Method for strengthening mechanical property of nanofiber membrane

A nanofiber membrane and mechanics technology, applied in fiber processing, radiation wave/microwave fiber processing, textiles and papermaking, etc., can solve the problems of high energy consumption and low energy utilization rate, achieve simple operation, enhanced mechanical properties, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) adding polyethyleneimine to 60wt% acetic acid solution to prepare a cationic polyelectrolyte solution with a mass fraction of 1wt%;

[0024] (2) adding pectin to 90wt% formic acid solution to prepare an anionic polyelectrolyte solution with a mass fraction of 50wt%;

[0025] (3) Blending the polyelectrolyte solution described in the above step 1) and step 2) with a mass ratio of 1:9, stirring for 2 hours to obtain a uniform and transparent electrospinning precursor solution;

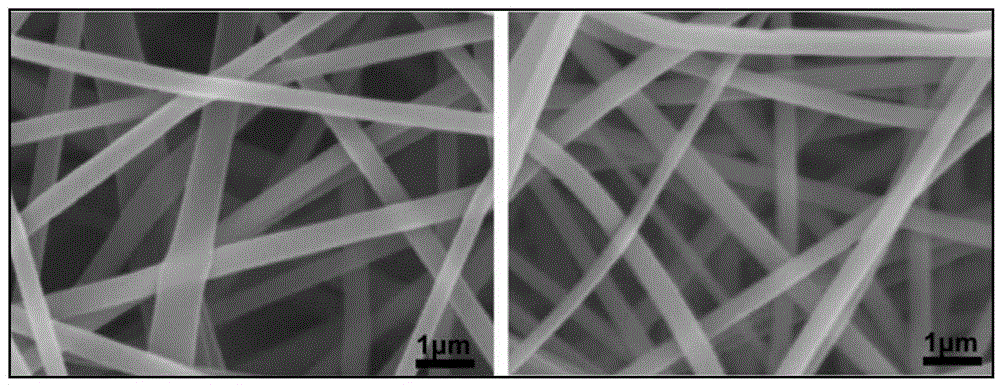

[0026] (4) The above-mentioned prepared solution is packed into a syringe, and fixed on the propeller of the electrospinning device, and the polyelectrolyte composite nanofiber membrane is prepared by electrospinning; wherein the conditions of the electrospinning are as follows: the spinning temperature is 20°C, humidity 20%, propulsion speed 1.0mL / h, voltage 35kV, distance from spinneret to receiving plate 10cm;

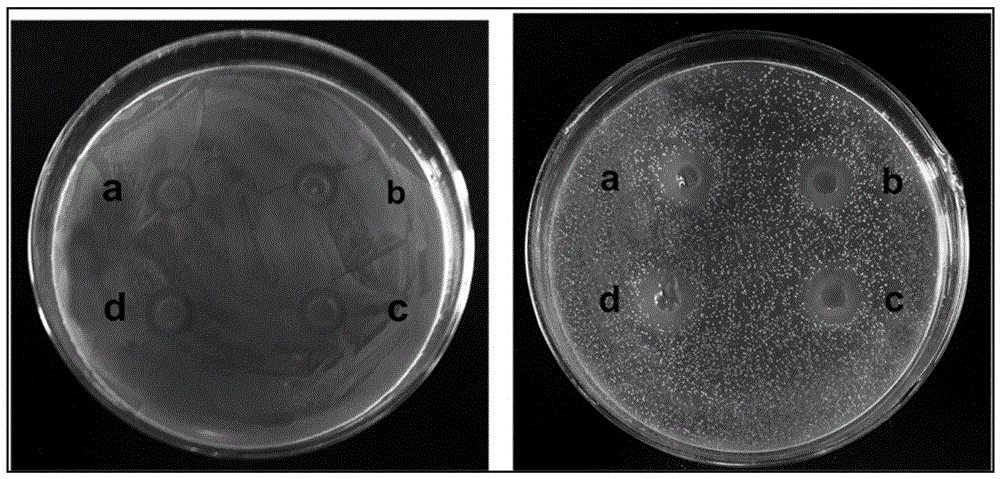

[0027] (5) The prepared polyelectrolyte composite nanofiber membrane was subje...

