A novel reducing agent for remediating polluted sites and its preparation method

A reducing agent and site technology, applied in the restoration of contaminated soil, contaminated groundwater/leachate treatment, water pollutants, etc., can solve the problems of increasing the application cost and operation difficulty of micron iron powder restoration technology, and achieve Improve the continuous suspension and migration ability, enhance the reduction ability, and restore the effect of high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the reducing agent of above-mentioned embodiment, comprises the following steps:

[0042] Step 10): dilute the waste molasses with water, the dilution factor is 2-5 times, and then vibrate at room temperature for 5 minutes to make a uniform turbid liquid.

[0043] In step 10), the waste molasses is diluted with water, so that the sugar content is within the range suitable for the development and proliferation of acetic acid bacteria.

[0044] Step 20): Treat the turbid solution obtained in step 10) with moist heat sterilization to obtain a sterilized waste molasses culture solution; specifically include: boiling the turbid solution obtained in step 10) to 100° C. under an atmospheric pressure, and continuously 10 minutes to kill the bacterial propagules, and cooled to 20°C to 40°C in a sterile environment to obtain a sterilized spent molasses culture solution.

[0045] The sterilization process used in step 20) is to avoid the possible inhibit...

Embodiment 1

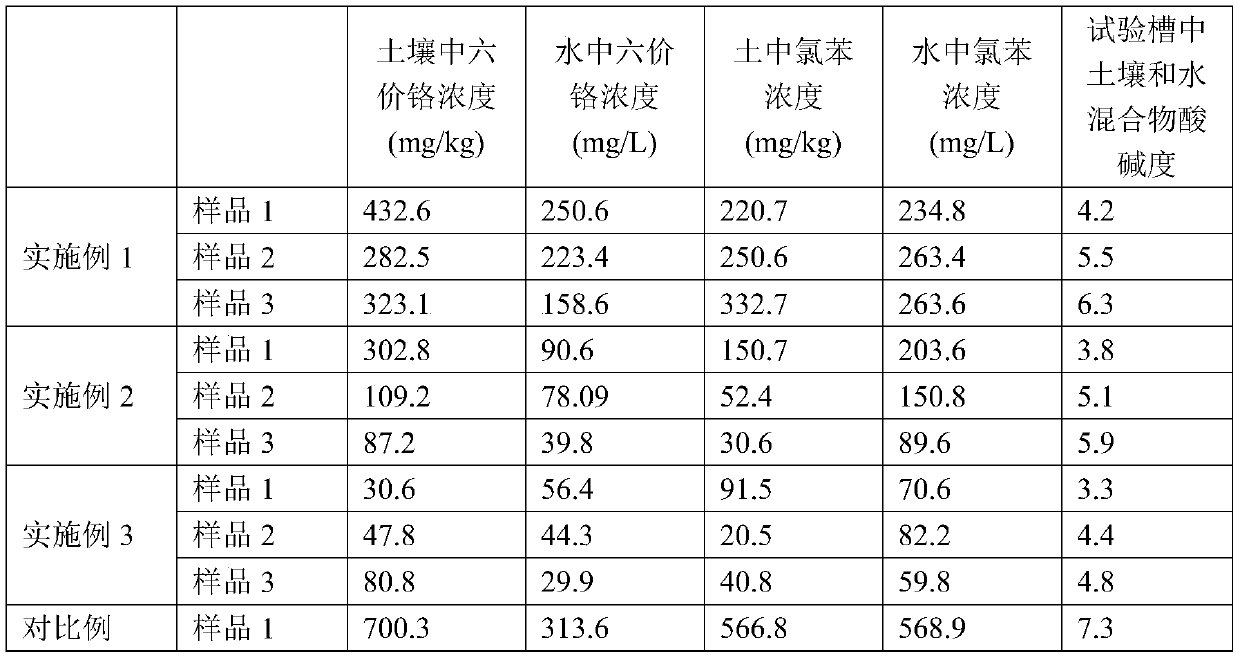

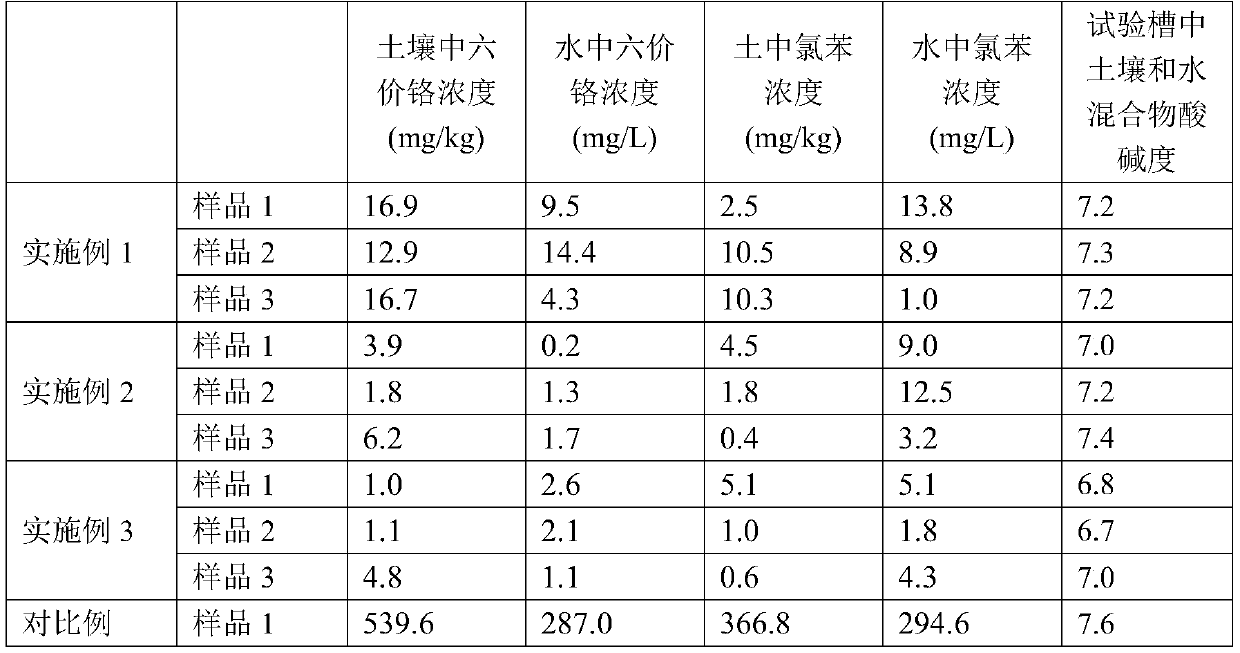

[0070]According to the preparation method of the reducing agent of the present invention and the distribution ratio of the sample components shown in Table 2, the reducing agent was prepared using the above-mentioned test materials. Mix the prepared reducing agent with the contaminated soil and groundwater in the model test tank prepared by test material 4) for 10 minutes until uniform, and the amount of the reducing agent is 3% (the weight of the dry basis in the reducing agent accounts for the soil and groundwater in the simulated contaminated site) total groundwater quality). Thereafter, the test cell was sealed and maintained at a temperature of 20°C and a humidity of >95%. At the age of 3 days and 10 days after curing, the soil and groundwater in the test tank were collected and the concentration of pollutants in the soil and groundwater and the pH of the soil and groundwater were detected.

Embodiment 2

[0072] The preparation process, maintenance and test process are the same as in Example 1, except that the dosage of the reducing agent is 6% (the dry weight of the reducing agent accounts for the total mass of soil and groundwater in the simulated polluted site).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com