Patents

Literature

117results about "Radio/micro wave fibre treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

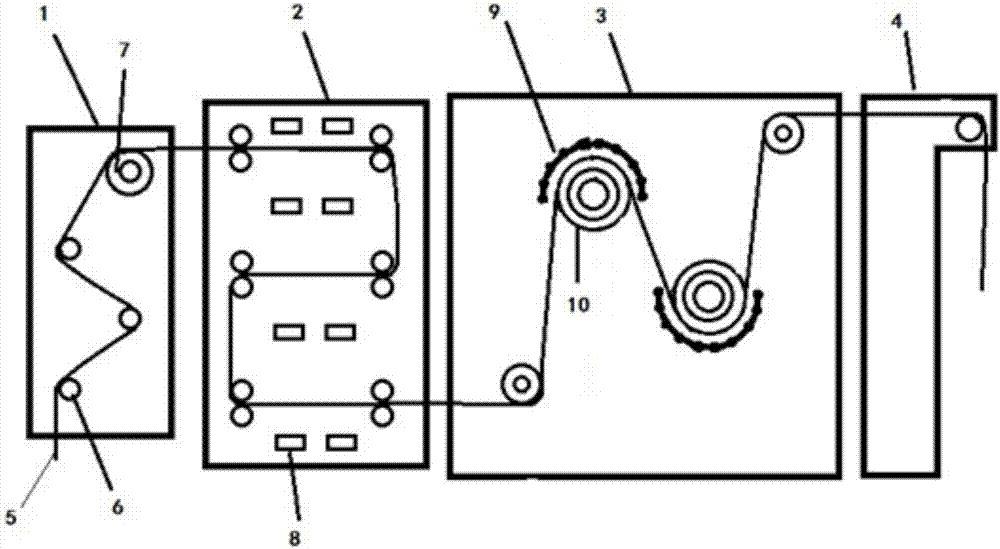

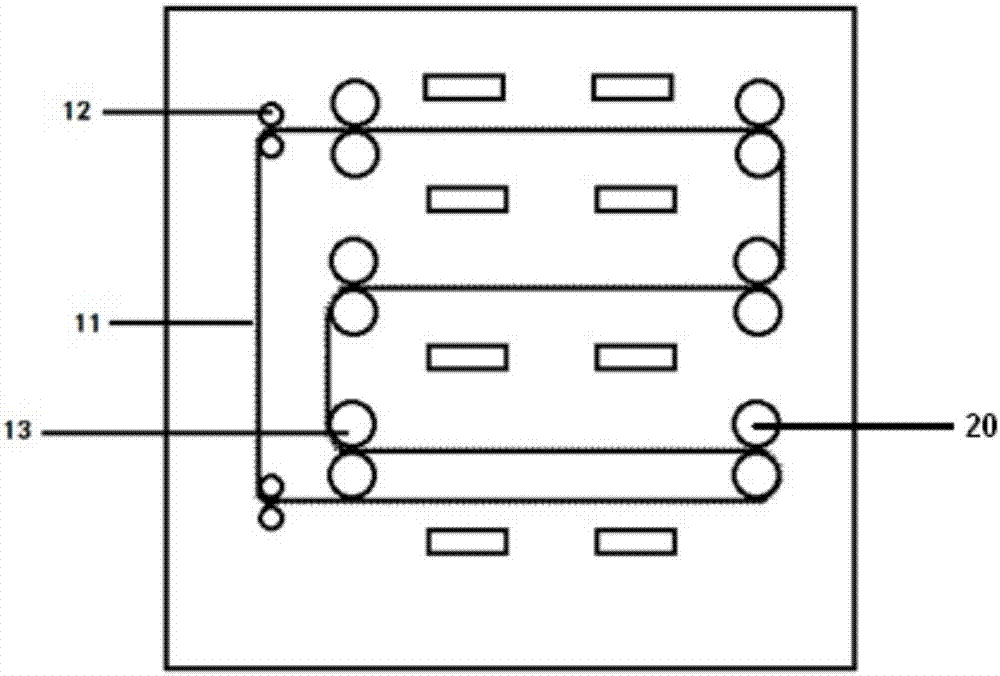

Method and apparatus for making on-line stabilized absorbent materials

InactiveUS6846448B2Short heating timeLow amountRadio/micro wave fibre treatmentWood working apparatusAbsorbent materialBiological activation

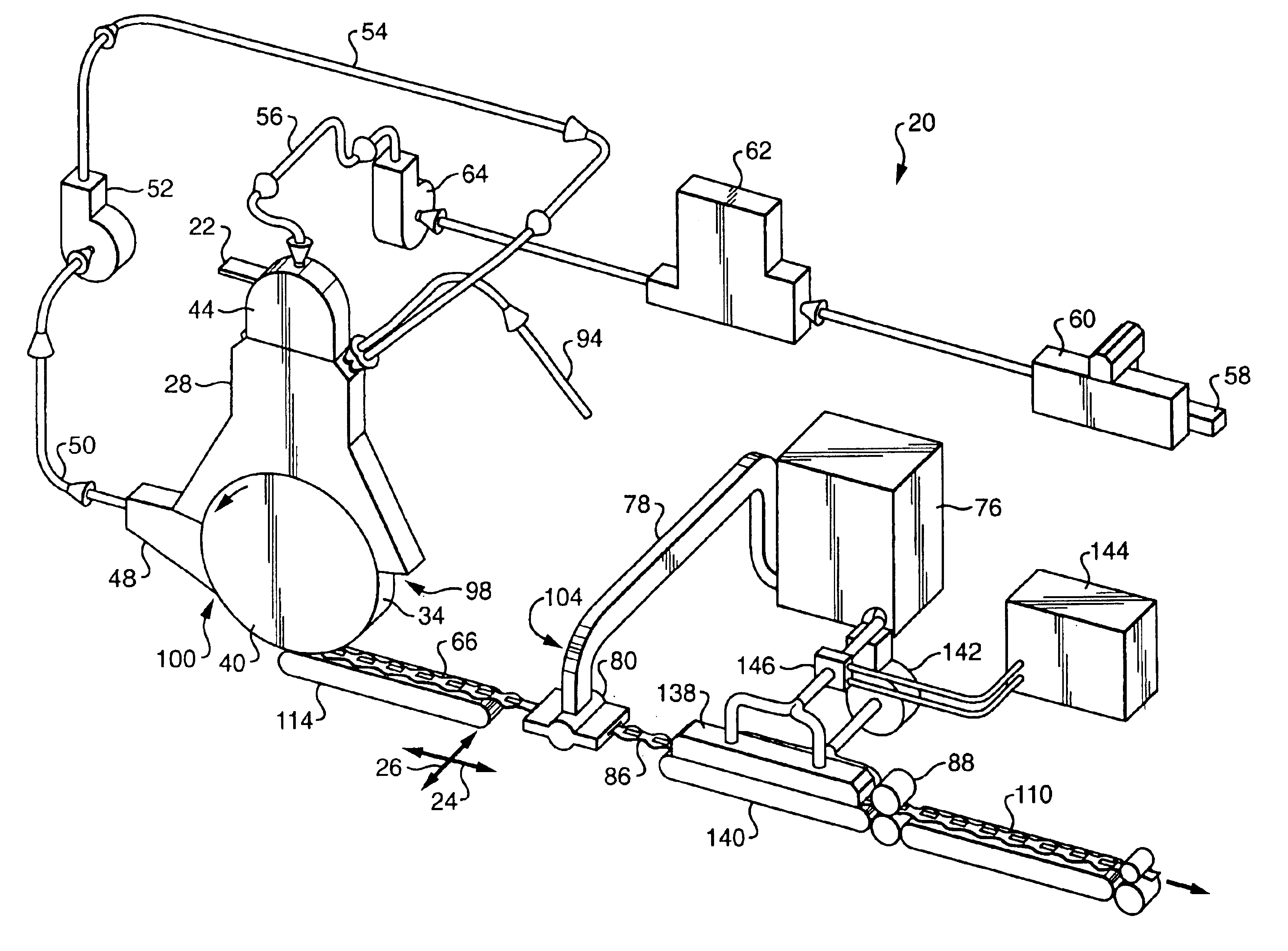

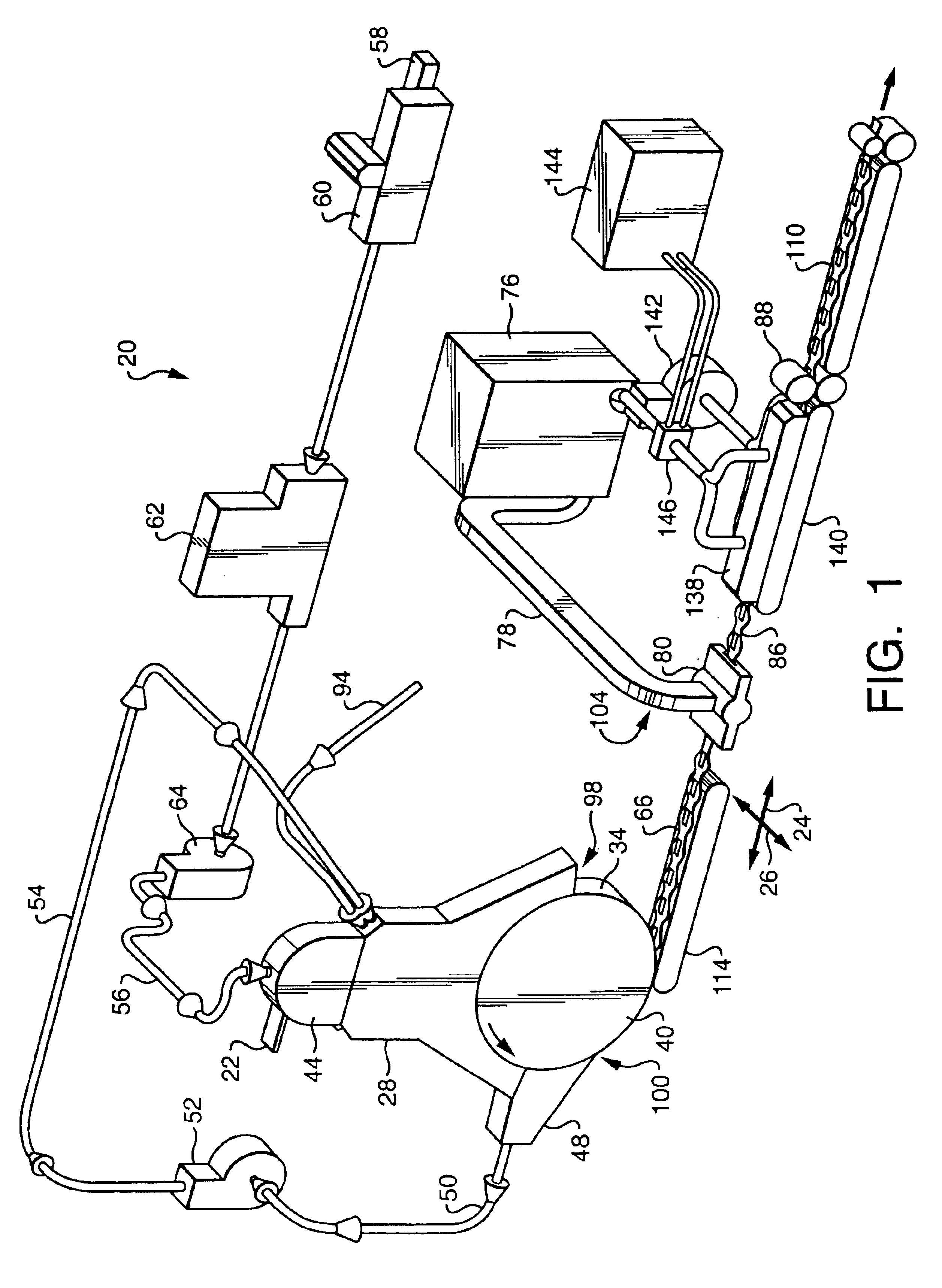

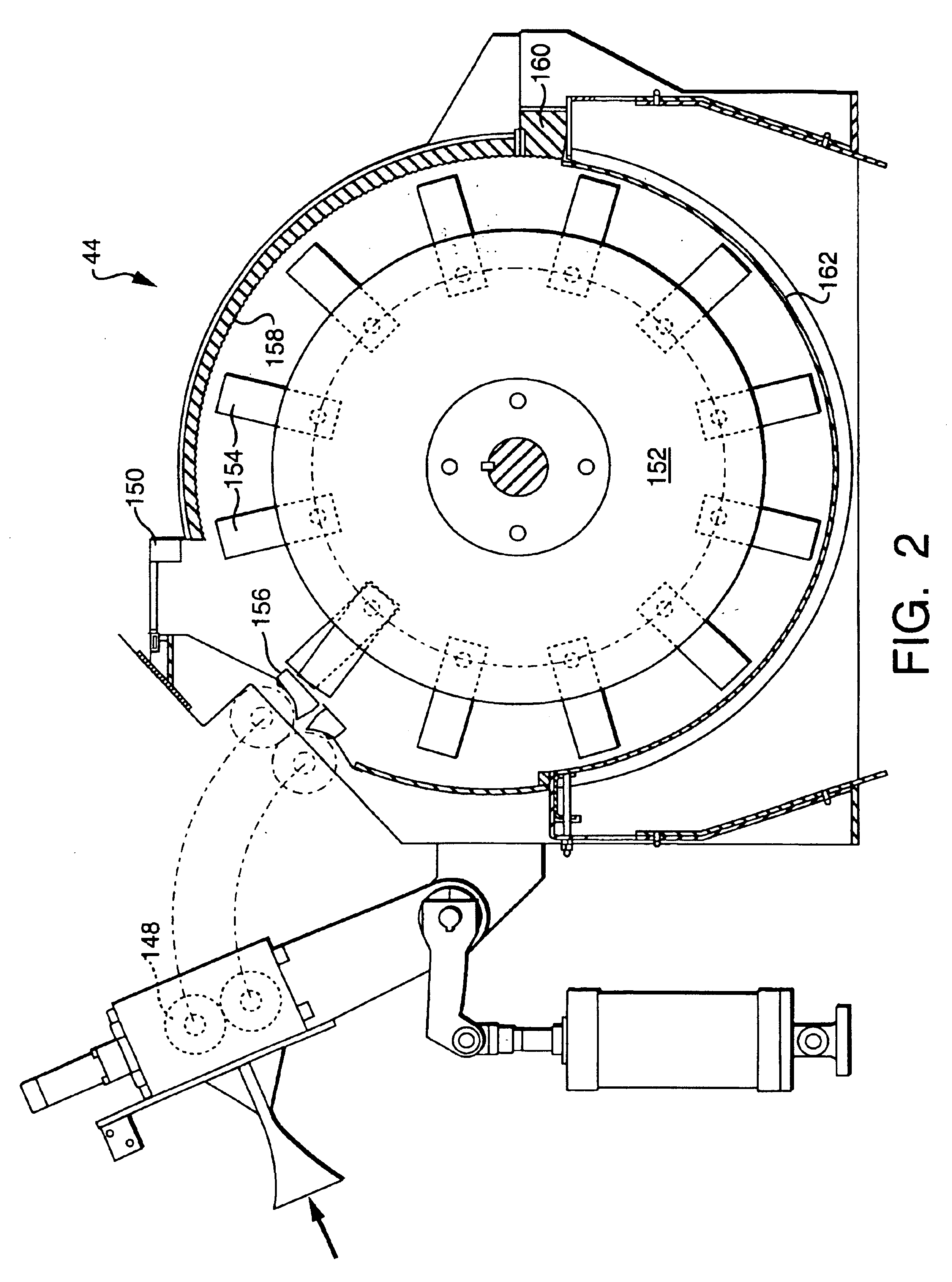

A method for forming a stabilized airlaid layer (86) can include an airforming of a substantially unbonded fibrous layer (66) which includes absorbent fibers and binder-fibers. The fibrous layer (66) is exposed to high-frequency electromagnetic energy during a distinctively short activation period to activate the binder-fibers to provide the stabilized, airlaid layer (86). In a particular aspect the activation period can be not more than about 3 sec.

Owner:KIMBERLY-CLARK WORLDWIDE INC

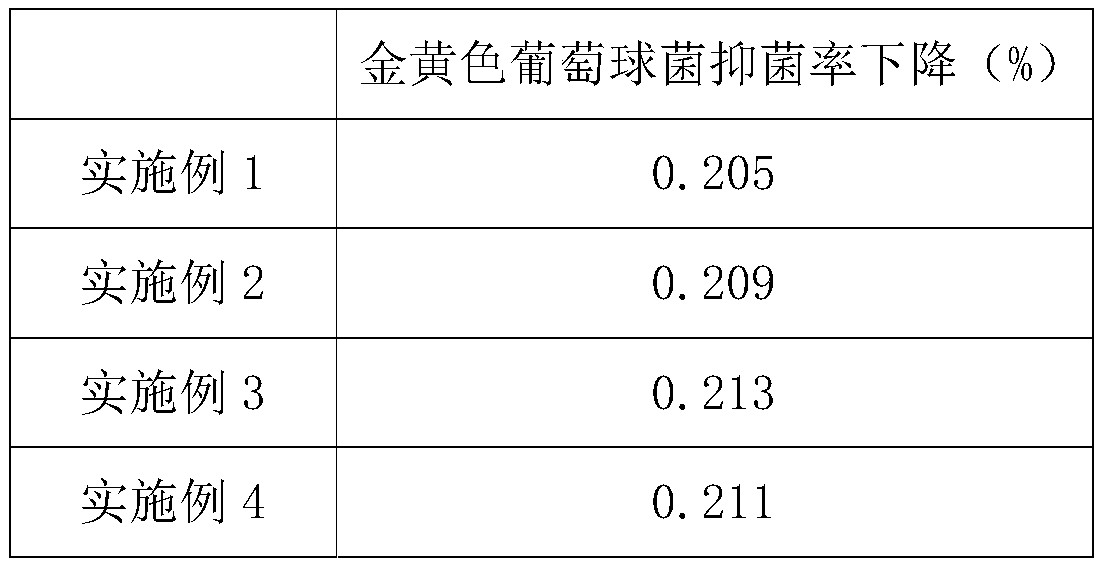

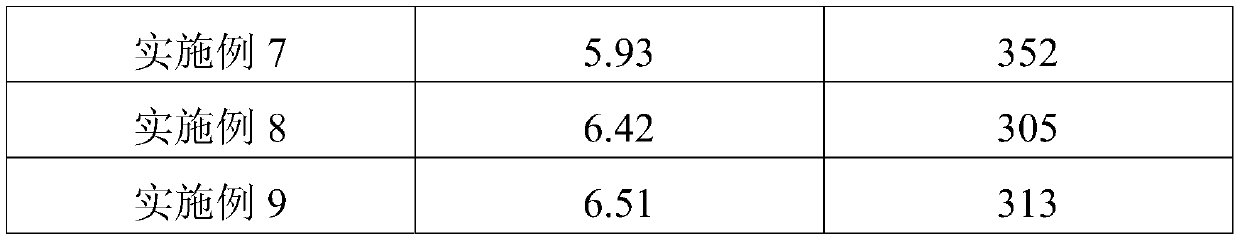

Preparation method of long-acting anti-microbial textile

InactiveCN106978721AImprove antibacterial propertiesReduce chemical pollutionRadio/micro wave fibre treatmentUltrasonic/sonic fibre treatmentMicrowaveRoom temperature

