Antibacterial fabric

A technology of antibacterial fabrics and fabrics, applied in the field of textile fabrics, can solve the problems of poor washability and antibacterial effect persistence, difficult production of antibacterial fibers, and high requirements for antibacterial agents, so as to achieve enhanced wearing performance, good development prospects, and improved recovery rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

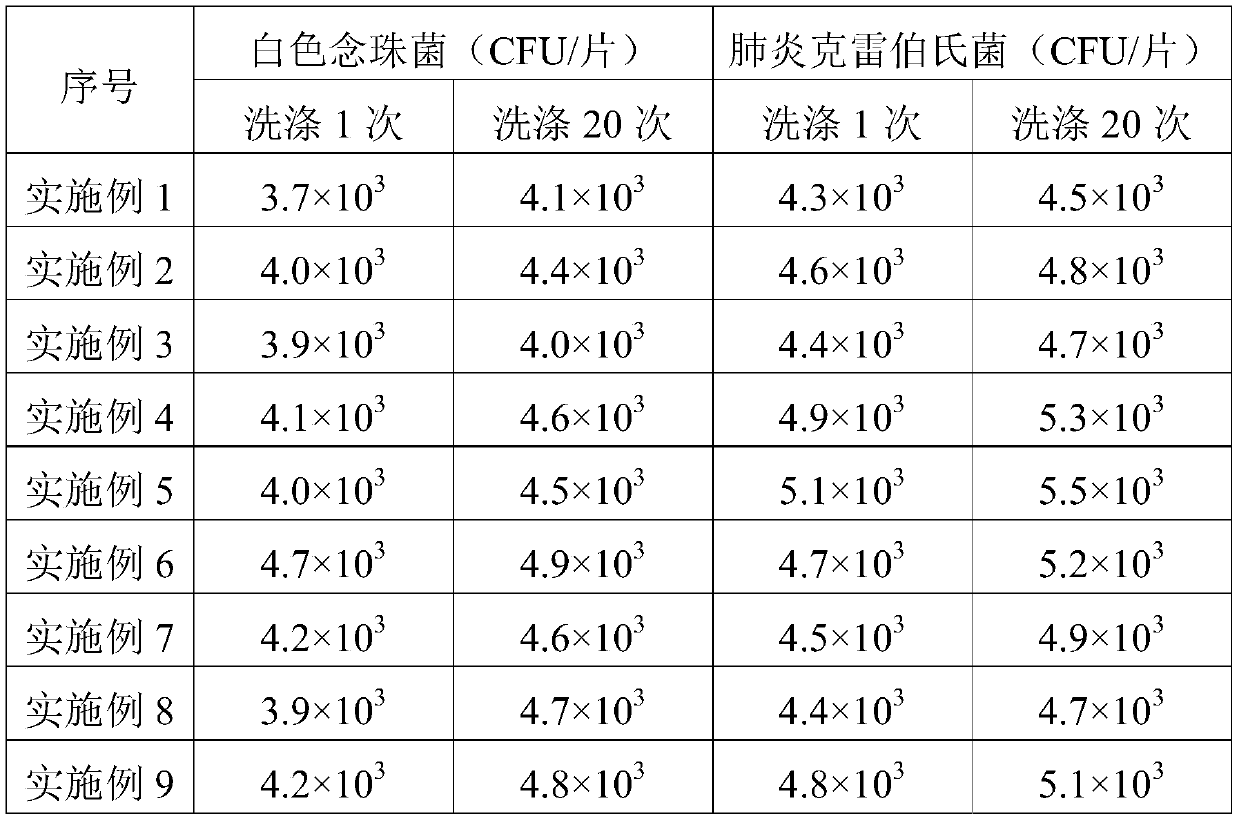

Examples

Embodiment 1

[0036] An antibacterial fabric prepared by the following method:

[0037] Step 1. Plasma treatment: Arrange 2g of cotton embryos in the microwave plasma processor chamber, pass through oxygen, and perform plasma treatment, wherein the treatment temperature is 40°C, the power is 300w, the time is 20min, the pressure is 150Pa, and the discharge frequency is 2.5GHz , and then placed in water at a temperature of 60°C for washing, and placed in an oven at a temperature of 70°C for drying;

[0038] Step 2, bleaching: mix the cotton gray cloth after washing and drying in step 1 with 50 mL of sodium hypochlorite aqueous solution with a mass fraction of 10%, and then place it in a constant temperature oscillating water bath with a temperature of 40°C for 30 minutes. Wash with distilled water and dry in an oven at a temperature of 70°C;

[0039] Step 3, mercerizing: soak the cotton gray cloth treated in step 2 in 30mL sodium hydroxide aqueous solution with a concentration of 180g / L, ta...

Embodiment 2

[0045] An antibacterial fabric prepared by the following method:

[0046] Step 1. Plasma treatment: Arrange 2g of cotton embryos in the microwave plasma processor chamber, pass through oxygen, and perform plasma treatment, wherein the treatment temperature is 40°C, the power is 300w, the time is 20min, the pressure is 150Pa, and the discharge frequency is 2.5GHz , and then placed in water at a temperature of 60°C for washing, and placed in an oven at a temperature of 70°C for drying;

[0047] Step 2, bleaching: mix the cotton gray cloth after washing and drying in step 1 with 50 mL of sodium hypochlorite aqueous solution with a mass fraction of 10%, and then place it in a constant temperature oscillating water bath with a temperature of 40°C for 30 minutes. Wash with distilled water and dry in an oven at a temperature of 70°C;

[0048] Step 3, mercerizing: soak the cotton gray cloth treated in step 2 in 30mL sodium hydroxide aqueous solution with a concentration of 180g / L, ta...

Embodiment 3

[0053] An antibacterial fabric prepared by the following method:

[0054] Step 1. Plasma treatment: Arrange 2g of cotton embryos in the microwave plasma processor chamber, pass through oxygen, and perform plasma treatment, wherein the treatment temperature is 40°C, the power is 300w, the time is 20min, the pressure is 150Pa, and the discharge frequency is 2.5GHz , and then placed in water at a temperature of 60°C for washing, and placed in an oven at a temperature of 70°C for drying;

[0055] Step 2, bleaching: mix the cotton gray cloth after washing and drying in step 1 with 50 mL of sodium hypochlorite aqueous solution with a mass fraction of 10%, and then place it in a constant temperature oscillating water bath with a temperature of 40°C for 30 minutes. Wash with distilled water and dry in an oven at a temperature of 70°C;

[0056] Step 3, mercerizing: soak the cotton gray cloth treated in step 2 in 30mL sodium hydroxide aqueous solution with a concentration of 180g / L, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com