Patents

Literature

34results about How to "Facilitation and effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wool product for preventing electric radiation and manufacturing technology thereof

PendingCN107237038AGood anti-electron radiation effectPromote absorptionWeft knittingBiochemical treatment with enzymes/microorganismsYarnPolyester

The invention provides a wool product for preventing electric radiation. The wool product comprises 10-20% of wool fiber, 30-40% of modified polyester fiber, 25-35% of silver-coated filament and 15-35% of bamboo pulp fiber, wherein the silver-coated filament is coated with the modified polyester fiber to form core spun yarn, the core spun yarn, the wool fiber and the bamboo pulp fiber are blended to form fabric with a function of preventing the electric radiation. Through the coordination of a manufacturing technology, the wool product which has a high electromagnetic shielding effect, comfortable in handfeel, is suitable for being worn can be obtained.

Owner:JIAXING ZHULANG CLOTHING CO LTD

Tea seed shell organic fertilizer and preparation method thereof

InactiveCN106588261AImprove the environmentImprove sustainable useBio-organic fraction processingExcrement fertilisersOrganic fertilizerRhizome

The invention relates to organic fertilizer and especially relates to tea seed shell organic fertilizer and a preparation method thereof. The tea seed shell organic fertilizer well utilizes tea seed shells, provides full and complete nutrients and improves disease and insect resistance. The tea seed shell organic fertilizer comprises, by mass, 1200 to 1400 parts of tea seed shells, 200 to 300 parts of straws, 300 to 400 parts of bean dregs, 240 to 300 parts of oil meal, 160 to 200 parts of arnebia root, 1400 to 1600 parts of chicken manure, 700 to 900 parts of pig manure, 450 to 550 parts of plant ash, 30 to 40 parts of isatis root, 20 to 30 parts of lalang grass rhizome and 20 to 30 parts of caulis akebiae. Processes A to F in the preparation method comprise fermenting fusion of the raw materials so that the tea seed shell organic fertilizer is obtained. The tea seed shell organic fertilizer is prepared from waste residues and has good economic and ecological benefits.

Owner:GANNAN NORMAL UNIV +1

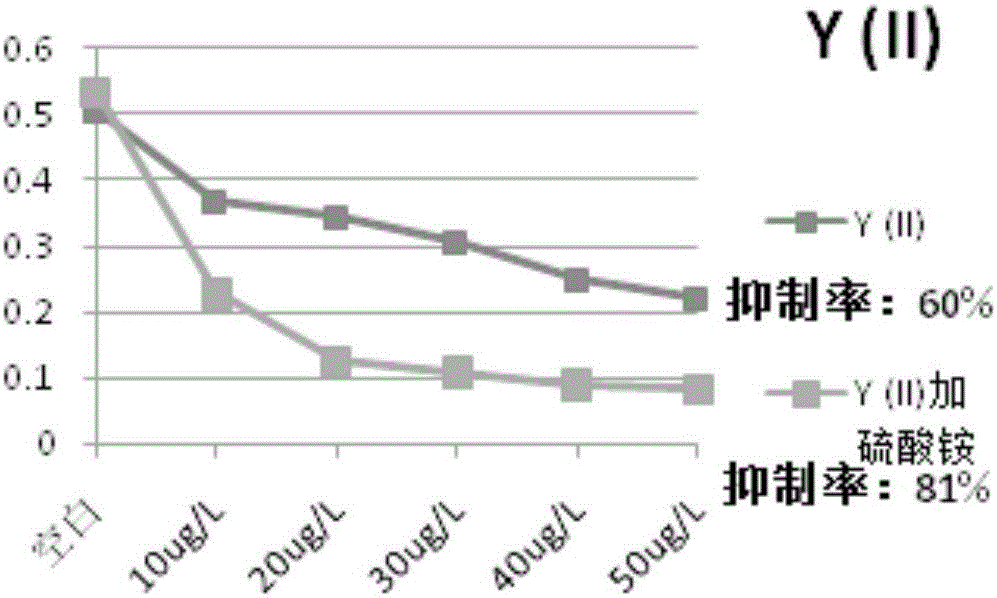

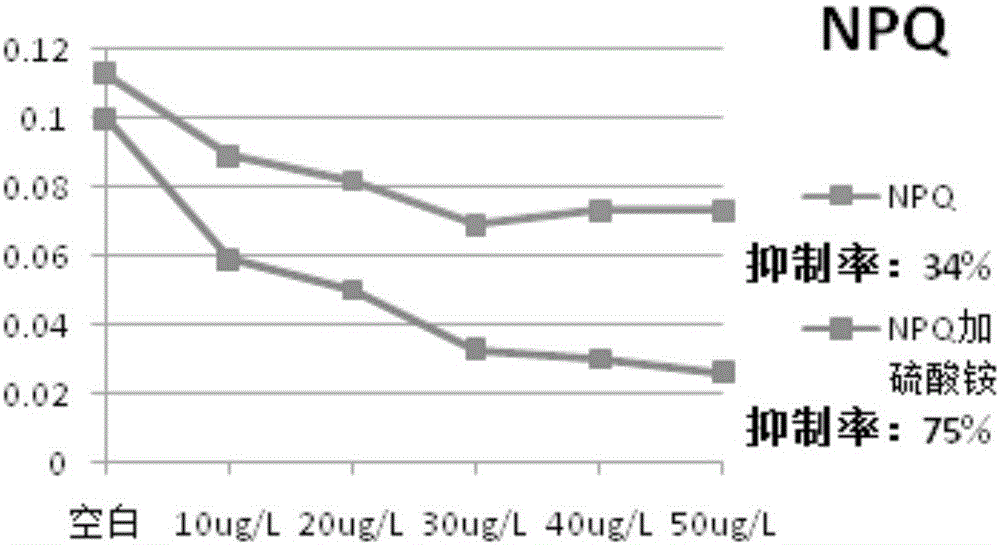

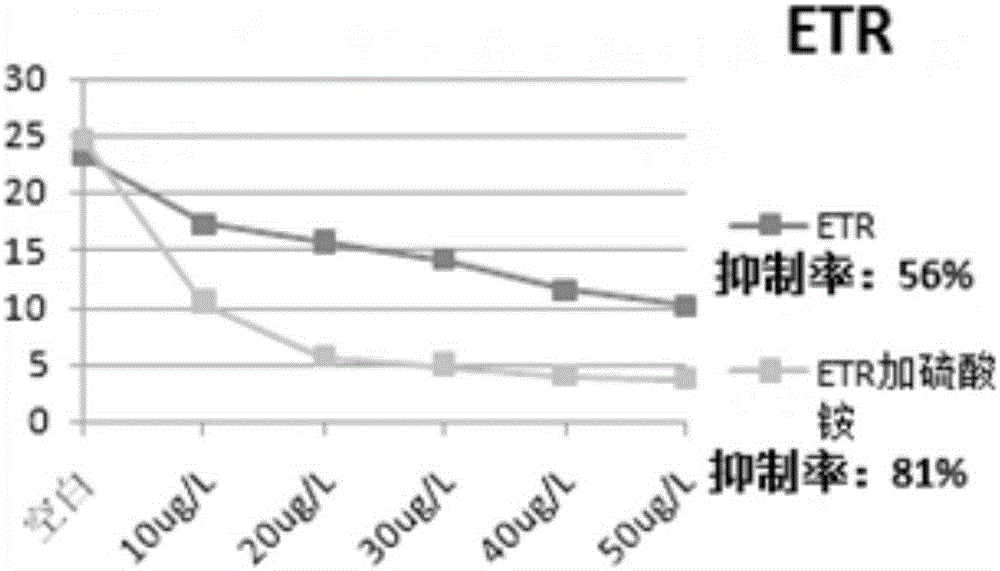

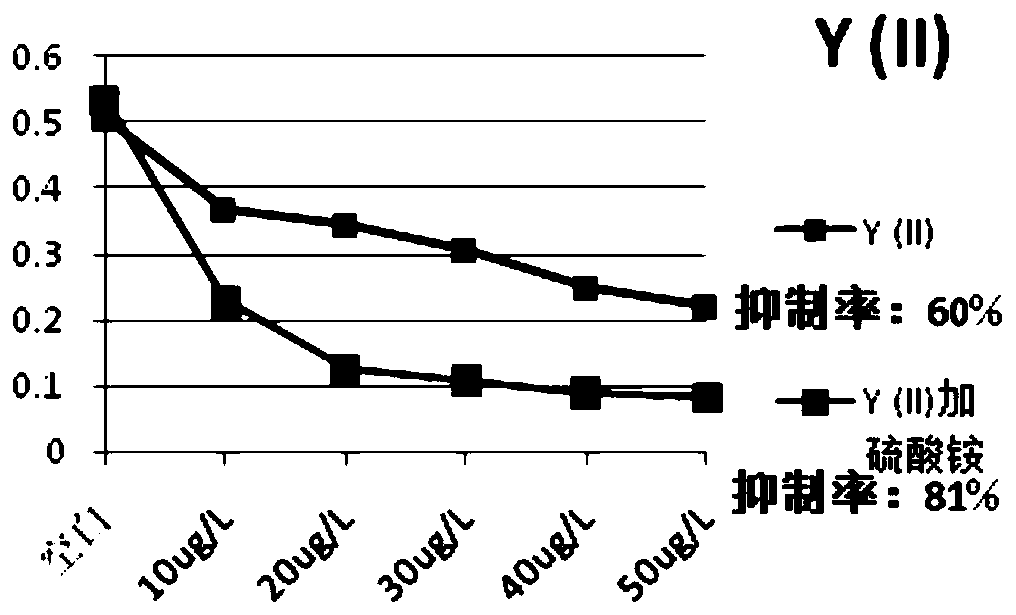

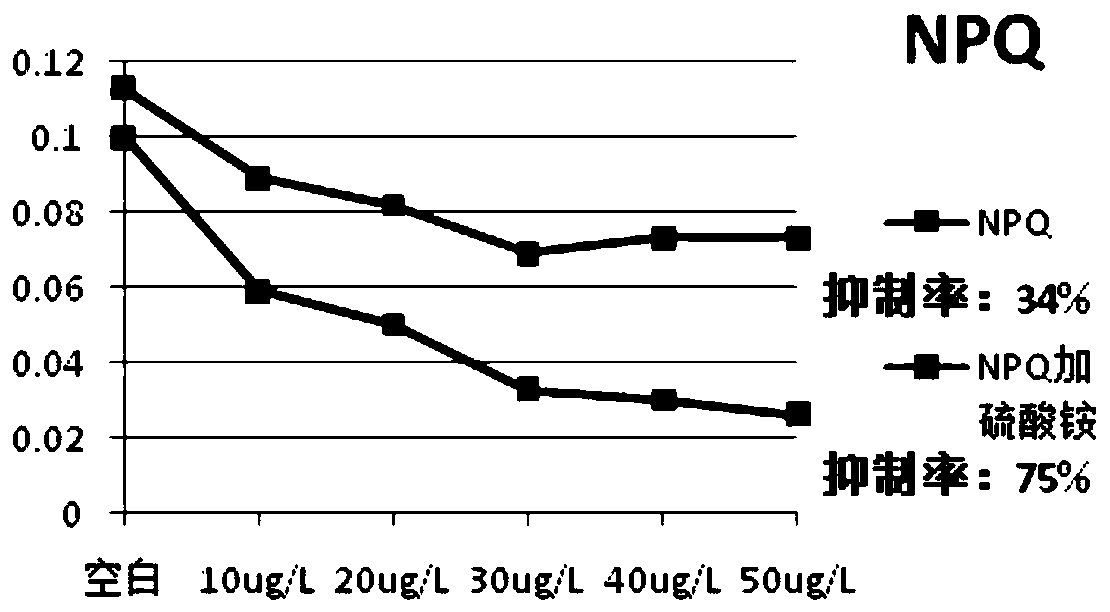

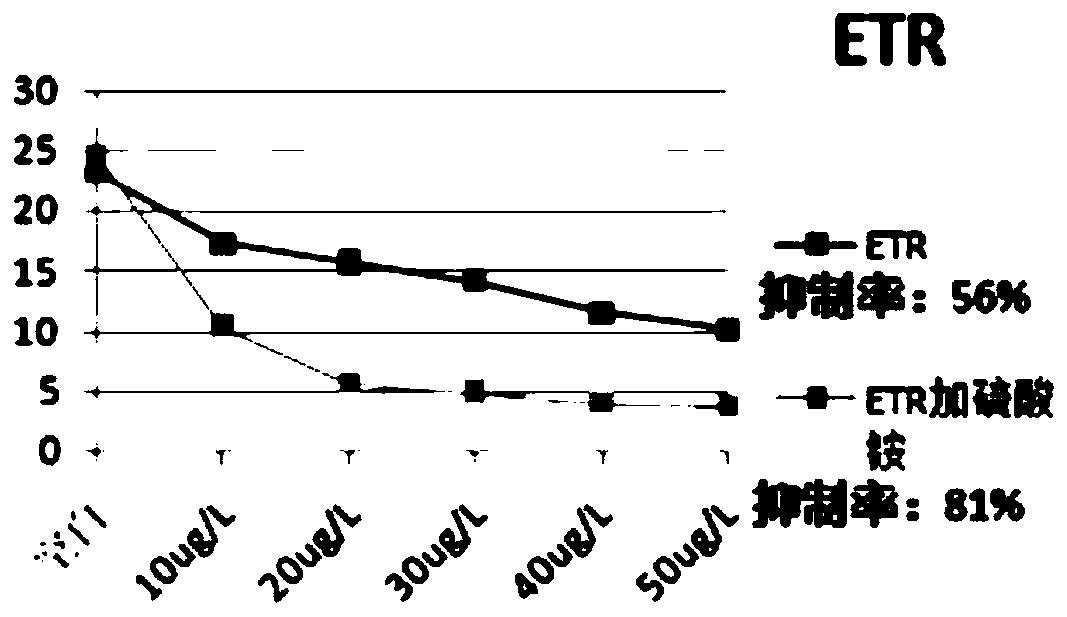

Method for fluorescence detection of biotoxicity of desmetryn by scenedesmus obliquus in ammonium salt environment

