Graphene composite antibacterial fiber

A graphene composite, antibacterial fiber technology, applied in the fiber field, can solve the problems of unsatisfactory bonding strength and washing resistance, lack of bonding effect of polyester fibers, etc., achieve excellent flame retardant and heat resistance, improve activity, and improve resistance. wash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

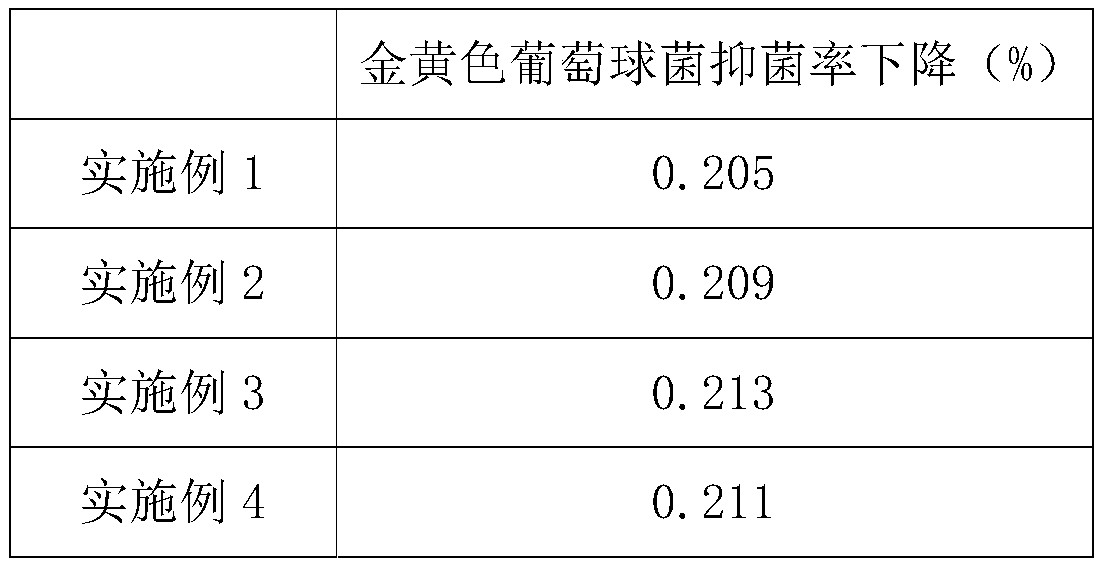

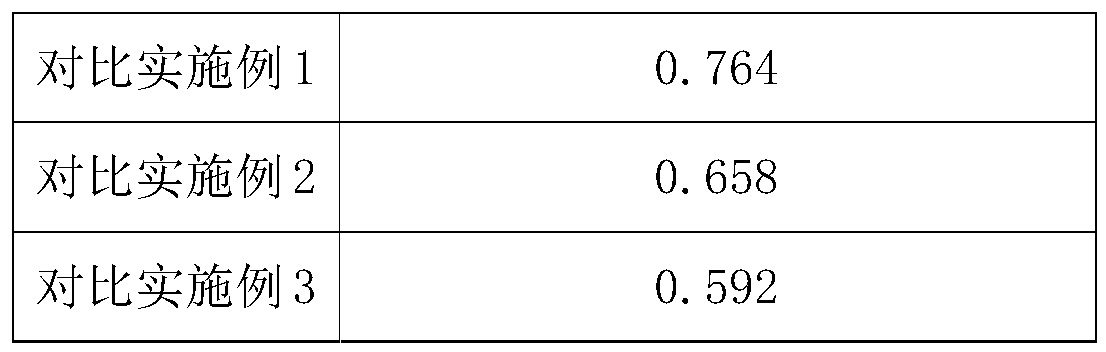

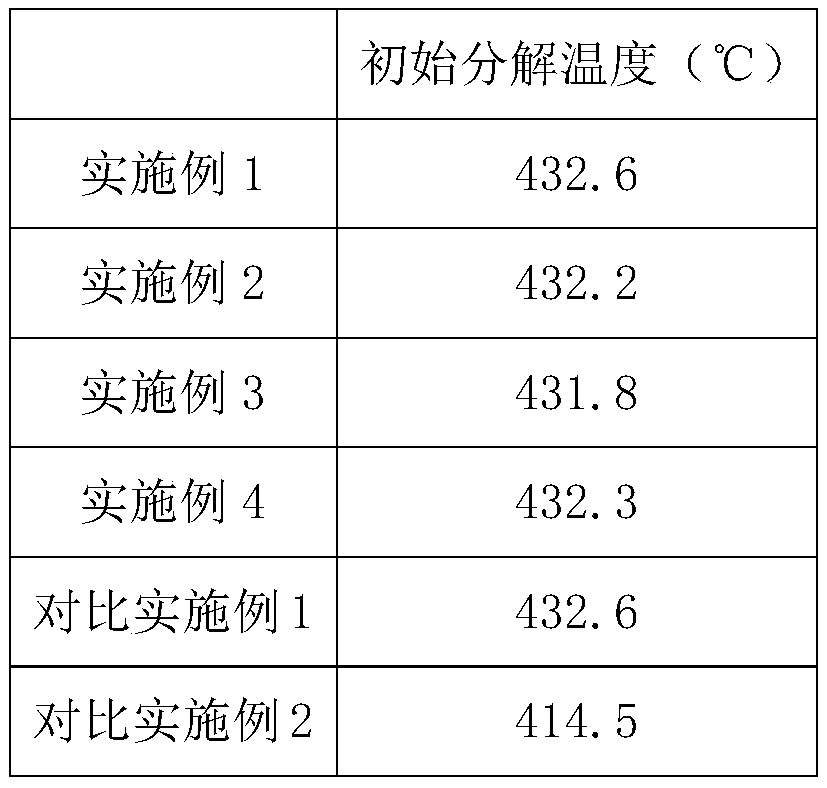

Examples

Embodiment 1

[0024] Follow the steps below to prepare graphene composite antibacterial fiber:

[0025] (1) After the graphene oxide is treated with a plasma with a power of 100W for 5 minutes, it is added to an ethanol aqueous solution with a volume fraction of 80%, stirred until the mixture is uniform, and then N-β-(aminoethyl)-γ-aminopropyl is added Methyldimethoxysilane and water were stirred and reacted for 3.5 hours to obtain reaction solution 1. The filter residue obtained after filtering the reaction solution was dried at 80°C to obtain aminated graphene, graphene oxide, ethanol aqueous solution, and N-β -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane and the mass ratio of water are 1:30:0.4:18;

[0026] (2) Add the aminated graphene obtained in step (1) to water, stir until the mixture is uniform, add glycidyltrimethylammonium chloride, heat to 80°C and stir for 1.5 hours to obtain reaction solution two, and add the reaction solution two The filter residue obtained after filtration is...

Embodiment 2

[0030] Follow the steps below to prepare graphene composite antibacterial fiber:

