A kind of quartz glass cleaning method

A kind of quartz glass, the fourth technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem of poor optical quality and mechanical strength, inability to remove rubber stains, quartz glass Surface damage and other problems, to reduce crosslinking, avoid workpiece damage, and facilitate aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

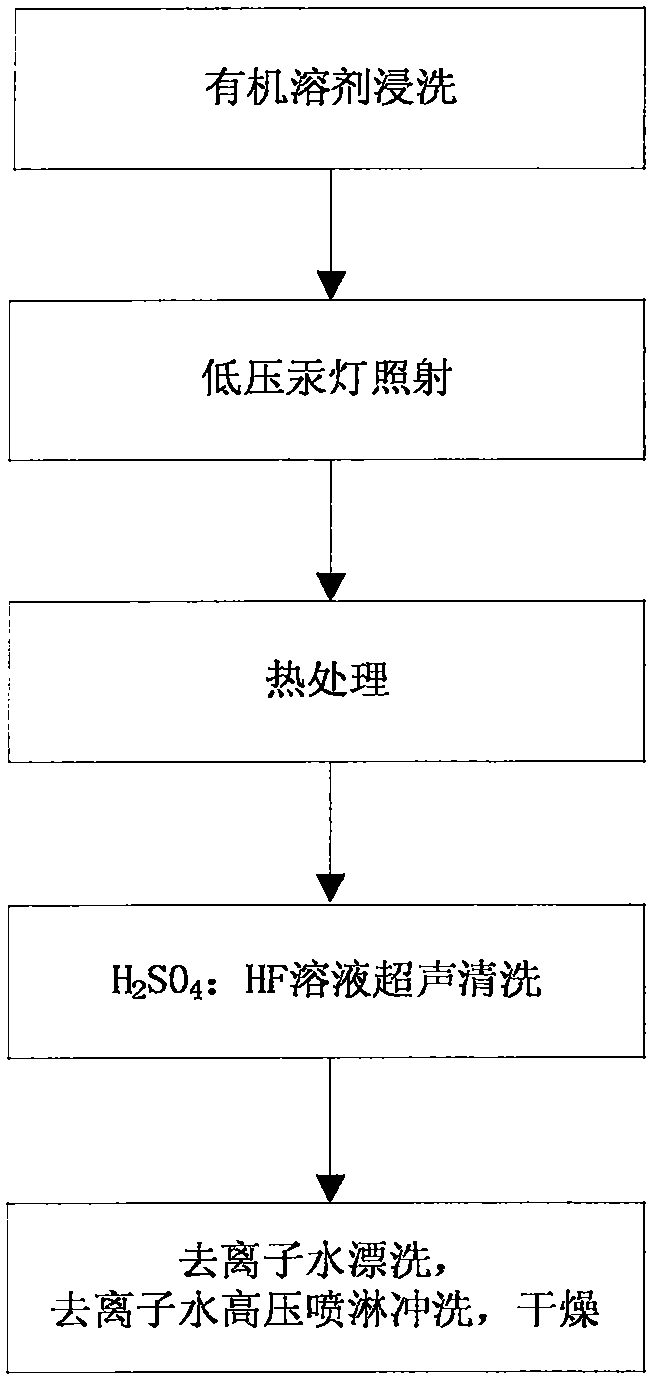

[0035] The invention as figure 1 shown, through the following steps:

[0036] 1. Dip the quartz glass in acetone at 50°C for 5 hours; take out the quartz glass and rinse it with deionized water at room temperature for 3 times, each time for 5 minutes;

[0037] 2. Irradiate the quartz glass with a 100-watt ultraviolet low-pressure mercury lamp at normal temperature and pressure for 15 hours, and irradiate in a closed chamber that is impenetrable to ultraviolet rays. The distance between the workpiece and the low-pressure mercury lamp is 10 cm;

[0038] 3. Heat the quartz glass in the air at 400°C for 5 hours, and cool down naturally after the heat treatment;

[0039] 4. Put the quartz glass into H at 40°C 2 SO 4: In HF solution, apply ultrasonic vibration simultaneously, clean 20 minutes, the proportioning of described solution is H 2 SO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com