Fabric coloring method and colored fabric

A fabric and color-producing technology, applied in dyeing, textiles and papermaking, vacuum evaporation plating, etc., can solve the problems of sensitive film thickness, different equipment, and poor universality of pigments, so as to improve operability and reduce resistivity , the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] This embodiment provides a fabric coloring method. The base fabric used is polyester-cotton blended and the weaving method is knitting. The specific processing technology is shown in Table 1 below.

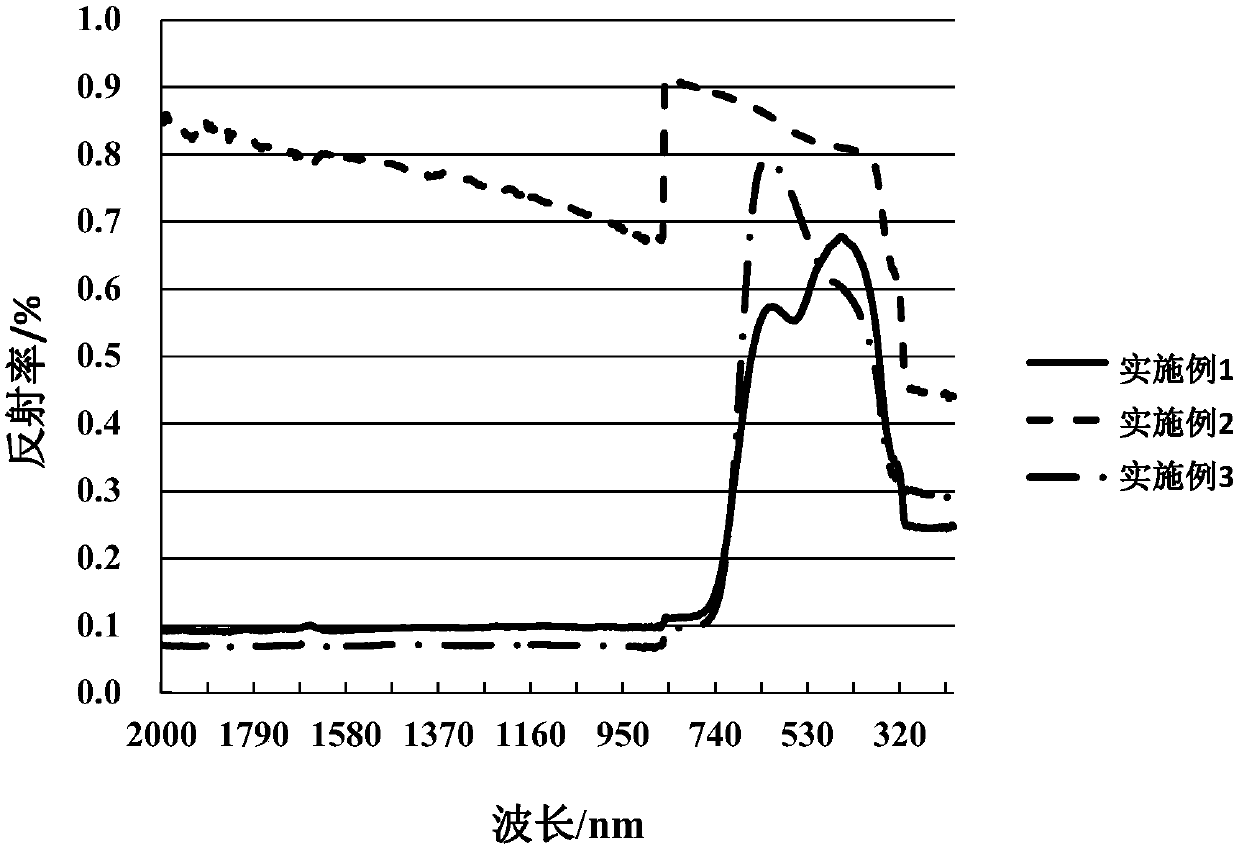

[0107] After the above processing, the final colored fabric obtained is uniform yellow-green, and its reflection spectrum in the wavelength range of 200nm-2000nm is as follows: figure 1 shown.