The invention discloses a preparation method of a long-acting anti-microbial textile. The preparation method concretely comprises the following processes: firstly a desizing or refining process is carried out for the textile, and pretreatment is carried out for the textile by using low temperature plasma; textile which is pretreated is dipped at a room temperature for 10-30 minutes in a mixed finishing solution which comprises a chitosan solution and a silver nitrate solution, the textile is taken out and superfluous finishing solution is rolled out, liquor retention is 100-150%, the textile which is dipped in the finishing solution is transferred into a piece of microwave equipment for carrying out treatment for a certain period of time, after the reaction ends, the textile is taken out and washed with water, and after drying, the anti-microbial textile is obtained. The anti-microbial textile has the advantages of excellent anti-microbial properties, washing resistance, lasting anti-microbial effects, simple preparation technology, and low chemical pollution; the method overcomes the problems of complex processes, bad stability of nanometer silver, bad anti-microbial durability and the like existed in the prior art.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

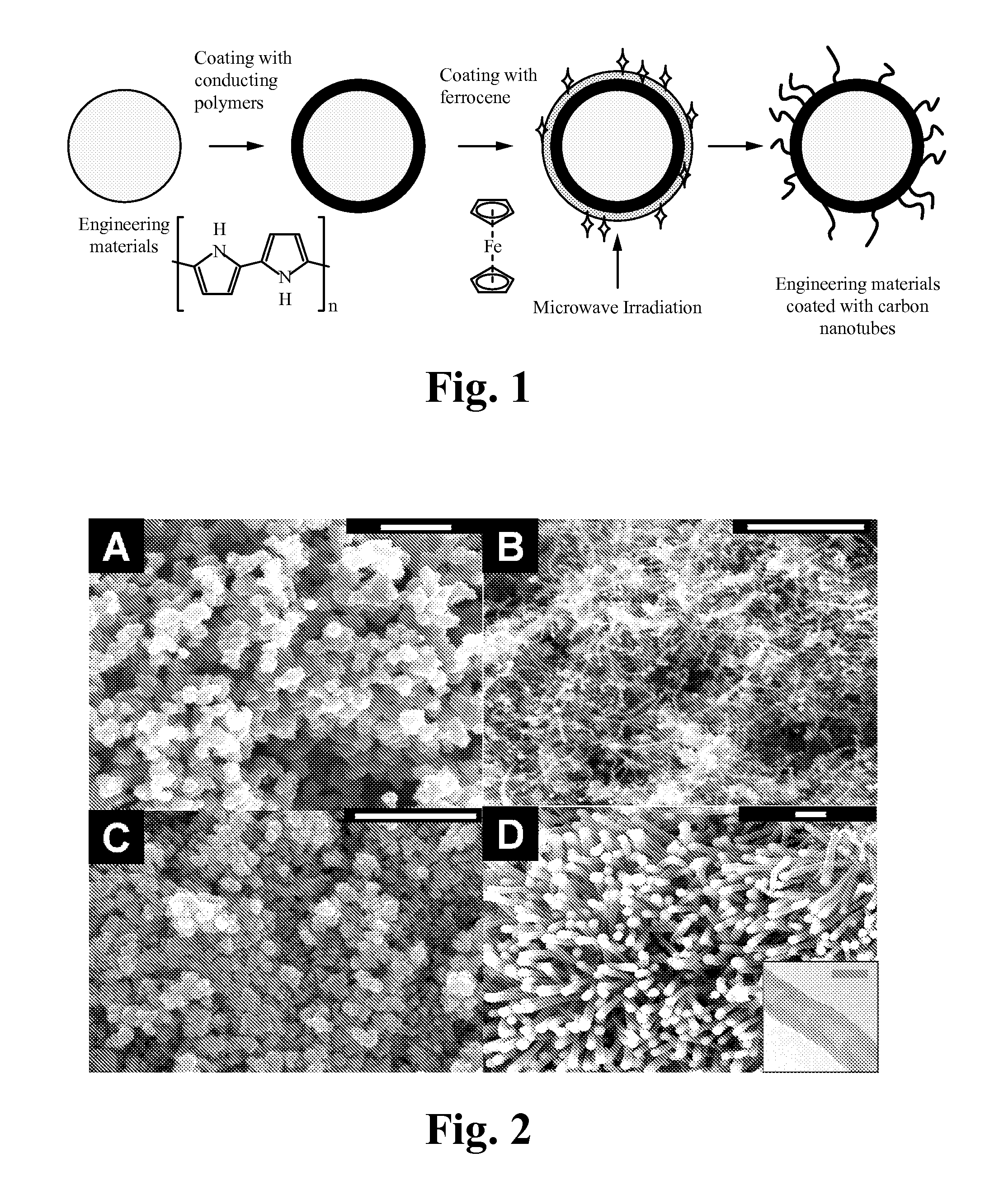

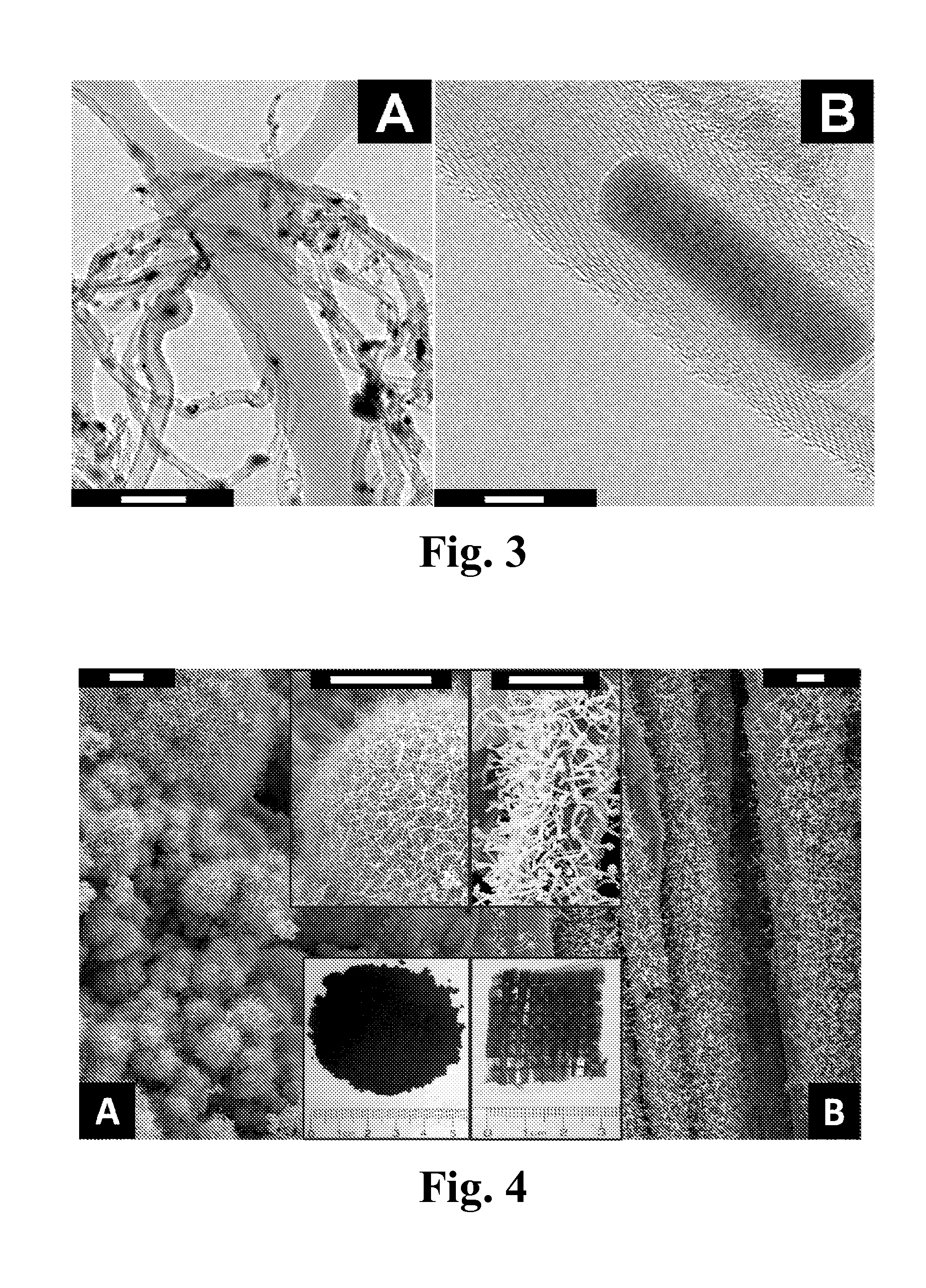

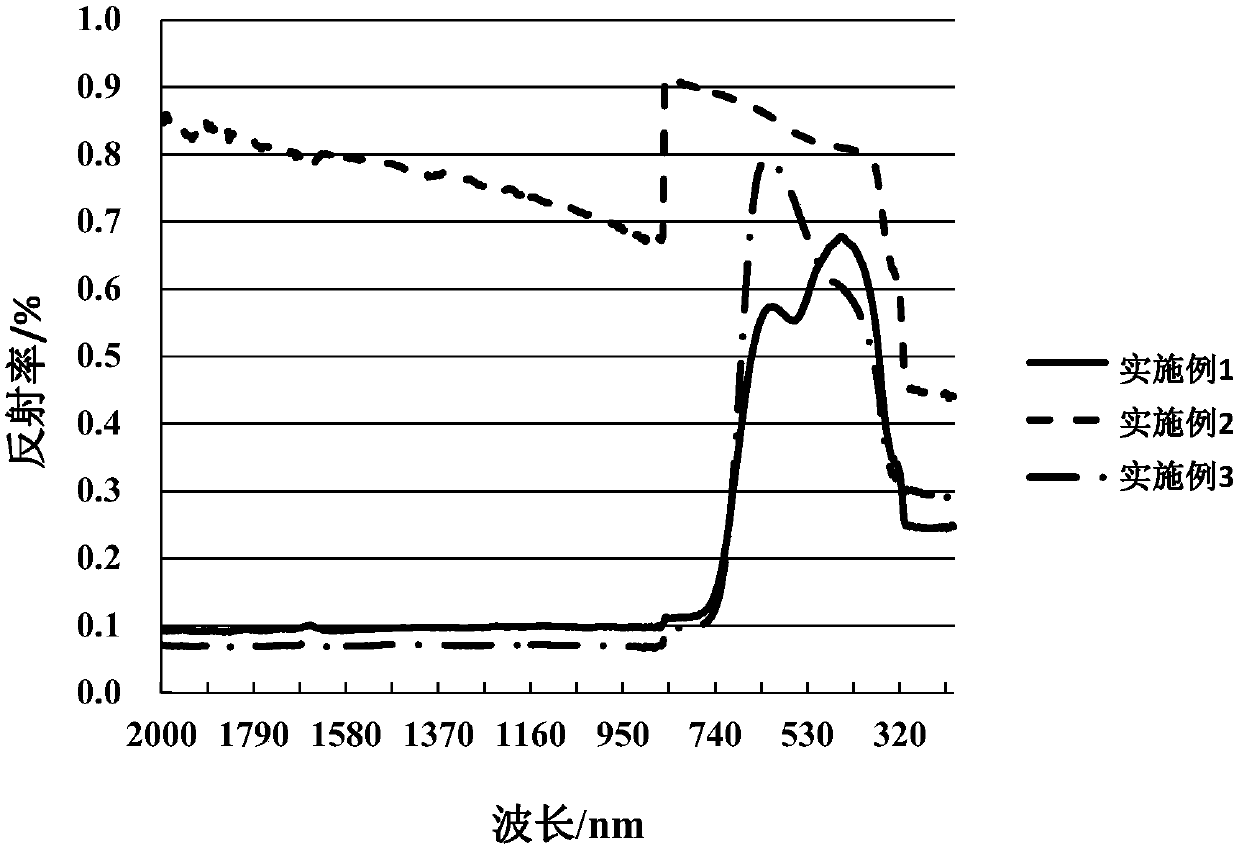

Novel nanocomposite for sustainability of infrastructure

InactiveUS20110223343A1Significant socialBig economyMaterial nanotechnologySolid waste managementAdhesiveFire resistance

A nanocomposite has significant social, economic and environmental benefits. By having high tensile strength and high toughness, a large number of opportunities of applying fly ashes are opened up. Besides replacing ordinary Portland cement, the nanocomposite is able to be used as an inorganic adhesive / resin to make fiber reinforced inorganic composites. The composite is fire resistant and has no volatile organic compounds. Due to its multifunctional character, the nanocomposite is able to be used as a sensing element in intelligent structures, corrosion protection coating for concrete and steel structures and even electronic devices.

Owner:AUBURN UNIV +1

Waterborne polyurethane synthetic leather and preparation method thereof

ActiveCN107881798AEvenly distributedSoft touchRadio/micro wave fibre treatmentMicrowaveManufacturing technology

The invention belongs to the technical field of production of synthetic leather and particularly relates to waterborne polyurethane synthetic leather and a preparation method thereof. The preparationmethod comprises the following steps: (1) impregnating non-woven fabric with a preimpregnating solution, and performing press-rolling and drying on the non-woven fabric to obtain pretreated non-wovenfabric; (2) impregnating the pretreated non-woven fabric in waterborne polyurethane size to obtain impregnated non-woven fabric; (3) solidifying the impregnated non-woven fabric under a microwave condition, washing the non-woven fabric with water, and drying the non-woven fabric to form non-woven fabric sheets; (4) performing veneering on the non-woven fabric sheets to obtain the waterborne polyurethane synthetic leather. According to the waterborne polyurethane synthetic leather and the preparation method, solidification is performed under the microwave condition, so that local polyurethane is prevented from forming a film under drying on the fiber surface, adhesion between polyurethane and fiber is reduced, and the polyurethane synthetic leather with soft feel and excellent folding resistance is prepared.

Owner:浙江昶丰新材料有限公司

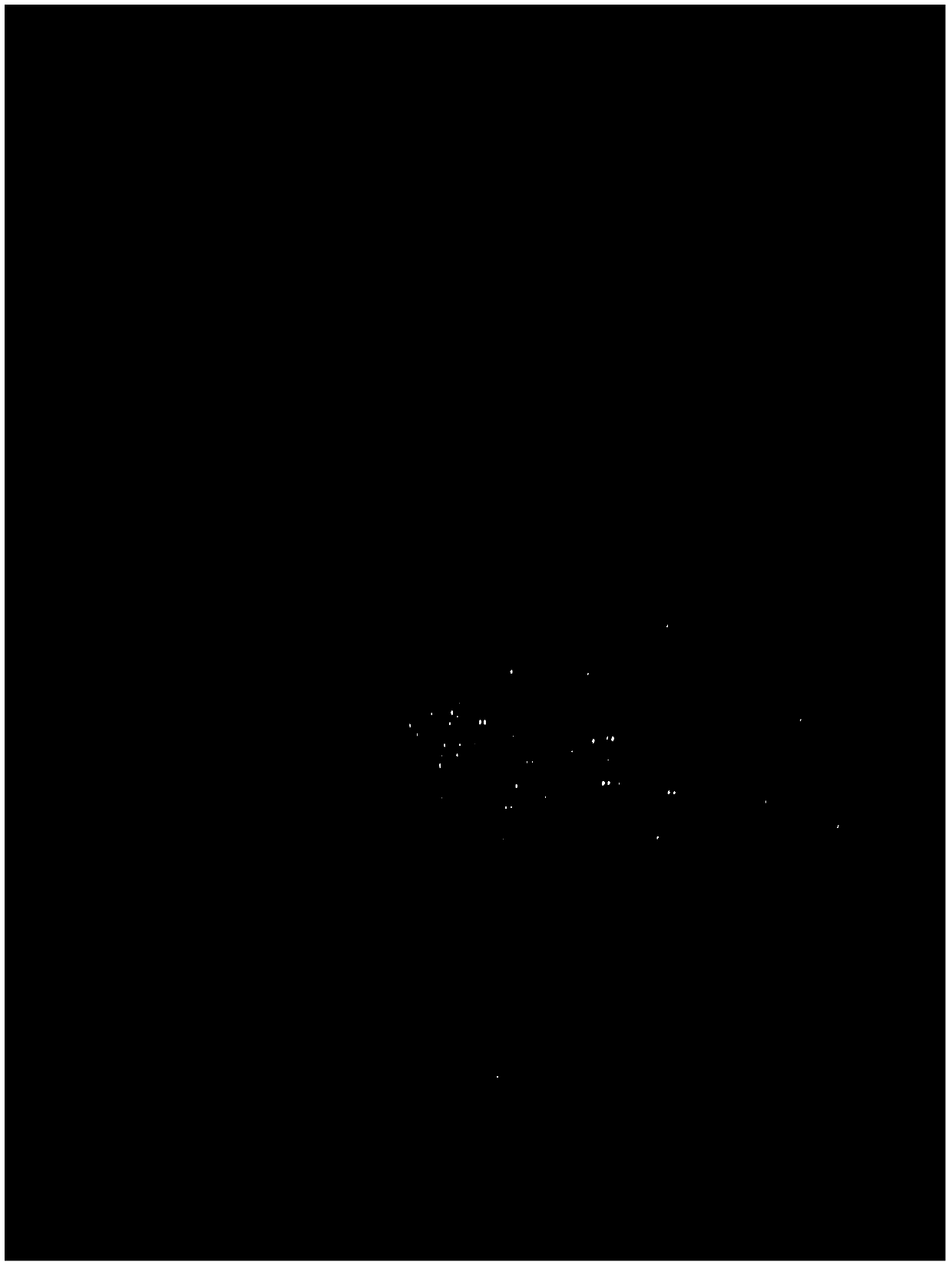

Fabric coloring method and colored fabric

PendingCN110629569ATo achieve the coloring effectIncrease richnessRadio/micro wave fibre treatmentVacuum evaporation coatingColour fastnessHigh color

The invention provides a fabric coloring method and a colored fabric. The fabric coloring method includes steps: subjecting base cloth to radiation drying treatment; performing vacuum deposition to sequentially form an adhesive layer and at least one coloring layer on the surface of the base cloth subjected to radiation drying treatment, wherein the adhesive layer comprises at least one of Ti, Cr,Si and Ni and is in thickness of 1-2000nm, each coloring layer comprises at least one of Al, Ti, Cu, Fe, Mo, Zn, Ag, Au and Mg, and the total thickness of the at least one coloring layer is 1-4000nm.By adoption of the coloring method, rich colors can be generated, high color fastness of the colored fabric is realized while film thickness sensitivity of the color of the colored fabric is reduced,and accordingly industrial operability is improved.

