Ecological dyeing antibacterial cotton fabric preparation method

An ecological dyeing and cotton fabric technology, applied in dyeing method, physical treatment, plant fiber, etc., can solve the problems of high requirements for process equipment, many components of finishing liquid, complex synthesis process, etc., and achieve less dye consumption and heat movement The effect of faster speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

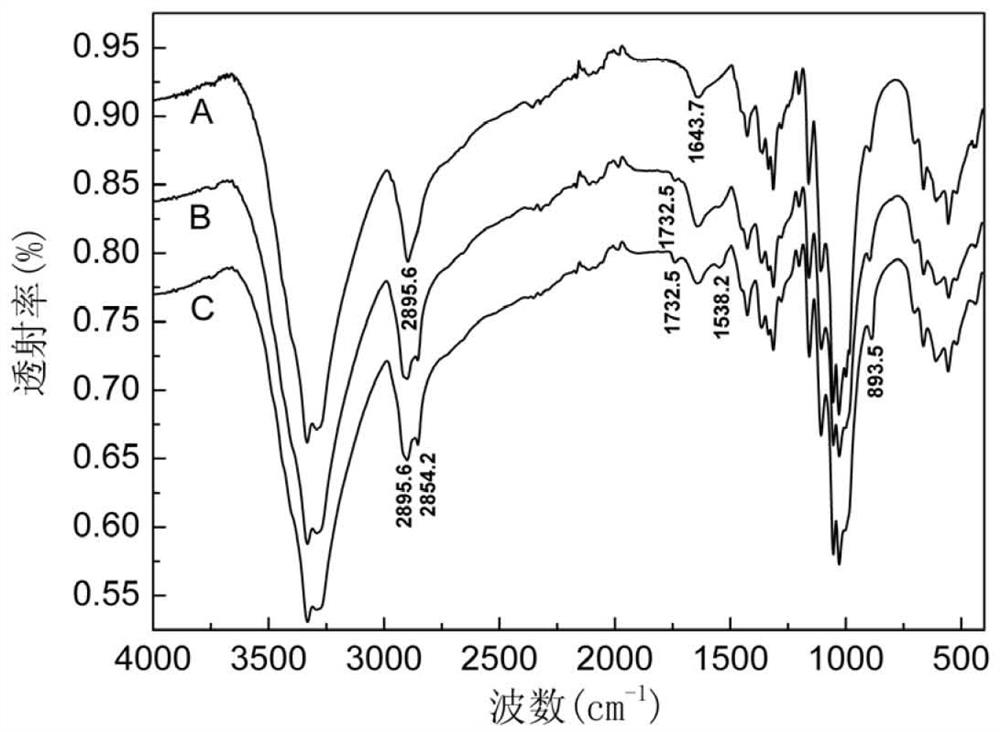

Image

Examples

Embodiment 1

[0024] (1) Add oxidized chitosan with a viscosity-average molecular weight of 120,000, a deacetylation degree of 93.5%, and an aldehyde content of 18.64% to a dilute acetic acid solution with a pH of 4.5 at 60°C and stir to dissolve to obtain a mass concentration of 1.5% Oxidized chitosan solution;

[0025] (2) Immerse the desized and scorched cotton fabric in a NaOH solution with a mass concentration of 15%, microwave-assisted treatment at 30°C for 3 minutes (microwave power is 268W), and then wash it with deionized water until it is neutral. pretreated cotton fabrics;

[0026] (3) Add the pretreated cotton fabric to the oxidized chitosan solution at a bath ratio of 1:50, and keep stirring at 70°C for 2 hours to make the hemiacetal reaction between the oxidized chitosan and the cotton fabric to obtain antibacterial Modified cotton fabric; after the reaction, the modified cotton fabric was vacuum-dried at 60°C for 4 hours, fully washed with deionized water, dehydrated, and dr...

Embodiment 2

[0028] (1) Add oxidized chitosan with a viscosity-average molecular weight of 120,000, a deacetylation degree of 93.5%, and an aldehyde content of 26.57% to a dilute acetic acid solution with a pH of 4.5 at 60°C and stir to dissolve to obtain a mass concentration of 1.5% Oxidized chitosan solution;

[0029] (2) Immerse the desizing and scouring cotton fabric in NaOH solution with a mass concentration of 15%, microwave-assisted treatment at 30°C for 3 minutes (microwave power is 300W), and then wash with deionized water until neutral. pretreated cotton fabrics;

[0030] (3) Add pretreated cotton fabric to the oxidized chitosan solution at a bath ratio of 1:50, and continue to stir at 70°C for 2 hours to allow hemiacetal reaction between oxidized chitosan and cotton fabric to obtain antibacterial Modified cotton fabric; after the reaction, the modified cotton fabric was vacuum-dried at 60°C for 4 hours, fully washed with deionized water, dehydrated, and dried, and then added to...

Embodiment 3

[0032] (1) Add oxidized chitosan with a viscosity-average molecular weight of 120,000, a degree of deacetylation of 93.5%, and an aldehyde content of 41.56% to a dilute acetic acid solution with pH=4.0 at 60°C and stir to dissolve it to obtain a mass concentration of 2.0% Oxidized chitosan solution;

[0033] (2) Immerse the desizing and scouring cotton fabric in NaOH solution with a mass concentration of 15%, microwave-assisted treatment at 30°C for 3 minutes (microwave power is 380W), and then wash it with deionized water until neutral. pretreated cotton fabrics;

[0034] (3) Add pretreated cotton fabric to the oxidized chitosan solution at a bath ratio of 1:50, and continue to stir at 70°C for 2 hours to allow hemiacetal reaction between oxidized chitosan and cotton fabric to obtain antibacterial Modified cotton fabric; after the reaction, the modified cotton fabric was vacuum-dried at 60°C for 4 hours, fully washed with deionized water, dehydrated, and dried, and then adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com