Patents

Literature

46results about How to "Effective degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

External traditional Chinese medicine liniment for treating acne dermatosis and preparation method thereof

ActiveCN102389515ADouble stabilityImprove stabilityHydroxy compound active ingredientsDermatological disorderAloinDrug efficiency

The invention provides an external traditional Chinese medicine liniment for treating acne dermatosis and a preparation method thereof. Raw materials comprises, by weight, 10-15 parts of kuh-seng, 10-15 parts of the root of red-rooted salvia, 5-10 parts of scutellaria baicalensis, 5-10 parts of hemsleya amabilis, 2-5 parts of aloe, 2-5 parts of liquorice and 1-2 parts of borneol. The medicament can be used for controlling acne of various types, has accurate curative effect according to clinical verification, an effect rate of 67.56% and a total efficiency of 97.66%. The medicament also has effects of removing fat, caring skin, mitigating chromatosis and preventing acne. Based on an existing traditional Chinese medicine extraction technology, the invention improves a traditional technology; traditional Chinese medicine pharmacological composition is employed in the formula to overcome large compound of a traditional Chinese medicine, reduce medicine and save cost, etc. A water extraction and alcohol precipitation method and an alcohol extraction and water precipitation method are improved in the traditional Chinese medicine extraction technology, so as to prepare an effective ingredient which is suitable for water alcoholic solution comprehensive extraction. Traditional ethanol concentrations of tincture and spirit are improved in the preparation, and a dosage form has dual stability without adding any antiseptic. Medicament stability and drug effect are enhanced.

Owner:CHENGDU YIHE BANGSEN TECH

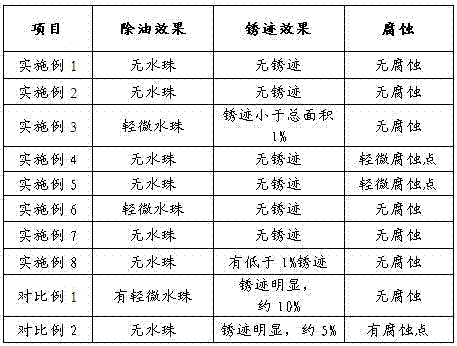

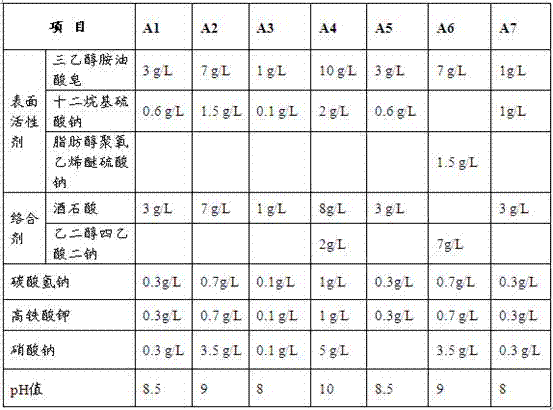

Metal surface cleaning agent, preparation method, and method for cleaning metal surface

The invention relates to a metal surface cleaning agent. The cleaning agent is an aqueous solution containing surfactants, emulsifiers, complexing agents, carbonate and ferrate. The invention also provides a preparation method of the metal surface cleaning agent, and a method for cleaning metal substrate with the cleaning agent. The cleaning agent provided by the invention can be used for removing oil and rust simultaneously, so that the processing steps are reduced. Moreover, corrosion to the metal surface is avoided while removing the rust from the substrate surface.

Owner:BYD CO LTD

Utilization of fish leftover

InactiveCN1432300AHigh surface areaStable chemical propertiesFood preservationFood preparationProtein solutionFish oil

The present invention relates to the industrial processing of aqueous product, especially the comprehensive utilization of fish leftover. The fish leftover including fish internal organs, filtered solid matter, etc. are sorted, washed, minced, enzymolyzed and filtered to eliminate residue; fish oil in the filtrate is absorbed with modified graphite; the other part of the enzymolyzed protein solution is used as feed and food material; the filter residue is used for producing organic fertilizer; and all these constitute one comprehensive technological process.

Owner:徐少云 +2

Preparation method of cellulose modified phenolic foams

The invention discloses a preparation method of cellulose phenolic foams. The preparation method comprises the following steps: preparing a mixed aqueous solution containing 7wt% of sodium hydroxide and 12wt% of urea, precooling the mixed aqueous solution to -12 DEG C, adding crushed cellulose, and stirring for 2-5 minutes to obtain a transparent cellulose solution; adding the cellulose solution into phenol to obtain biomass phenol; mixing the biomass phenol with formaldehyde according to a mole ratio of 1:1.5-1:2.0, adding a catalyst to perform condensation polymerization, performing reduced pressure dehydration, cooling and discharging to obtain fluid cellulose phenolic resin; and uniformly mixing 100 parts of fluid cellulose phenolic resin, 4-8 parts of surfactant, 3-10 parts of foaming agent and 10-20 parts of curing agent in parts by weight, foaming for 10-20 minutes at 60-80 DEG C to obtain the cellulose modified phenolic foams. By adopting the preparation method disclosed by the invention, cellulose replaces part of phenol, so that the production cost of the phenolic foams is reduced, and meanwhile, efficient utilization of biomass resources is promoted.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Solid multifunctional mask composition and method for preparing mask