Owner:GUANGDONG XINFENG TECH

Modified aramid fiber reinforced PA66 material and preparation method thereof

InactiveCN103709742AIncreased transverse tensile strengthHigh strengthRadio/micro wave fibre treatmentAbrasion resistant fibresRadiation DosagesRadiation frequency

The invention relate to a modified aramid fiber reinforced PA66 material and a preparation method thereof. The preparation method comprises the steps of modifying the aramid fibers by using microwave radiation, with radiation frequency being 0.5-5 GHZ, radiation dosage being 0.1-2 mW / cm<2> and radiation time being 1-240 s; and then processing the modified aramid fibers by using low temperature plasma, with a processing power being 10-400 W, a processing atmosphere being composed of 5-15% of hydrogen, 5-15% of fluorine and 70-90% of helium, a processing temperature being 0-150 DEG C and a processing time being 1-20 min. The surface layer and the core layer of the aramid fibers modified by the microwave radiation are crosslinked, so that transverse tensile strength of the fibers is increased; and after the low temperature plasma modification, the surfaces of the aramid fibers become rough and are rich in active free radicals and functional groups. The mechanical and wear resistant performances of the composite material prepared by blending and extruding the modified aramid fibers together with the PA66 resin through a double-screw extruder are increased by 15-20% than that of similar products at abroad, and can meet the requirements of the fields such as high speed railways and aerospace for high-performance wear-resistant components.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

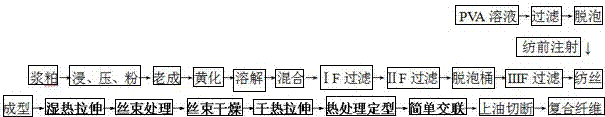

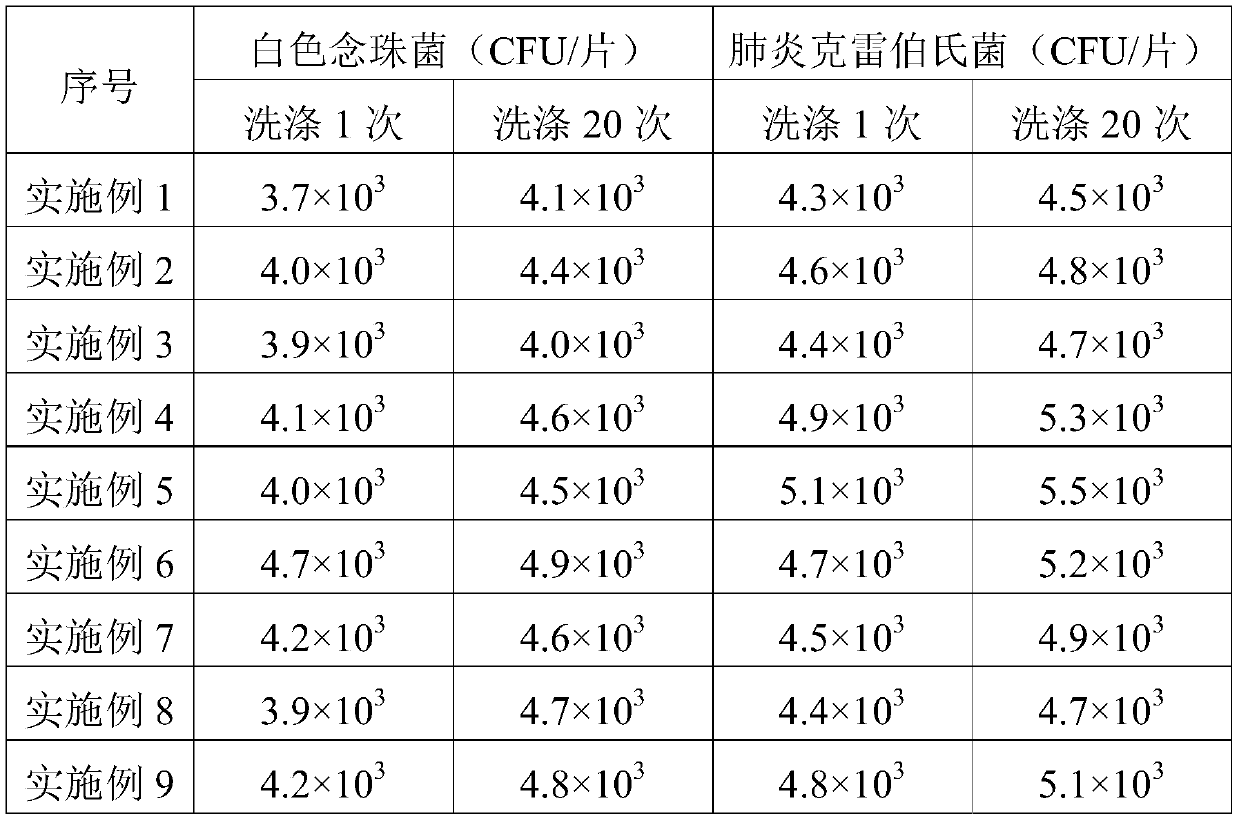

Preparation method of PVA/cellulose composite fiber

ActiveCN107090607AAchieve blendingImprove water resistanceRadio/micro wave fibre treatmentConjugated cellulose/protein artificial filamentsCelluloseFiber

The invention provides a preparation method of a PVA / cellulose composite fiber. The preparation method comprises the following steps: preparing a spinning solution, performing spinning moulding, carrying out damp and hot drawing, carrying out tow treatment, carrying out tow drying, carrying out dry and hot drawing, carrying out heat treatment type approval, and simply crosslinking. The preparation method provided by the invention has the advantages that PVA solution precrosslinking and further crosslinking bath are eliminated; the prepared PVA / cellulose composite fiber not only can enable advantages of two components to be complementary, but also can realize blending of the two components in structure, dry strength of the prepared PVA / cellulose composite fiber is more than or equal to 2.12cN / dtex, and wet strength is more than or equal to 1.08cN / dtex; and the prepared composite fiber has high water tolerance, good textile processing property and moisture absorption rate of 7.6-12.0%.

Owner:潍坊欣龙生物材料有限公司

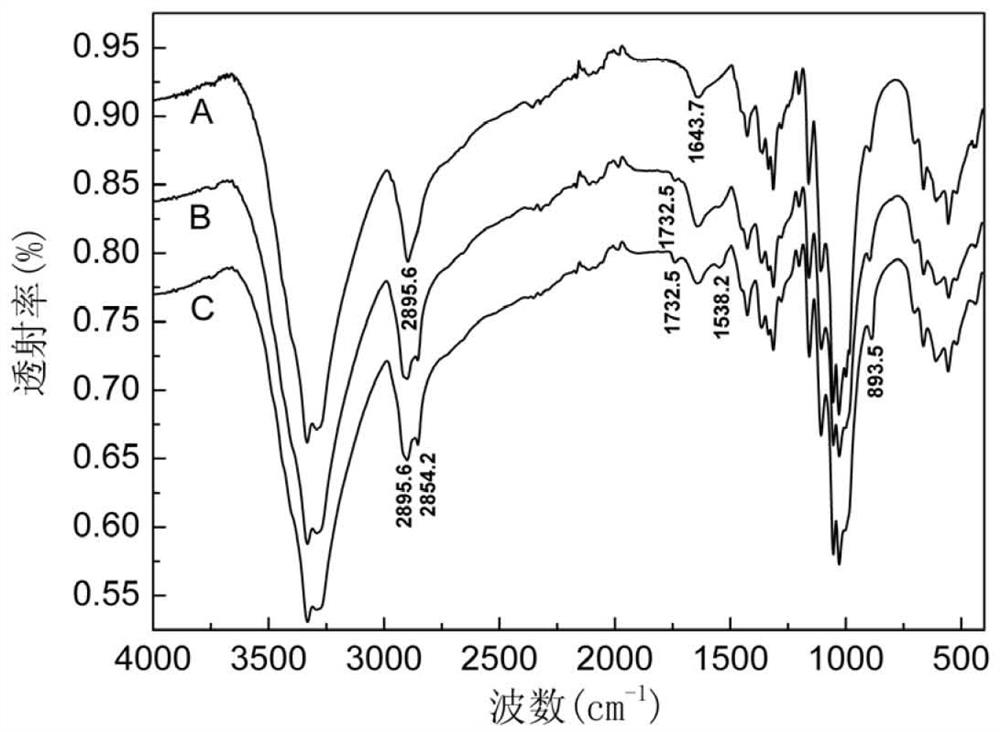

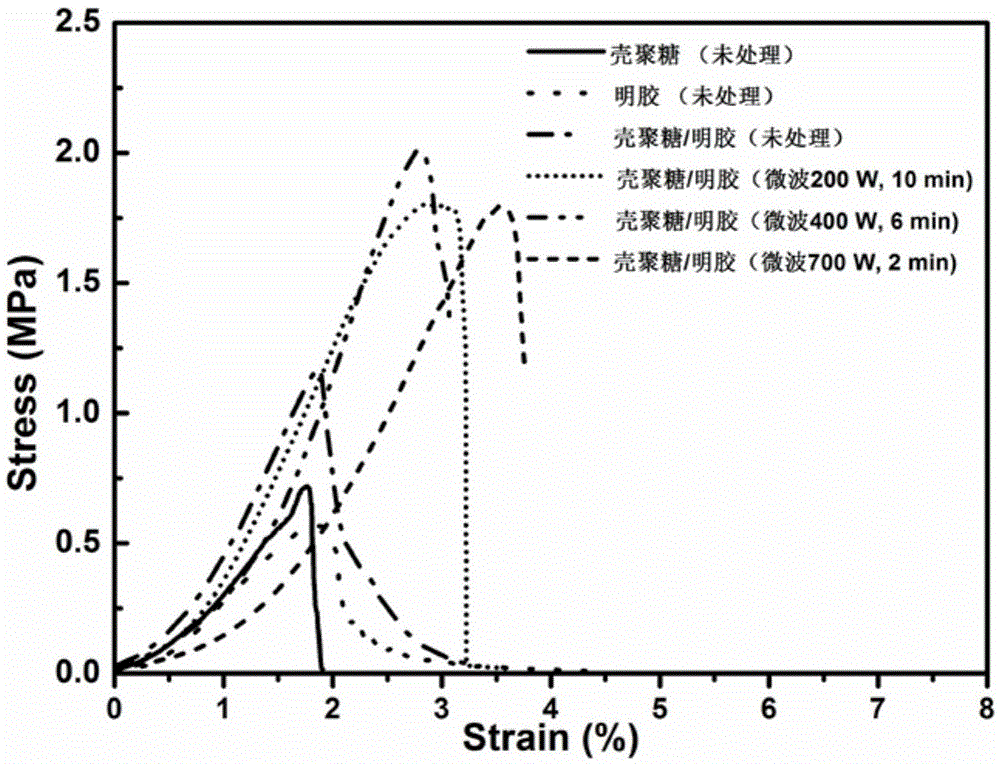

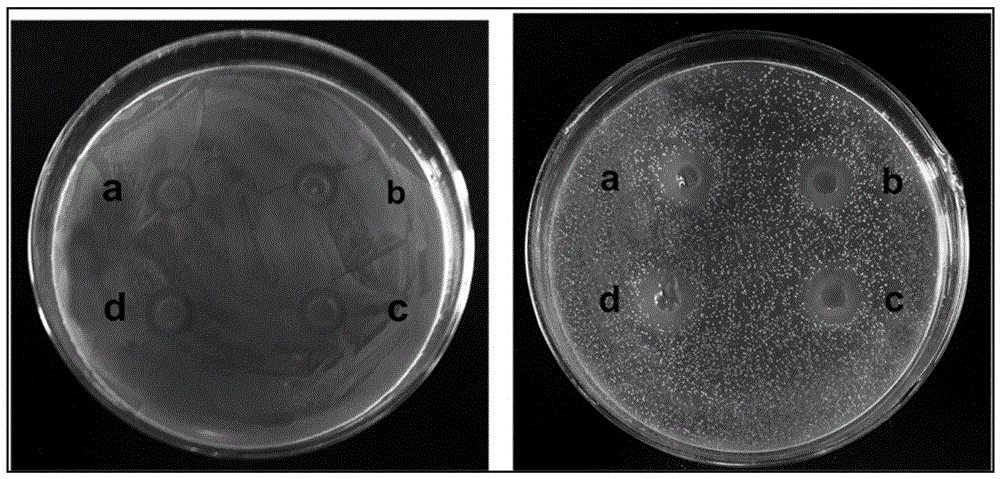

Chitosan antibiotic finish method for textiles

InactiveCN106930108AImprove antibacterial washabilityFull penetrationRadio/micro wave fibre treatmentBiochemical fibre treatmentEscherichia coliFiber

The invention discloses a chitosan antibacterial finishing method for textiles. Firstly, it is pretreated, and then the surface of the fiber is activated with a large amount of high-energy electrons, ions and free radicals generated by microwave plasma; , flush the antibacterial finishing agent containing chitosan with a certain temperature into the reaction chamber by using the negative pressure in the reaction chamber to react with the activated clothing for a certain period of time, then dehydrate the finished clothing to maintain the liquid retention rate between 30-60%; and microwave-dried it, finally rinsed with clean water, dehydrated, dried, and packaged. The pure cotton garment of the present invention exhibits good durability after chitosan antibacterial finishing, and after 60 times of soaping, the antibacterial rate of Escherichia coli is still over 80%, and the antibacterial rate of Staphylococcus aureus is over 89%.

Owner:深圳优普莱等离子体技术有限公司

Ecological dyeing antibacterial cotton fabric preparation method

ActiveCN111663334AReduce dosageNo pollution in the processRadio/micro wave fibre treatmentBiochemical fibre treatmentInorganic saltsAntibacterial activity

The invention discloses an ecological dyeing antibacterial cotton fabric preparation method. An antibacterial cotton fabric is obtained by carrying out a hemiacetal reaction on aldehyde groups at C6 positions in oxidized chitosan molecules and hydroxyl groups in cotton fabric, and then carrying out salt-free dyeing with reactive dyes. The oxidized chitosan modified cotton fabric prepared by the invention has durable and efficient antibacterial activity and good salt-free dyeing performance, has good affinity with human bodies, is green and environmentally friendly, overcomes the problem of environmental pollution caused by using a large amount of inorganic salts and electrolytes in conventional dyeing of cotton fabrics, and has practical application potential.

Owner:SHAOXING MAIBAO TECH CO LTD

Graphene composite antibacterial fiber

PendingCN111364237AImprove antibacterial propertiesImprove washabilityCarbon compoundsRadio/micro wave fibre treatmentFiberPolyester

The invention provides a graphene composite antibacterial fiber. The graphene composite antibacterial fiber is mainly prepared by the following steps of (1) enabling N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane to react with graphene oxide subjected to plasma treatment to obtain aminated graphene; (2) enabling glycidyl trimethyl ammonium chloride to react with the aminated graphene to obtain quaternized graphene with quaternary ammonium salt at the tail end; and (3) enabling a polyester fiber and the quaternized graphene to undergo dipping mixing treatment to obtain the graphenecomposite antibacterial fiber. The provided graphene composite antibacterial fiber has better antibacterial property and washability at the same time.

Owner:旷达纤维科技有限公司 +1

Multifunctional modification treatment method for silk

InactiveCN105862385AImprove wrinkle resistanceImprove antibacterial propertiesRadio/micro wave fibre treatmentBiochemical fibre treatmentCarboxylic acidAcid dye

The invention discloses a method for multifunctional modification of silk, which comprises: dipping and rolling silk twice in a finishing liquid containing chitosan guanidine hydrochloride, polycarboxylic acid and sodium hypophosphite, and the excess ratio is 80~120%, microwave irradiation for 1~5min, power 300~700W, fully wash with hot water at 50℃, wash with cold water, and finally dry. The invention has simple process, saves energy, reduces or prevents environmental pollution, and is suitable for industrialized production; the silk fabric modified by the invention not only has good wrinkle resistance and antibacterial properties, but also can greatly improve the active dyes used in silk after treatment. Dyeing performance of silk fabrics with acid dyes.

