Preparation method of nylon 6/chitosan/noble metal nanofibers

A technology of nanofibers and nanofiber membranes, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., to achieve low cost and improve dye degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

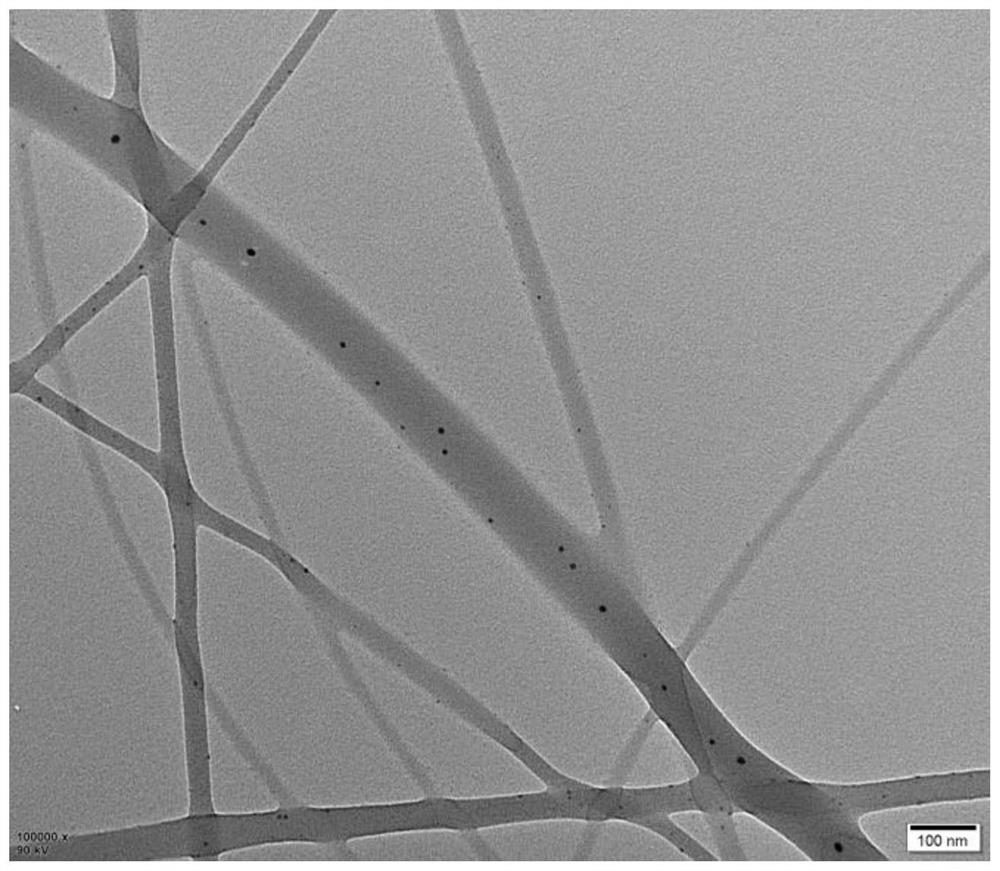

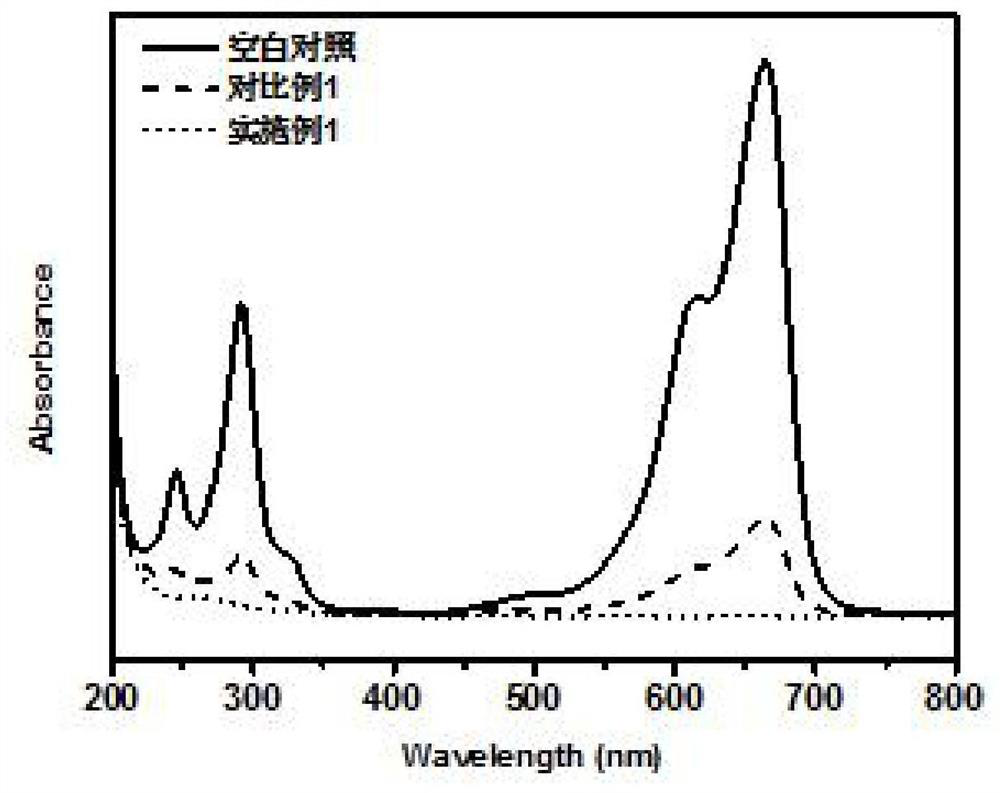

[0031] 1.935 g of nylon 6 with a molecular weight of 10000 g / mol was dissolved in 10 ml of formic acid to obtain a mother liquor. Add molecular weight in mother liquor and be 10000g / mol chitosan, deacetylation degree 95%, the weight ratio 10% of chitosan and nylon, stir 24h, obtain nylon 6 / chitosan mixed solution; (3) to nylon 6 / Add 0.05g silver nitrate to the chitosan mixed solution, the total mass ratio of silver nitrate to chitosan and nylon 6 is 2%, after stirring for 24 hours, stand still for 8 hours to obtain the nylon 6 / chitosan / silver nitrate mixed solution, the solution viscosity It is 960cP; (4) above-mentioned nylon 6 / chitosan / silver nitrate mixed solution is packed in the syringe of electrospinning device, carry out electrospinning, the voltage of electrospinning is 17kv, and ejection flow rate is 4 μ l / min, obtains Nylon 6 / chitosan / Ag nanofiber membrane. The metal particles in the nylon 6 / chitosan / noble metal nanofiber film are 0 valence, and exposed on the fibe...

