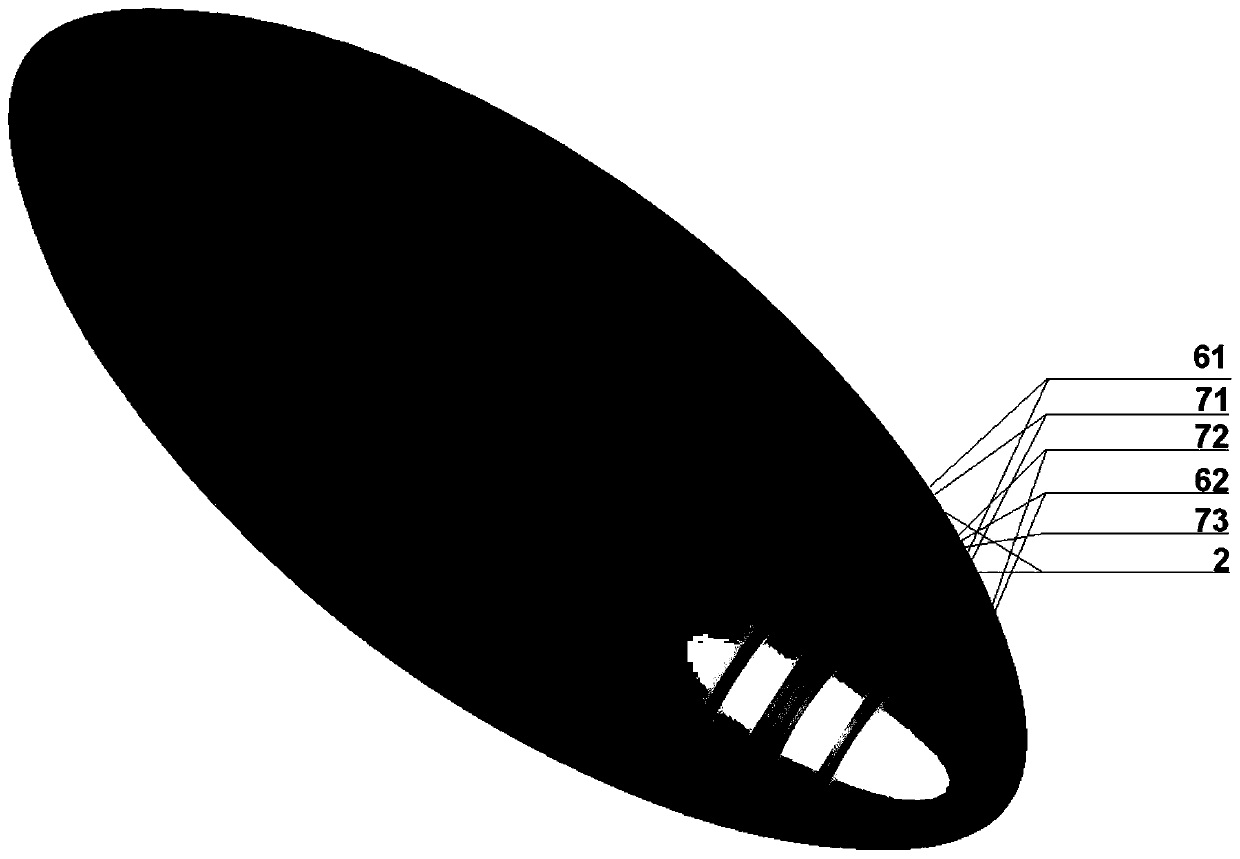

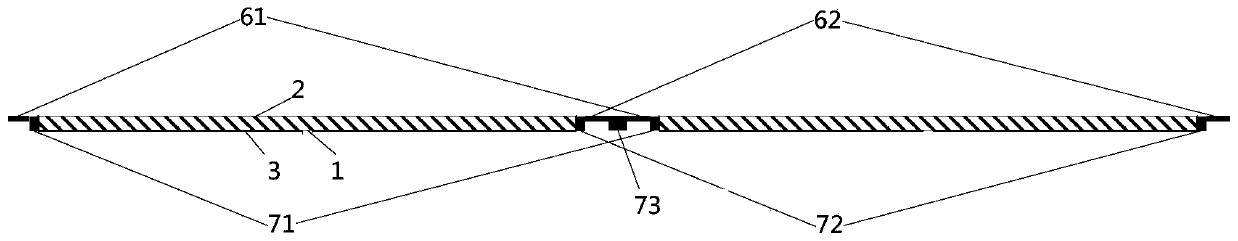

[0020] figure 1 It is a structural schematic diagram of the plasma flow control device for airship drag reduction in adjacent space according to the present invention. Such as figure 1 As shown, the plasma flow control device for airship drag reduction in adjacent space includes: a drag reduction unit, a wire 4 , a DC power supply 5 , a third insulating layer 73 , a microwave generator 8 and a first waveguide 91 . in,

[0021] The drag reducing unit includes a slot antenna 1, a quartz glass plate 2, a metal film 3, a first insulating layer 71, a second insulating layer 72, a first electrode 61, a second electrode 62 and a second waveguide 92, wherein the metal film 3 Plated on the lower surface, left side and right side of the quartz glass plate 2; the metal film 3 plated on the lower surface of the quartz glass plate 2 has a slit, and the slot antenna 1 is embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com