ActiveCN106770121AFacilitation and effectUnderstanding Biological ToxicityFluorescence/phosphorescenceArbitrary Fluorescence UnitDistilled water

The invention provides a method for fluorescence detection of biotoxicity of desmetryn by scenedesmus obliquus in ammonium salt environment, and belongs to the technical field of scenedesmus obliquus. The method comprises the steps of scenedesmus obliquus seed culture and scenedesmus obliquus liquid preparation, and also comprises influence determination of the desmetryn on the scenedesmus obliquus fluorescence effect in the ammonium salt environment. According to the method, the series concentration of desmetryn standard solutions added with ammonium salt solution are taken and are added into the scenedesmus obliquus solution; sufficient mixing and uniform shaking are performed; the volume ratio of the ammonium salt solution to the desmetryn standard solution to the scenedesmus obliquus liquid is controlled to be 2:(1 to 2):(1 to 2); meanwhile, distilled water is used for replacing a blank control group of the scenedesmus obliquus standard solution; after the dark placement for 10 to 15min, a water sample fluorescence detection instrument is used for determining each chlorophyll fluorescence dynamic parameter of the scenedesmus obliquus. The method provided by the invention has the advantages that the method is simple; the operation is easy; the biotoxicity of the desmetryn can be directly reflected.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of thamnaconus multiradiatus fish skin bacterium-inhibiting peptide

InactiveCN108315377ASimple preparation processFacilitation and effectPeptide preparation methodsFermentationWater bathsFiltration

The invention provides a preparation method of thamnaconus multiradiatus fish skin bacterium-inhibiting peptide. The preparation method comprises the following steps: a) pre-treating fish skin: mincing the thamnaconus multiradiatus fish skin; then carrying out degreasing and calcium removal in sequence to obtain degreased and calcium-removed fish skin; then removing non-collagen to obtain degreased, calcium-removed and non-collagen-removed thamnaconus multiradiatus fish skin; b) carrying out enzymolysis: adding the degreased, calcium-removed and non-collagen-removed thamnaconus multiradiatus fish skin which is sufficiently dried into a buffering solution according to the material / liquid ratio of 1g to (8 to 12mL); regulating the pH (Potential of Hydrogen) value to 6.5 to 7.5; carrying outheat preservation at 45 to 55 DEG C for 10 to 15min; adding compound proteinase according to 2 to 5 percent of the mass of the fish skin and carrying out the enzymolysis at 45 to 55 DEG C for 4 to 6h;c) preparing the bacterium-inhibiting peptide: deactivating an enzymolysis solution in a water bath for 10 to 15min and obtaining supernatant through ultrasonic extraction or microwave extraction; carrying out ultra-filtration and chromatography or ultra-filtration, spraying and drying on the supernatant in sequence to obtain the thamnaconus multiradiatus fish skin bacterium-inhibiting peptide. The preparation method provided by the invention has the characteristics that a preparation technology is simple, an enzymolysis or hydrolysis method is used for specifically obtaining hydrolyzed polypeptide with a bacterium-inhibiting effect and the effect of the proteinase on fish skin protein is promoted so that efficient preparation of the bacterium-inhibiting peptide is realized and the like.

Owner:ZHEJIANG OCEAN UNIV

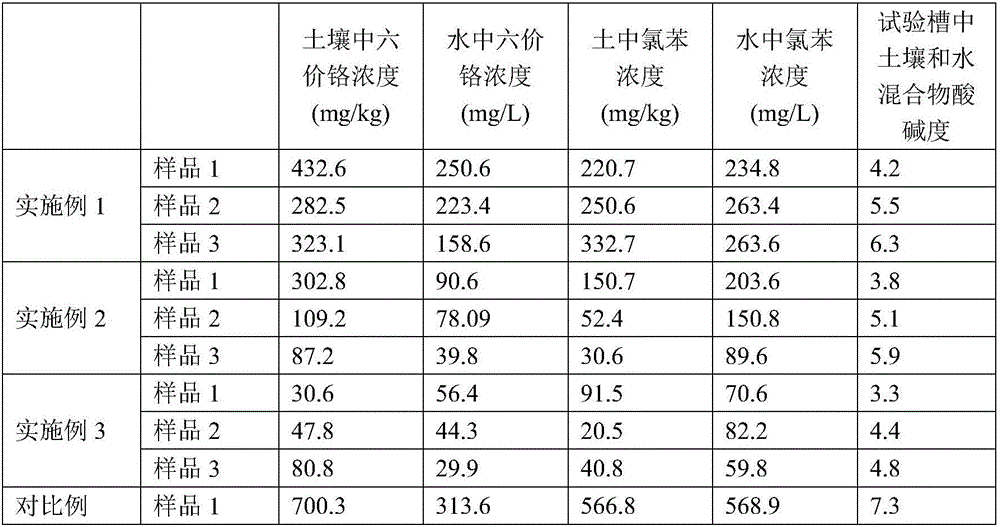

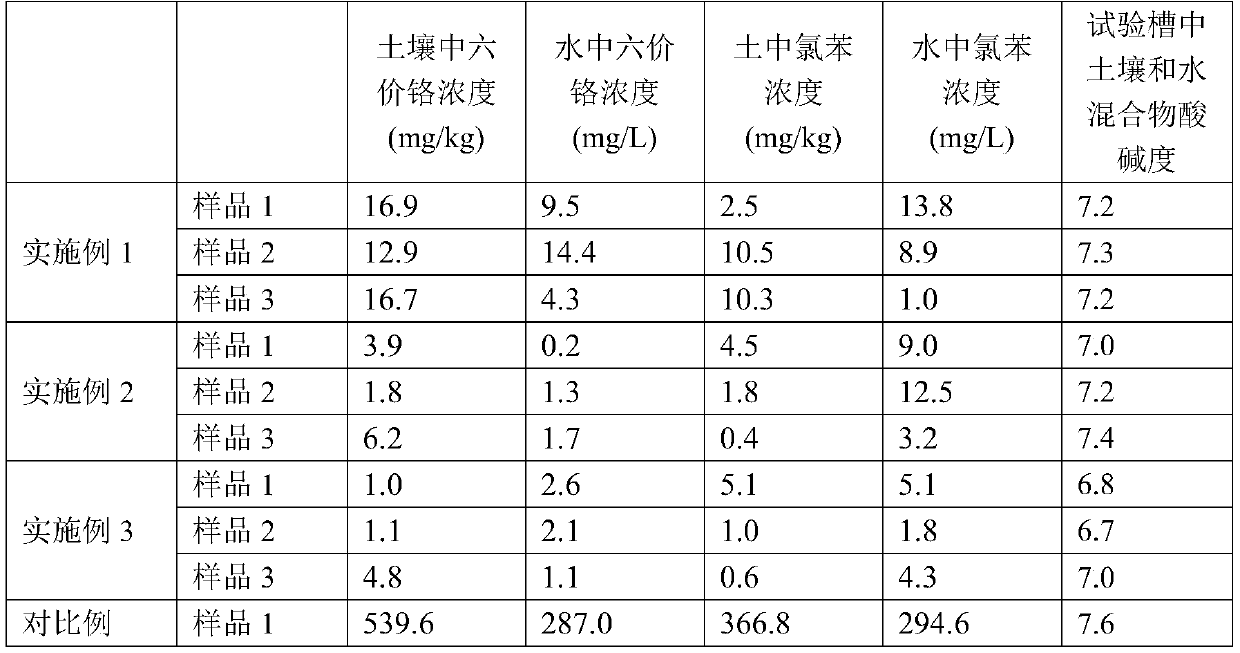

Novel reducing agent for repairing contaminated site and preparation method of novel reducing agent

ActiveCN106825027AHigh recovery and repair efficiencyAvoid passivationWater contaminantsContaminated soil reclamationHydrogenIron powder

The invention discloses a novel reducing agent for repairing a contaminated site. The novel reducing agent is prepared from the following components in percentage by mass: 70 percent to 95 percent of micron iron powder and 5 percent to 30 percent of an auxiliary agent, wherein the auxiliary agent is prepared from the following components in percentage by mass: 45 percent of xanthan gum, 54 percent of waste molasses and 1 percent of acetic acid bacteria powder. The reducing agent can also be used for effectively avoiding deposition and agglomeration phenomena in a utilization process of the micron iron powder, and uniform dispersion degrees of the micron iron powder in a polluted soil body and a polluted water body are remarkably improved; an oxidation-reduction potential of a reaction system is greatly reduced, and the reduction removal rate of the micron iron powder on pollutants in the soil and underground water is remarkably improved; the potential of hydrogen of a balance reaction system can be effectively balanced; finally, efficient reduction and recovery of the pollutants in the soil and underground water is realized. Meanwhile, the invention further provides a preparation method of the reducing agent; the utilization rate of waste materials can be realized, the preparation cost is low and the operation is simple and easy.

Owner:SOUTHEAST UNIV

Special healthcare dog food for bitches and preparation method of special healthcare dog food

InactiveCN104886352ABalanced nutritionPromote absorptionAntibacterial agentsAnimal feeding stuffLepus timidusSide effect

The invention discloses a special healthcare dog food for bitches and a preparation method of the special healthcare dog food. The special healthcare dog food is prepared from chicken livers, corn flour, sweet potatoes, Chinese yams, apples, okras, jackfruits, leonurus, mountain hares, jewelweeds, hawthorns, forsythia, purslane, black fungi, pig blood, prepared rehmannia roots, angelica, camellia oil and salt. The dog food is effective in antibacterial and anti-inflammation performances and capable of accelerating discharging of purulent blood in uteruses of the bitches to eliminate symptoms of weakness and anemia of sick bitches in treatment; in addition, the dog food is capable of promoting appetites and digestive absorption of the bitches and effective in treatment of open pyometra of the bitches, safety and significant treatment effects are achieved while toxic and side effects are avoided, and the sick bitches are less prone to relapsing after being healed up.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Biological enzyme compound refining agent for cotton fabrics and using method thereof

InactiveCN107034660AImprove catalysisPromote the effect of enzymesRadio/micro wave fibre treatmentBiochemical treatment with enzymes/microorganismsChemistryCarboxylate

The invention discloses a biological enzyme compound refining agent for cotton fabrics and a using method thereof. The biological enzyme compound refining agent for the cotton fabrics is characterized by comprising, by weight parts, a component 1 and a component 2, wherein the component 1 comprises 30-40 parts of protopectinase, 14-22 parts of protease, 11-15 parts of xylanase, 8-11 parts of laccase, 3-5 parts of 1-hydroxybenzotriazole, 5-9 parts of sodium fatty alcohol polyoxyethylene ether carboxylate and 20-50 parts of water; the component 2 comprises 40-50 parts of alkaline pectinase, 22-34 parts of cellulase, 11-17 parts of cutinase, 10-14 parts of keratinase, 1-2 parts of span-40, 6-10 parts of alkyl polyglucoside and 20-50 parts of water. After the cotton fabrics are processed through the refining agent, the wettability is remarkably improved, and a refining effect is good. The refining agent is simple in using method, convenient to operate, green and free of pollution.