Embodiment 2

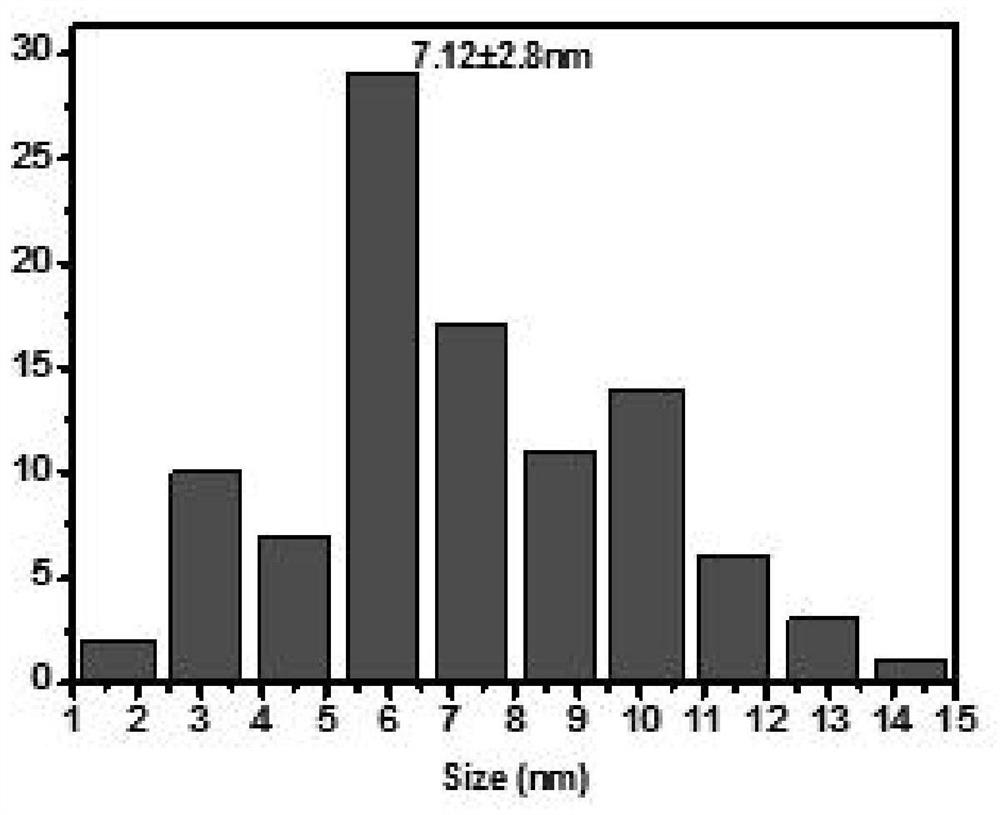

[0034]6.8 g of nylon 6 with a molecular weight of 100,000 g / mol was dissolved in 50 ml of formic acid to obtain a mother liquor. Add molecular weight in mother liquor and be 200000g / mol chitosan, deacetylation degree 70%, the weight ratio of chitosan and nylon 25%, after stirring 72h, obtain nylon 6 / chitosan mixed solution; (3) to nylon 6 Add 0.85g silver nitrate in the / chitosan mixed solution, the total mass ratio of silver nitrate and chitosan and nylon 6 is 10%, after stirring 24h, stand still 8h, obtain nylon 6 / chitosan / silver nitrate mixed solution, solution The viscosity is 400cP; (4) the above-mentioned nylon 6 / chitosan / silver nitrate mixed solution is loaded into the syringe of the electrospinning device, and the electrospinning is carried out, the voltage of the electrospinning is 17kv, and the ejection flow rate is 1μl / min A nylon 6 / chitosan / Ag nanofiber membrane was obtained. By spinning on a copper net for 1min, the sample of TEM was prepared to analyze the partic...

Embodiment 3

[0036] 0.5 g of nylon 6 with a molecular weight of 1000 g / mol was dissolved in 5 ml of formic acid to obtain a mother liquor. Add molecular weight in mother liquor and be 2000g / mol chitosan, deacetylation degree 100%, chitosan and nylon weight ratio 45%, obtain nylon 6 / chitosan mixed solution after stirring 12h; (3) to nylon 6 / Add 0.005g silver nitrate to the chitosan mixed solution, the total mass ratio of silver nitrate to chitosan and nylon 6 is 1%, after stirring for 48h, stand still for 8h to obtain the mixed solution of nylon 6 / chitosan / silver nitrate, the solution viscosity It is 5000cP; (4) above-mentioned nylon 6 / chitosan / silver nitrate mixed solution is packed in the syringe of electrospinning device, carry out electrospinning, the voltage of electrospinning is 20kv, and ejection flow rate is 20 μ l / min, obtains Nylon 6 / chitosan / Ag nanofiber membrane. By spinning on a copper net for 1min, the sample of TEM was prepared to analyze the particle size of the metal part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com