Organic high-sulfur stabilizer and synthesis method thereof, and applications in remediation of heavy metal contaminated soil

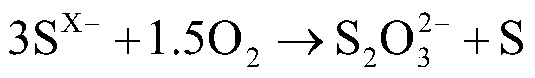

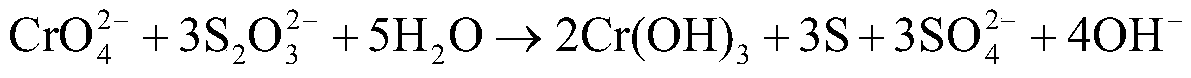

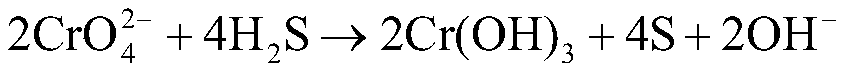

A synthetic method and a technology for polluting soil, which is applied in the fields of organic high-sulfur stabilizers and high-sulfur reagents, can solve the problems of chromium slag not being disposed of in a timely and effective manner, large-scale engineering application restrictions, and high price of sodium dithionite, etc., and achieve reduction and repair efficiency High, guaranteed reduction efficiency, and the effect of reducing the content of hexavalent chromium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh 180g of elemental sulfur powder, fully grind, pass through a 20-mesh sieve, add 25g of ethanol solution, stir quickly and evenly, and let it stand for use. Weigh 300g of sodium sulfide solid (60% active ingredient of industrial sodium sulfide) and add it to the container containing elemental sulfur, stir fully, add 600g of water after stirring evenly, use mechanical stirring, the speed is set at 100r / min, add 40L The polysaccharide solution with a concentration of 10g / L, and then continue to stir. After observing that the yellow elemental sulfur in the liquid has fully reacted, add 100L of PAM solution with a concentration of 1g / L, stir slowly, and let it stand for one hour. After observing the obvious stratification of the liquid, slowly pour the upper liquid into the suction filter and perform suction filtration to obtain a ruby-colored clear organic high-sulfur stabilizer product with an effective sulfide content of about 26%. The whole preparation time is one h...

Embodiment 2

[0048] Weigh 150g of elemental sulfur powder, fully grind, pass through a 20-mesh sieve, add 25g of ethylene glycol solution, stir quickly and evenly, and let it stand for use. Weigh 280g of sodium sulfide solid (industrial sodium sulfide active ingredient 60%) and add it to the container containing elemental sulfur, stir fully, add 550g of water after stirring evenly, use mechanical stirring, the speed is set at 100r / min, add 40L Carboxylate sugar solution with a concentration of 10g / L, and then continue to stir. After observing that the yellow elemental sulfur in the liquid has fully reacted, add 120L of PAM solution with a concentration of 1g / L, stir slowly, and let it stand for one hour. After observing the obvious stratification of the liquid, slowly pour the upper liquid into the suction filter and perform suction filtration to obtain a ruby-colored clear organic high-sulfur stabilizer product with an effective sulfide content of about 24.6%. The whole preparation time is...

Embodiment 3

[0050] Weigh 200g of elemental sulfur powder, fully grind, pass through a 20-mesh sieve, add 20g of ethanol solution and 10g of ethylene glycol solution, stir quickly and evenly, and let it stand for use. Weigh 280g of sodium sulfide solid (60% active ingredient of industrial sodium sulfide) and add it to the container containing elemental sulfur, stir fully, add 600g of water after stirring evenly, use mechanical stirring, the speed is set at 100r / min, add 50L Polysaccharide solution with a concentration of 10g / L, and then continue to stir. After the yellow elemental sulfur in the liquid is fully reacted, add 100L of aluminum sulfate solution with a concentration of 1g / L, stir slowly, and let it stand for one hour. After observing the obvious stratification of the liquid, slowly pour the upper liquid into the suction filter and perform suction filtration to obtain a ruby-colored clear organic high-sulfur stabilizer product with an effective sulfide content of about 26.7%. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com