Owner:苏州凯邦生物技术有限公司

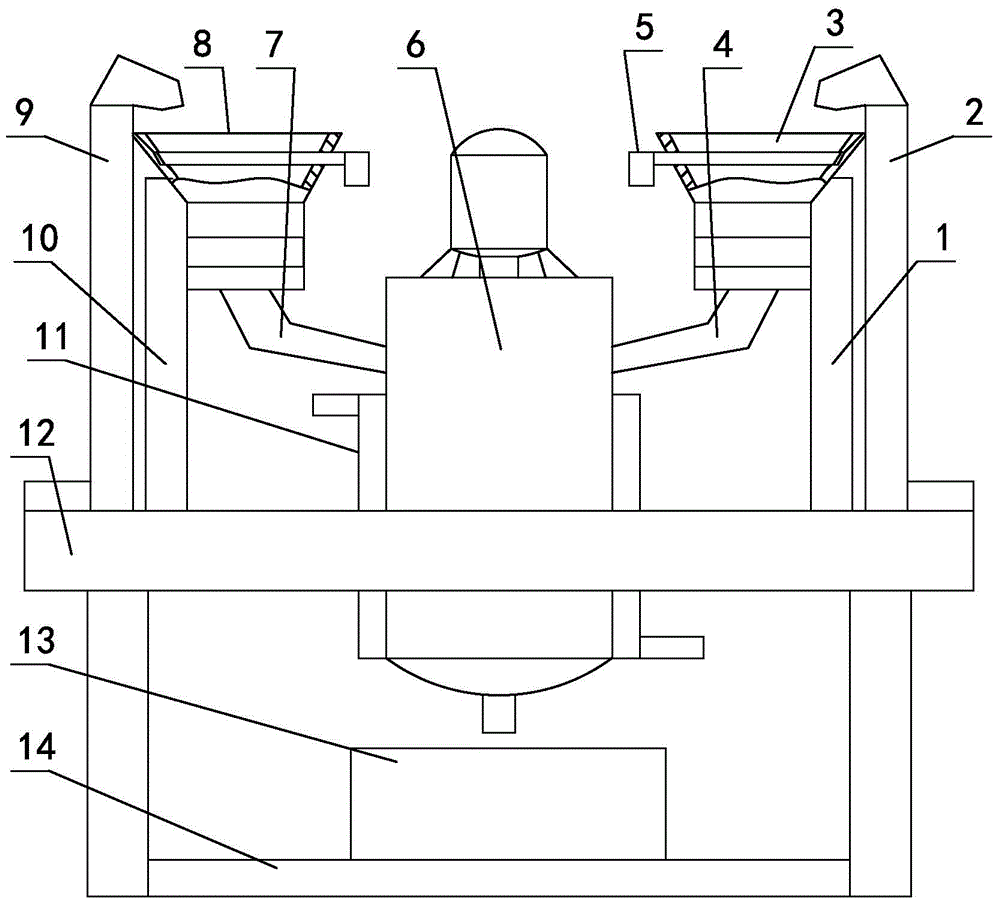

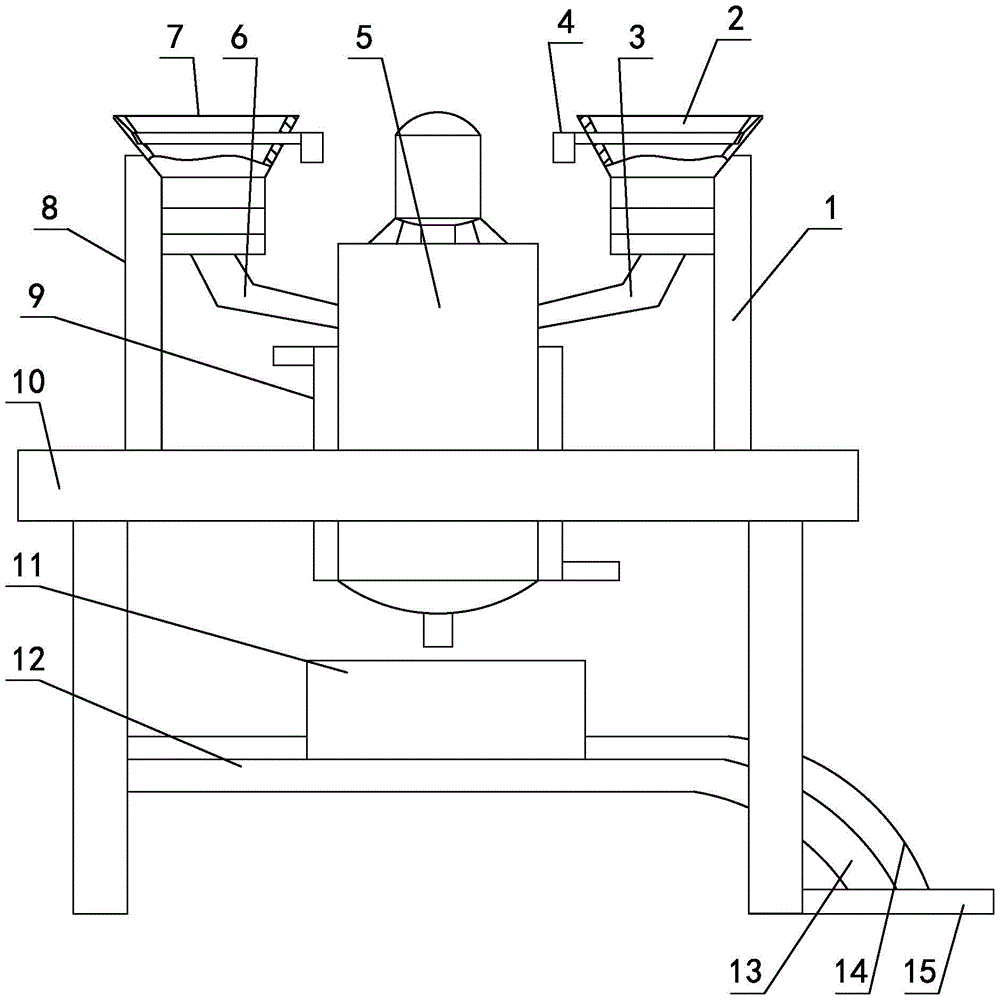

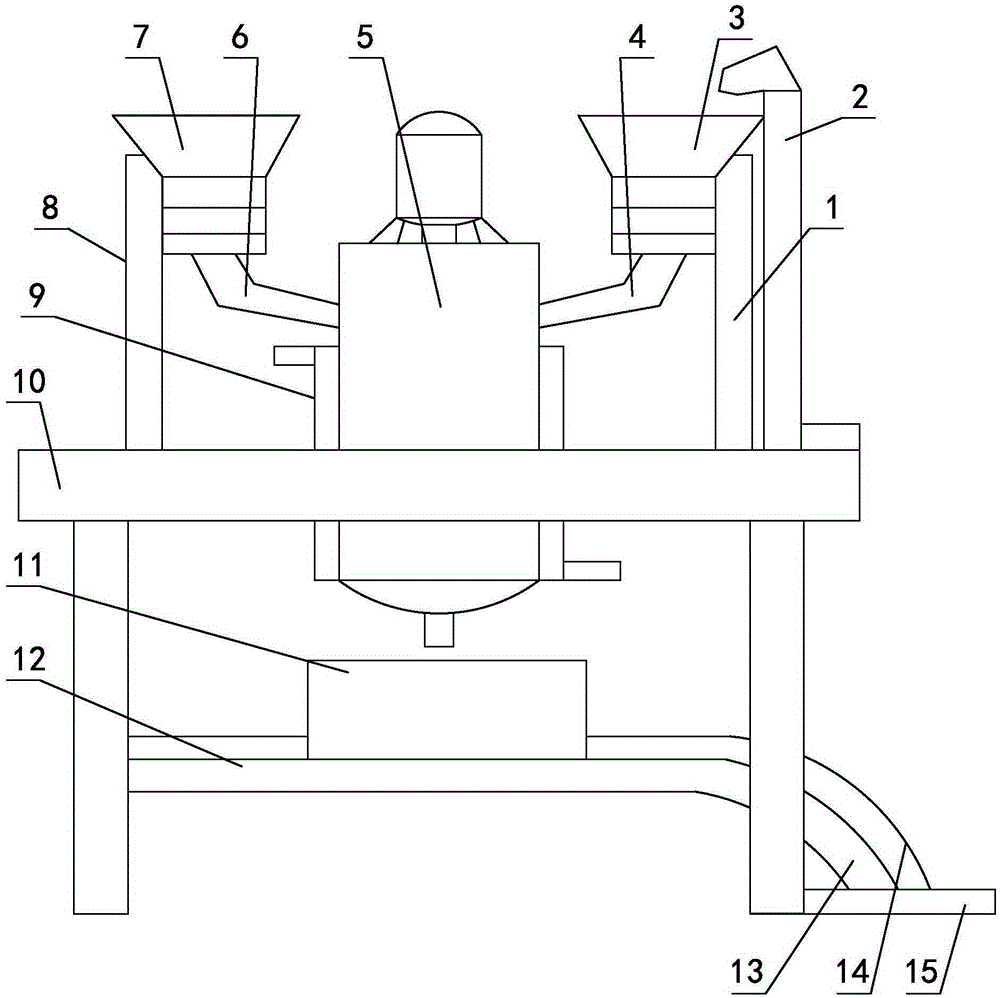

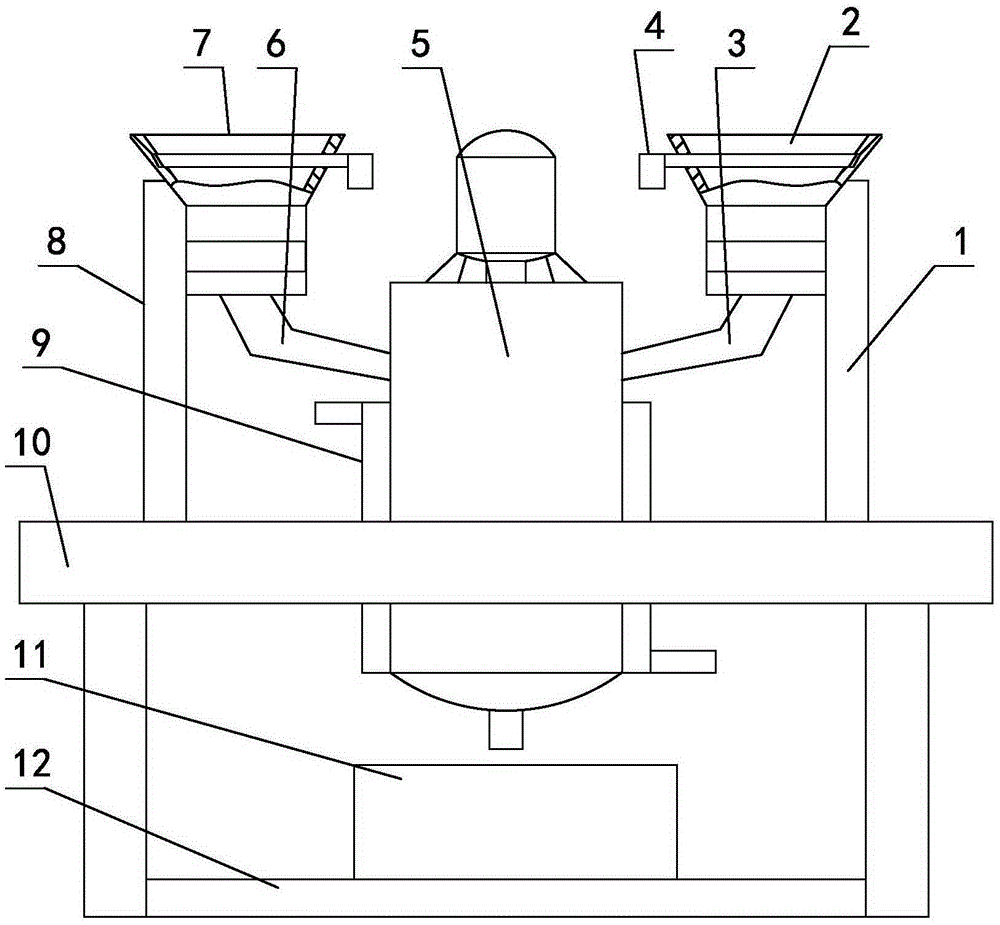

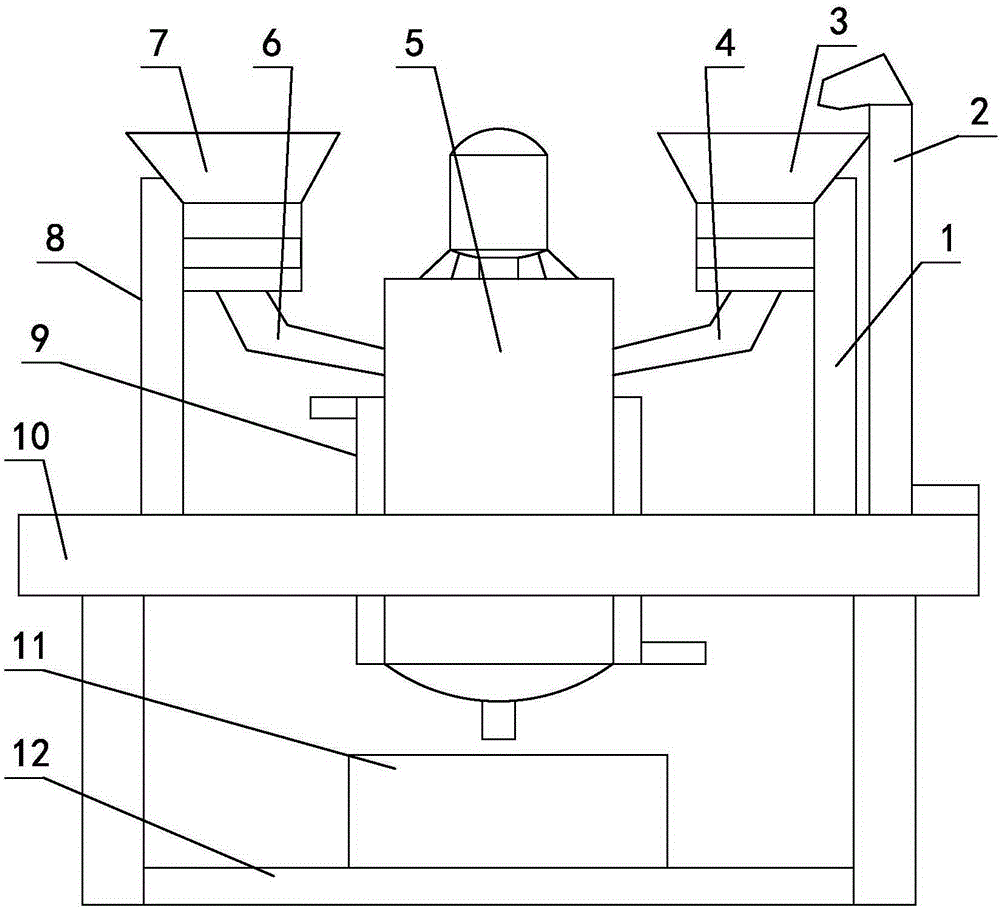