Owner:SHAOXING UNIVERSITY

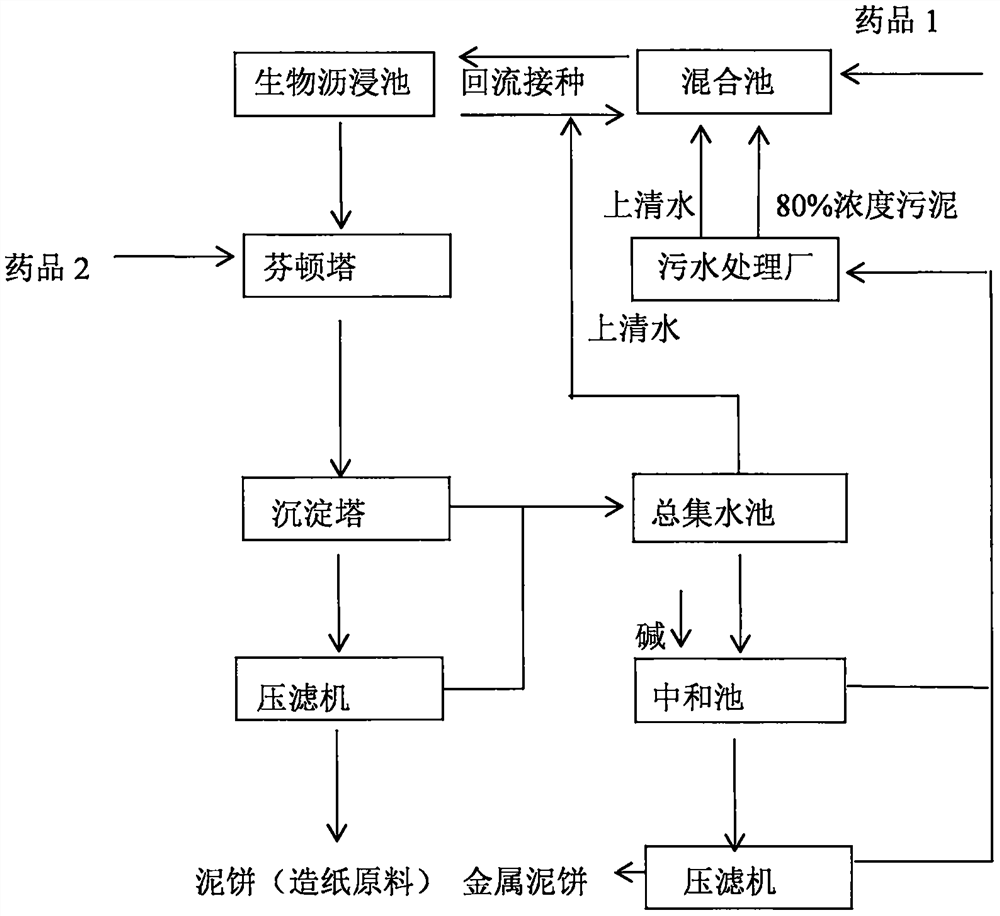

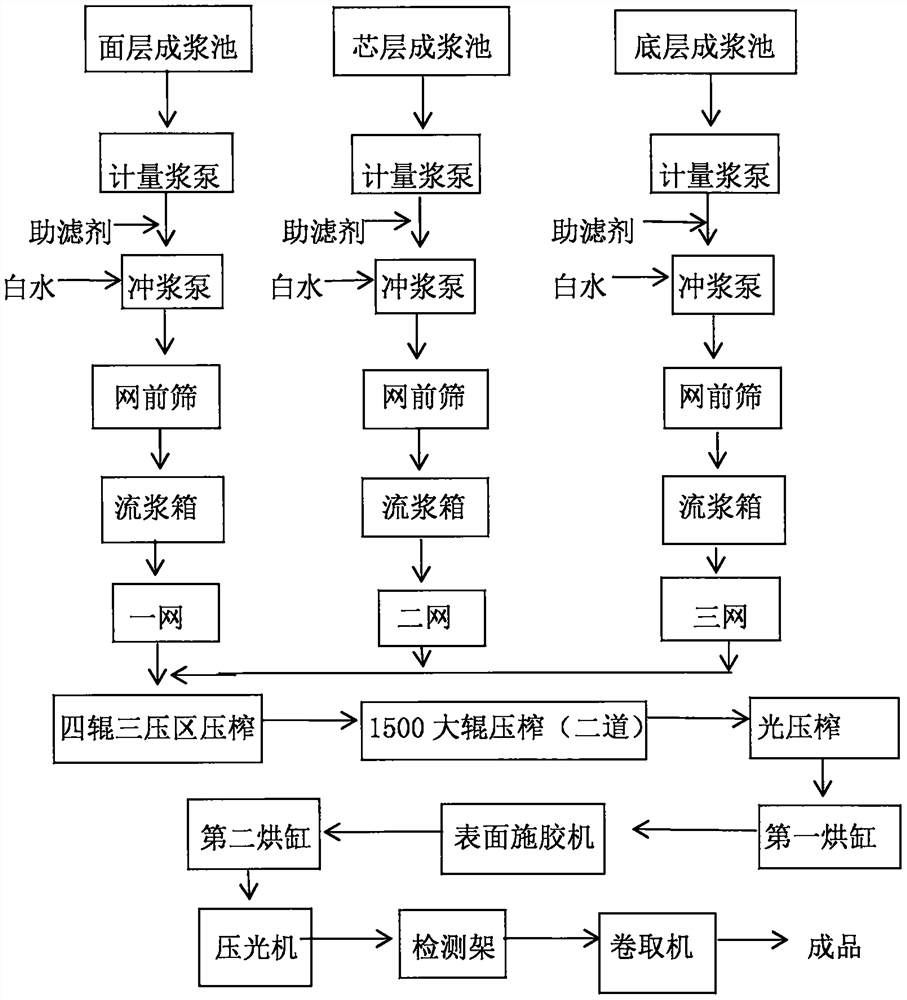

Paper made of textile, industrial and agricultural waste residues and papermaking method

ActiveCN112709092AImprove moisture absorption capacityImprove bindingWaste product additionRadio/micro wave fibre treatmentFiberPapermaking

The invention discloses paper produced by taking textile, industrial and agricultural waste residues as raw materials and a papermaking method, and belongs to the technical field of papermaking. Waste fibers generated in industry and agriculture are subjected to surface modification and blended with papermaking sludge, cottonseed velvet, cotton ash, vinasse, waste mushroom residues, traditional Chinese medicine residues, starch leftovers, potato residues, waste leather, straws, waste veneers, sawdust, waste bamboos, nutshells and other waste residues and corresponding additives for high-speed, medium-speed and low-speed industrial production of paper, 10-1500 g / m<2> paper can be produced, and paper quality reaches national standards. The pollution problem of the industrial and agricultural waste residues is solved from the source, more than 20 million tons of papermaking fibers are found for the papermaking industry, and the problem of domestic waste paper shortage caused by national limit on imported ocean garbage is effectively solved; and meanwhile, 95% of papermaking raw materials are waste residues and garbage, and the raw materials do not need to be purchased, so that the production cost is low, and very high benefits are brought to enterprises.

Owner:夏振明

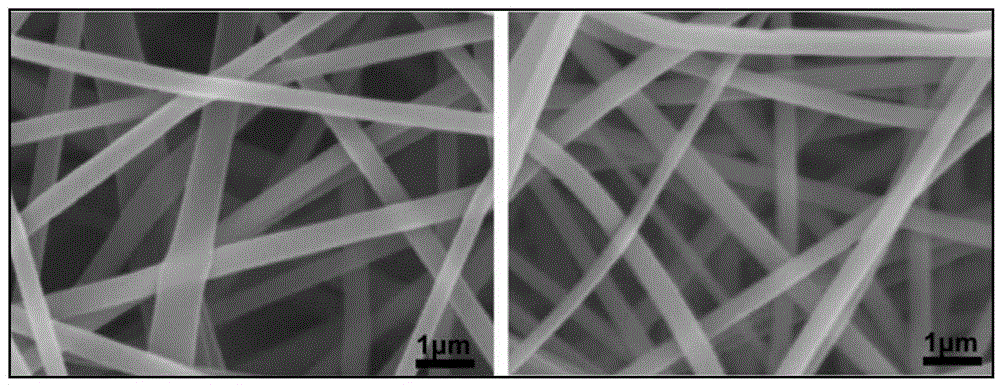

Method for strengthening mechanical property of nanofiber membrane

ActiveCN105420923AImprove mechanical propertiesExcellent mechanical propertiesRadio/micro wave fibre treatmentNon-woven fabricsComposite nanofibersMicrowave

The invention relates to a method for strengthening the mechanical property of nanofiber membrane. The method comprises the following steps that 1, cationic polyelectrolyte is added to good solvent of the cationic polyelectrolyte to be fully dissolved, and a solution is obtained; 2, anionic polyelectrolyte is added to good solvent of the anionic polyelectrolyte to be fully dissolved, and a solution is obtained; 3, polyelectrolyte solutions obtained in the first step and the second step are mixed together according to the the mass ratio of 1:9 to 9:1, stirring is conducted, and an electrostatic spinning precursor solution is obtained; 4, electrostatic spinning is conducted on the electrostatic spinning precursor solution obtained in the third step, and a polyelectrolyte composite nanofiber membrane is prepared; 5, the prepared polyelectrolyte composite nanofiber membrane is put into a microwave reactor for microwave treatment. The method for strengthening the mechanical property of the nanofiber membrane has the advantages of being easy to operate, outstanding in effect, low in cost, green and environmentally friendly, the method is expected to be used for industrial production, and a new method can be provided for rapidly and efficiently strengthening the mechanical property of the composite nanofiber membrane.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

