A kind of preparation method of expanded graphite and its application in the adsorption of aromatic compounds

A technology of aromatic compounds and expanded graphite, applied in the direction of carbon compounds, other chemical processes, chemical instruments and methods, etc., can solve the problems of high emission, high cost, consumption of strong oxidizing chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of expanded graphite, comprising the following steps:

[0022] 5 g of natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.), add 5 ml of methanol and 2 ml of water, mix well, then 500 watts ultrasonic for 30 minutes, filter directly and wash 5 times, then dried at 105°C for 1 hour, and cooled to below 50°C to obtain pre-expanded graphite;

[0023] The obtained pre-expanded graphite was transferred to the autoclave, 0.5 ml of benzene was added, and the intercalation was sealed in the autoclave at 120° C. for 90 minutes, and then cooled to room temperature;

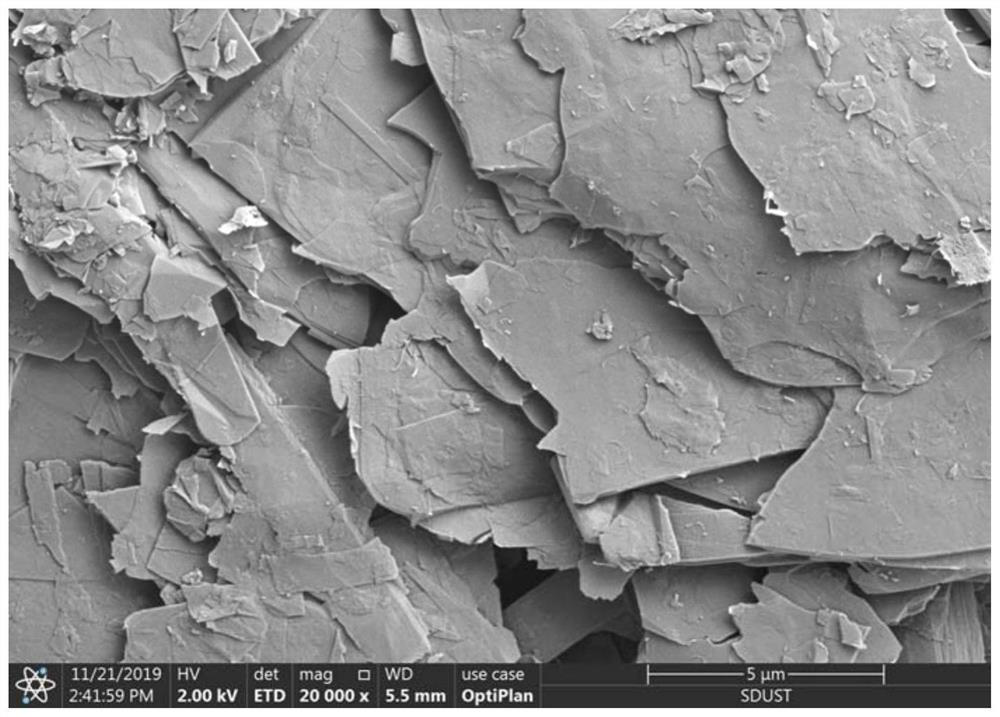

[0024] Open the autoclave cover, transfer the intercalated graphite into a 1000mL glass beaker in 5 times, and expand under 500 watt microwave power for 1 minute respectively to obtain the FEG of the present invention;

[0025] Its expansion ratio was 76 times measured by the graduated cylinder method.

Embodiment 2

[0027] A preparation method of expanded graphite, comprising the following steps:

[0028] 5 grams of natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.), add 4 ml of ethanol and 4 ml of water, mix well, then 500 watts ultrasonic for 40 minutes, directly filter and wash 5 times, then dried at 105°C for 1.5 hours, and cooled to below 50°C to obtain pre-expanded graphite;

[0029] The pre-expanded graphite was transferred to the autoclave, 0.25 ml of petroleum ether and 0.25 ml of benzene were added, and the intercalation layer was sealed in the autoclave at 150°C for 60 minutes, and then cooled to room temperature;