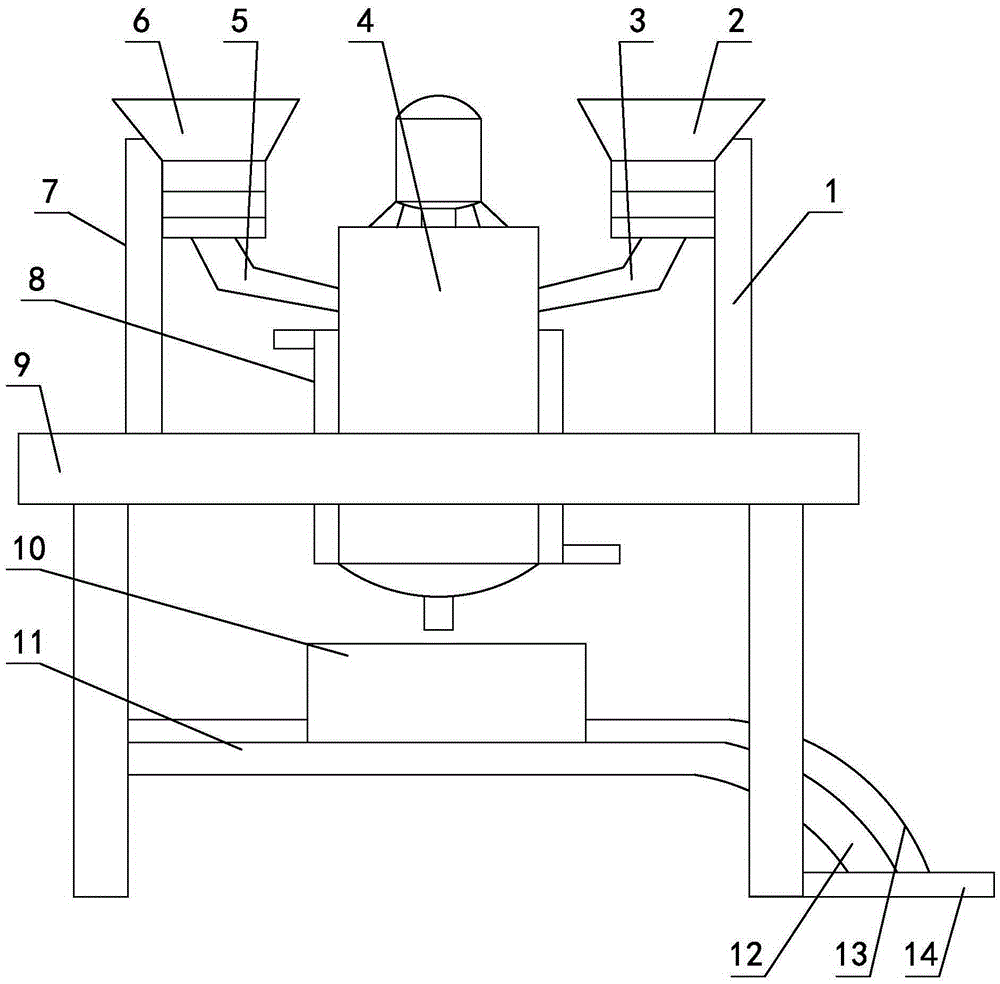

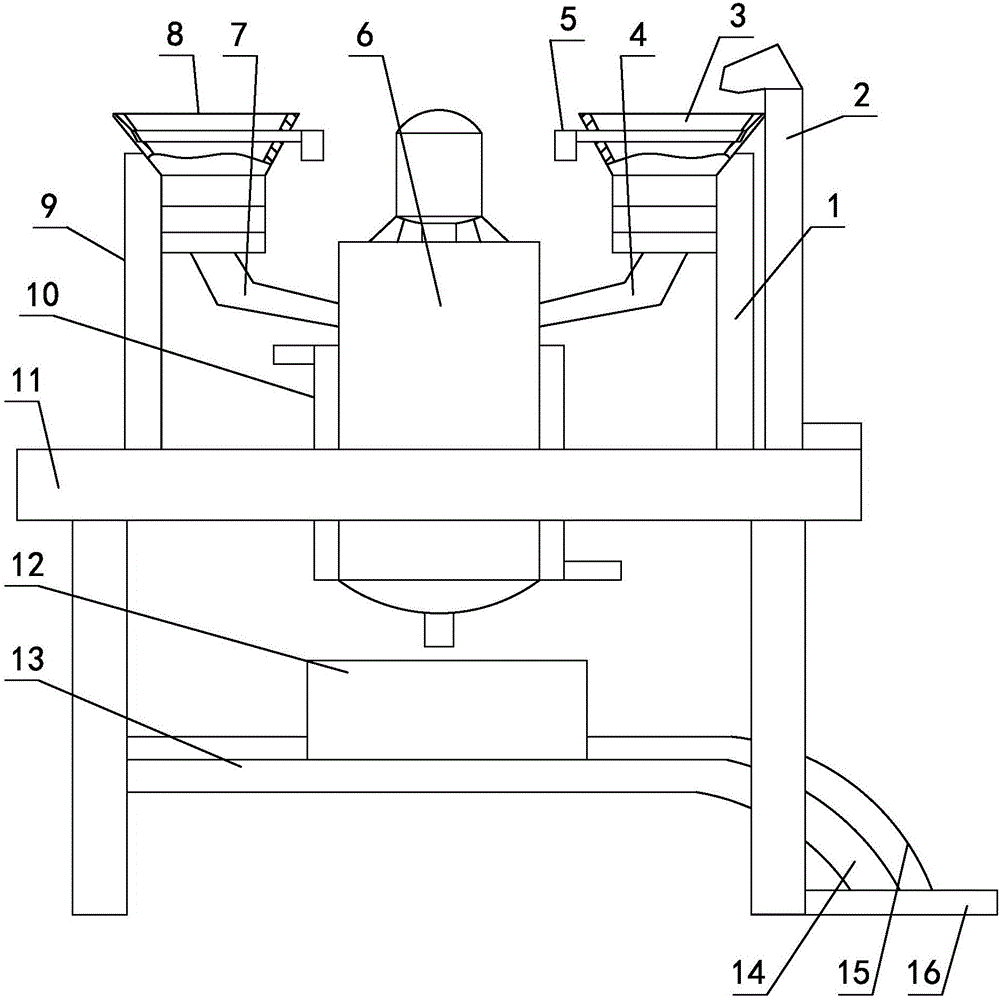

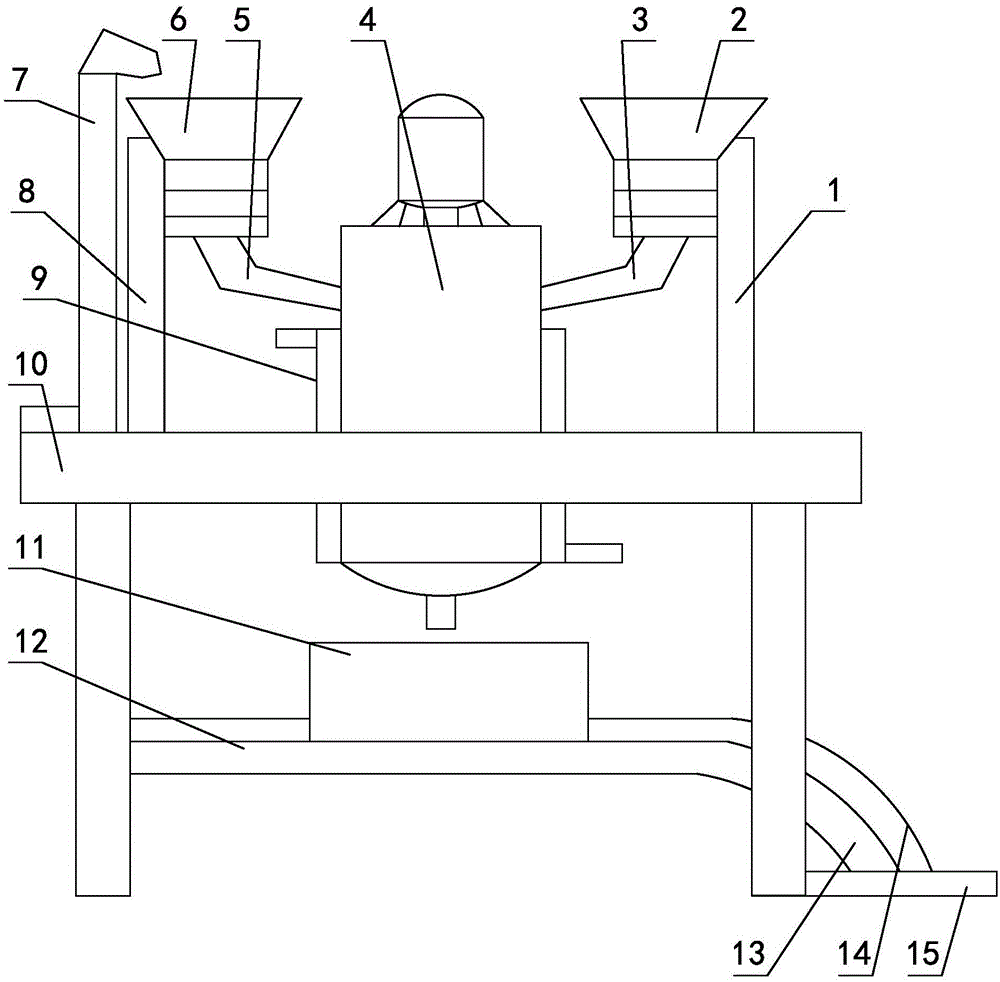

Integrated constant-temperature mixing machine for biological and chemical fertilizers

