Preparation method of zinc oxide affinity anti-ultraviolet and antibacterial silk fibers

A silk fiber, anti-ultraviolet technology, applied in the textile field, can solve the problems of poor antibacterial and anti-ultraviolet resistance, easy loss, poor affinity, etc., to achieve the effect of good hygroscopicity, not easy to run off, and improve affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

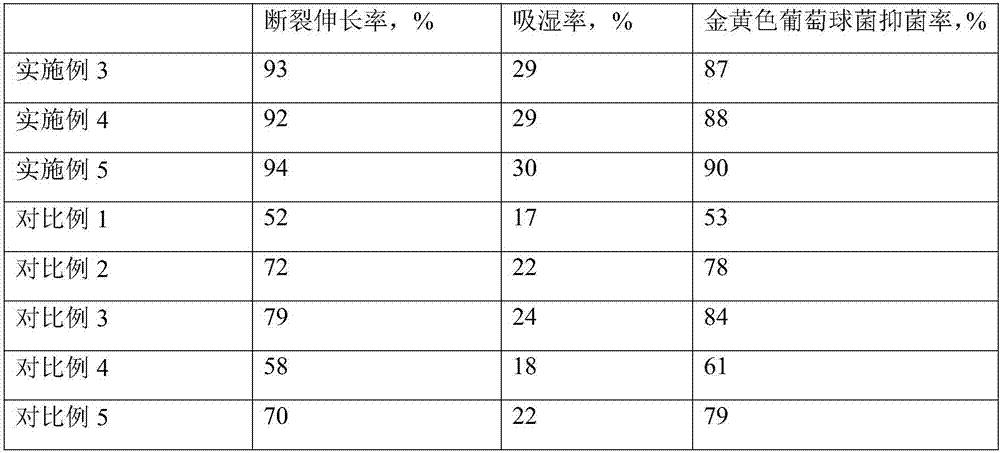

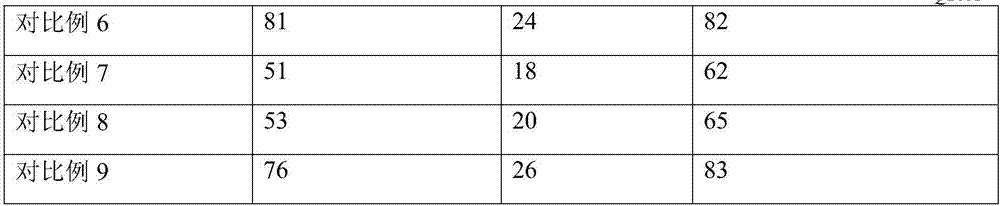

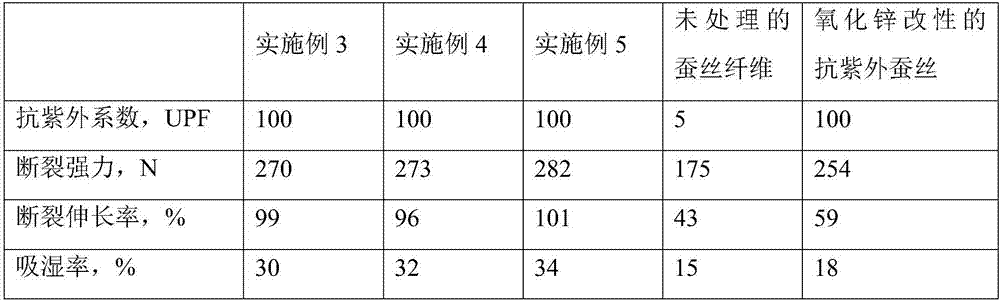

Examples

Embodiment 1

[0020] A method for preparing zinc oxide affinity anti-ultraviolet and antibacterial silk fiber, comprising the following steps:

[0021] S1, removing impurities from the silk, degumming, washing with deionized water, and drying to obtain degummed silk;

[0022] S2. Activate the degummed silk with a strong oxidant, then immerse it in an aqueous zinc sulfate solution with a mass fraction of 30% for 20 minutes, filter, wash, then soak it in ammonia water with a mass fraction of 40%, adjust the temperature to 60°C, and keep it warm for 10 minutes , to obtain pre-covered silk fibers;

[0023] S3, add 60 parts of dichloromethane to 10 parts of pre-covered silk fibers by weight and mix evenly, add 10 parts of polyethylene glycol monomethyl ether, 0.5 part of lactide, and 0.06 part of stannous isooctanoate and mix them under nitrogen protection , microwave treatment for 15 minutes, the power of microwave treatment is 240W, filtering, washing, standing in heated and humidified steam,...

Embodiment 2

[0025] A method for preparing zinc oxide affinity anti-ultraviolet and antibacterial silk fiber, comprising the following steps:

[0026] S1, removing impurities from the silk, degumming, washing with deionized water, and drying to obtain degummed silk;

[0027] S2. Activate the degummed silk with a strong oxidant, then immerse it in an aqueous solution of zinc sulfate with a mass fraction of 40% for 10 minutes, filter, wash, then soak it in ammonia water with a mass fraction of 50%, adjust the temperature to 50°C, and keep it warm for 20 minutes , to obtain pre-covered silk fibers;

[0028] S3, add 80 parts of dichloromethane to 4 parts of pre-covered silk fibers by weight and mix evenly, add 4 parts of polyethylene glycol monomethyl ether, 2 parts of lactide, 0.01 part of stannous isooctanoate and mix, and then mix them under nitrogen protection microwave treatment for 25 minutes, the microwave treatment power is 150W, filtered, washed, placed in heated and humidified steam...

Embodiment 3

[0030] A method for preparing zinc oxide affinity anti-ultraviolet and antibacterial silk fiber, comprising the following steps:

[0031] S1, removing impurities from the silk, degumming, washing with deionized water, and drying to obtain degummed silk;

[0032] S2. Activate the degummed silk with a strong oxidant, then immerse it in an aqueous solution of zinc sulfate with a mass fraction of 32% for 18 minutes, filter, wash, then soak it in ammonia water with a mass fraction of 40%, adjust the temperature to 58°C, and keep it warm for 12 minutes , to obtain pre-covered silk fibers;

[0033] S3, add 65 parts of dichloromethane to 8 parts of pre-covered silk fibers by weight and mix evenly, add 8 parts of polyethylene glycol monomethyl ether, 1 part of lactide, and 0.04 part of stannous isooctanoate and mix them under nitrogen protection microwave treatment for 18 minutes, the microwave treatment power is 220W, filtered, washed, placed in heated and humidified steam to stand s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com