An automatic coloring device for porcelain bowl mouth

A technology of automatic coloring and bowl opening, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of low work efficiency and cumbersomeness, and achieve the effect of improving work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

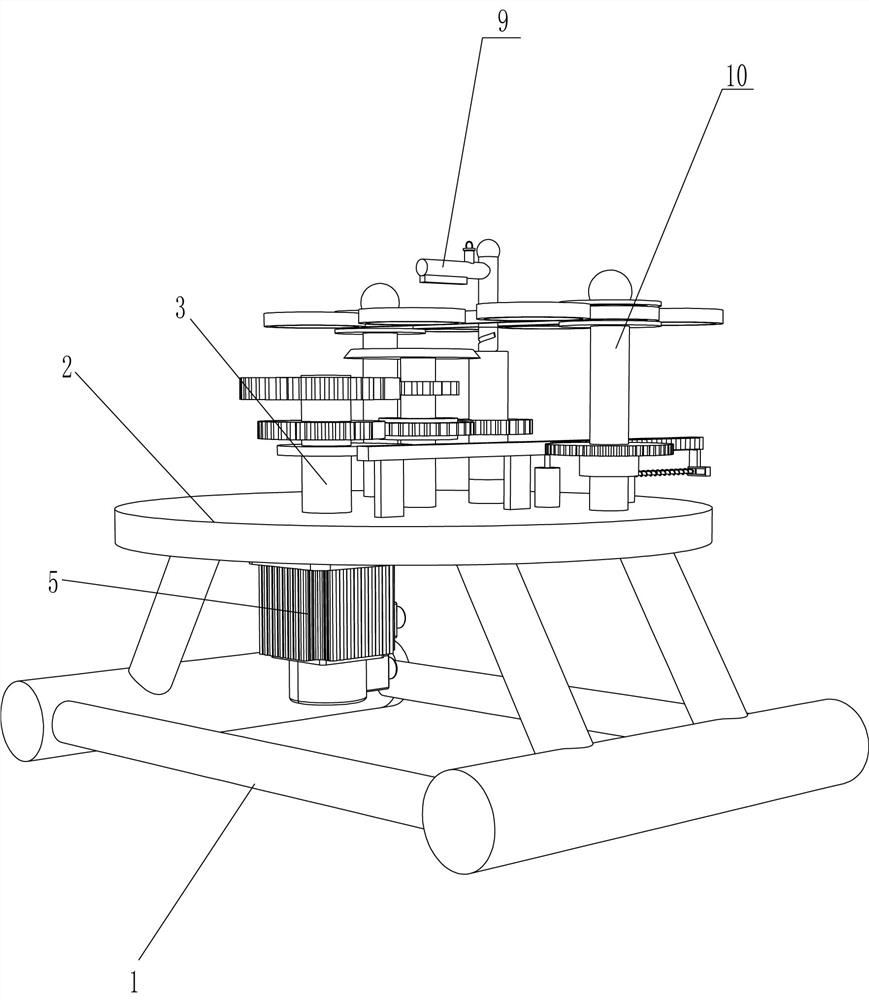

[0023] An automatic coloring device for the mouth of a porcelain bowl, such as Figure 1-2 As shown, it includes a bracket 1 and a chassis 2, the top of the bracket 1 is connected to the chassis 2, and also includes a transmission shaft 3, a first sector gear 4, a motor 5, a pole 6, a beveled turntable 7 and a first gear 8, and the chassis 2 The top is rotatably connected with a transmission shaft 3 and a pole 6, the transmission shaft 3 is located on the left side of the pole 6, a motor 5 is installed at the bottom of the chassis 2, the output shaft of the motor 5 is connected with the transmission shaft 3, and the top of the transmission shaft 3 is connected with a first The sector gear 4 is connected with the first gear 8 meshing with the first sector gear 4 on the top of the pole 6 , and the inclined turntable 7 is connected on the top of the pole 6 .

[0024] When it is necessary to paint the mouth of the porcelain bowl, this device can be used. First, the user places the...