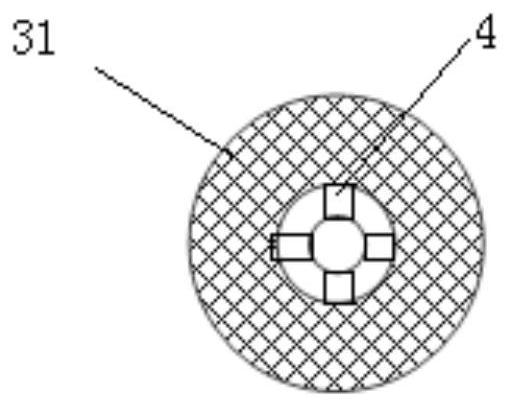

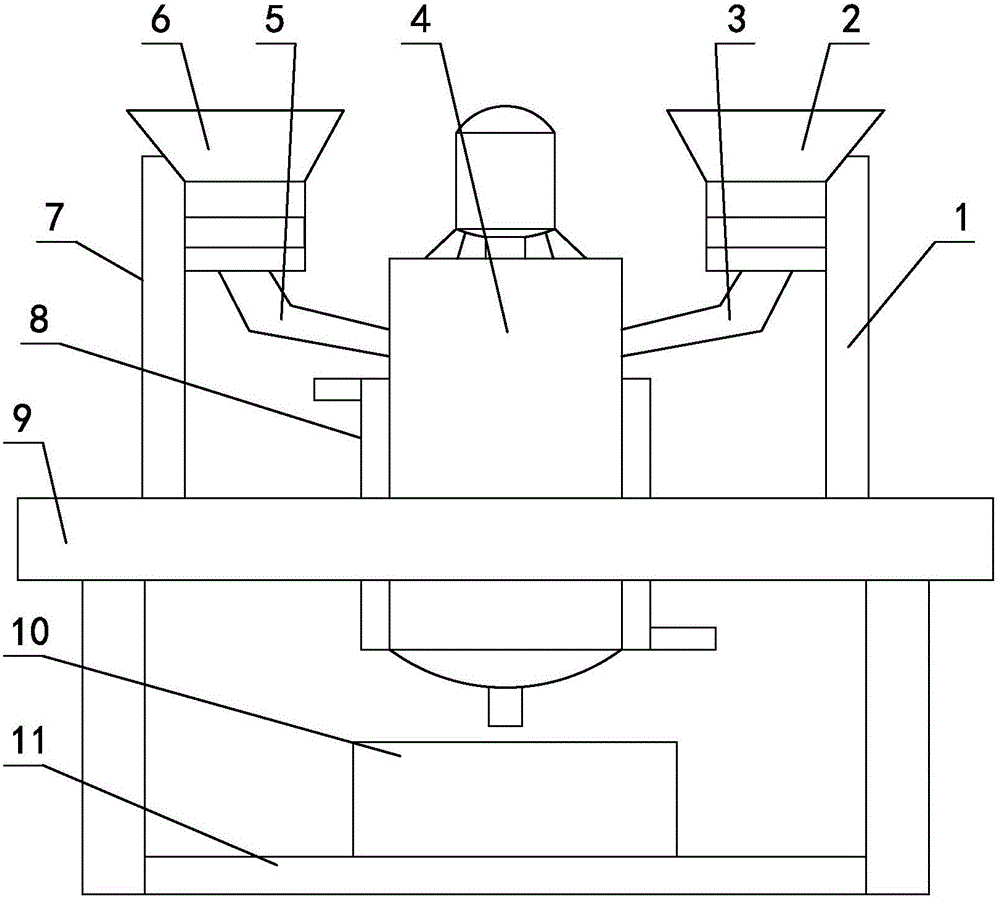

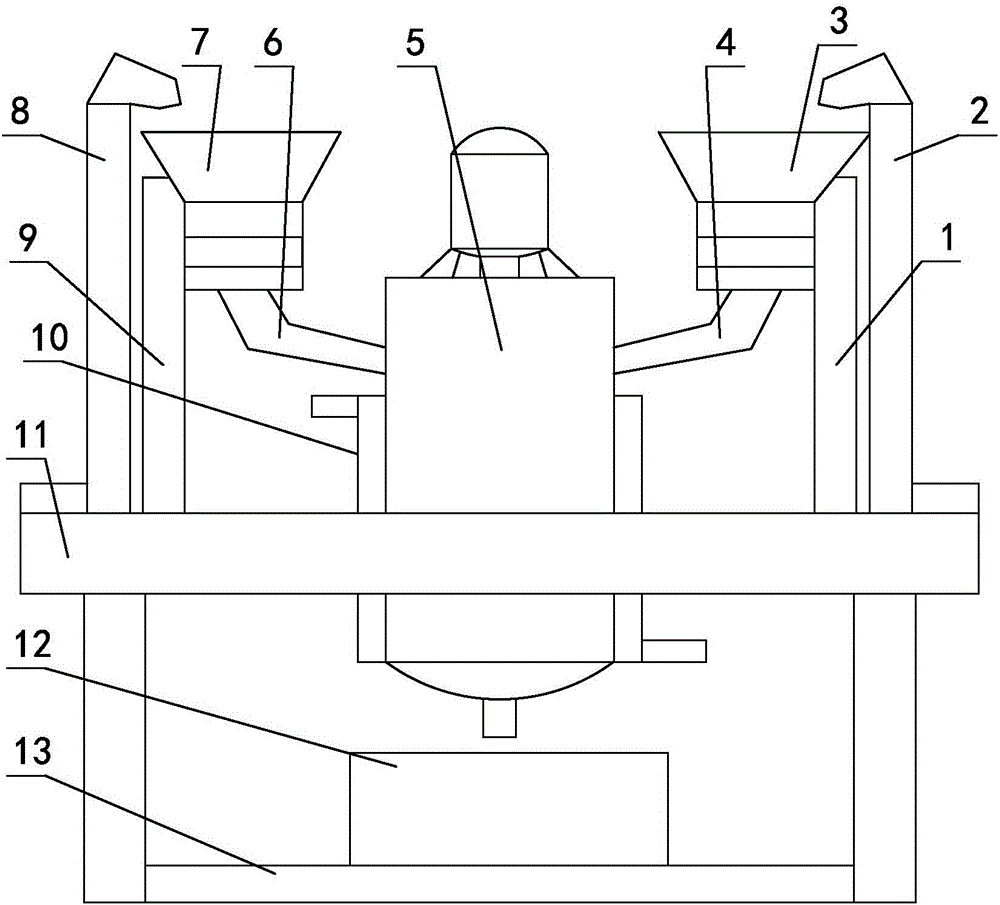

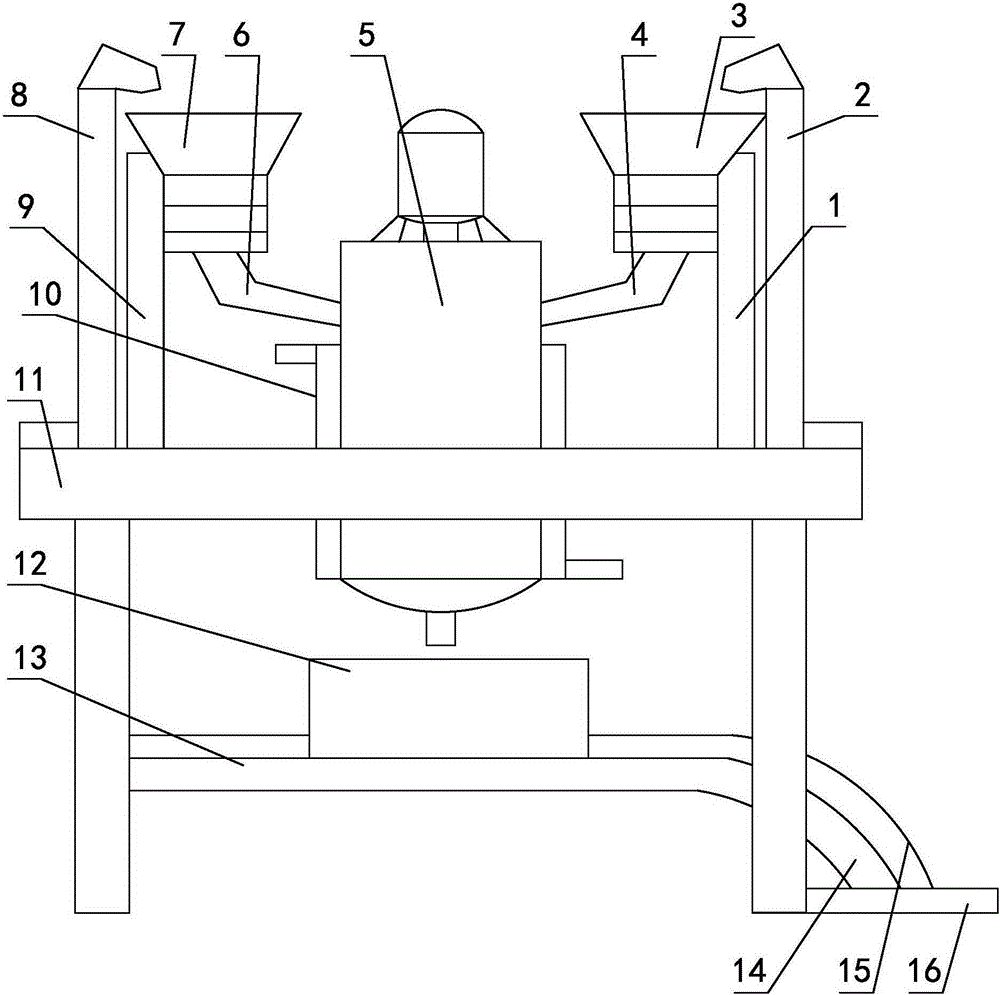

InactiveCN106378053AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesMixing tankSupport plane

The invention relates to an integrated constant-temperature mixing machine for biological and chemical fertilizers, belonging to the technical field of fertilizer mixing. The integrated constant-temperature mixing machine comprises a mixing tank with a stirrer and workbenches, wherein a first bracing frame and a second bracing frame are respectively and vertically mounted on the workbenches respectively located at the left and right sides of the mixing tank; a first feeding chute is installed on the first bracing frame and is communicated with the top of the mixing tank via a first feeding pipeline; a second feeding chute is installed on the second bracing frame and is communicated with the top of the mixing tank via a second feeding pipeline; a product collecting tank is arranged just below a discharge outlet located in the bottom of the mixing tank and is placed on a placing plate; the periphery of the mixing tank is provided with a heat-preserving jacket layer capable of carrying out temperature adjustment; the right sides of the first bracing frame and the second bracing frame are respectively provided with a first feeding chute conveyer and a second feeding chute conveyer; and the interior of each of the first feeding chute and the second feeding chute is provided with a filter screen. The mixing machine provided by the invention can realize convenient mixing of a plurality of fertilizers before fertilization.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Special nutrient ointment for bitches, and preparation method thereof

InactiveCN104984119APromote absorptionGuaranteed unobstructedAntibacterial agentsDigestive systemSide effectWeakness

The invention discloses a special nutrient ointment for bitches, and a preparation method thereof. The special nutrient ointment is prepared from the following raw materials: chicken liver, maize meal, sweet potato leaves, rhizoma dioscoreae, apples, malabar spinach, jack fruit, herba leonuri, snow hare, flowers or roots of lightyellow snapweed, fructus crataegi, Eucalyptus globulus Labill., herba portulacae, white fungus, pig blood, radix rehmanniae praeparata, radix angelicae sinensis, camellia oil and salt. The special nutrient ointment for bitches can effectively resist bacteria and diminish inflammation, promote discharge of purulent blood in uteruses of the bitches, and eliminate weakness and anemia symptoms in the therapeutic process of the sick bitches, is easy to feed, can promote the appetite and digestive absorption of the bitches and effectively treat open pyometra of the bitches, has a remarkable curative effect, is safe, has no toxic or side effects, and achieves low probability of recurrence after healing.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

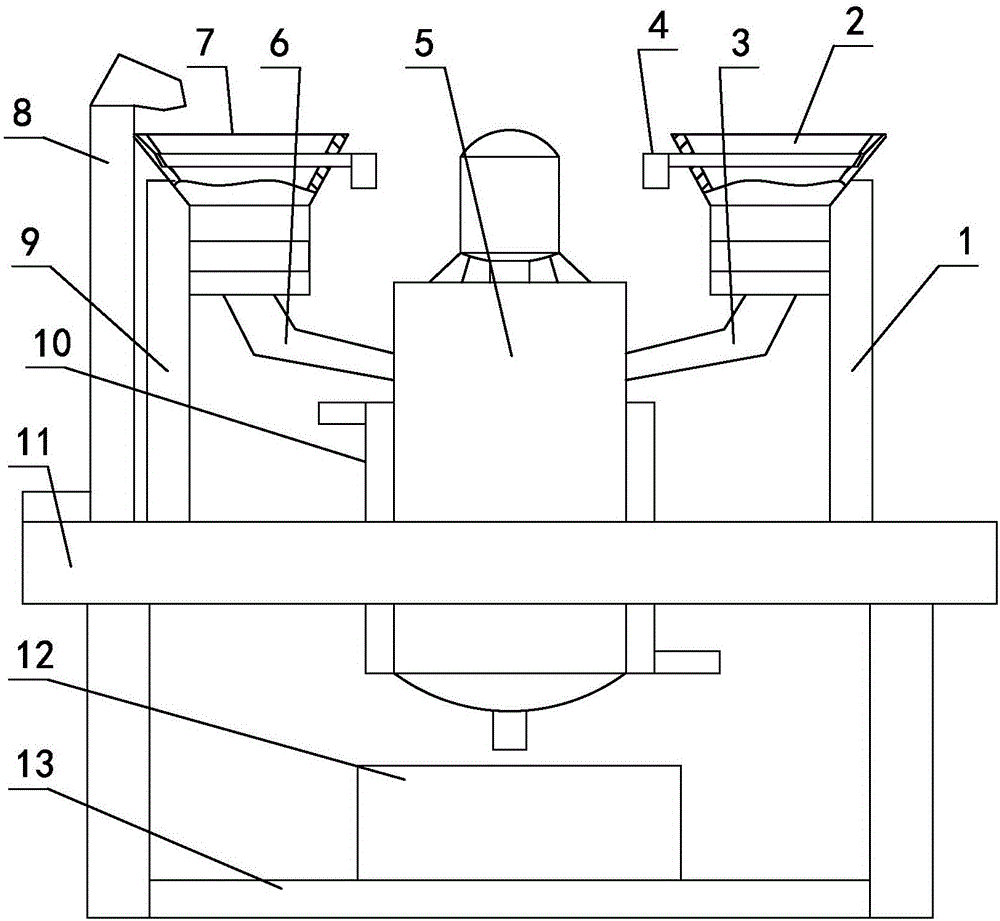

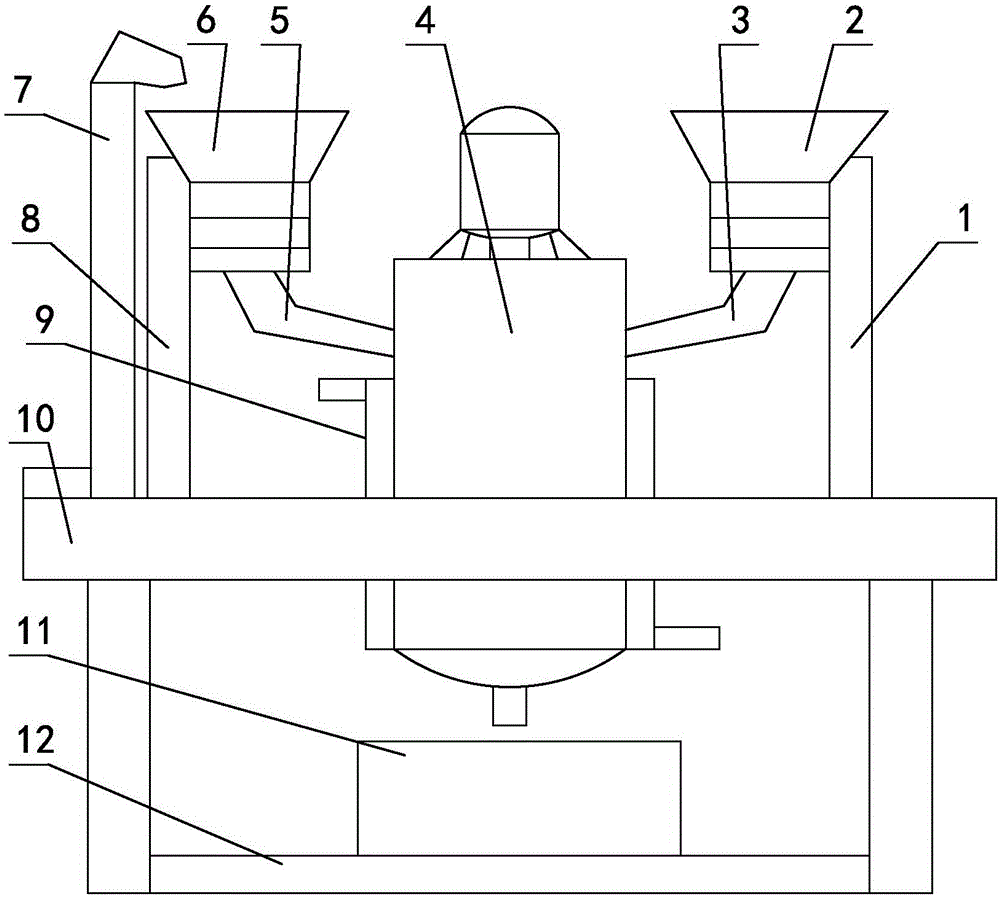

Fertilizer mixing apparatus with jacket temperature adjustment mechanism

InactiveCN106540572AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesFertilizerEngineering

The invention relates to a fertilizer mixing apparatus with a jacket temperature adjustment mechanism, and belongs to the technical field of fertilizer mixing. The fertilizer mixing apparatus includes a mixing tank provided with a stirrer and a workbench, wherein the mixing tank is vertically installed on the workbench; a first bracing frame and a second bracing frame are vertically arranged at the left and right sides of the mixing tank and on the workbench, wherein the first bracing frame is provided with a first feed tank communicating with the top part of the mixing tank through a first feed pipe, and the second bracing frame is provided with a second feed tank communicating with the top part of the mixing tank through a second feed pipe; a product collecting tank is arranged right below a discharge port formed in the bottom of the mixing tank and is disposed on a placing plate; a heat preservation jacket layer is arranged at the periphery of the mixing tank; a second feed tank conveyor used for conveying materials to the second feed tank is installed at the left side of the second bracing frame; and filter screens are installed in the first and second feed tanks, respectively. The apparatus is quite convenient for mixing fertilizers before fertilizer application, and is saved in time and labor.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Fertilizer mixer used before fertilization of crops

InactiveCN106378023AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesEngineeringMixing tank

The invention relates to a fertilizer mixer used before fertilization of crops, belonging to the technical field of fertilizer mixing. The fertilizer mixer comprises a mixing tank and a workbench, wherein a first bracing frame and a second bracing frame are separately mounted on the workbench; a first feeding chute is installed on the first bracing frame and is communicated with the top of the mixing tank via a first feeding pipeline; a second feeding chute is installed on the second bracing frame and is communicated with the top of the mixing tank via a second feeding pipeline; a product collecting tank is arranged just below a discharge outlet located in the bottom of the mixing tank and is placed on a placing plate; slide rails are parallely mounted on the placing plate; a chute is arranged at the bottom of the product collecting tank; the periphery of the mixing tank is provided with a heat-preserving jacket layer; the right sides of the first bracing frame and the second bracing frame are respectively provided with a first feeding chute conveyer and a second feeding chute conveyer; and the interior of each of the first feeding chute and the second feeding chute is provided with a filter screen. The fertilizer mixer provided by the invention can realize convenient mixing of a plurality of fertilizers before fertilization.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Fertilizer mixing machine applied before farm fertilization

InactiveCN106540563AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesLine tubingEngineering