[0031] (1) After the graphene oxide is treated with a plasma with a power of 100W for 5 minutes, it is added to an ethanol aqueous solution with a volume fraction of 80%, stirred until the mixture is uniform, and then N-β-(aminoethyl)-γ-aminopropyl is added Methyldimethoxysilane, water, stir and react for 3 hours to obtain reaction solution 1. The filter residue obtained after filtering the reaction solution is dried at 80°C to obtain aminated graphene, graphene oxide, ethanol aqueous solution, N-β -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane and the mass ratio of water are 1:30:0.4:18;

[0032] (2) Add the aminated graphene obtained in step (1) to water, stir until the mixture is uniform, add glycidyltrimethylammonium chloride, heat to 80°C and stir for 2 hours to obtain reaction solution two, The filter residue obtained after filtration is dried at 80°C to obtain quaternized graphene, and the ...

Embodiment 3

[0036] Follow the steps below to prepare graphene composite antibacterial fiber:

[0037] (1) After the graphene oxide is treated with a plasma with a power of 100W for 5 minutes, it is added to an ethanol aqueous solution with a volume fraction of 80%, stirred until the mixture is uniform, and then N-β-(aminoethyl)-γ-aminopropyl is added Methyldimethoxysilane, water, stirred and reacted for 4 hours to obtain reaction solution 1. The filter residue obtained after filtering the reaction solution was dried at 80°C to obtain aminated graphene, graphene oxide, ethanol aqueous solution, N-β -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane and the mass ratio of water are 1:30:0.4:18;

[0038] (2) Add the aminated graphene obtained in step (1) to water, stir until the mixture is uniform, add glycidyltrimethylammonium chloride, heat to 80°C and stir for 1 hour to obtain reaction solution two, and add the reaction solution two The filter residue obtained after filtration is dried at 80°C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com