Embodiment 2

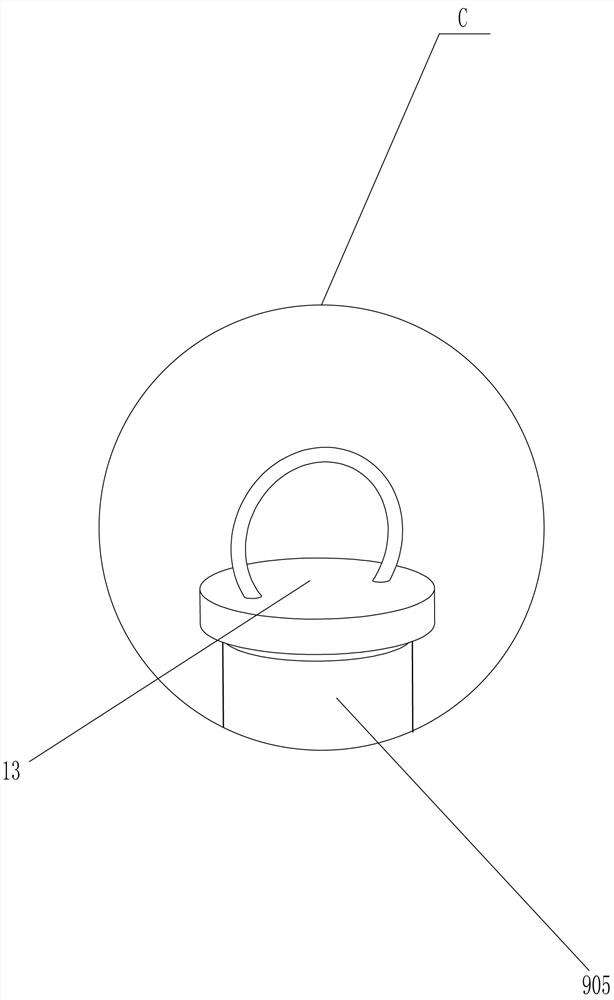

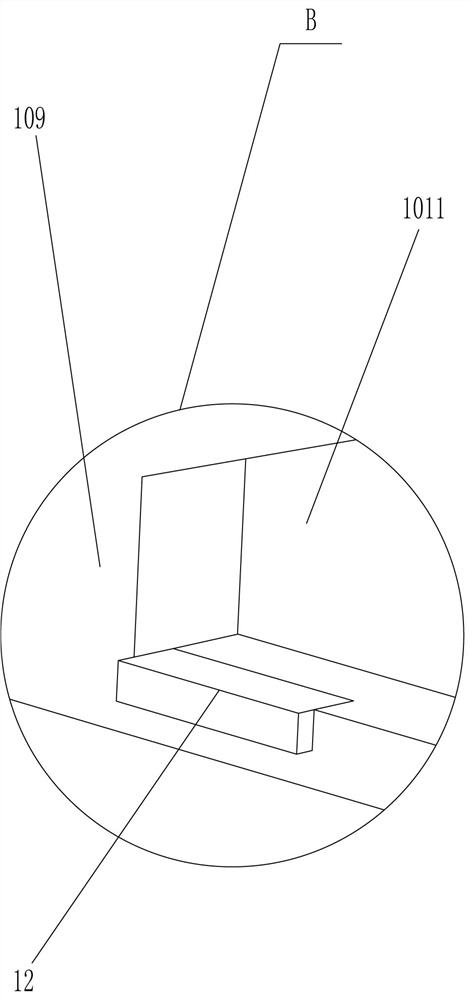

[0028] On the basis of Example 1, such as Figure 5-8 As shown, a refueling mechanism 10 is also included, and the refueling mechanism 10 includes a connecting shaft 101, a sprocket 102, a chain 103, a snap ring 104, a second gear 105, a third sector gear 106, a first rack 107, a slide Seat 108, the second tooth bar 109, L-shaped sliding frame 1012, slide bar 1013, back-moving spring 1014 and slide block 1015, the front and rear both sides of chassis 2 top right sides are all rotatably connected with connecting shaft 101, both sides connecting shaft 101 The upper part is connected with a sprocket 102, and a chain 103 is wound between the two sprockets 102. On the chain 103, six snap rings 104 are evenly spaced and densely distributed along the circumferential direction, and one of the snap rings 104 is located directly above the inclined-plane turntable 7, and the front A second gear 105 is connected to the bottom of the connecting shaft 101, a third sector gear 106 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com