The invention relates to a fertilizer mixing machine applied before farm fertilization and belongs to the technical field of fertilizer mixing. The fertilizer mixing machine applied before farm fertilization comprises a mixing tank and a workbench. The mixing tank is vertically arranged on the workbench; a first support frame and a second support frame are arranged on the workbench; a first feed chute is formed in the first support frame, and communicates with the top part of the mixing tank through a first feed pipeline; a second feed chute is formed in the second support frame, and communicates with the top part of the mixing tank through a second feed pipeline; a product collecting tank is arranged right below a discharge hole in the bottom part of the mixing tank, and is placed on a placement plate; a slide rail is parallelly arranged on the placement plate; a sliding chute is formed in the bottom part of the product collecting tank; a heat-insulating jacket layer capable of regulating temperature is arranged on the periphery of a tank body of the mixing tank; and drawer type matched filter screens are arranged in the first feed chute and the second feed chute. The fertilizer mixing machine applied before farm fertilization provided by the invention can be used for conveniently mixing several fertilizers before fertilization, and is time-saving and labor-saving.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

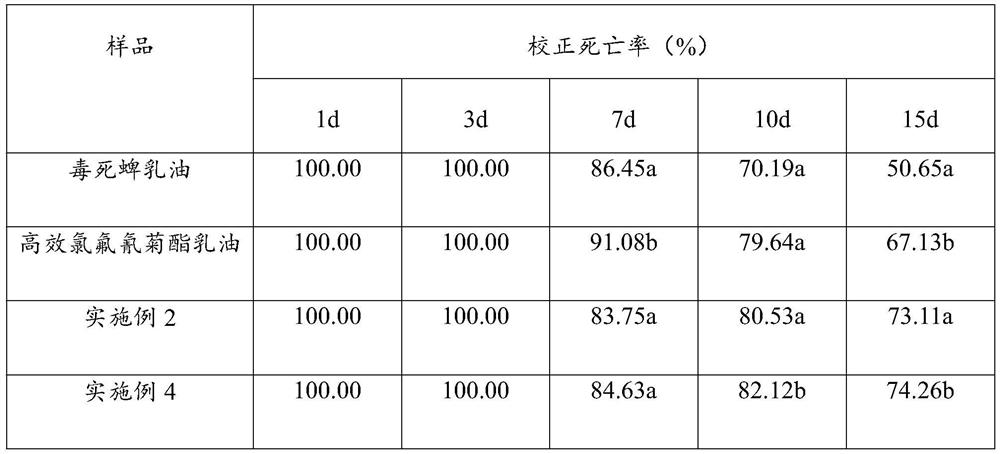

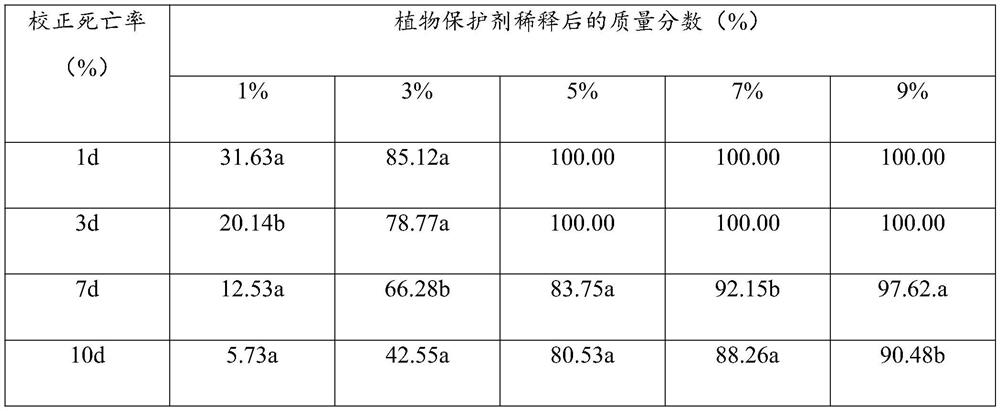

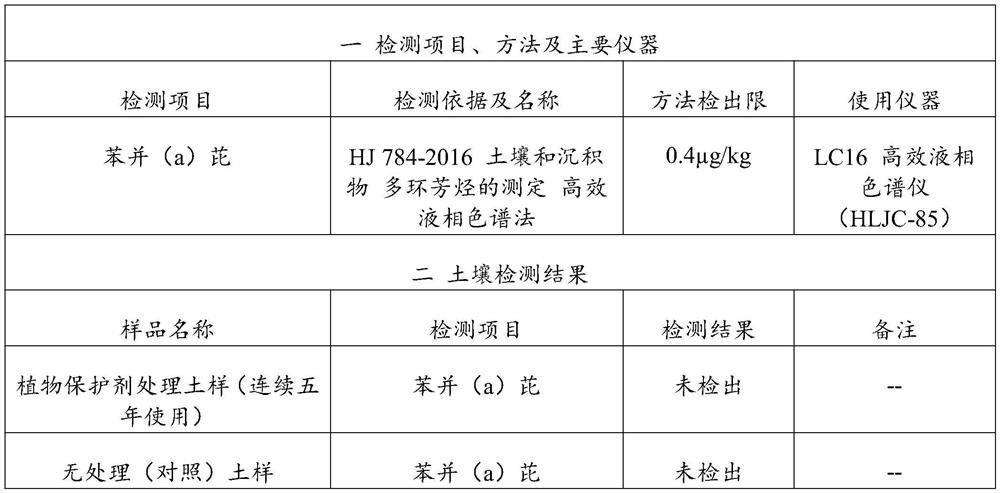

Plant protective agent as well as preparation method and application thereof

The invention relates to the technical field of plant protection, in particular to a plant protective agent as well as a preparation method and application thereof. The plant protective agent is prepared from the following raw materials in percentage by weight: 60-70% of carboxymethyl chitosan; 5-10% of polyethylene glycol; 10-20% of a deinsectization and sterilization material; 3-8% of a moisturizing material; 2-4% of an emulsifier; 0% or 3-6% of asphalt; and 0% or 1-3% of a surfactant. The deinsectization and sterilization material is prepared from the following raw materials in parts by weight: 15-20 parts of tobacco leaf waste; 5-10 parts of folium artemisiae argyi; 5-10 parts of pericarpium citri reticulatae; 35-50 parts of radix sophorae flavescentis; 25-40 parts of cortex meliae; 10-15 parts of derris trifoliata; 10-20 parts of cinnamic acid; and 10-20 parts of phenyllactic acid. The plant protective agent is environment-friendly, can inhibit plant diseases and insect pests, and can promote plant growth, and the plant protective agent can be applied together with agricultural chemicals.

Owner:张艳华

Integrated constant-temperature fertilizer mixing machine for farms

InactiveCN106390797ASpeed up the mixingSave time and costRotary stirring mixersMixer accessoriesFertilizerLine tubing

The invention relates to an integrated constant-temperature fertilizer mixing machine for farms and belongs to the technical field of fertilizer mixing. The machine comprises a mixing tank and a working platform, wherein the mixing tank is vertically mounted on the working platform, a first supporting frame and a second supporting frame are separately arranged on the working platform, a first feed tank is mounted on the first supporting frame and communicates with the top of the mixing tank through a first feed pipeline, a second feed tank is mounted on the second supporting frame and communicates with the top of the mixing tank through a second feed pipeline, a product collecting tank is arranged just below a bottom discharging opening of the mixing tank and is placed on a placement plate, slide rails are arranged on the placement plate in parallel, sliding grooves are formed in the bottom of the product collecting tank, heat-insulating jacket layers for temperature regulation are arranged at the periphery of a tank body of the mixing tank, and a first feed tank conveyor which is used for feeding the first feed tank is arranged at the right side of the first supporting frame. According to the integrated constant-temperature fertilizer mixing machine for the farms, the mixing of several kinds of fertilizers before fertilizer application is very convenient, so that time and labor are saved.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

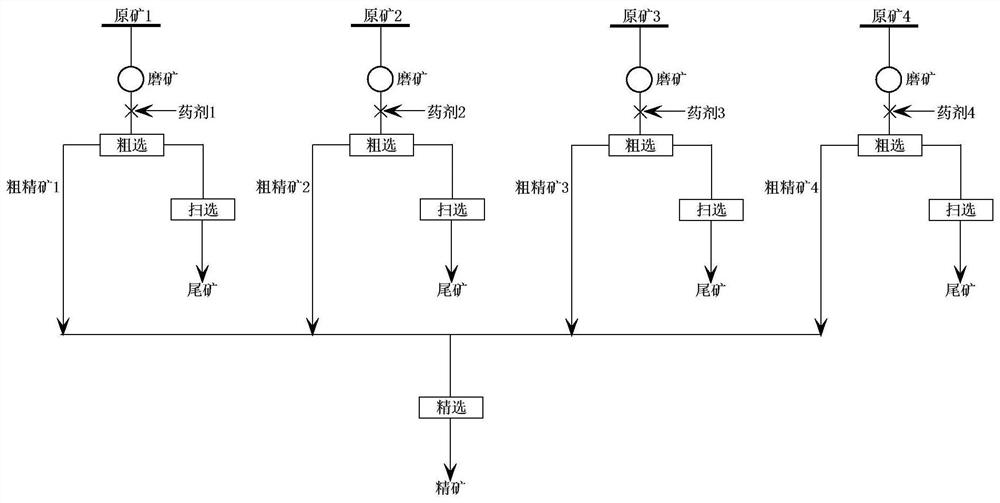

Beneficiation method for copper-molybdenum ore

InactiveCN113385301AReduce the impact of floatability differencesFacilitation and effectSolid separationCopperMaceral

The invention relates to the technical field of beneficiation, and particularly relates to a beneficiation method for copper-molybdenum ore. The beneficiation method comprises the steps that after the copper-molybdenum raw ore is classified according to grades, mineral types or ore properties, ore grinding and roughing are conducted, and rough concentrates and rough tailings are obtained; and after all the rough concentrates are combined, concentration is conducted. According to the beneficiation method, on one hand, the influence of floatability differences of the ore of different properties is reduced, corresponding medicament systems are adopted in a targeted manner, the action effect of medicaments and the surfaces of the ore is promoted, the operation efficiency of roughing and concentration is improved, and the grading index is improved; and on the other hand, all the rough concentrates are combined and concentrated, the number of concentration equipment is reduced, large-scale and automatic equipment is promoted, the equipment management efficiency is optimized, and finally the purpose of improving the grading index is achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

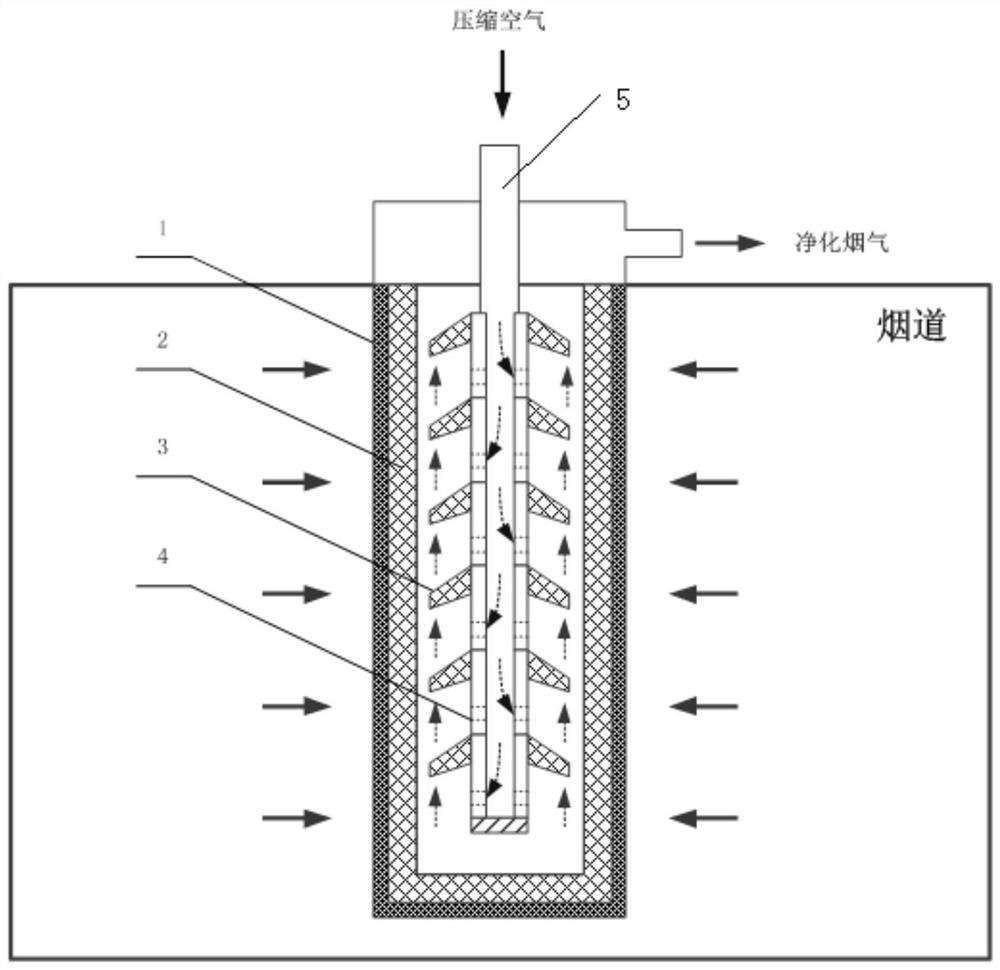

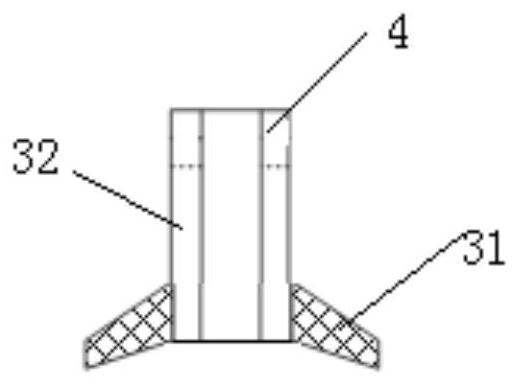

A porous ceramic tubular filter catalytic denitrification unit and its flue gas purification method

ActiveCN110639364BReduce washoutRealize deep denitrificationGas treatmentDispersed particle filtrationFlue gasPorous ceramics

Owner:SHANGHAI JIAOTONG UNIV

Constant-temperature fertilizer mixing tank

InactiveCN106540575AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesEngineeringTime cost

