Preparation method of PVA/cellulose composite fiber

A composite fiber and cellulose technology, which is applied in radiation wave/microwave fiber processing, cellulose/protein conjugated rayon, fiber processing, etc. Deterioration and other problems, to achieve the effect of improving spinning effect and working environment, improving spinning efficiency and good textile processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: A kind of preparation method of PVA / cellulose composite fiber

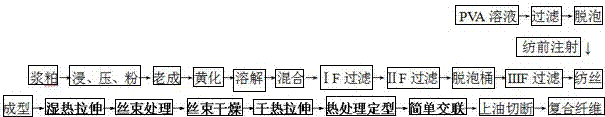

[0038] The specific preparation process of PVA / cellulose composite fiber with a specification of 1.33dtex*38mm is as follows: figure 1 shown.

[0039] Include the following steps:

[0040] (1) Preparation steps of spinning dope:

[0041]Dissolving polyvinyl alcohol with an average degree of polymerization of 500 to prepare a polyvinyl alcohol (PVA) solution with a mass fraction of 20%; adding the prepared PVA solution to the viscose solution prepared by the viscose method to obtain a spinning stock solution; The weight ratio of PVA in silk stock solution: cellulose A in viscose collagen solution is 10:90.

[0042] (2) Spinning forming step

[0043] The spinning stock solution is spun through the adjusted coagulation bath. The coagulation bath is composed of 80g / L sulfuric acid, 10.0g / L zinc sulfate, and 380g / L sodium sulfate. The concentration drop of the coagulation bath is 10.0g / L. The ...

Embodiment 2

[0057] Embodiment 2: A kind of preparation method of PVA / cellulose composite fiber

[0058] The specific preparation process of the PVA / cellulose composite fiber with a specification of 1.56dtex*38mm is as follows: figure 1 shown.

[0059] Include the following steps:

[0060] (1) Preparation steps of spinning dope

[0061] Dissolving polyvinyl alcohol with an average degree of polymerization of 1000 to prepare a polyvinyl alcohol (PVA) solution with a mass fraction of 18%; adding the prepared PVA solution to the viscose solution prepared by the viscose method to obtain a spinning stock solution; The weight ratio of PVA in the silk stock solution: cellulose A in the viscose collagen solution is 20:80.

[0062] (2) Spinning forming step

[0063] The spinning stock solution is spun by the adjusted coagulation bath, and the coagulation bath is composed of 75 g / L sulfuric acid, 7.6 g / L zinc sulfate, and 392 g / L sodium sulfate, and the drop of the coagulation bath concentration...

Embodiment 3

[0077] Embodiment 3: A kind of preparation method of PVA / cellulose composite fiber

[0078] The specific preparation process of the PVA / cellulose composite fiber with a specification of 1.67dtex*38mm is as follows: figure 1 shown.

[0079] Include the following steps:

[0080] (1) Preparation steps of spinning dope

[0081] Dissolving polyvinyl alcohol with an average degree of polymerization of 1700 to prepare a polyvinyl alcohol (PVA) solution with a mass fraction of 15%; adding the prepared PVA solution to the viscose solution prepared by the viscose method to obtain a spinning stock solution; The weight ratio of PVA in the silk stock solution: cellulose A in the viscose collagen solution is 25:75.

[0082] (2) Spinning forming step

[0083] The spinning stock solution is spun through the adjusted coagulation bath. The coagulation bath is composed of 68g / L sulfuric acid, 6.5g / L zinc sulfate, and 398g / L sodium sulfate. The concentration drop of the coagulation bath is 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com