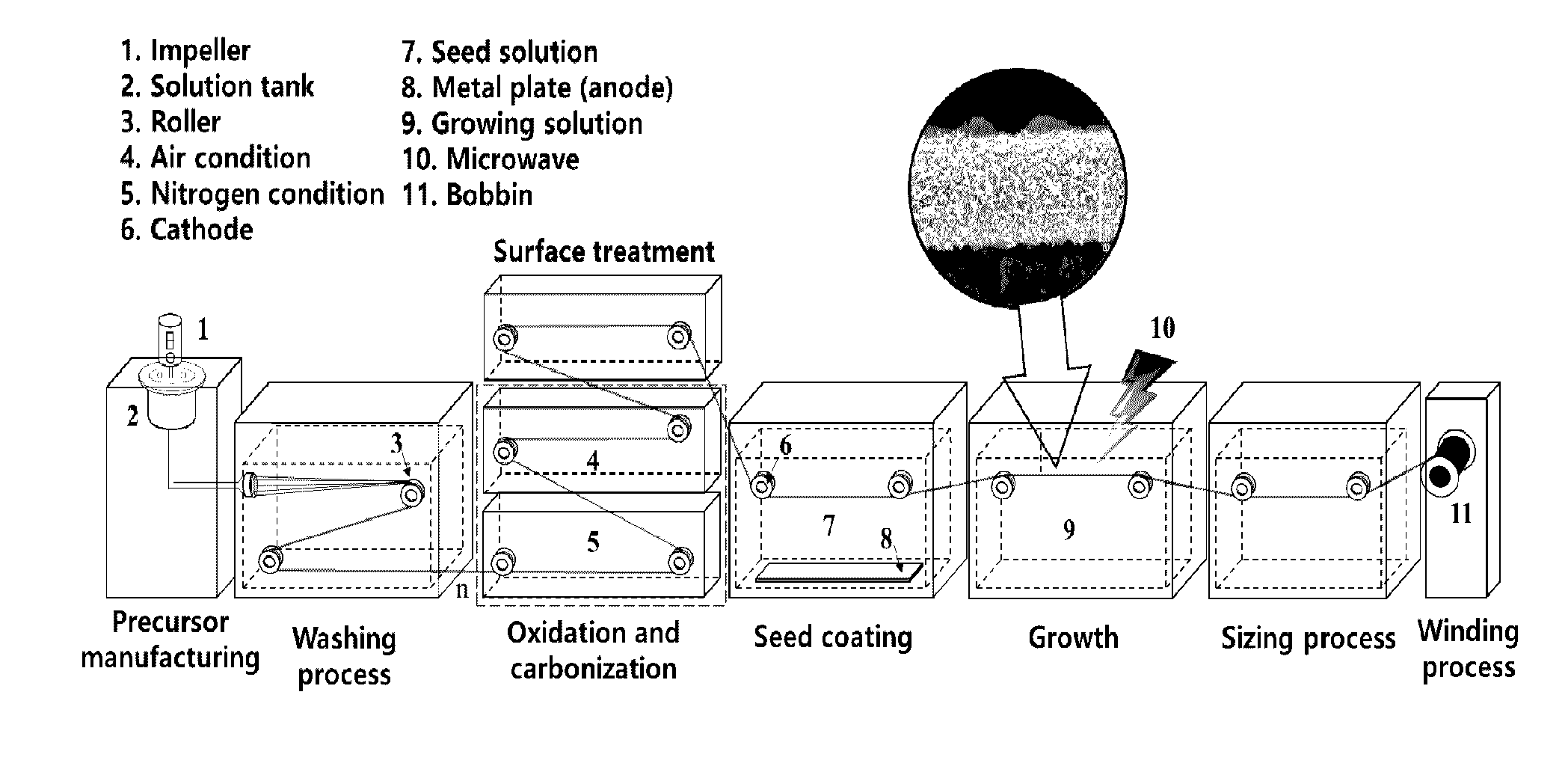

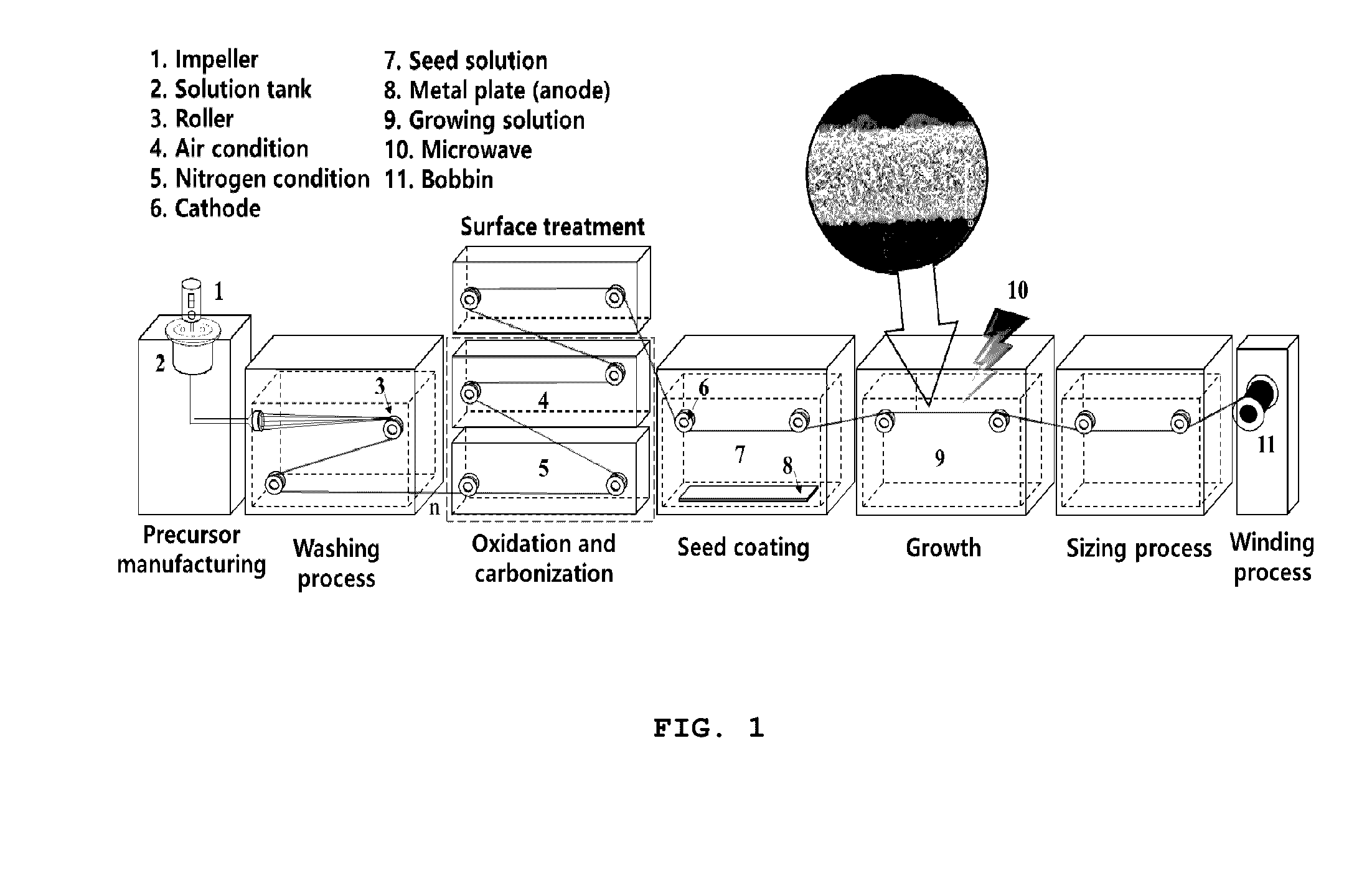

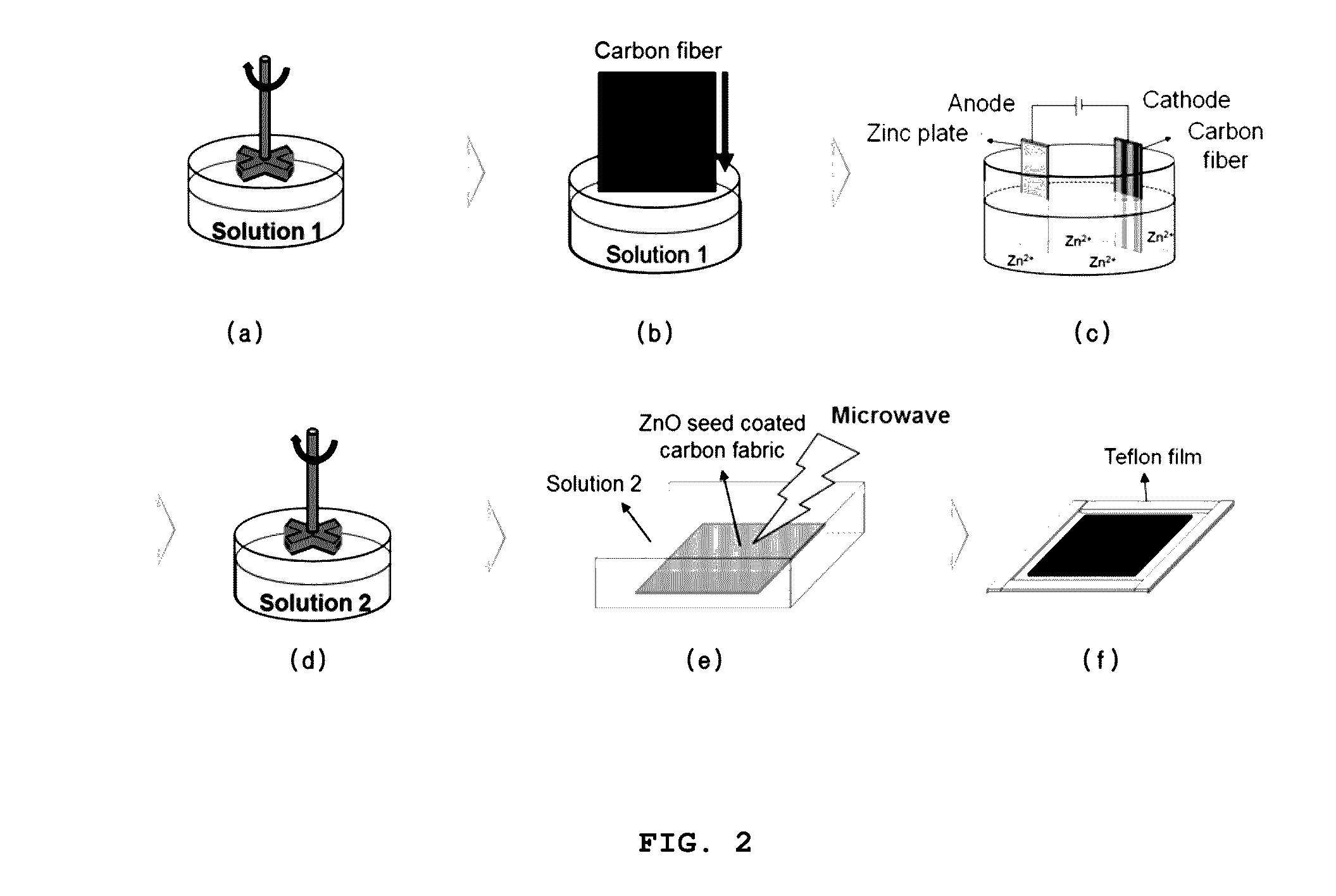

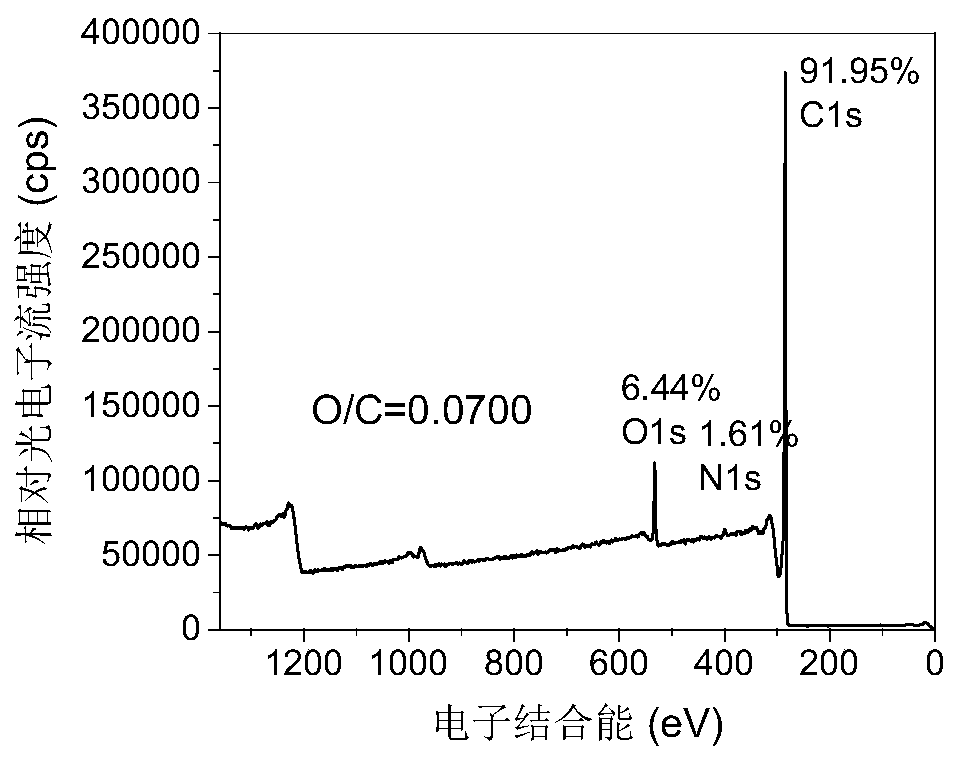

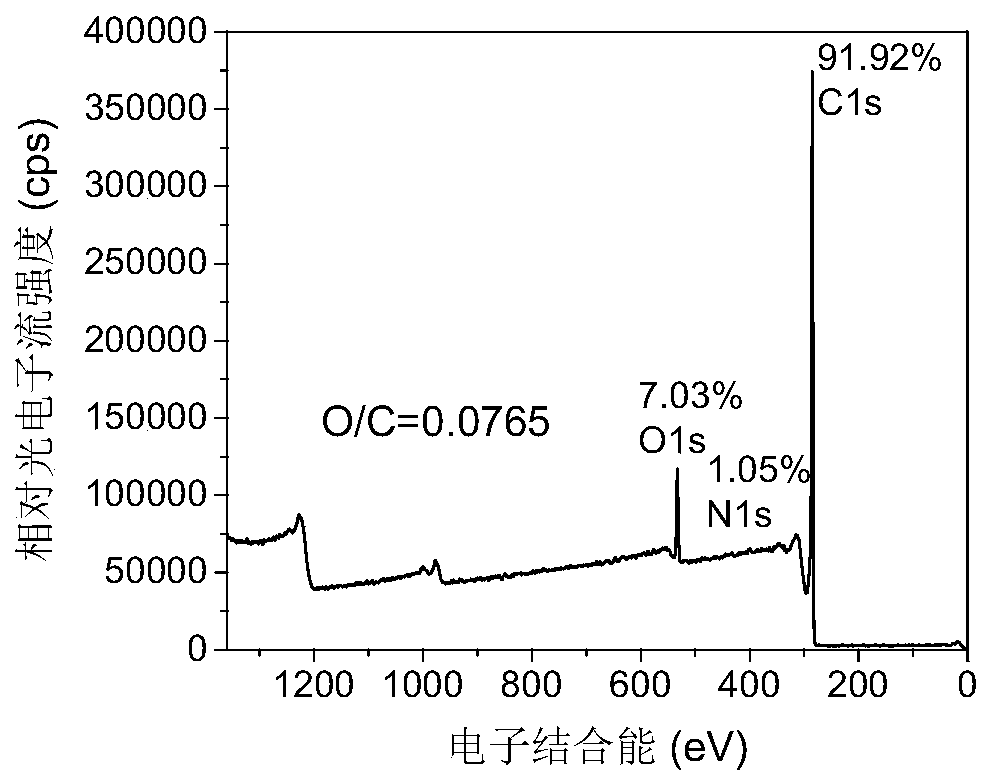

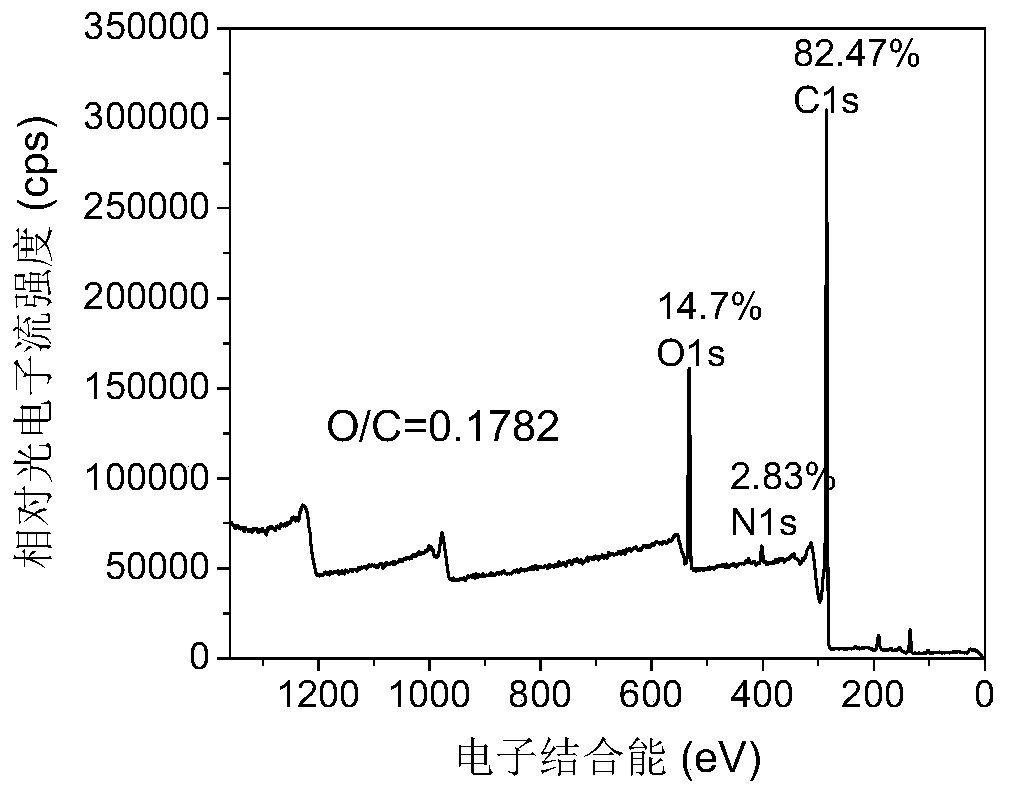

Manufacturing method for carbonfiber grown metal oxide

ActiveUS20170058419A1Reduce processing timeImprove efficiencyElectrolytic inorganic material coatingRadio/micro wave fibre treatmentMicrowaveCarbon fibers

A method for manufacturing metal oxide-grown carbon fibers including immersing carbon fibers in a solution for forming a metal oxide seed layer and electrodepositing a metal oxide seed on the surfaces of carbon fibers, or irradiating microwave thereto to form a metal oxide seed layer, and irradiating microwave to the metal oxide seed layer-formed carbon fibers to grow metal oxide. The method for manufacturing metal oxide-grown carbon fibers can reduce process time, and improve process energy efficiency and production efficiency. The method for manufacturing metal oxide-grown carbon fibers can offer metal oxide-grown carbon fibers with improved interfacial shear stress.

Owner:IND COOP FOUND CHONBUK NAT UNIV

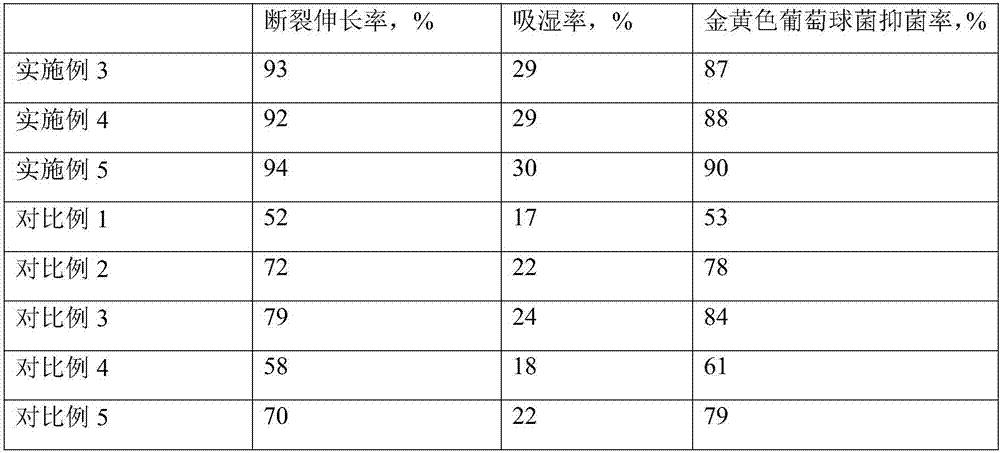

Microwave-assisted method for preparing chelate fibers

InactiveCN107780198AGreat application potentialEfficient removalRadio/micro wave fibre treatmentOther chemical processesSynthetic fiberMercuric ion

The invention relates to the technical field of synthetic fiber technology, in particular to a microwave-assisted method for preparing chelate fibers. A microwave-assisted method for preparing chelate fibers, comprising the following steps: (1) activation of polyacrylonitrile fibers; (2) pre-crosslinking of activated fibers; (3) preparation of chelate fibers. The chelating fiber made by the invention realizes efficient removal of mercury ions in water. The maximum adsorption capacity for mercury ions can reach 333.1 mg / g, and the adsorption capacity does not change much after regeneration for 5 times. It can be seen that chelating fibers have great application potential in treating mercury ion water pollution.

Owner:SHAANXI SHENGMAI PETROLEUM

Method for Stabilizing Carbon-Containing Fibre and Method for Producing Carbon Fibre

InactiveUS20120181162A1Improve conductivityBoost fibre processing timeRadio/micro wave fibre treatmentArtificial filament physical treatmentFiberCarbon fibers

The group of inventions pertains to the field of producing high-strength carbon fibres, which can be primarily manufactured from an organic starting material (precursor). A method for stabilizing a carbon-containing fibre (precursor) is claimed, in which the fibre is placed into a gaseous medium and subjected to treatment with microwave radiation as the gaseous medium is heated. More specifically, the fibre is placed into a working chamber filled with a gaseous medium, the latter is heated by heating the chamber (for example, the walls thereof) while the fibre is treated with microwave radiation. According to a second aspect of the invention, a method for producing a carbon fibre is claimed, comprising, as a minimum, fibre stabilizing and carbonizing stages, in which the precursor is stabilized by means of the above-described method by subjecting the fibre to microwave radiation as the medium in which the fibre is immersed is heated. After the fibre has been carbonized, it is possible, as an alternative, for said fibre to be additionally coated with graphite. If necessary, the stabilized fibre can also be carbonized and / or coated with graphite by the complex treatment thereof with microwave radiation as the medium in which the fibre has been placed for carbonizing / coating with graphite is heated. As a result, the time taken to stabilize the precursor fibres is reduced, thereby affording a reduction in the energy consumption and an increase in the productivity of the process for producing carbon fibre.

Owner:SOBOLEVA MARINA VLADIMIROVNA +2

CF/PEEK composite material with high fatigue strength and preparation method thereof

ActiveCN111572115APossibility of industrial scale productionGuaranteed normal windingRadio/micro wave fibre treatmentSynthetic resin layered productsPolyetherimideFlexural modulus

The invention relates to a CF / PEEK composite material with high fatigue strength and a preparation method of the CF / PEEK composite material. The preparation method comprises the following steps of: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on the CF in a saturatedwater vapor environment, and marking a product as ACF; (3) immersing ACF into a polyetherimide / dichloromethane / carbon nanotube suspension, taking out a product, and drying the product to obtain sizedmodified carbon fiber MCF; (4) laminating and hot-pressing the MCF and a PEEK material so as to obtain the CF / PEEK composite material with high fatigue strength is obtained. The bending strength of the finally prepared CF / PEEK composite material is 700 to 800 MPa; the bending fatigue strength of the material after 107 times of circular bending is 360-440 MPa; the bending modulus of the material is 55-62 GPa; the interlayer shear strength of the material is 87-100 MPa; the residual compression strength after impact of the materialis 220-260 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production; and the prepared composite material can replace metal to be applied to the fields of aerospace, medical treatment, machinery, automobiles, rail transit, petroleum transportation and the like.

Owner:DONGHUA UNIV

Preparation method of natural plant fiber-rubber composite material

ActiveCN109206760ALoose structureInternal porosityRadio/micro wave fibre treatmentBiochemical treatment with enzymes/microorganismsFiberStearic acid

The invention discloses a preparation method of a natural plant fiber-rubber composite material, degummed natural plant short fiber is first treated with cellulase, then subjected to microwave irradiation treatment, then vacuum-impregnated in an impregnating solution obtained by mixing nano silica, a silane coupling agent and ethanol, dried and cooled to obtain modified natural plant short fiber,and the modified natural plant short fiber, butyl rubber, zinc oxide, stearic acid, an accelerator, sulfur and an anti-aging agent are together added into a mixer for mixing, and then vulcanized in avulcanizer to obtain the natural plant fiber-rubber composite material. The preparation method is simple and convenient, and the obtained rubber composite material not only has excellent sound absorption and vibration damping effects, but also has good mechanical properties, is safe to use, good in environmental protection performance, and is suitable for noise reduction inside automobiles.

Owner:宿州学院

Anti-pilling treatment method for cotton type wool knitted fabric

InactiveCN108004661ASmall finenessHigh strengthWeft knittingRadio/micro wave fibre treatmentYarnEngineering

The invention relates to an anti-pilling treatment method for a cotton type wool knitted fabric. The method comprises: selecting Australasian wool whose quality count is 64-80, performing stretch breaking, blending the Australasian wool with blend fibers or performing pure spinning, to obtain yarns, weaving, when a fabric is off a loom, cooking cloth and dehydrating, then scotching, washing wool fabric, cleaning, and dehydrating; putting the fabric in a microwave drying setting-low temperature normal pressure plasma treatment device, firstly performing microwave drying setting, then performinglow temperature normal pressure plasma treatment; finally performing soft finishing, to obtain the anti-pilling fabric. Through pretreatment of stretch breaking, varieties of wool fibers which can beblended are greatly increased, so woolen fabrics are more enriched. The wool fibers after stretch breaking can be spun on a cotton spinning device, and wool spinning process flow is shortened. The wool fibers after stretch breaking have a series of variations on physical and mechanical properties, so microwave drying setting-low temperature normal pressure plasma treatment has more obvious effecton surface modification effect of wool fibers, and reduces felting of wool fibers and improves anti-pilling property of the fabric.