The invention relates to a constant-temperature fertilizer mixing tank, and belongs to the technical field of fertilizer mixing. The constant-temperature fertilizer mixing tank comprises a mixing tank body provided with a stirrer and a workbench, the mixing tank body is vertically mounted on the workbench, a first supporting frame and a second supporting frame are vertically arranged at the positions, at the left side and the right side of the mixing tank body, of the workbench respectively, and a first feeding trough is mounted on the first supporting frame and communicated with the top of the mixing tank body through a first feeding pipeline. A second feeding trough is mounted on the second supporting frame and communicated with the top of the mixing tank body through a second feeding pipeline. A product collecting trough is arranged under a bottom discharging opening of the mixing tank body and placed on a containing plate, and a heat preservation jacket layer for temperature adjustment is arranged around the tank body of the mixing tank. According to the constant-temperature fertilizer mixing tank, several kinds of fertilizers are mixed conveniently before fertilization, the mixing speed is greatly increased, the time cost is reduced, meanwhile, the labor intensity is reduced, and time and labor are saved.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Constant-temperature mixer for biological and chemical fertilizers

InactiveCN106540555AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesLine tubingEngineering

The invention relates to a constant-temperature mixer for biological and chemical fertilizers and belongs to the technical field of fertilizer mixing. The constant-temperature mixer comprises a mixing tank and a workbench; a stirrer is mounted in the mixing tank; the mixing tank is vertically mounted on the workbench; a first support frame and a second support frame are respectively and vertically disposed on the workbench at the left and right sides of the mixing tank; a first feeding chute is mounted in the first support frame; the first feeding chute communicates with the top of the mixing tank through a first feeding pipeline; a second feeding chute is mounted in the second support frame; the second feeding chute communicates with the top of the mixing tank through a second feeding pipeline; a product collecting tank is disposed under a discharge port at the bottom of the mixing tank; the product collecting tank is placed on a placing plate; a heat-insulation jacket layer for temperature regulation is disposed at the periphery of a tank body of the mixing tank; and a first feeding chute conveyor and a second feeding chute conveyor are respectively mounted on the right sides of the first support frame and the second support frame. According to the constant-temperature mixer, before fertilization, fertilizers are mixed conveniently and both time and labor are saved.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Fertilizer reprocessing apparatus before fertilization

InactiveCN106540558AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesLine tubingMixing tank

The invention relates to a fertilizer reprocessing apparatus before fertilization, and belongs to the technical field of fertilizer mixing. The apparatus comprises a mixing tank and a workbench, the mixing tank is vertically arranged on the workbench, a first supporting rack and a second supporting rack are respectively arranged on the workbench, the first supporting rack is provided with a first feeding tank, the first feeding tank is connected with the top of the mixing tank through a first feeding pipeline, the second supporting rack is provided with a second feeding tank, the second feeding tank is connected with the top of the mixing tank through a second feeding pipeline, a product collecting tank is arranged just below a material outlet at the bottom of the mixing tank, the product collecting tank is arranged on a placing plate, a slide rail is arranged on the placing plate in parallel, a chute is arranged in the bottom of the product collecting tank, a heat insulation jacket layer is arranged in the periphery of the tank body of the mixing tank, a first feeding tank conveyor is arranged at the right side of the first supporting rack, and a second feeding tank conveyor is arranged at the right side of the second supporting rack. The apparatus allows multiple fertilizers to be very conveniently mixed before fertilization, so the apparatus saves time and labor.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

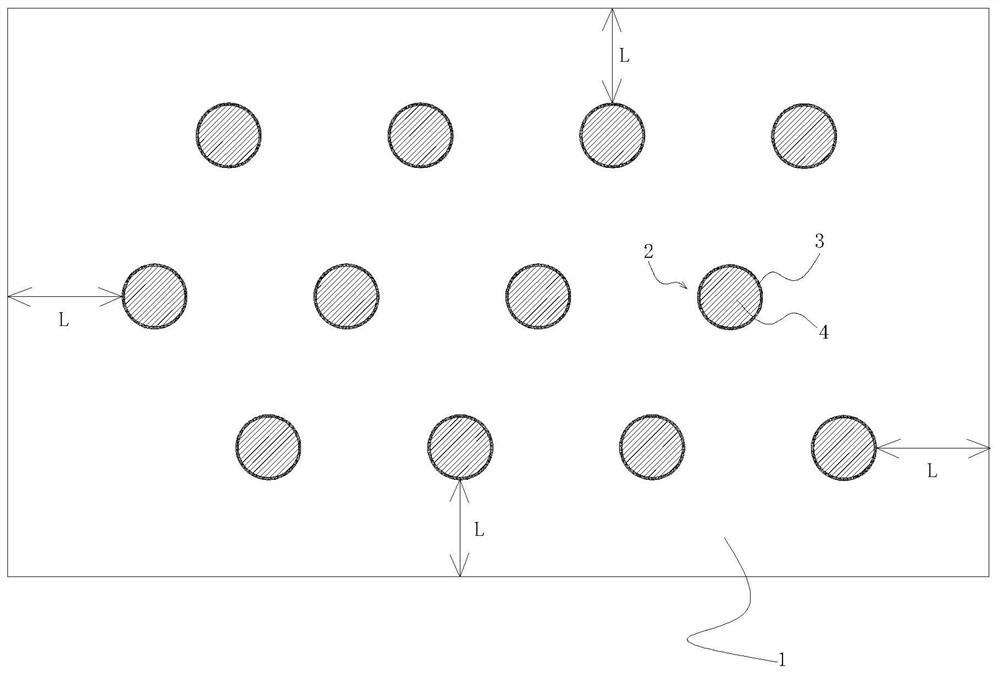

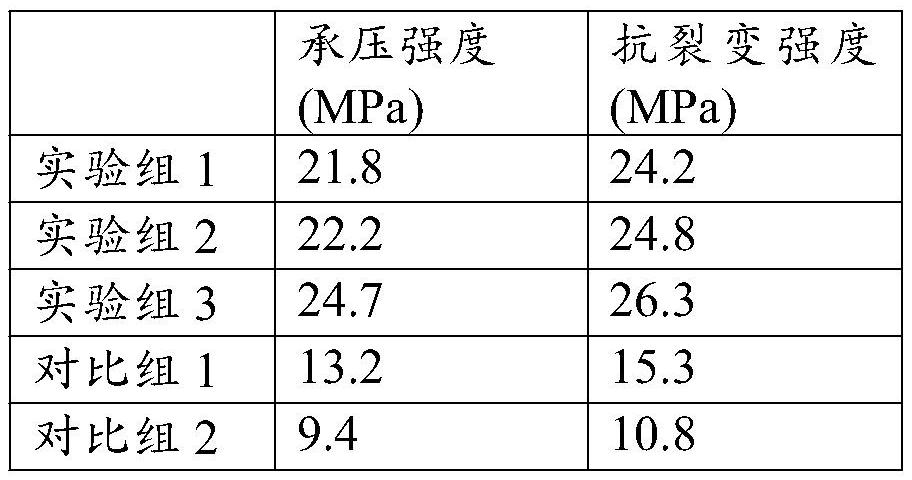

A kind of building plate and preparation method thereof

The invention relates to a building board with a good pressure bearing effect and a preparation method of the building board. The building board comprises a board body, wherein the body comprises a main filling part; the main filling part comprises ingredients in parts by weight as follows: 25-50 parts of zeolite, 50-80 parts of quartz sand, 20-40 parts of bentonite, 8-15 parts of phenolic resin,8-15 parts of epoxy resin, 8-15 parts of urea formaldehyde resin, 8-15 parts of polyvinyl chloride, 0.5-2 parts of bicyclic amidine, 1-3 parts of diethylene triamine, 0.5-1 part of phthalic anhydride,0.5-1 part of a foaming agent, 0.1-0.5 parts of Si, 0.05-0.1 parts of Ti, 0.2-0.3 parts of Cr, 0.5-2 parts of fiber, 8-15 parts of calcium oxide, 3-8 parts of magnesium sulfate and 50-400 parts of water, wherein the fiber is strip-shaped. Through interaction of whole ingredients in the building board, the high pressure-resisting effect can be realized, and the compressive strength can reach 20 MPa or above.

Owner:济南高投能源发展有限公司

A novel rodent sterile bait and its preparation method

The invention belongs to the field of pharmacology, and specifically relates to novel rodent sterile bait and a preparation method of the novel rodent sterile bait. By using quinestrol and an anti-coagulant as effective components, the bait provided by the invention is simple in component and is suitable for male rodents, but also suitable for female rodents. The anti-coagulant is added into the sterile bait, so that the rodents are further killed, and the deficiency that the sterile bait has no remarkable effect on some rodents is avoided. Quinestrol can further reduce the toxicity of the anti-coagulant, so that the anti-coagulant acts in the bodies of the rodents for a long time so as to further solve the problem of food refusal of the rodents. Meanwhile, by adding oleandrin C as an effective component, the effect to the rodents by the quinestrol and anti-coagulant is greatly promoted. By adopting the bait provided by the invention, the total quantity of sterile and dead rodents is over 97%, so that the effect is remarkable.

Owner:HENAN UNIV OF SCI & TECH

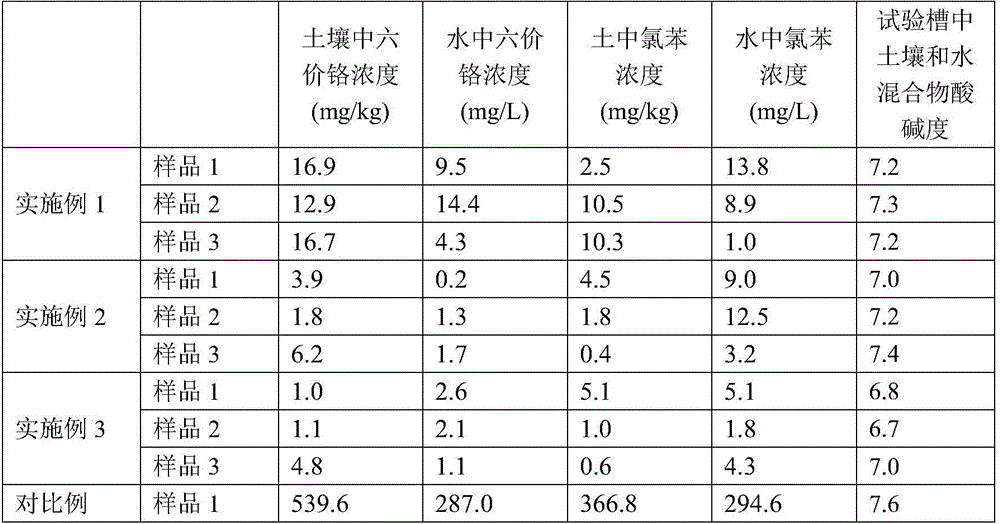

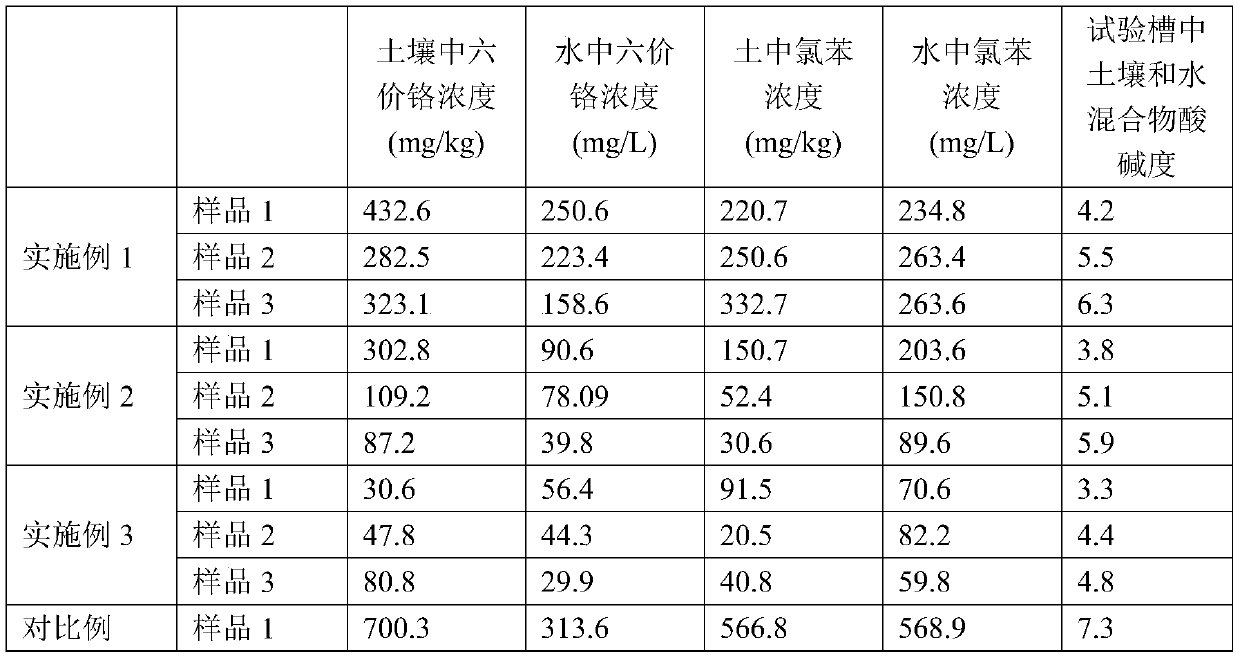

A novel reducing agent for remediating polluted sites and its preparation method

ActiveCN106825027BHigh recovery and repair efficiencyAvoid passivationWater contaminantsContaminated soil reclamationEthylic acidEnvironmental engineering

The invention discloses a novel reducing agent for repairing a contaminated site. The novel reducing agent is prepared from the following components in percentage by mass: 70 percent to 95 percent of micron iron powder and 5 percent to 30 percent of an auxiliary agent, wherein the auxiliary agent is prepared from the following components in percentage by mass: 45 percent of xanthan gum, 54 percent of waste molasses and 1 percent of acetic acid bacteria powder. The reducing agent can also be used for effectively avoiding deposition and agglomeration phenomena in a utilization process of the micron iron powder, and uniform dispersion degrees of the micron iron powder in a polluted soil body and a polluted water body are remarkably improved; an oxidation-reduction potential of a reaction system is greatly reduced, and the reduction removal rate of the micron iron powder on pollutants in the soil and underground water is remarkably improved; the potential of hydrogen of a balance reaction system can be effectively balanced; finally, efficient reduction and recovery of the pollutants in the soil and underground water is realized. Meanwhile, the invention further provides a preparation method of the reducing agent; the utilization rate of waste materials can be realized, the preparation cost is low and the operation is simple and easy.

