Thick Oil Mixed Thin Mixing Tool

A technology for heavy oil and tools, applied in the field of oil production equipment, can solve the problems of increased energy consumption of the oil pumping system, high mixing pressure, waste of thin oil, etc., to enhance the jet effect of thin oil, reduce the oil hydraulic pressure, and reduce the failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and therefore are only used as examples, and cannot be used to limit the protection scope of the present invention.

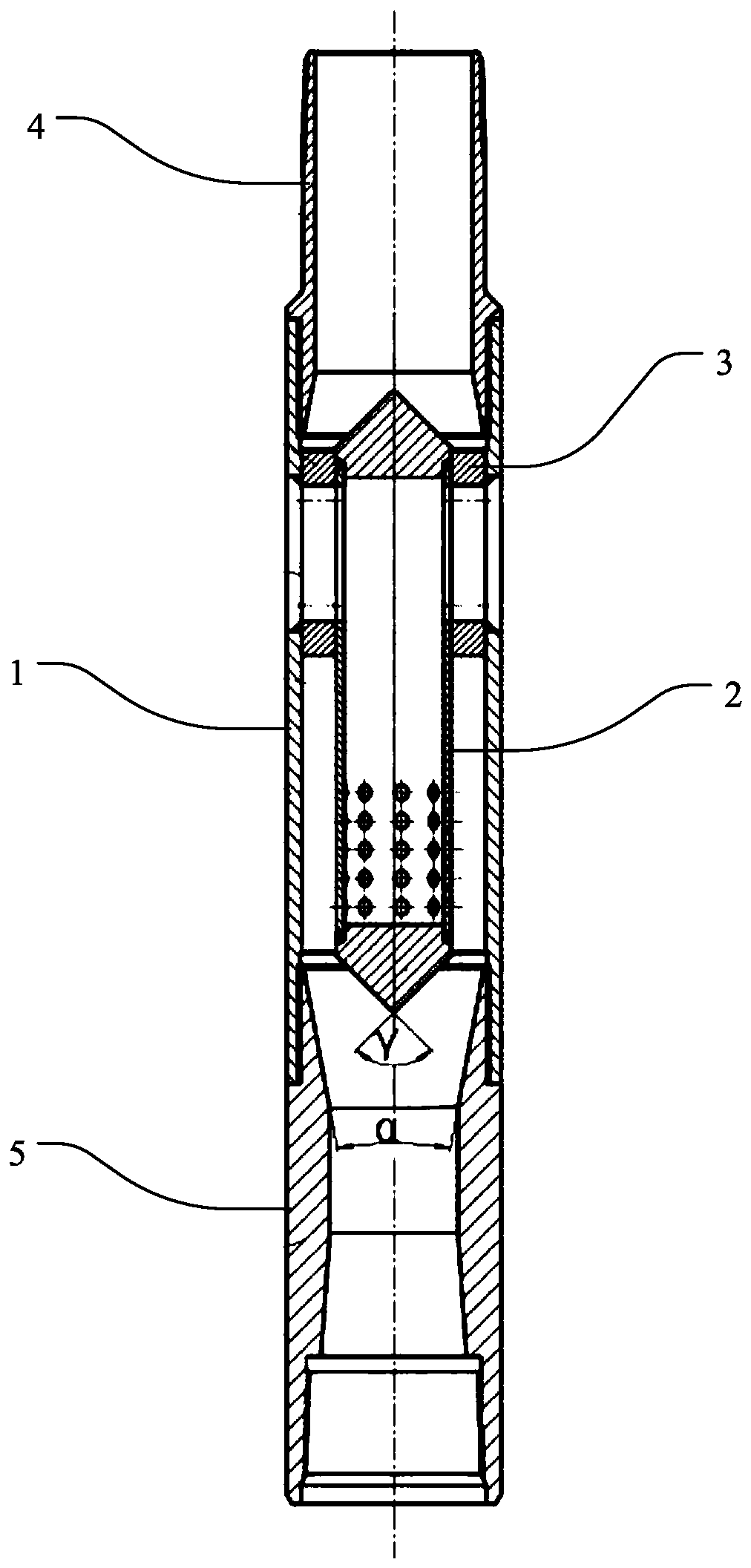

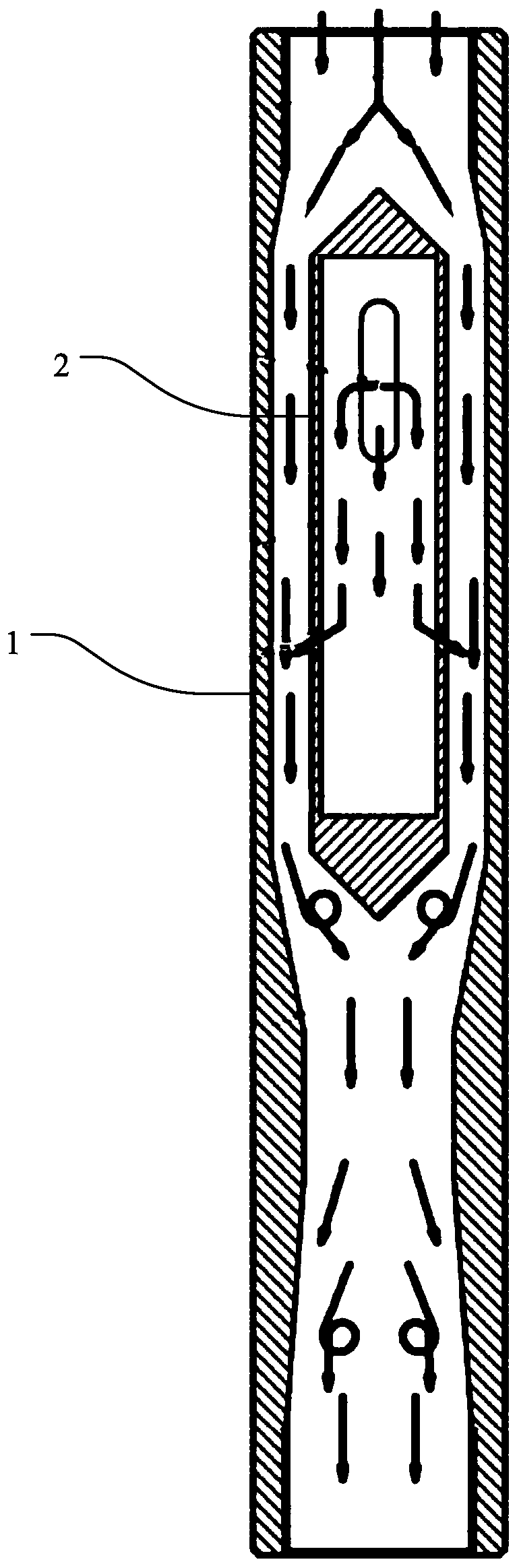

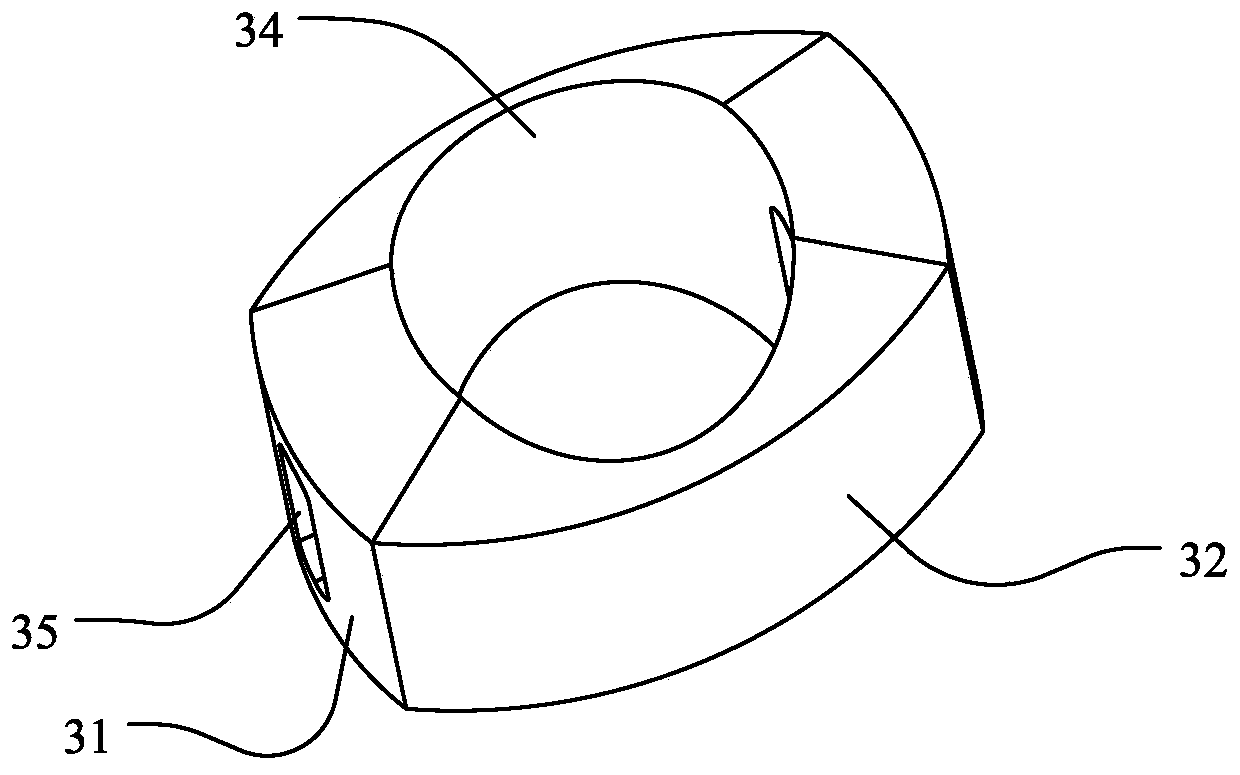

[0037] Such as Figure 1 to Figure 8 As shown, the present invention provides a thick oil blending and mixing tool, which includes an outer cylinder 1, a spray tube 2, a support block, a first joint 4 and a second joint 5, the first joint 4 and the second joint 5 respectively Connected to both ends of the outer cylinder 1, and the spray tube 2 is sleeved in the outer cylinder 1. In this embodiment, the first joint 4 and the second joint 5 are respectively connected to the outer cylinder 1 through a threaded connection, and the spray tube 2 and the outer cylinder 1 are arranged coaxially. The two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com