Method for improving microwave curing efficiency of artificial stone

A microwave curing and artificial stone technology, applied in the field of artificial stone preparation, can solve the problems of poor microwave thermal effect, high energy consumption, and small dielectric loss, and achieve the effects of shortening microwave curing time, high thermal conductivity, and reducing microwave power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

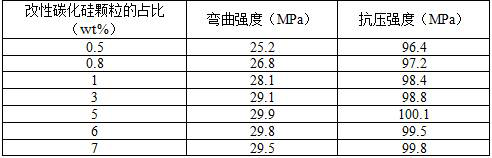

Examples

Embodiment 1

[0023] A method for improving the efficiency of microwave solidified artificial stone, comprising the following steps:

[0024] (1) Mix vinylsilane, lower alcohol and deionized water evenly to obtain a mixed solution, the mass concentration of vinylsilane in the mixed solution is 3wt%, and the mass ratio of lower alcohol and deionized water is 2:1, and then the mixed solution is used Adjust the pH to 5 with glacial acetic acid, and stir and react at 30°C for 90 minutes to obtain a silane hydrolysis solution; add silicon carbide to the silane hydrolysis solution, stir and react at 30°C and a stirring speed of 300r / min for 45 minutes, and then After standing for 40 minutes, the modified silicon carbide particles were obtained by filtration, and then washed twice with absolute ethanol and deionized water to remove excess vinyl silane on the surface of the silicon carbide particles, and then the modified silicon carbide particles were placed in an oven at 65°C Internal heating and...

Embodiment 2

[0028] A method for improving the efficiency of microwave solidified artificial stone, comprising the following steps:

[0029] (1) Mix vinylsilane, lower alcohol and deionized water evenly to obtain a mixed solution. The mass concentration of vinylsilane in the mixed solution is 5wt%, and the mass ratio of lower alcohol and deionized water is 3:1, and then the mixed solution is used Adjust the pH to 4 with glacial acetic acid, and stir the reaction at 25°C for 120 minutes to obtain a silane hydrolysis solution; add silicon carbide to the silane hydrolysis solution, stir and react at 40°C and a stirring speed of 200r / min for 30 minutes, and then After standing for 30 minutes, filter the modified silicon carbide particles, then wash them twice with absolute ethanol and deionized water to remove excess vinyl silane on the surface of the silicon carbide particles, and then place the modified silicon carbide particles in an oven at 50°C Internal heating and solidification for 30 m...

Embodiment 3

[0033] A method for improving the efficiency of microwave solidified artificial stone, comprising the following steps:

[0034](1) Mix vinylsilane, lower alcohol and deionized water evenly to obtain a mixed solution, the mass concentration of vinylsilane in the mixed solution is 4wt%, and the mass ratio of lower alcohol and deionized water is 4:1, and then the mixed solution is used Adjust the pH to 6 with glacial acetic acid, and stir and react at 35°C for 60 minutes to obtain a silane hydrolysis solution; add silicon carbide to the silane hydrolysis solution, stir and react at 45°C and a stirring speed of 400r / min for 60 minutes, and then After standing for 50 minutes, the modified silicon carbide particles were obtained by filtration, and then washed three times with absolute ethanol and deionized water to remove excess vinylsilane on the surface of the silicon carbide particles, and then the modified silicon carbide particles were placed in an oven at 75°C Internal heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com