Multifunctional modification treatment method for silk

A treatment method and multifunctional technology, which is applied in the field of multifunctional modification of silk, can solve problems such as uneven heating and long heating time, and achieve the effects of less energy consumption, improved production efficiency, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

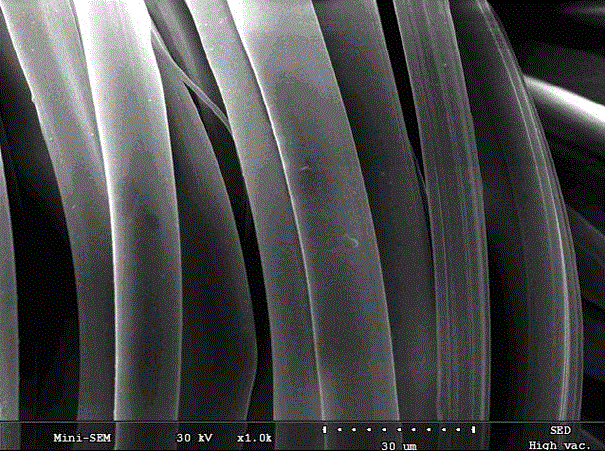

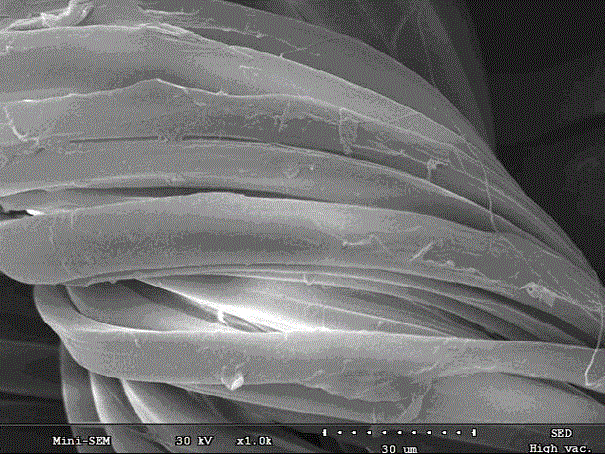

Image

Examples

Embodiment 1

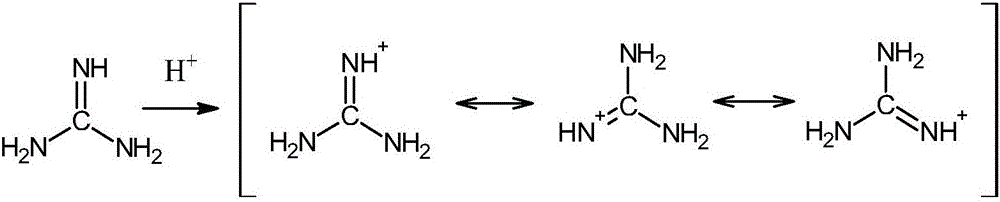

[0029] A method for multifunctional modification of silk, comprising the steps of: preparing 100 g of a finishing solution containing 0.5 g of chitosan monoguanidine hydrochloride, 0.5 g of tetracarboxylic acid, and 0.5 g of sodium hypophosphite Secondary dipping and second rolling, the excess rate is 80%, microwave irradiation for 1-5min, power 300-700W, 50℃ hot water washing, cold water washing, and finally drying.

Embodiment 2

[0031] A method for multifunctional modification of silk, comprising the steps of: preparing 100 g of a finishing solution containing 1.0 g of chitosan monoguanidine hydrochloride, 1.0 g of tetracarboxylic acid, and 1.0 g of sodium hypophosphite Secondary dipping and second rolling, the excess rate is 80%, microwave irradiation for 1-5min, power 300-700W, 50℃ hot water washing, cold water washing, and finally drying.

Embodiment 3

[0033] A multifunctional modification treatment method for silk, comprising the steps of: placing silk fabric in a finishing liquid containing 1.5 g of chitosan biguanide hydrochloride, 1.0 g of tricarboxylic acid, and 1.5 g of sodium hypophosphite configured as 100 g Two dipping and two rolling, the excess rate is 100%, irradiated by microwave for 1-5min, power is 300-700W, fully washed with hot water at 50℃, washed with cold water, and finally dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com