Owner:SOUTHEAST UNIV

Constant-temperature fertilizer mixing tank with filtering and feeding components

InactiveCN106540564AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesAgricultural engineeringMatched filter

The invention relates to a constant-temperature fertilizer mixing tank with filtering and feeding components, and belongs to the technical field of fertilizer mixing. The constant-temperature fertilizer mixing tank comprises a mixing tank with a stirrer and a working table, the mixing tank is vertically installed on the working table, and the portions, at the left side and the right side of the mixing tank, of the working table are vertically provided with a first support frame and a second support frame respectively; a first feeding tank is installed on the first support frame and is in communication connection with the top of the mixing tank through a first feeding pipeline, and a second feeding tank is installed on the second support frame and is in communication connection with the top of the mixing tank through a second feeding pipeline; a product collection tank is arranged under a discharge port formed in the bottom of the mixing tank and arranged on a carrying plate, a heat insulating jacket layer for temperature adjusting is arranged at the periphery of a tank body of the mixing tank, and drawer-type matched filter screens are installed in the first feeding tank and the second feeding tank respectively. According to the constant-temperature fertilizer mixing tank, mixing of several kinds of fertilizer is very convenient before fertilizing, and time and labor are saved.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Constant-temperature fertilizer mixing tank for farm

InactiveCN106540559AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesLine tubingEngineering

The invention relates to a constant-temperature fertilizer mixing tank for a farm and belongs to the technical field of fertilizer mixing. The constant-temperature fertilizer mixing tank comprises a mixing tank and a workbench; a stirrer is mounted in the mixing tank; the mixing tank is vertically mounted on the workbench; a first support frame and a second support frame are respectively and vertically disposed on the workbench at the left and right sides of the mixing tank; a first feeding chute is mounted in the first support frame; the first feeding chute communicates with the top of the mixing tank through a first feeding pipeline; a second feeding chute is mounted in the second support frame; the second feeding chute communicates with the top of the mixing tank through a second feeding pipeline; a product collecting tank is disposed under a discharge port at the bottom of the mixing tank; the product collecting tank is placed on a placing plate; a heat-insulation jacket layer for temperature regulation is disposed at the periphery of a tank body of the mixing tank; and a first feeding chute conveyor for feeding a material to the first feeding chute is disposed on the right side of the first support frame. According to the constant-temperature fertilizer mixing tank, before fertilization, fertilizers are mixed conveniently and both time and labor are saved.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Fluorescence detection method of dichlor biotoxicity using Scenedesmus obliquus in ammonium salt environment

ActiveCN106770121BFacilitation and effectUnderstanding Biological ToxicityFluorescence/phosphorescenceArbitrary Fluorescence UnitDistilled water

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

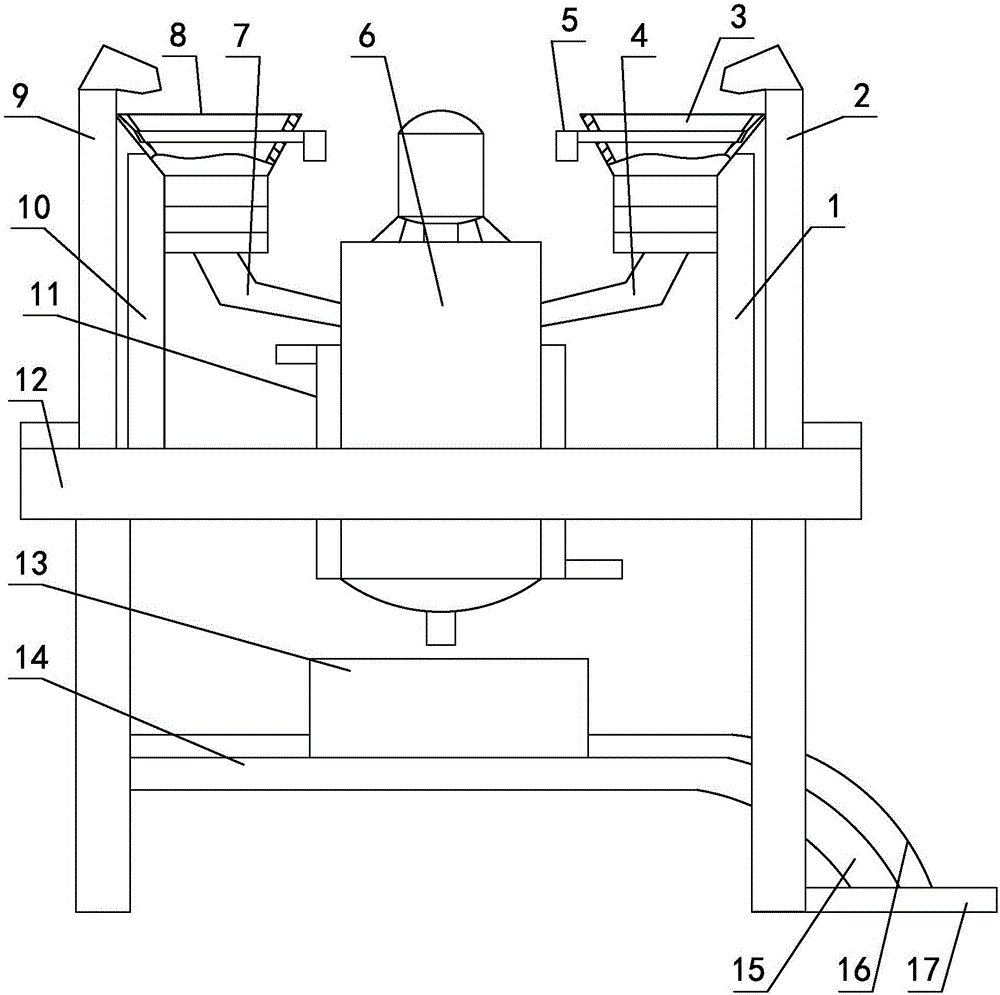

Portable constant-temperature fertilizer mixing machine

InactiveCN106540561AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesLine tubingAgricultural engineering

The invention relates to a portable constant-temperature fertilizer mixing machine, and belongs to the technical field of fertilizer mixing. The fertilizer mixing machine comprises a mixing tank and a workbench, the mixing tank is vertically installed on the workbench, the workbench is provided with a first support frame and a second support frame, a first feed tank is installed on the first support frame and communicated with the top of the mixing tank through a first feed pipeline, a second feed tank is installed on the second support frame and communicated with the top of the mixing tank through a second feed pipeline, a product collection tank is arranged under a discharge port formed in the bottom of the mixing tank and placed on a carrying plate, a left sliding rail and a right sliding rail which are used for allowing the product collection tank to slide left and right are arranged on the carrying plate in parallel, sliding grooves are formed in the bottom of the product collection tank, and a heat preservation jacket layer achieving temperature adjustment is arranged on the periphery of a tank body of the mixing tank. According to the portable constant-temperature fertilizer mixing machine, before fertilization is conducted, various fertilizers are mixed very conveniently, the mixing speed is greatly increased, the time cost is reduced, and time and labor are saved.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

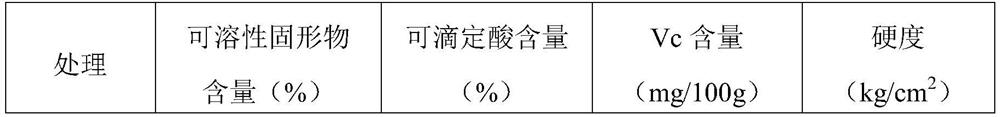

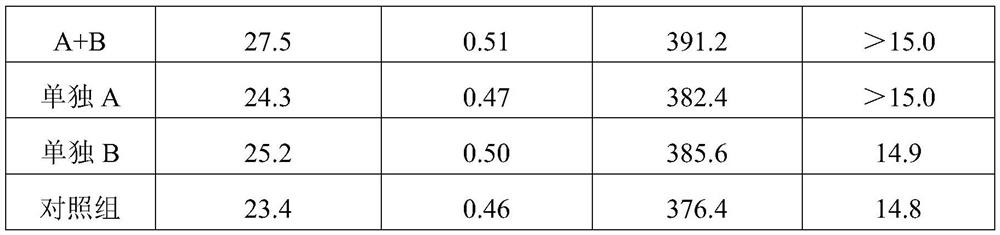

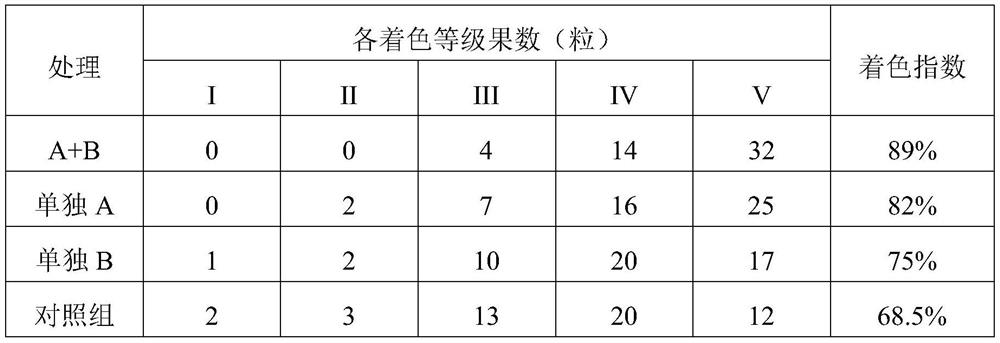

Preharvest Molecular Intercalation Quality Inducer for Lingwu Changzao Jujube

ActiveCN107711881BImprove flavor profileImprove disease resistanceBiocidePlant growth regulatorsFruit maturationArginine

The invention relates to a preharvest molecular intercalation quality inducer for Lingwu long jujubes. The inducer consists of a component A and a component B, wherein the component A contains 0.2g / L-0.5g / L of manganese sulfate, zinc acetate, boric acid, potassium dihydrogen phosphate, an SOD preparation, calcium chloride, linoleic acid, acetic acid, jasmonic acid methyl ester and arginine; and the component B contains heteroauxin, gibberellic acid, brassinolide, phytic acid and graphene. Specific to the improvement of the four preharvest qualities of color, fragrance, smell and taste, a quality improver A and a quality inducer B are respectively prepared and generate a synergistic effect, so that the plant absorption effect is improved, the maturing of fruits is promoted, and the qualities of color, sugar degree, brittleness and the like are improved.

Owner:天津绿新低温科技有限公司

Complete equipment for mixing fertilizers in farms

InactiveCN106540562AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesThermal insulationMixing tank

The invention relates to complete equipment for mixing fertilizers in farms, and belongs to the technical field of fertilizer mixing. The complete equipment comprises a mixing tank and a work bench. A first support frame and a second support frame are arranged on the work bench. A first feed chute is arranged on the first support frame. The first feed chute is connected and communicated with the top part of the mixing tank through a first feed pipeline. A second feed chute is arranged on the second support frame. The second feed chute is connected and communicated with the top part of the mixing tank through a second feed pipeline. A product collecting tank is arranged right under the discharge opening in the bottom of the mixing tank. The product collecting tank is placed on a bearing plate, a guide rail is parallelly arranged on the bearing plate, the bottom of the product collecting tank is provided with a chute, the periphery of the body of the mixing tank is provided with a thermal insulation jacket layer, the right side of the first support frame is provided with a first feed chute conveyer for feeding materials to the first feed chute, and the first feed chute and the second feed chute are both provided with a filter screen. The complete equipment can conveniently mix several fertilizers before fertilizing.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Constant-temperature fertilizer mixing device

InactiveCN106540573AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesEngineeringMixing tank

The invention relates to a constant-temperature fertilizer mixing device, belonging to the technical field of fertilizer mixing. The constant-temperature fertilizer mixing device comprises a mixing tank and a workbench, wherein the mixing tank is provided with a stirrer and vertically installed on the workbench, a first supporting frame and a second supporting frame are respectively vertically arranged on the workbench on the left and right sides of the mixing tank, a first feed tank is installed on the first supporting frame and connected and communicated with the top of the mixing tank through a first feed pipeline, a second feed tank is installed on the second supporting frame and connected and communicated with the top of the mixing tank through a second feed pipeline, a product collecting tank is arranged just below a bottom discharge port of the mixing tank and placed on a placement plate, a thermoregulated heat-insulating jacket layer is arranged around the body of the mixing tank, and a second feed tank conveyer for feeding the second feed tank is installed on the left side of the second supporting frame. The constant-temperature fertilizer mixing device is very convenient for mixing several kinds of fertilizer before fertilization, and saves time and labor.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Fast fertilizer mixer

InactiveCN106540568AWell mixedSpeed up the mixingRotary stirring mixersMixer accessoriesThermal insulationMixing tank

The invention relates to a fast fertilizer mixer and belongs to the technical field of fertilizer mixing. The fast fertilizer mixer comprises a mixing tank and a work table. The mixing tank is vertically mounted on the work table. The work table is provided with a first support frame and a second support frame. The first support frame is provided with a first feeding tank. The first feeding tank is communicated with the top of the mixing tank through a first feeding pipe. The second support frame is provided with a second feeding tank. The second feeding tank is connected to the top of the mixing tank through a second feeding pipe. A product collection tank is arranged right below a discharge outlet at the bottom of the mixing tank. The product collection tank is arranged on a placement plate. The placement plate is provided with two parallel sliding rails for sliding the product collection tank left and right. A chute is arranged at the bottom of the product collection tank. Four sides of the mixing tank are provided with thermal insulation jacket layers with the effect of adjusting a temperature. The left side of the second support frame is provided with a second feeding tank conveyor for transmitting materials to the second feeding tank. The fast fertilizer mixer can conveniently mix fertilizer materials before fertilization and save time and labor.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com