Owner:DONGHUA UNIV +1

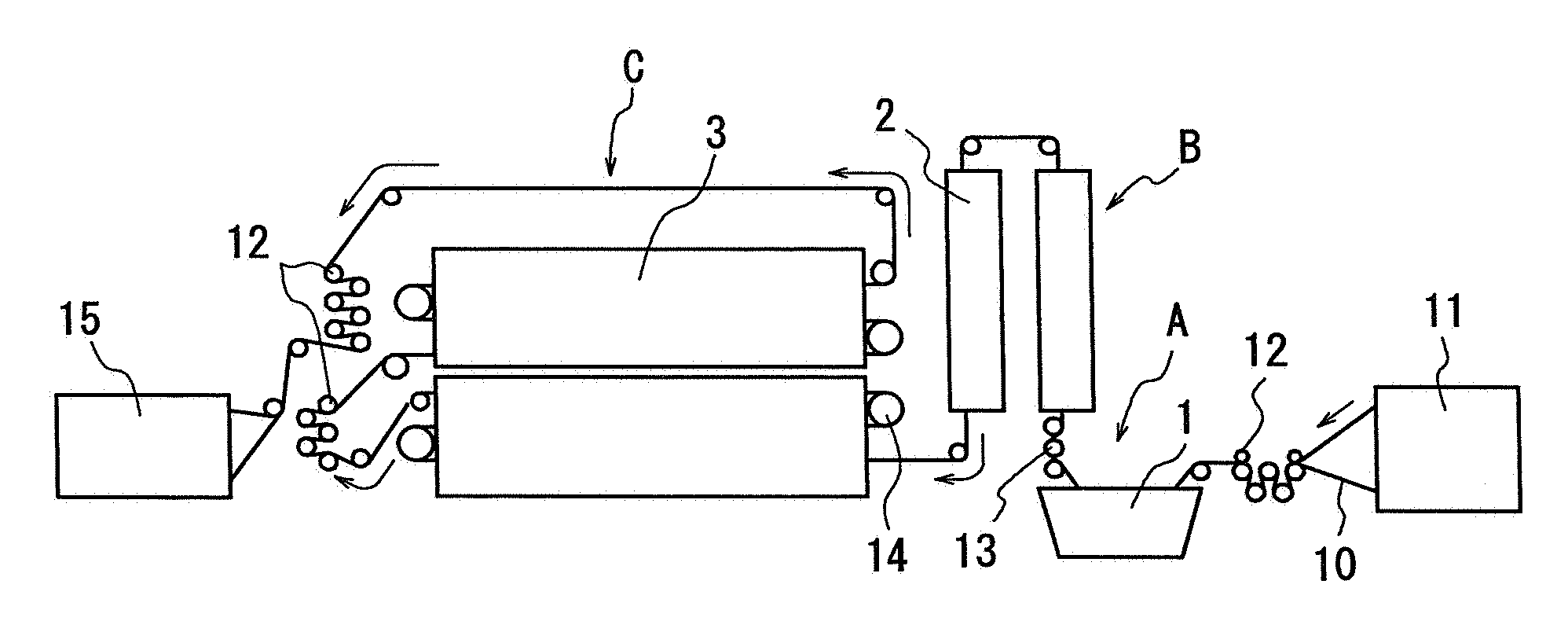

Method for modifying organic fiber cord

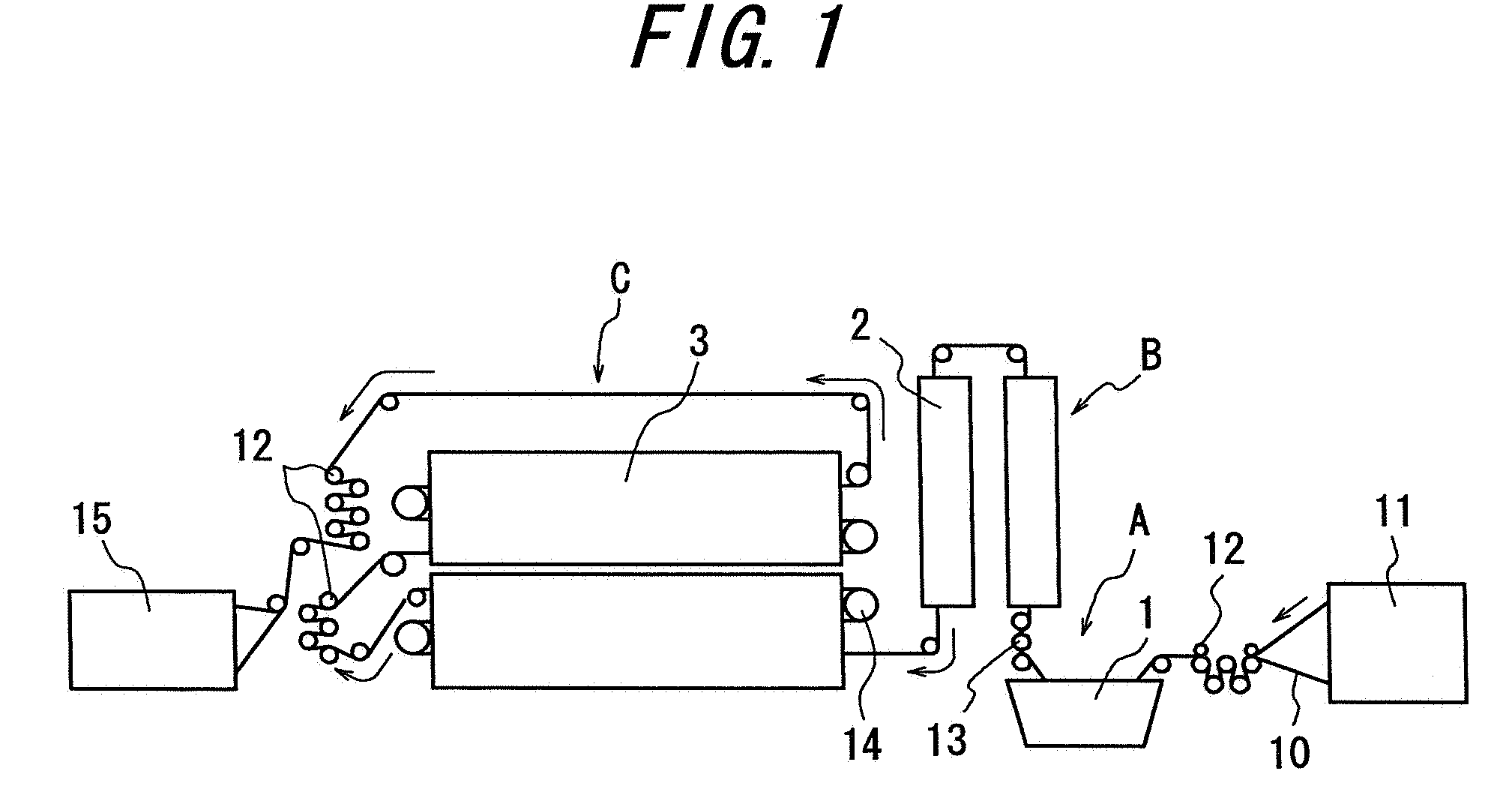

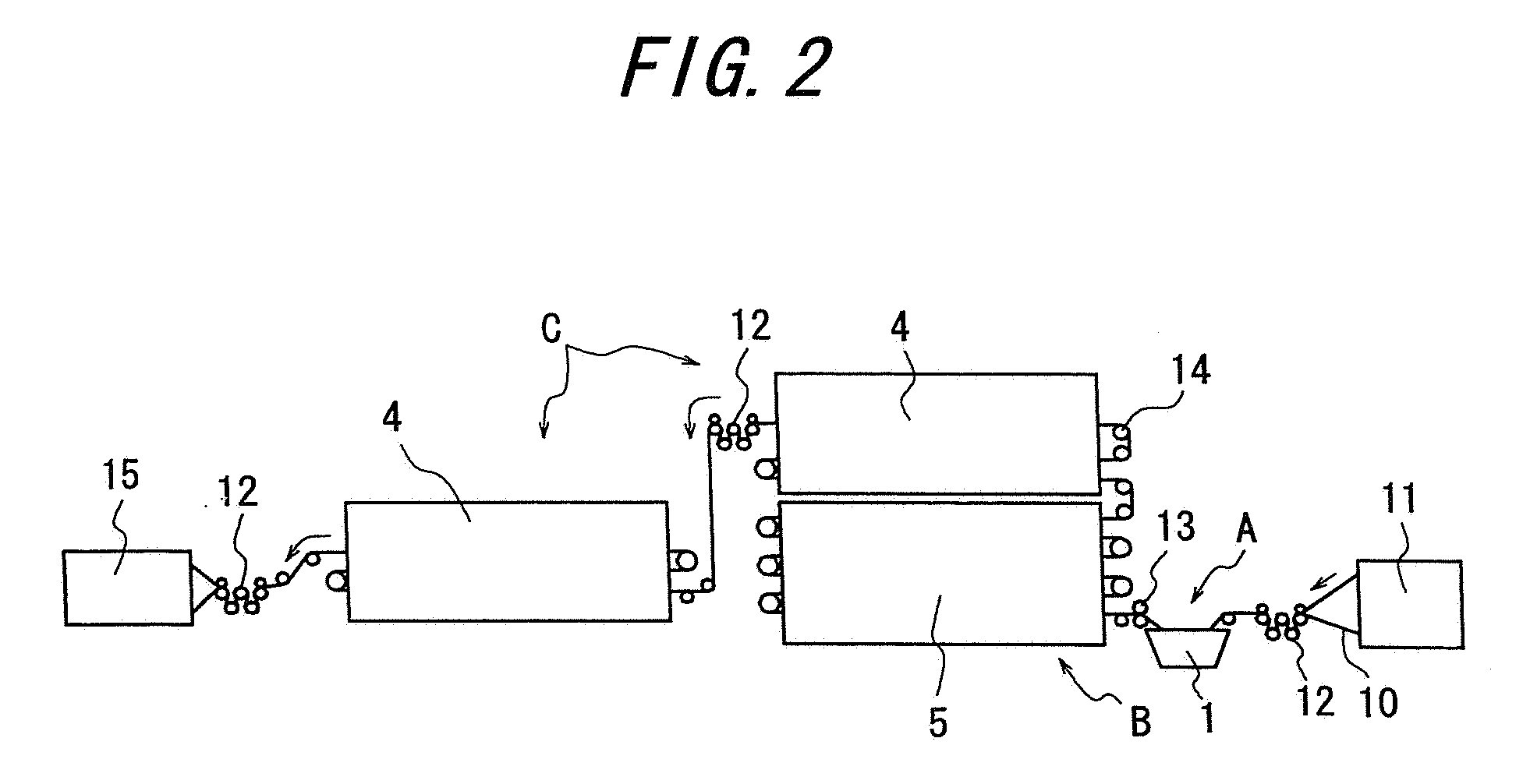

InactiveUS20090022904A1Process stabilityControl deteriorationRadio/micro wave fibre treatmentRadiation applicationsInfraredFiber

A method for modifying an organic fiber cord according to the invention comprises the step (A) of dipping the organic fiber cord (10) into an adhesive, the step (B) of drying the dipped organic fiber cord and the step (C) of heat-treating the dried organic fiber cord to modify it, and is characterized in that the drying step (B) is conducted by irradiating microwaves to the dipped organic fiber cord and / or the heat-treating step (C) is conducted by irradiating far-infrared rays to the dried organic fiber cord.

Owner:BRIDGESTONE CORP

Modified cotton fiber and easy-care fabric prepared therefrom

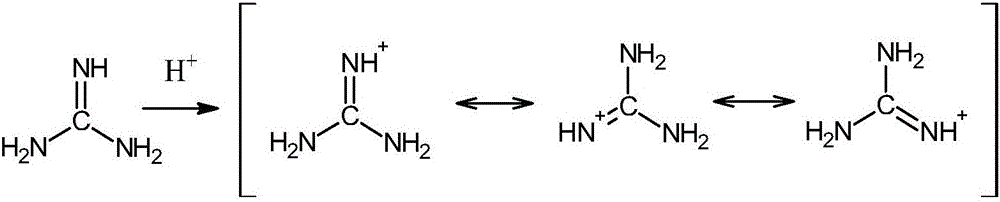

InactiveCN108823961AIncrease the curvatureAmnesticRadio/micro wave fibre treatmentVegetal fibresHydroxymethylTitanium sulfate

The invention relates to the technical field of cotton textiles and specifically relates to a modified cotton fiber and easy-care fabric prepared therefrom. A preparation method of the modified cottonfiber comprises the following steps: performing alkaline water dipping on cotton fibers with sodium hydroxide solution, bleaching the cotton fibers, pretreating the treated cotton fibers with organicsolution, and performing modifier treatment and centrifugal purification on the cotton fibers, wherein a cotton fiber modifier comprises titanium sulfate, urea, butyl titanate, sodium hydroxymethyl acrylamide and chitosan. The fabric prepared by mixing the modified cotton fibers, polypropylene fibers and chinlon is good in skin-friendly performance and also has air permeability and anti-wrinkle performance.

Owner:合肥云都棉花有限公司

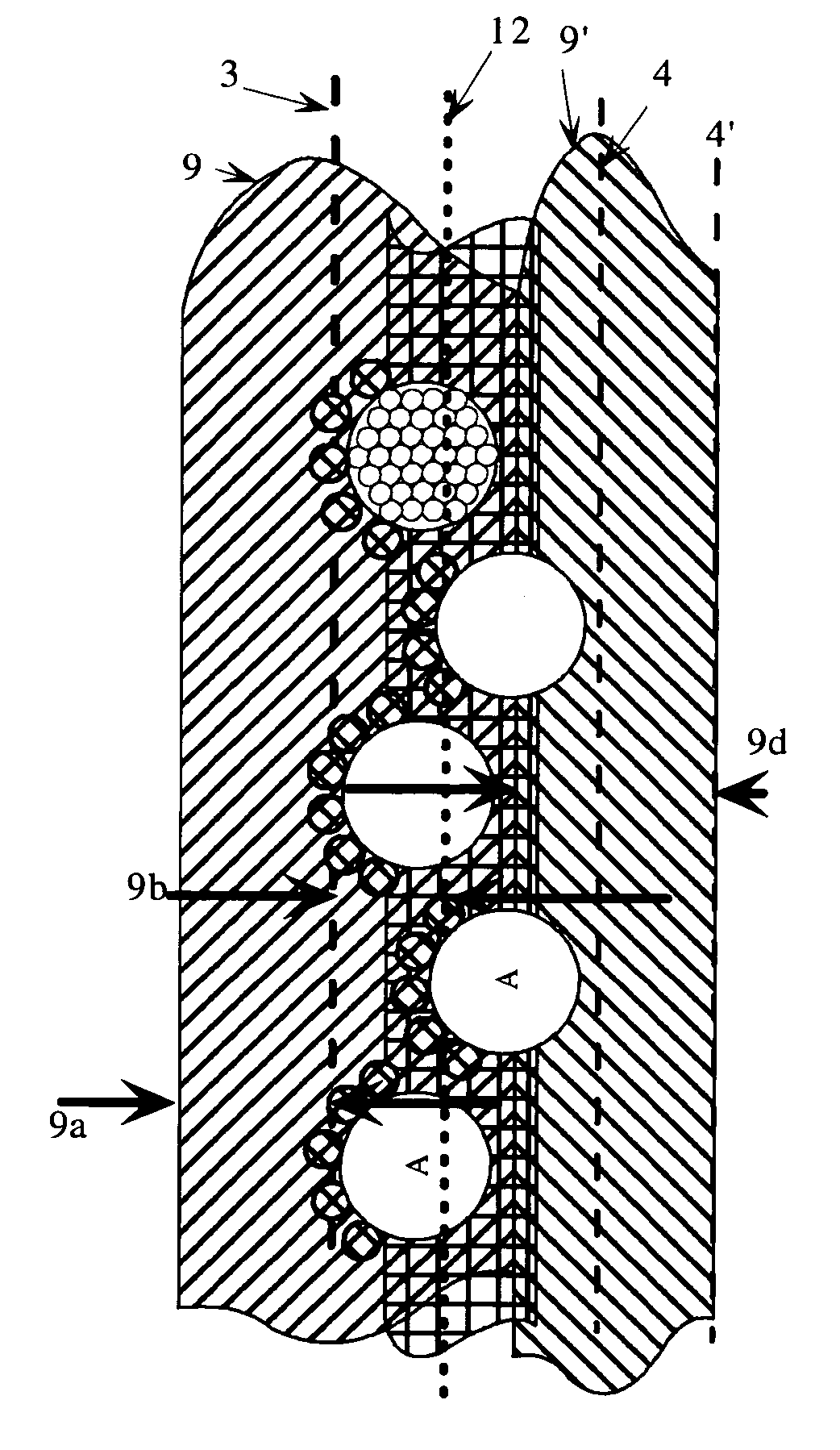

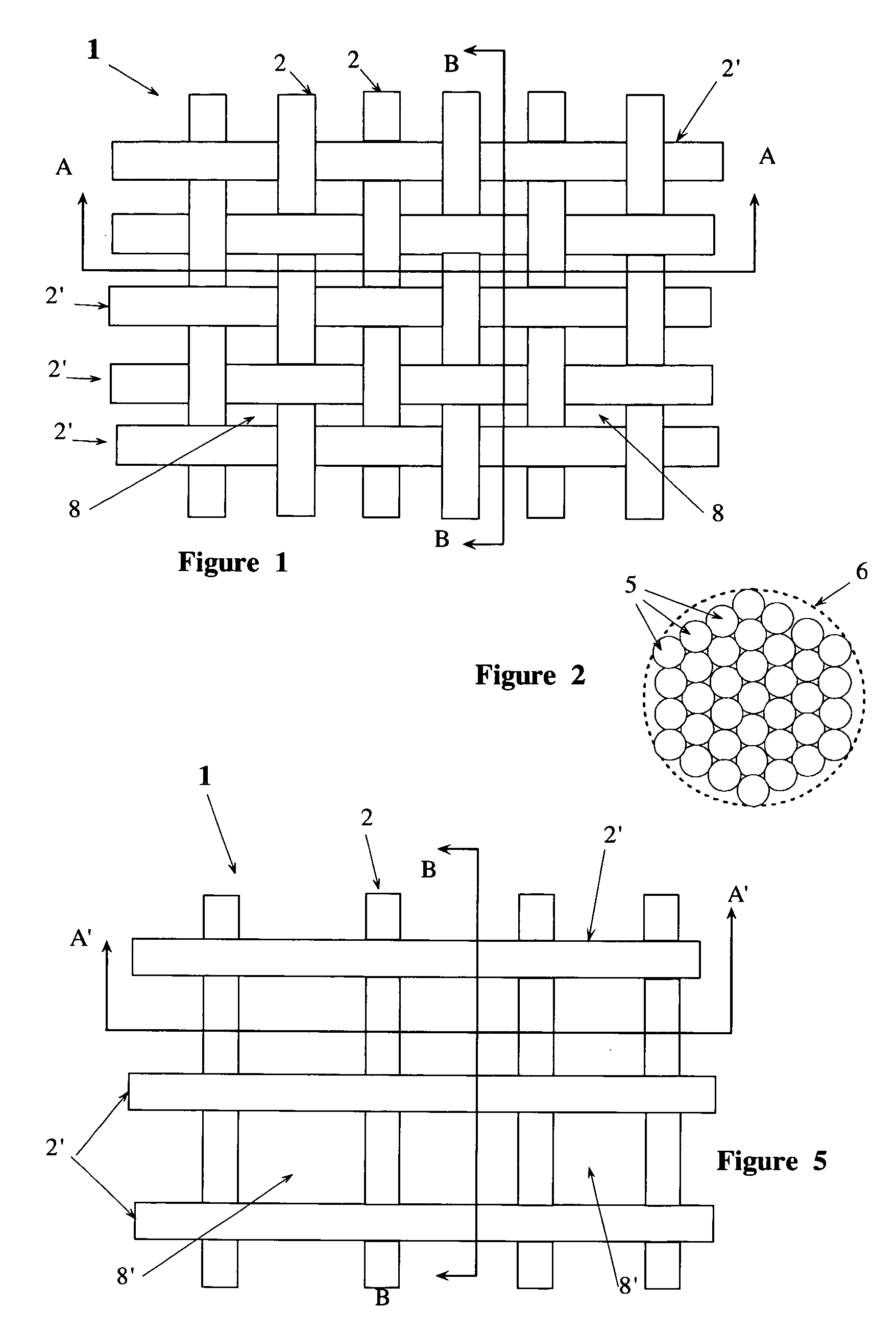

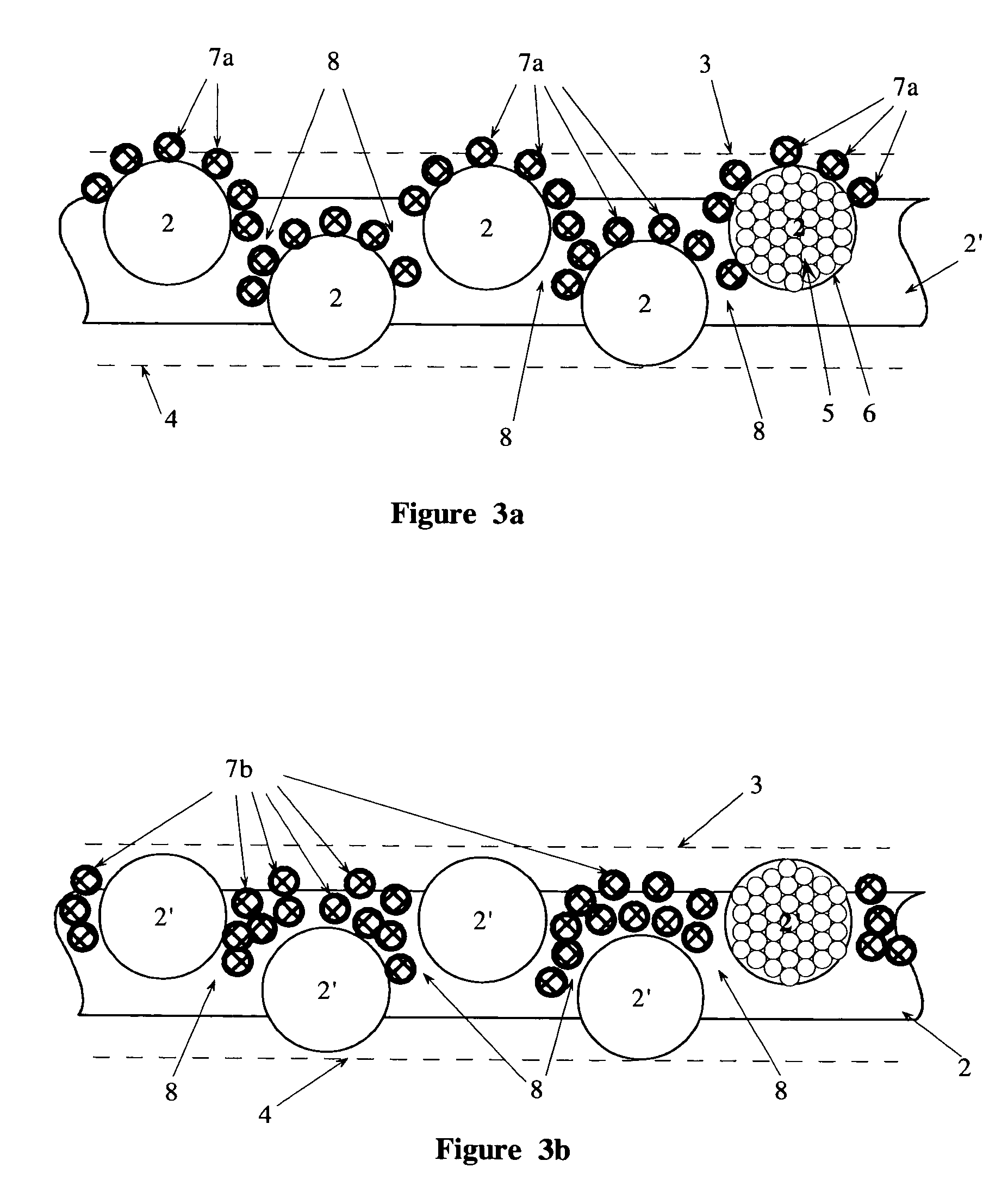

Method of coating fiber strands with a plastic coating composition from individual coating constituents

InactiveUS6838123B2Avoid dissociationAvoids any kind of crateringRadio/micro wave fibre treatmentSynthetic fibresFiberPolymer science

The invention relates to a method for coating fibers shaped as fiber strands (roving and mats) using a fluidized bed technique, wherein (i) the desired composition of the individual coating constituents is directly applied from the fluidized bed without previous compounding and (ii) the individual coating constituents contained in the fluidized bed are additionally mixed in the mass so that dissociation of individual constituents is substantially avoided. The invention also relates to a device for implementing the method.

