Dyeing method for dyeing wool fibers through walnut green seedcase pigment

A technology of wool fiber and walnut green husk, which is applied in the field of textile printing and dyeing, can solve the problems of affecting color fixing rate, increasing dyeing cost, drying wool fiber, etc., and achieves the effects of improving color fixing efficiency, shortening color fixing time, and reducing microwave power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment provides a kind of extraction method of walnut green peel pigment stoste, comprises the following steps:

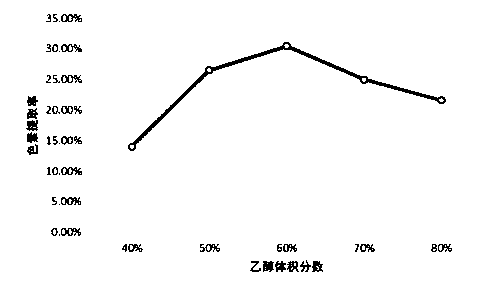

[0041] Step 1: According to the liquid-to-material ratio of 24:1, 2.0 g of green walnut peel powder was added to 48 mL of ethanol solution, fully stirred and dissolved, and a suspension of walnut green peel powder was prepared, and the volume fraction of the ethanol solution was 60%;

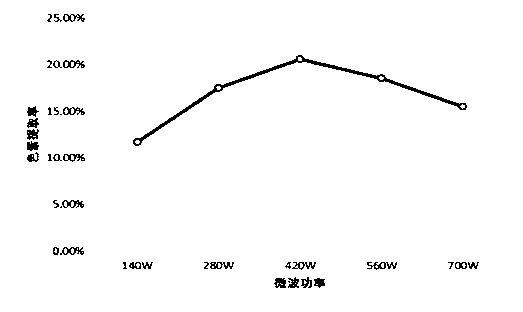

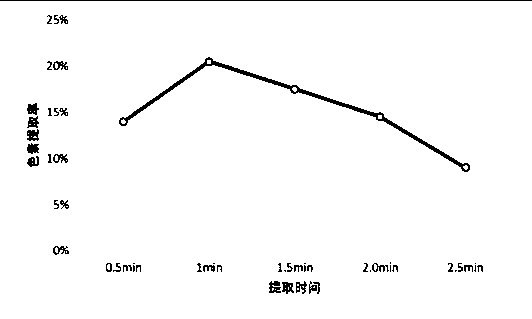

[0042] Step 2: placing the walnut green husk powder suspension in a microwave oven, and extracting it for 1 min under a microwave condition with a power of 450W;

[0043] Step 3: Leave the suspension extracted in Step 3 to room temperature, filter through filter paper, and collect the ethanol pigment solution and filter residue respectively, wherein the ethanol pigment solution is the walnut green peel pigment stock solution;

[0044] The filter residue is placed in a vacuum drying oven to dry and weigh;

[0045] After the walnut green peel pigment stock solut...

Embodiment 2

[0065] Present embodiment provides a kind of dyeing method that utilizes walnut green peel pigment to dye wool fiber, and its steps are as follows:

[0066] Step 1: At a temperature of 20-25°C and a humidity of 60-70%, after the wool fiber sample is conditioned and balanced, put it into a polyethylene film bag that does not absorb microwaves and seal it, and then Place in a microwave oven and pretreat for 3 minutes under a microwave condition with a power of 700W;

[0067] Step 2: Add a leveling agent (Pingpinga O-25) to the walnut green peel pigment stock solution prepared according to the extraction method of Example 1, and after adjusting its pH to 4.5, make the walnut green peel pigment stock solution, and then prepare it at a liquor ratio of 1:50, under the condition that the temperature is 80°C, the wool fiber sample pretreated in step 1 is exhaust-dyeed for 60 minutes, and the wool fiber sample is fully washed with water after dyeing, and naturally dried for later use. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com