Novel caramel color food additive and preparation method thereof

A food additive, caramel color technology, applied in the preparation of sugar derivatives, food ingredients as antioxidants, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

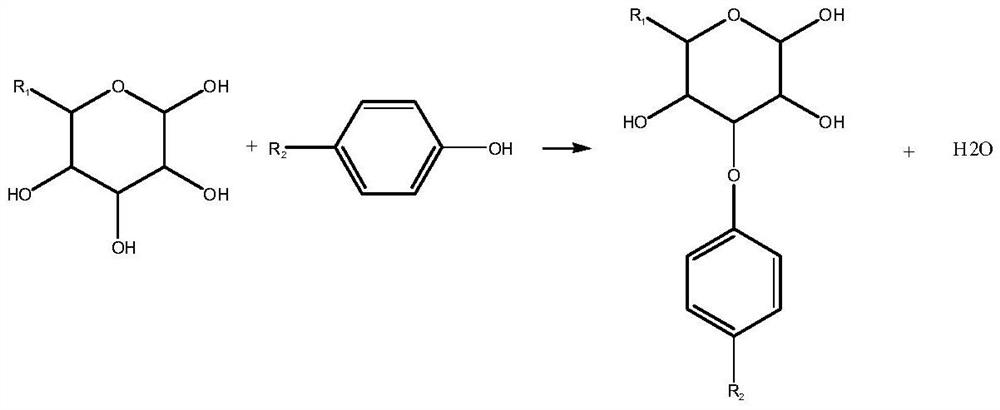

Method used

Image

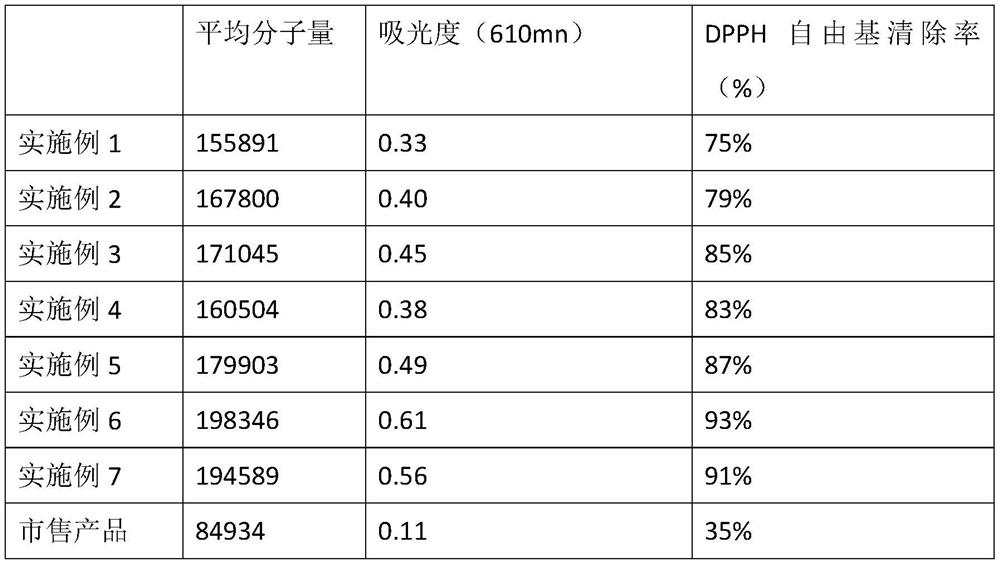

Examples

Embodiment 1

[0030] A novel caramel-colored food additive is prepared by the following preparation method:

[0031] (1) Add a certain amount of sulfuric acid to the 70% solid content sucrose aqueous solution of 1000g to adjust the pH to 3;

[0032] (2) Heating the sucrose solution to 110° C. for reaction, and performing a dehydration reaction until the system quality is stable;

[0033] (3) the polyphenolic compound caffeic acid of 10g (structural formula is ) was added to the system, and then the system was heated to 130° C. for reaction for 3 hours;

[0034] (4) Then the system was heated up to 145°C, and vacuum dehydration was carried out at 600mbar under vacuum control, and the reaction was carried out for 3 hours;

[0035] (5) After the reaction is finished, the system is lowered to 60-80° C., and 80° C. hot water and 30% sodium hydroxide solution are added for preparation to obtain the desired caramel-colored food additive.

Embodiment 2

[0037] A novel caramel-colored food additive is prepared by the following preparation method:

[0038] (1) Add a certain amount of sulfuric acid to the 80% solid content sucrose aqueous solution of 1000g to adjust the pH to 2.5;

[0039] (2) Heating the sucrose solution to 100°C for reaction, and performing a dehydration reaction until the system quality is stable;

[0040] (3) the polyphenolic compound chlorogenic acid of 10g (structural formula is ) was added to the system, and then the system was heated to 130° C. for reaction for 3 hours;

[0041] (4) Then the temperature of the system was raised to 145° C., and vacuum dehydration was carried out at 700 mbar by controlling the vacuum degree, and the reaction was carried out for 2 hours;

[0042] (5) After the reaction is finished, the system is lowered to 60-80° C., and 80° C. hot water and 30% sodium hydroxide solution are added for preparation to obtain the desired caramel-colored food additive.

Embodiment 3

[0044] A novel caramel-colored food additive is prepared by the following preparation method:

[0045] (1) Adding a certain amount of sulfuric acid to the 60% solid content sucrose aqueous solution of 1000g adjusts the pH to 3;

[0046] (2) Heating the sucrose solution to 120° C. for reaction, and performing a dehydration reaction until the system quality is stable;

[0047] (3) the polyphenolic compound gallic acid of 10g (structural formula is ) was added to the system, and then the system was heated to 130° C. for reaction for 3 hours;

[0048] (4) Then the system was heated up to 145°C, and vacuum dehydration was carried out at 700mbar under vacuum control, and the reaction was carried out for 3 hours;

[0049] (5) After the reaction is finished, the system is lowered to 60-80° C., and 80° C. hot water and 30% sodium hydroxide solution are added for preparation to obtain the desired caramel-colored food additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com