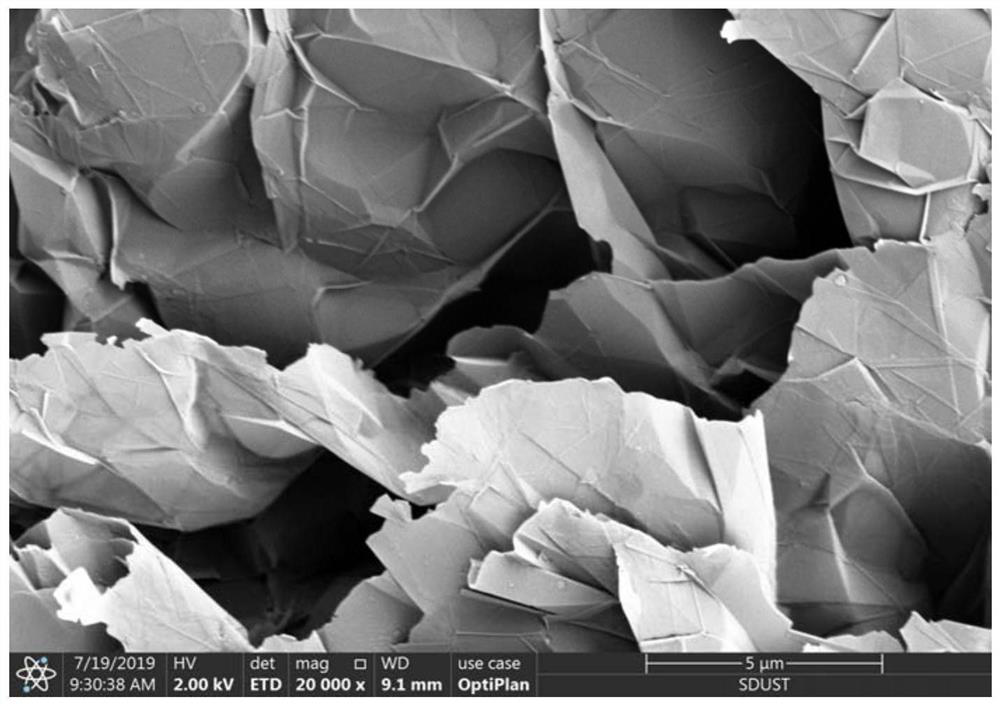

[0030] Open the autoclave cover, transfer the intercalated graphite into a 1000 mL glass beaker in 5 times, and expand under 500 watt microwave power for 40 seconds to obtain the FEG of the present invention;

[0031] Its expansion ratio was 101 times measured by the graduated cylinder method.

Embodiment 3

[0033] A preparation method of expanded graphite, comprising the following steps:

[0034] 5 grams of natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.), add 4 ml of propanol and 4 ml of water, mix well, then 500 watts ultrasonic for 60 minutes, directly filter and wash 5 times, then dried at 105°C for 1.5 hours, and cooled to below 50°C to obtain pre-expanded graphite;

[0035] The pre-expanded graphite was transferred to the autoclave, 0.1 ml of petroleum ether, 0.2 ml of benzene, 0.2 ml of n-hexane were added, and the autoclave was sealed and intercalated at 150 ° C for 60 minutes, and then cooled to room temperature;

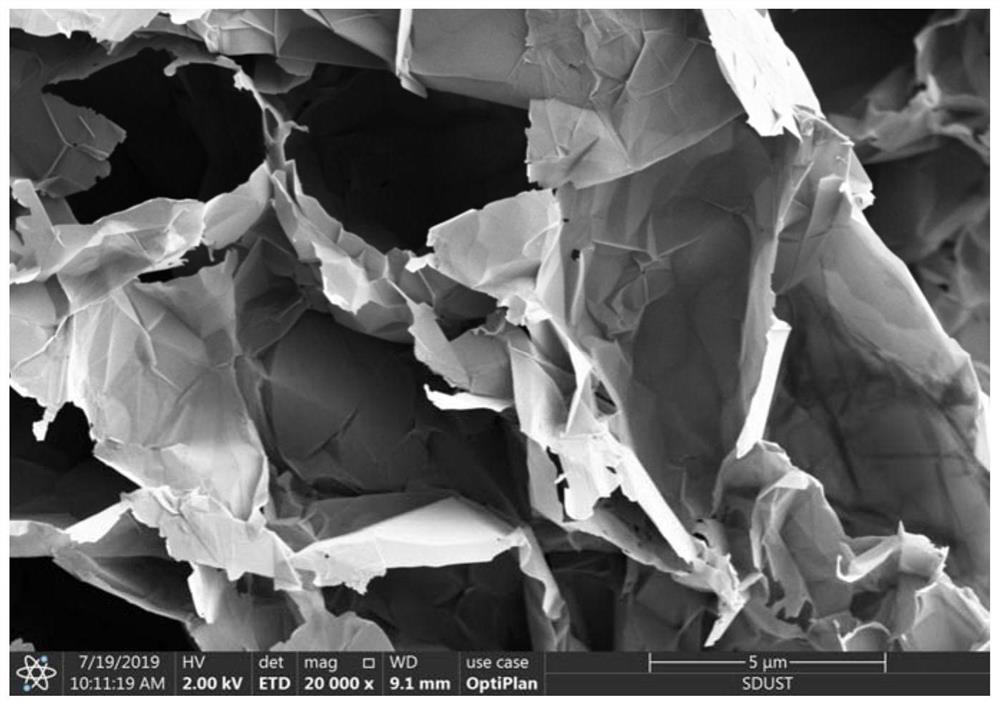

[0036] Open the autoclave cover, transfer the intercalated graphite into a 1000 mL glass beaker in 5 times, and expand under 500 watt microwave power for 40 seconds to obtain the FEG of the present invention;

[0037] Its expansion ratio was 108 times measured by the graduated cylinder method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com