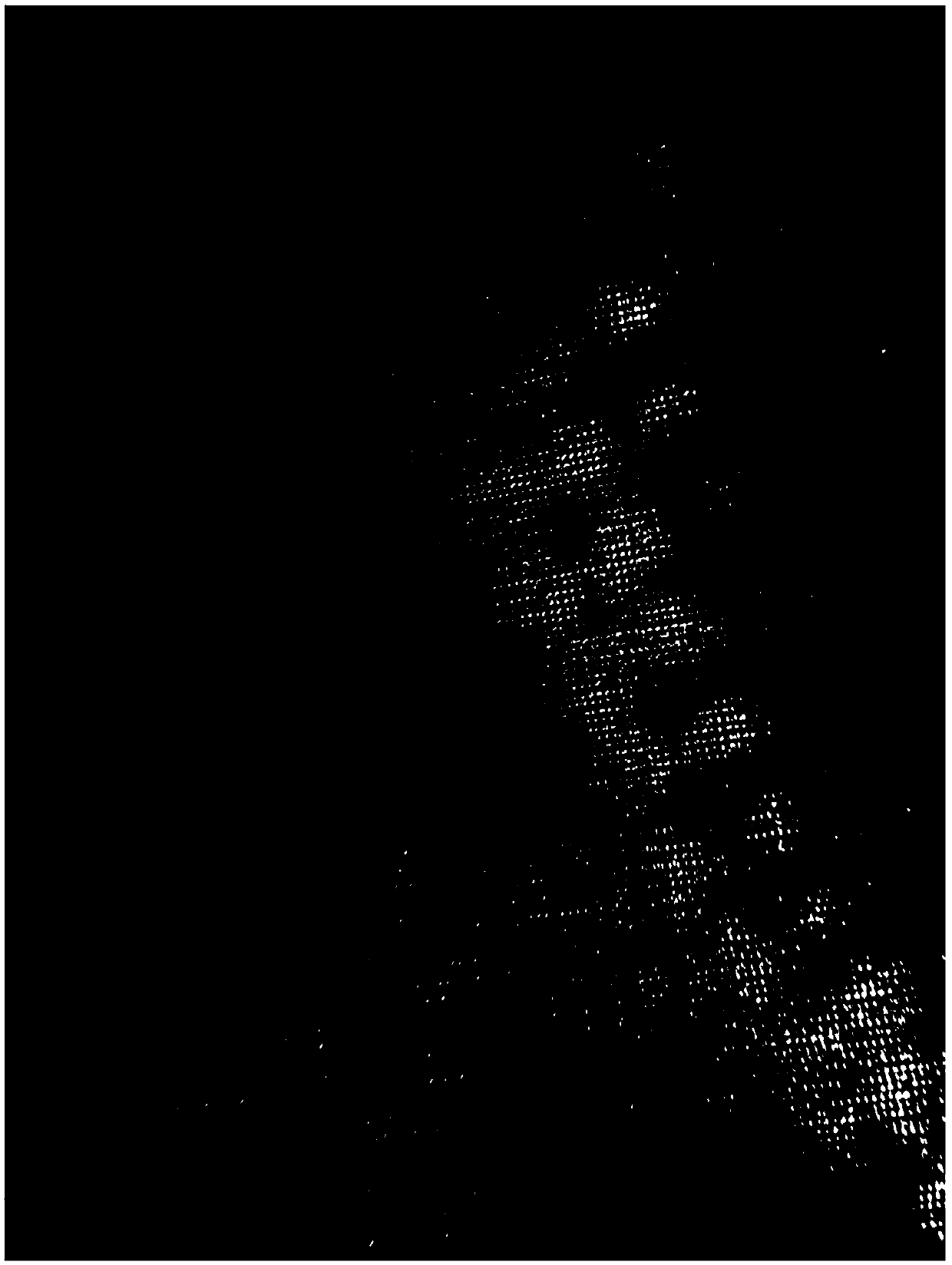

[0108] figure 2 is a photograph of the surface of the above colored fabric. according to figure 2 It can be seen that a very uniform film layer is deposited on the surface of the colored fabric; it can also be observed with the naked eye that a film layer is deposited on the entire surface of the colored fabric, and there is no problem of uneven coloring.

[0109] Color fastness test is carried out to the colored fabric of present embodiment, and result shows, comprises water fastness (GB / T 5713-2013), perspiration color fastness (GB / T 3922-2013), color fastness to rubbing (GB / ...

Embodiment 2

[0118] This embodiment provides a fabric coloring method, the base fabric used is polyester, the weaving method is woven, and the specific processing technology is shown in Table 2 below.

[0119] After the above processing, the final colored fabric obtained is brownish red, and its reflection spectrum in the wavelength range of 200nm-2000nm is as follows: figure 1 shown.

[0120] Color fastness test is carried out to the colored fabric of present embodiment, and result shows, comprises water fastness (GB / T 5713-2013), perspiration color fastness (GB / T 3922-2013), color fastness to rubbing (GB / T 5713-2013), color fastness to rubbing (GB / T 5713-2013), / T 3920-2008), color fastness to soaping (GB / T 3921-2008), color fastness to dry cleaning (GB / T 5711-1997), color fastness to light (GB / T 8427-2008) in The internal color fastness has reached level 4 or 4-5, which meets the requirements for first-class products in the GB / T 2660-2017 "Shirt" standard.

[0121] Table 2

[0122] ...

Embodiment 3

[0132] This embodiment provides a kind of coloring method of fabric, and its used base cloth is glass fiber, and weaving mode is weaving, and specific processing technology is as shown in table 4 below:

[0133] Table 4

[0134]

[0135]

[0136] After the above processing, the final colored fabric obtained is blue-green, and its reflection spectrum in the wavelength range of 200nm-2000nm is as follows: figure 1 shown.

[0137] Color fastness test is carried out to the colored fabric of present embodiment, and result shows, comprises water fastness (GB / T 5713-2013), perspiration color fastness (GB / T 3922-2013), color fastness to rubbing (GB / T 5713-2013), color fastness to rubbing (GB / T 5713-2013), / T 3920-2008), color fastness to soaping (GB / T 3921-2008), color fastness to dry cleaning (GB / T 5711-1997), color fastness to light (GB / T 8427-2008) in The internal color fastness has reached level 4 or 4-5, which meets the requirements for first-class products in the GB / T 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com