Owner:NEOPREG

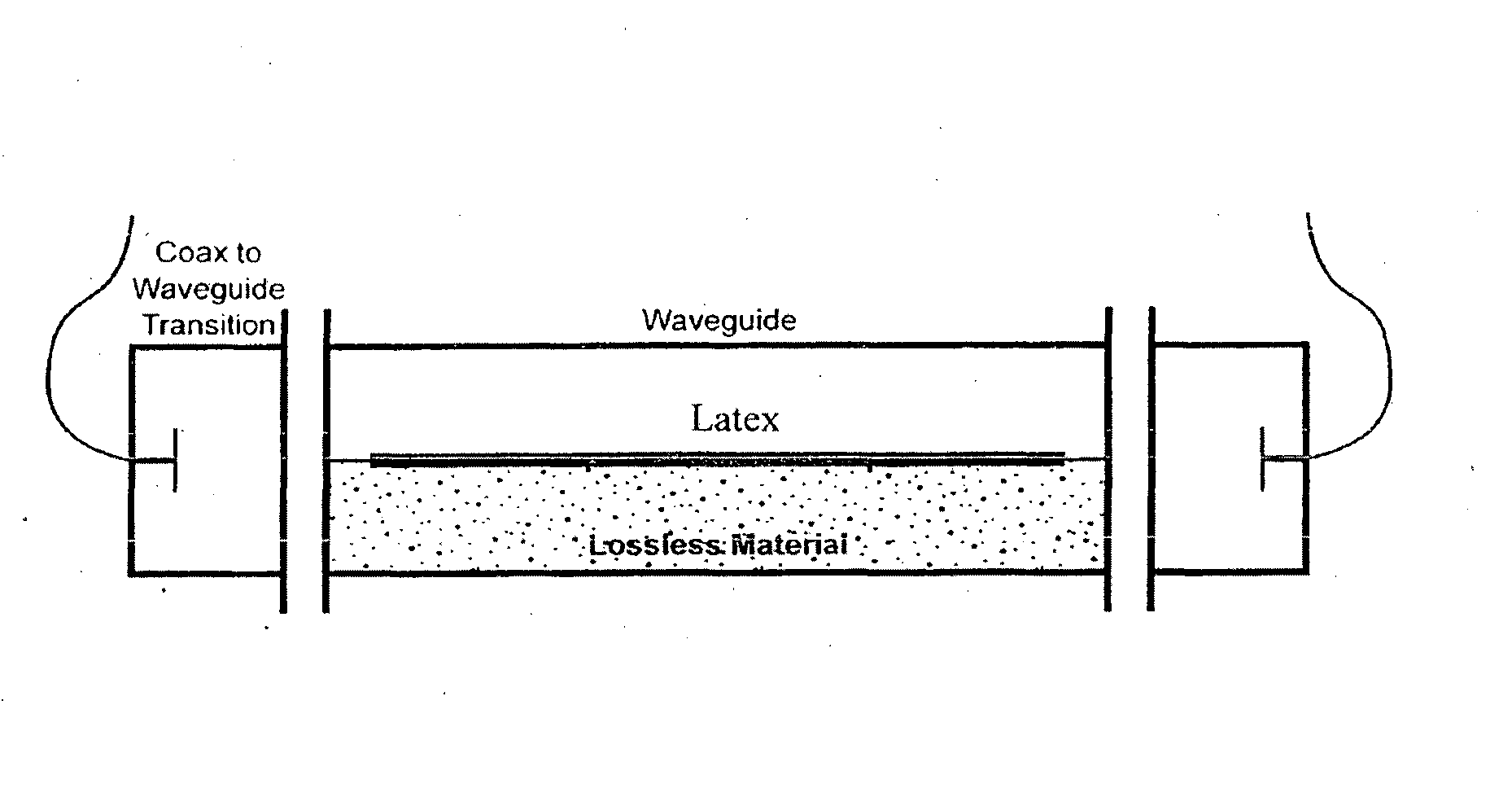

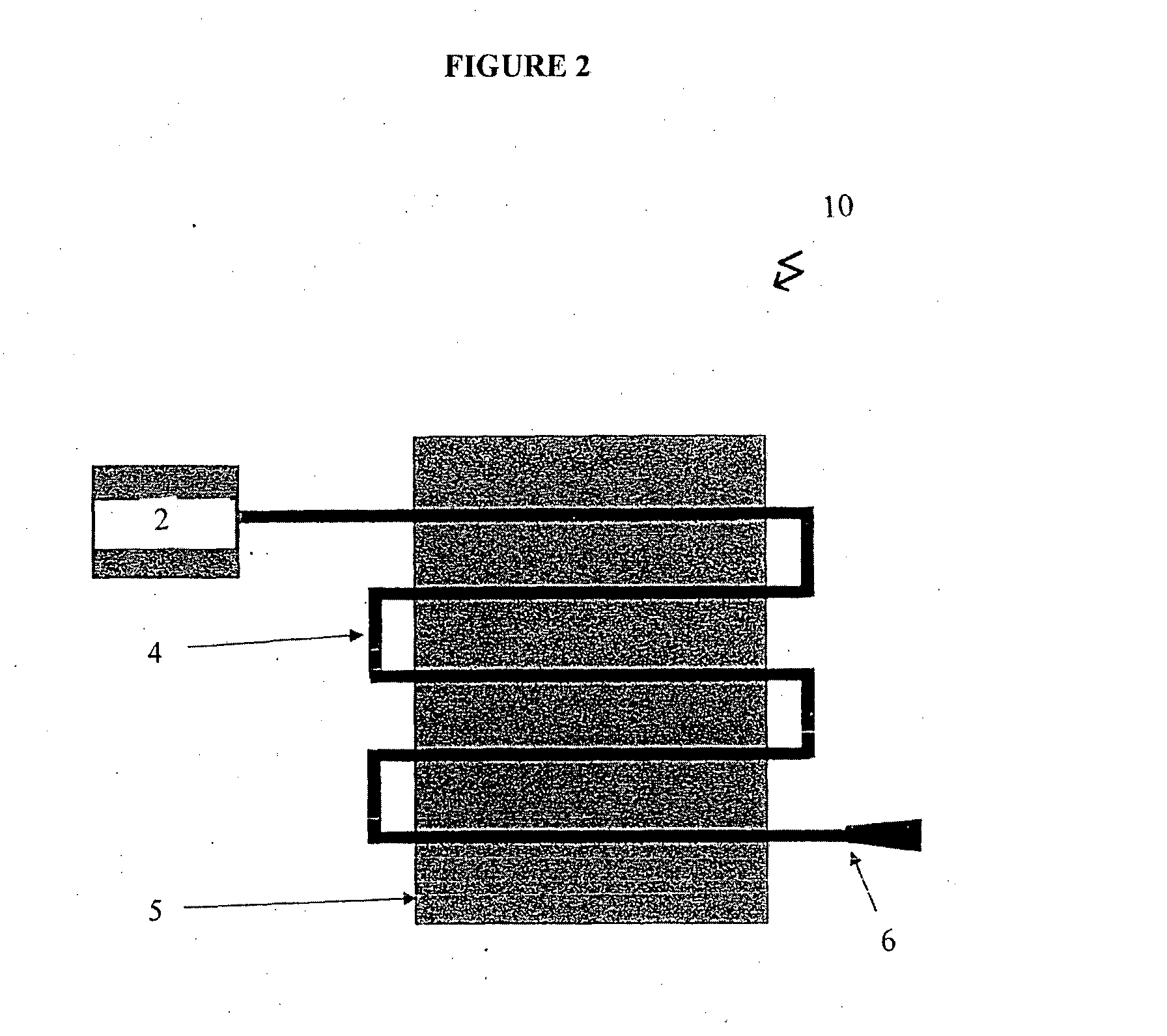

Microwave curing of uncured latex carpet

There is disclosed a floor covering comprising a primary backing having a fibrous face and an underside; and a microwave cured precoat layer on the underside of the primary backing. There is also disclosed herein a method of making a floor covering comprising: tufting or implanting a fibrous material or yarn into a primary backing; precoating the underside of the primary backing layer by applying a precoating composition followed by microwave curing the precoating. An apparatus for curing a precoated primary backing layer also described.

Owner:INTERFACE AUST

Antibacterial fabric

InactiveCN110424164AHas antibacterial propertiesAntibacterial performance achievedRadio/micro wave fibre treatmentBiochemical fibre treatmentOrganic solventAlkene

The invention discloses an antibacterial fabric, which is made by the sequential steps of plasma treatment, bleaching, mercerizing, graft polymerization, post-treatment, and washing and drying. Afterpre-treatment, antibacterial property is imparted to the fabric by graft-polymerizing an antibacterial quaternary ammonium salt alkene unit to the fabric using an organic solvent as a finishing medium. The antibacterial fabric produced herein can inhibit the growth and propagation of bacteria and occurrence of peculiar odor for long time; breathability of the antibacterial is further improved, wearability of the antibacterial fabric is enhanced, and the antibacterial fabric has good development prospect.

Owner:闵兵

Highly-antibacterial novel slightly-soluble nonwoven cloth capable of adsorbing heavy metal particles

ActiveCN105624920AIncrease contentFluffy goodRadio/micro wave fibre treatmentBiochemical fibre treatmentPolymer scienceDegree of substitution

The invention discloses highly-antibacterial novel slightly-soluble nonwoven cloth capable of adsorbing heavy metal particles.The nonwoven cloth is prepared from carboxymethyl chitosan fibers, chitosan fibers and low-melting-point ES fibers, the ES fibers are of a structure with an inner core which is PP fibers, outer skin is PE fibers, content of the carboxymethyl chitosan fibers is 1-10%, degree of substitution at O positions is 0.7, degree of substitution at N positions is 0.5, content of the chitosan fibers is 5-10%, content of the ES fibers is 70-94%, and the nonwoven cloth is prepared by bonding the carboxymethyl chitosan fibers, the chitosan fibers and the ES fibers through hot air.The nonwoven cloth is soft, breathable, high in strength, less prone to breakage and remarkably higher in moisture absorbing and maintaining performance.The carboxymethyl chitosan fibers and the chitosan fibers can be dissolved at different degrees when temperature is 25-40 DEG C and PH is 5.0-8.0 to be in a slightly-soluble state, so that particles can be blocked and filtered effectively and the nonwoven cloth has higher antibacterial performance and higher performance in adsorbing the heavy metal particles.

Owner:湖北立天生物工程有限公司

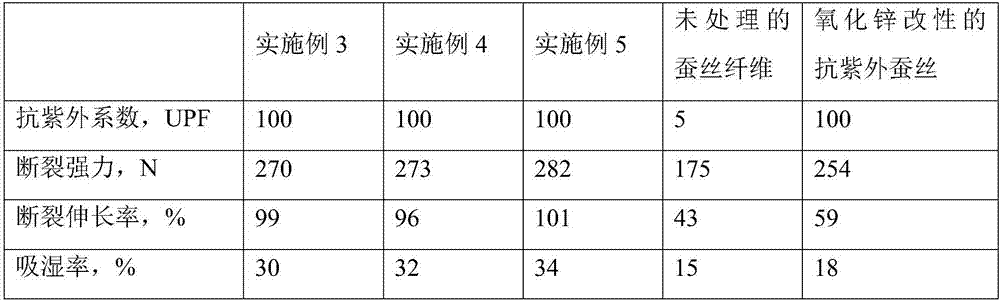

Preparation method of zinc oxide affinity anti-ultraviolet and antibacterial silk fibers

InactiveCN107419519AHigh affinityImprove stabilityRadio/micro wave fibre treatmentBiochemical fibre treatmentLactideUltraviolet

The invention provides a preparation method of zinc oxide affinity anti-ultraviolet and antibacterial silk fibers. The preparation method includes the steps: performing degumming on silk after impurities in the silk are removed, washing the degummed silk by the aid of deionized water, and drying the washed silk to obtain the degummed silk; performing activating treatment on the degummed silk by the aid of strong oxidizing agents, soaking the degummed silk after activating treatment into zinc nitrate water solution, filtering and washing the soaked degummed silk, soaking the filtered and washed degummed silk into ammonium hydroxide, adjusting temperature, and keeping the temperature to obtain pre-covering silk fibers; adding dichloromethane into the pre-covering silk fibers, uniformly mixing mixture, adding polyethylene glycol monomethyl ether, lactide and stannous iso caprylate, mixing mixture, performing microwave treatment, filtering and washing on the mixture under protection of nitrogen, standing in heating and humidifying steam, and washing and drying the mixture to obtain the zinc oxide affinity anti-ultraviolet and antibacterial silk fibers. The obtained silk fibers have excellent ultraviolet resistance, inhibit and resist bacteria, remove odor and are resistant to soak and wash, good in moisture absorption performance, and a user feels comfortable when wearing a product made of the silk fibers.

Owner:长沙善道新材料科技有限公司

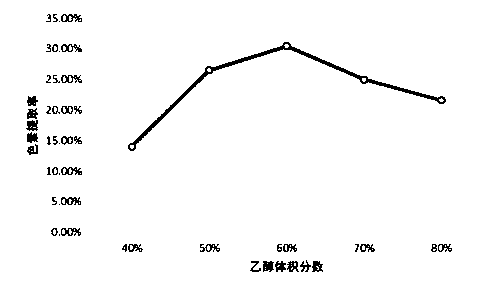

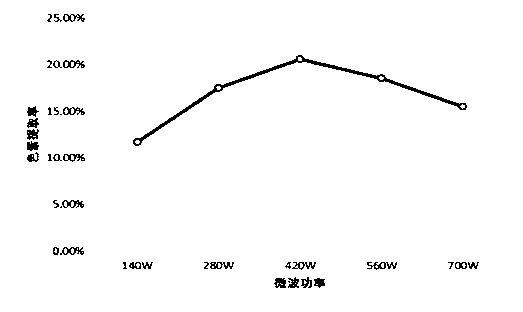

Dyeing method for dyeing wool fibers through walnut green seedcase pigment

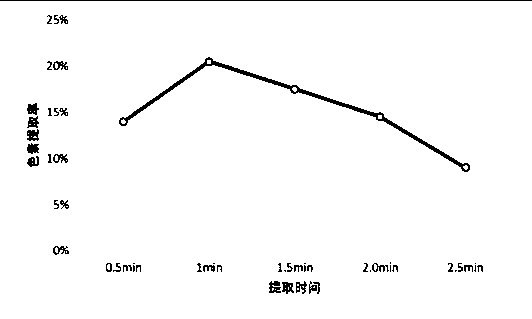

ActiveCN111519453ALow microwave powerShorten the fixation timeRadio/micro wave fibre treatmentNatural dyesTextile printerColour fastness

The invention discloses a dyeing method for dyeing wool fibers through a walnut green seedcase pigment, and belongs to the technical field of textile printing and dyeing. The dyeing method comprises the steps: the wool fibers are subjected to humidity conditioning equilibrium and then pretreated in microwaves with the power being 560-700 W for 1-3 min; the wool fibers are dyed through a walnut green seedcase pigment stock dye solution, and after being dyed, the wool fibers are washed with water and naturally aired; the dyed wool fibers are immersed in mordanting color-fixation liquid and subjected to mordanting color fixation for 1-5 min under the condition of microwaves with the power being 140-420 W; and after the wool fibers subjected to color fixation are washed with water and dried, the walnut green seedcase pigment dyed wool fibers are obtained. Dip dyeing is conducted through the walnut green seedcase pigment, mordanting color fixation is conducted under the condition of the microwaves with the power being 140-420 W, thus the microwave power is decreased, the color-fixation time is shortened, the color-fixation efficiency is improved, microwave energy consumption is reduced,the color difference of the dyed wool fibers reaches 43.85, and meanwhile the color fastness to washing is grade 4 or above.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

