Beneficiation method for copper-molybdenum ore

A mineral processing method, copper and molybdenum technology, applied in the direction of solid separation, etc., can solve the problems of complex ore composition, waste of resources, large changes in oxidation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

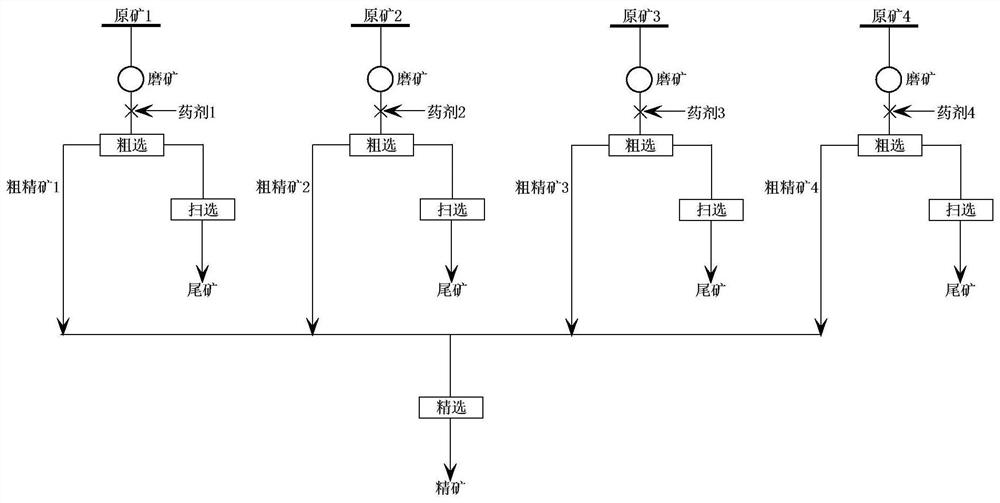

[0036] This embodiment provides a kind of beneficiation method of copper-molybdenum ore, such as figure 1 shown, including the following steps:

[0037] The raw ore copper grade of a copper-molybdenum mine is 0.42% and the molybdenum grade is 0.036%. The process mineralogy research shows that the raw ore is a mixed ore with an oxidation rate between 10 and 20%. The copper-bearing minerals in the raw ore mainly include chalcopyrite and a small amount of Bornite and copper blue, at the same time, also contains a part of malachite, molybdenum minerals are mainly molybdenite. This raw ore is classified according to the content of main mineral species, and is divided into raw ore I based on copper sulfide chalcopyrite and raw ore II based on mixed ore (chalcopyrite, malachite, etc.), respectively for raw ore I and Raw ore II is subjected to ore grinding and roughing. During the roughing process, regulators, collectors and foaming agents suitable for each raw ore are added to obtai...

Embodiment 2

[0040] This embodiment provides a kind of beneficiation method of copper-molybdenum ore, such as figure 1 shown, including the following steps:

[0041] The raw ore copper grade of a copper-molybdenum mine is 0.33% and the molybdenum grade is 0.029%. Technological mineralogy research shows that the copper-bearing minerals in the raw ore are mainly chalcopyrite, bornite, chalcocite, copper blue, etc., and some malachite , Molybdenum-containing minerals are mainly molybdenite. The raw ore is classified according to the content of main mineral types, and is divided into raw ore I mainly composed of primary copper sulfide chalcopyrite, raw ore II mainly composed of secondary copper sulfide such as chalcocite and copper blue, and mixed ore (chalcopyrite, malachite, etc.) as the main raw ore III, the raw ore I, raw ore II and raw ore III are subjected to grinding and roughing, and the adjustment agent and capture agent suitable for each raw ore are added during the roughing process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com