Embodiment 2

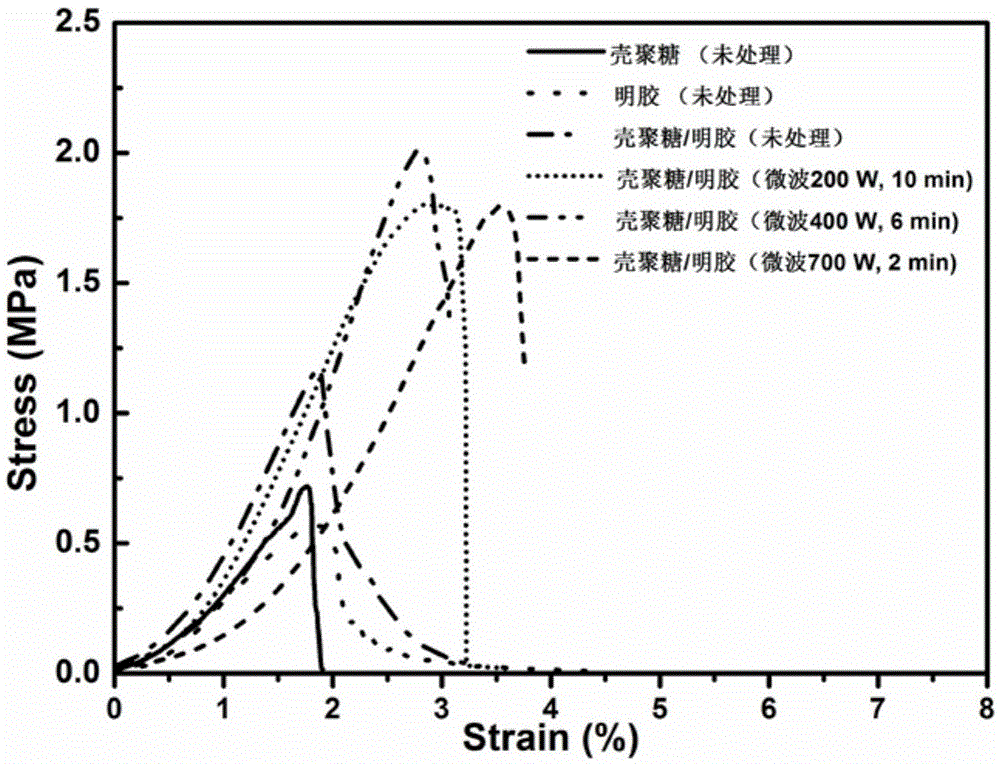

[0030] (1) Chitosan is added in the acetic acid solution of 80wt% to prepare the cationic polyelectrolyte solution that mass fraction is 20wt%;

[0031] (2) adding gelatin to 60wt% formic acid solution to prepare an anionic polyelectrolyte solution with a mass fraction of 30wt%;

[0032] (3) Blending the polyelectrolyte solution described in the above step 1) and step 2) with a mass ratio of 2:8, stirring for 10 hours to obtain a uniform and transparent electrospinning precursor solution;

[0033] (4) The above-mentioned prepared solution is packed into a syringe, and fixed on the propeller of the electrospinning device, and the polyelectrolyte composite nanofiber membrane is prepared by electrospinning; wherein the conditions of the electrospinning are as follows: the spinning temperature is 40°C, humidity 60%, propulsion speed 2.0mL / h, voltage 25kV, distance from spinneret to receiving plate 20cm;

[0034] (5) The prepared polyelectrolyte composite nanofiber membrane was su...

Embodiment 3

[0037] (1) adding chitosan quaternized derivatives to 70wt% acetic acid solution to prepare a cationic polyelectrolyte solution with a mass fraction of 15wt%;

[0038] (2) adding gum arabic to 40wt% trifluoroacetic acid solution to prepare an anionic polyelectrolyte solution with a mass fraction of 10wt%;

[0039] (3) blending the above-mentioned polyelectrolyte solution with a mass ratio of 5:5, and stirring for 5 hours to obtain a uniform and transparent electrospinning precursor solution;

[0040] (4) Put the above prepared solution into a syringe, and fix it on the propeller of the electrospinning device, and prepare the polyelectrolyte composite nanofiber membrane by electrospinning. Wherein the condition of electrospinning is as follows: spinning temperature is 30 ℃, and humidity is 30%, and advancing speed is 0.8mL / h, and voltage is 15kV, and the distance from spinneret to receiving plate is 15cm;

[0041] (5) The prepared polyelectrolyte composite nanofiber membrane was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com