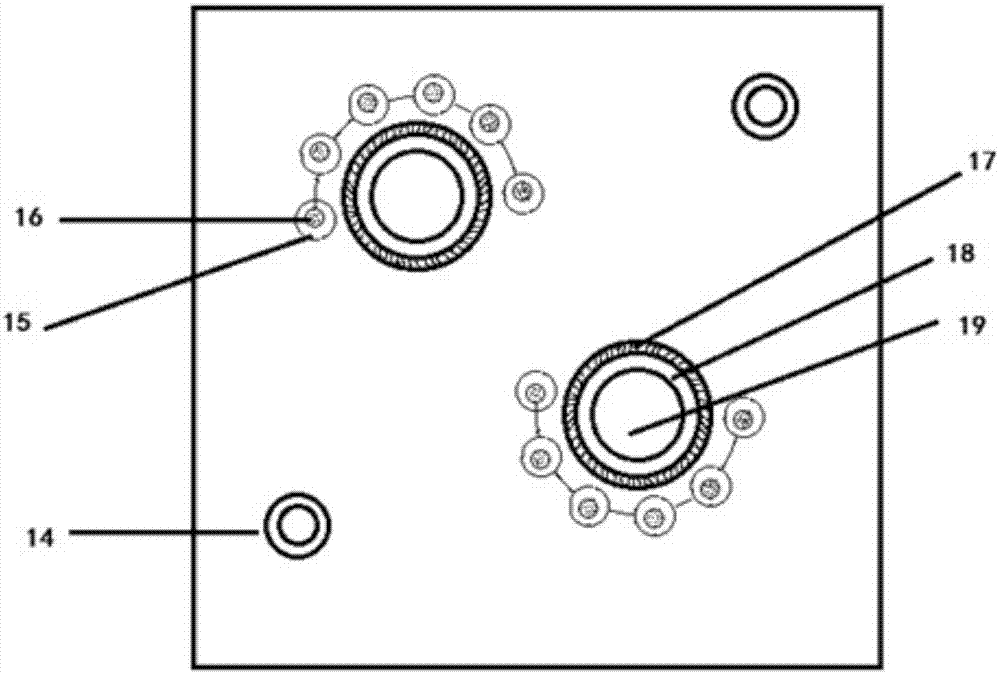

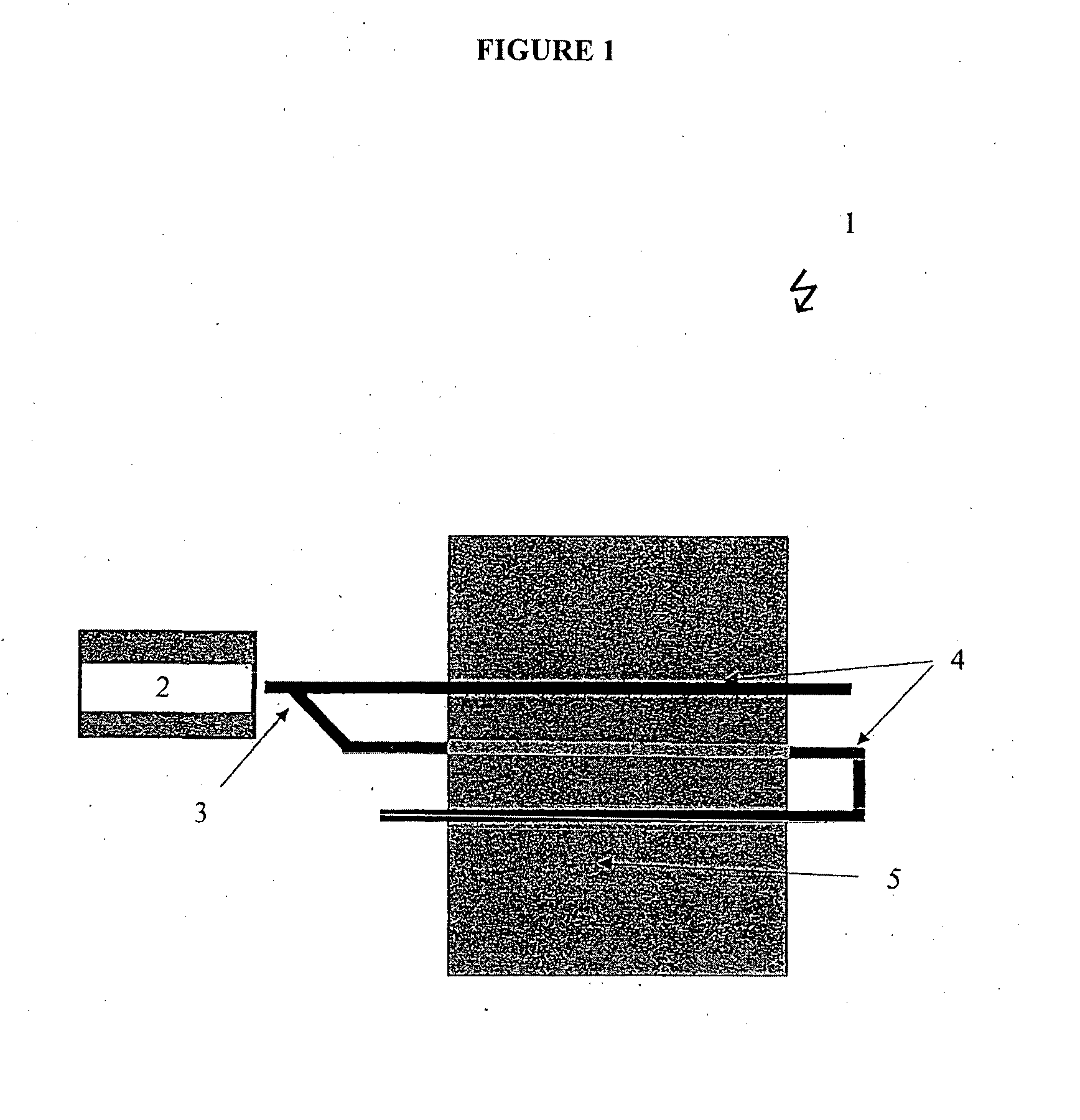

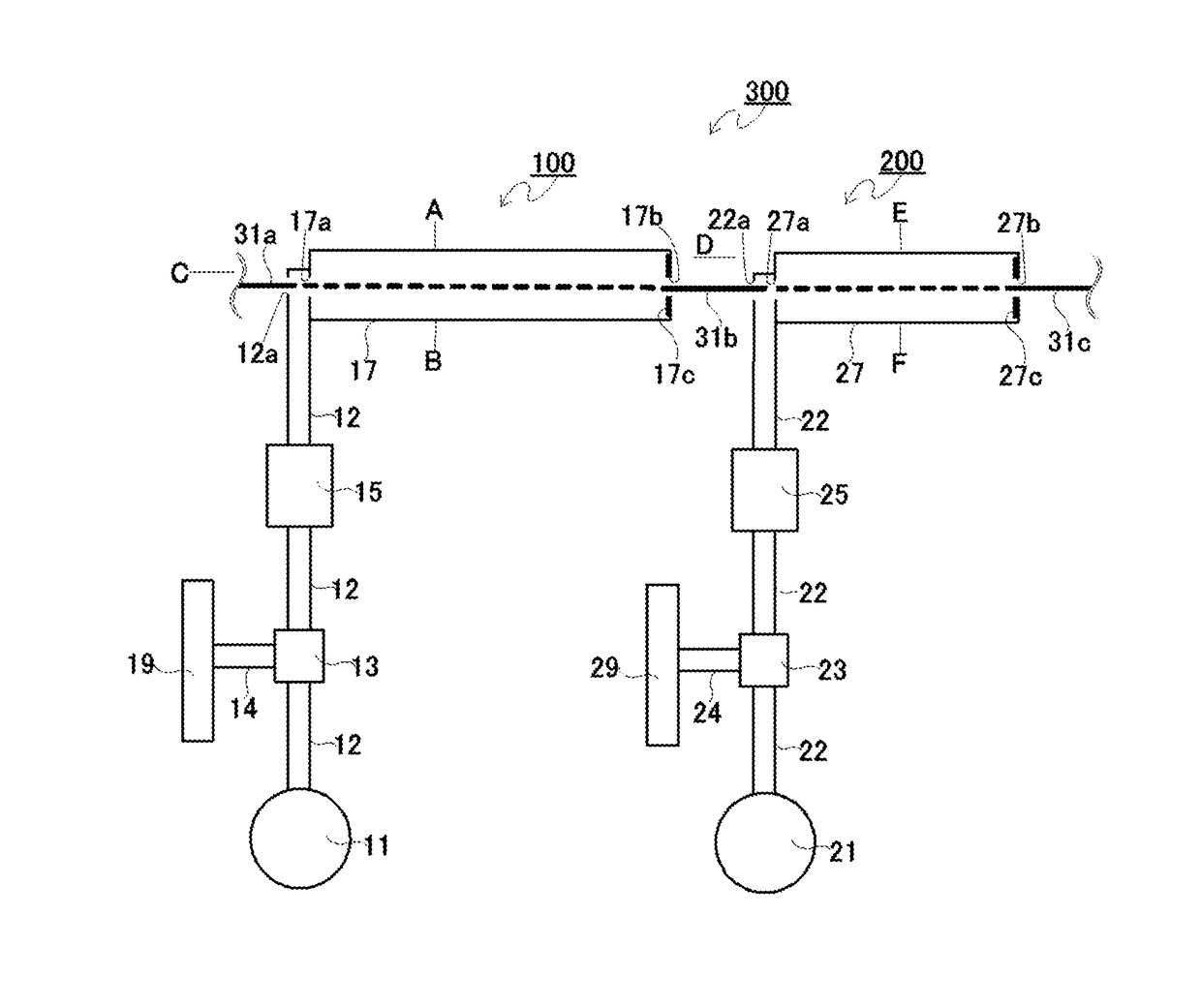

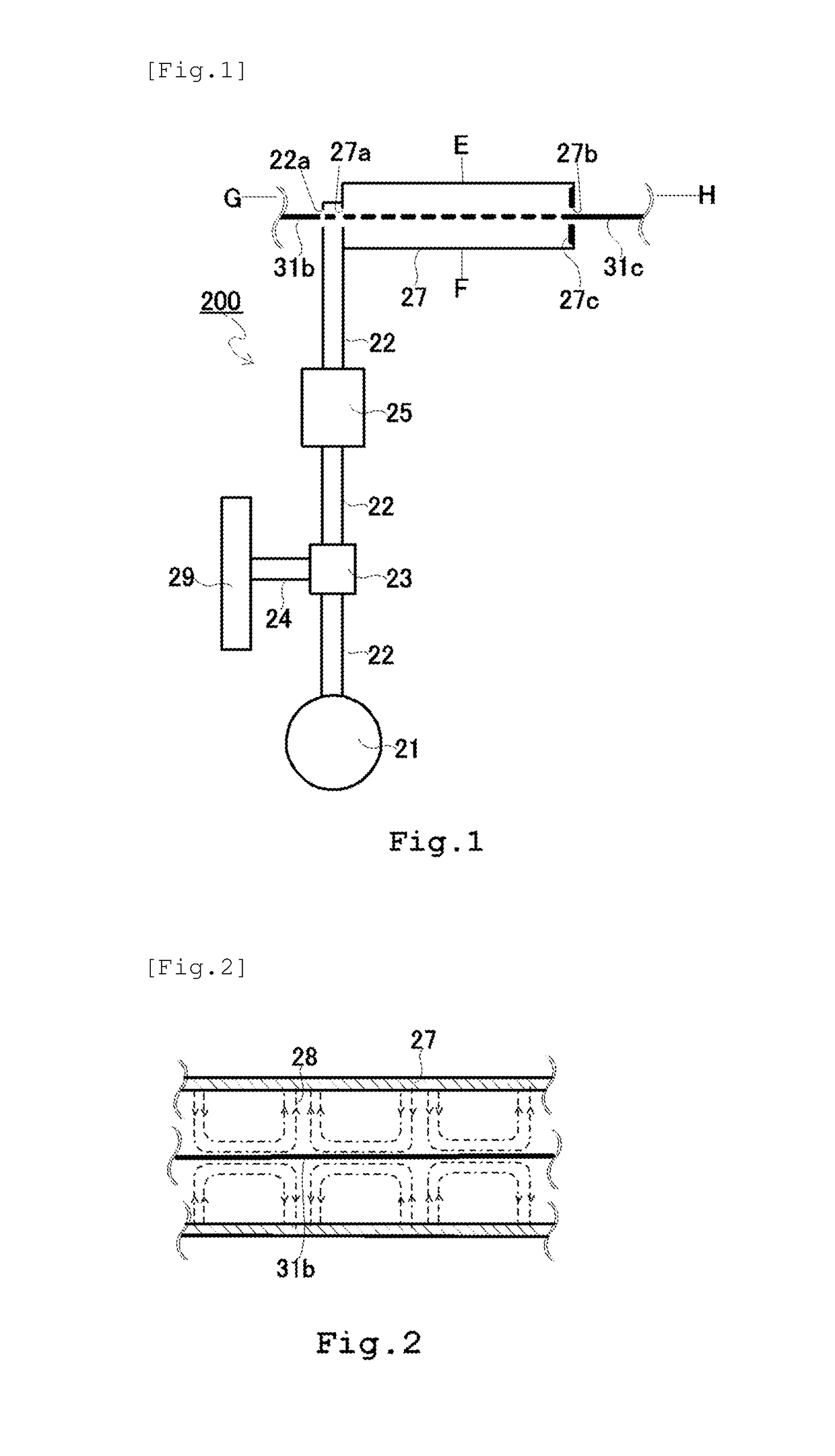

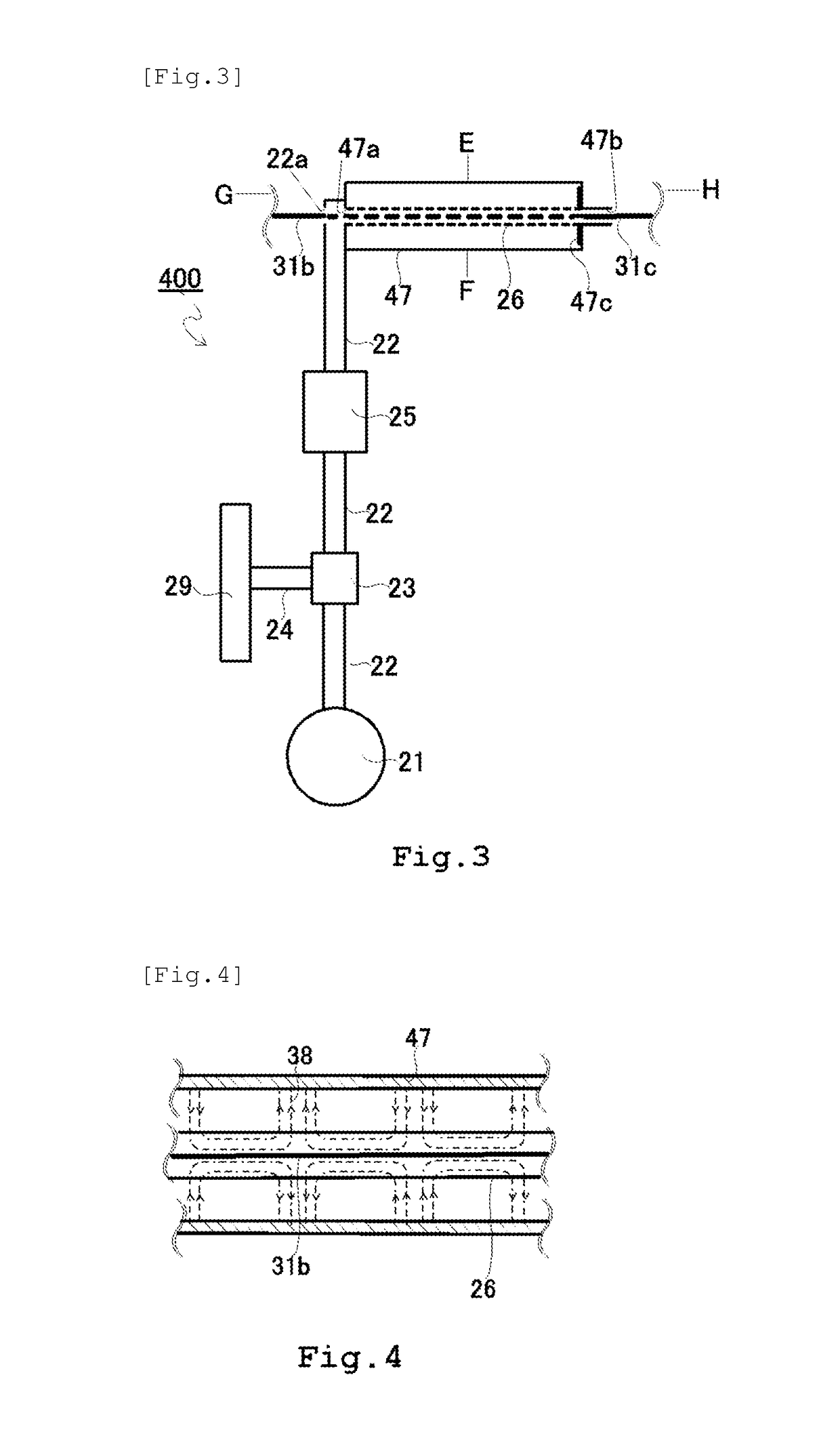

Carbon fiber manufacturing device and carbon fiber manufacturing method

ActiveUS20170327974A1Carbonized quicklyIncrease contentRadio/micro wave fibre treatmentFibre chemical featuresElectromagnetic wave absorberFiber

The problem of the present invention is to provide a carbon fiber manufacturing device in which fiber to be carbonized is irradiated with microwaves and thereby heated, wherein the carbon fiber manufacturing device is compact and capable of performing carbonization at atmospheric pressure without requiring an electromagnetic wave absorber or other additives or preliminary carbonization through external heating. This carbon fiber manufacturing device (200) includes: a cylindrical furnace (27) comprising a cylindrical waveguide in which one end is closed, a fiber outlet (27b) being formed in the one end of the cylindrical waveguide and a fiber inlet (27a) being formed in the other end of the cylindrical waveguide; a microwave oscillator (21) for introducing microwaves into the cylindrical furnace (27); and a connection waveguide (22) having one end connected to the microwave oscillator (21) side and the other end connected to one end of the cylindrical furnace (27).

Owner:TEIJIIN LTD +2

Anti-static treatment method of underwear

InactiveCN107476043AWith antistatic abilityImprove durabilityRadio/micro wave fibre treatmentGrip property fibresChemistryAqueous solution

The invention belongs to the technical field of textile, and in particular discloses an anti-static treatment method of underwear. The method comprises the following steps: (1) adding an anti-static agent into water at the temperature of 40-50 DEG C, and evenly stirring to prepare an anti-static agent aqueous solution with a mass concentration of 3-6%; (2) putting the underwear, shaped by processing, into the anti-static agent aqueous solution for carrying out anti-static treatment; (3) washing the underwear, subjected to the anti-static treatment, with clear water, and then carrying out dehydration; (4) adding a film-forming agent into water and evenly stirring to prepare a film-forming agent aqueous solution; (5) putting the underwear, subjected to the dehydration in the step (3), into the film-forming agent aqueous solution for carrying out film formation treatment; (6) washing the underwear, subjected to the film formation treatment, with clear water, and then dehydrating; (7) putting the dehydrated underwear into a laundry drier, and drying the underwear to constant weight. The anti-static treatment method of the underwear is simple and easy to operate, and can enable the underwear to obtain excellent antistatic property.

Owner:王露

Coated metalized fabric and process for edge bonding

InactiveUS20060194488A1Increased durabilityDomestic upholsteryRadio/micro wave fibre treatmentFiberMetallurgy

Owner:COGHILL TRENT T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com