ActiveCN105796474AHigh preservative doseStrong irritantCosmetic preparationsToilet preparationsBiotechnologySurface layer

The invention relates to a solid multifunctional mask composition and a method for preparing a mask. The solid multifunctional mask composition comprises the following components in parts by weight: 0.1-6.0 parts of a whitening functional additive, 0.5-13.0 parts of a moisturizing functional additive, 0.5-12.0 parts of an anti-aging functional additive, 0.5-7.0 parts of extracted natural essential oil, 2.0-8.0 parts of a skin nutritional agent, 0.1-2.5 parts of a biological preservative, 0.5-3.0 parts of a surfactant, 3.0-5.0 parts of a functional protective agent, 1.0-2.0 parts of a stabilizer, and 0.5-3.0 parts of a refrigerant. The invention also provides a method for preparing a mask by using the mask composition. The solid multifunctional mask composition comprises coordination of micro-molecule and macro-molecule components, and has a surface layer moisturizing effect on skin to enable the epidermis to be soft and stretched and pores to be opened instinctively; moreover, the micro-molecular nutritional ingredients can effectively penetrate into skin for absorption, and meanwhile, the components in the mask can effectively inhibit mites and bacteria in the skin.

Owner:QILU UNIV OF TECH +1

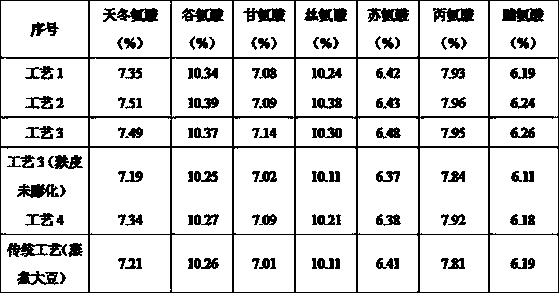

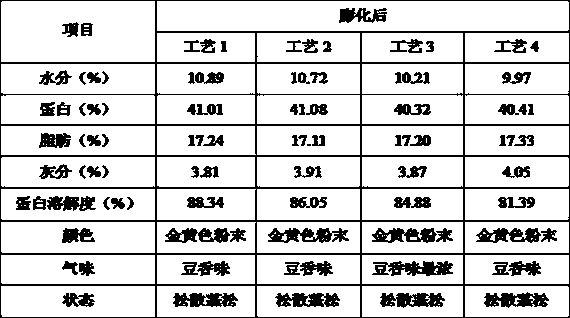

Method for brewing soy sauce through puffing soybeans

The invention provides a method for brewing a soy sauce through puffing soybeans. The method comprises the steps of pretreating raw materials: performing dust removal and impurity removal on soybeans,cleaning the soybeans after dust removal and impurity removal, crushing the cleaned soybeans to obtain bean granules, performing dust removal and impurity removal on bran, and cleaning the bran afterdust removal and impurity removal; puffing the raw materials: puffing the bean granules and the bran; preparing mother culture: weighing the puffed bran, flour and water, uniformly mixing the weighedbran with the weighed flour and the weighed water in the mass ratio of the weighed bran to the weighed flour to the weighed water being 4 to 1 to 4, performing sterilization, performing inoculation with aspergillus oryzae spores, and performing culturing until the mother culture is mature; preparing finished culture: weighing the puffed bean granules, the flour, the puffed bran and distilled water, uniformly mixing the weighed puffed bean granules with the weighed flour, the weighed puffed bran and the weighed distilled water in the mass ratio of the weighed puffed bean granules to the weighed flour, to the weighed puffed bran to the weighed distilled water being 20 to 16 to 1 to 16, performing sterilization, performing scattering, performing inoculation with mature mother culture havingthe same mass, and performing culturing until materials are covered with peak green spores so that finished culture is obtained; and preparing undecanted wine and performing fermentation: uniformly mixing the finished culture with salt water in the volume ratio of the finished culture to the salt water being 1 to 1.7, performing loading into a jar, and performing fermentation. Compared with a traditional technology, the method for brewing a soy sauce through puffing soybeans provided by the invention has the advantages that the time for brewing the soy sauce is shortened, the utilization rateof protein and the yield rate of the soy sauce can be increased, and the soy sauce is outstanding in palatable taste and unique in flavor and has scorch aroma compared with finished products in the prior art.

Owner:HENAN SHENNONG FEED TECH CO LTD

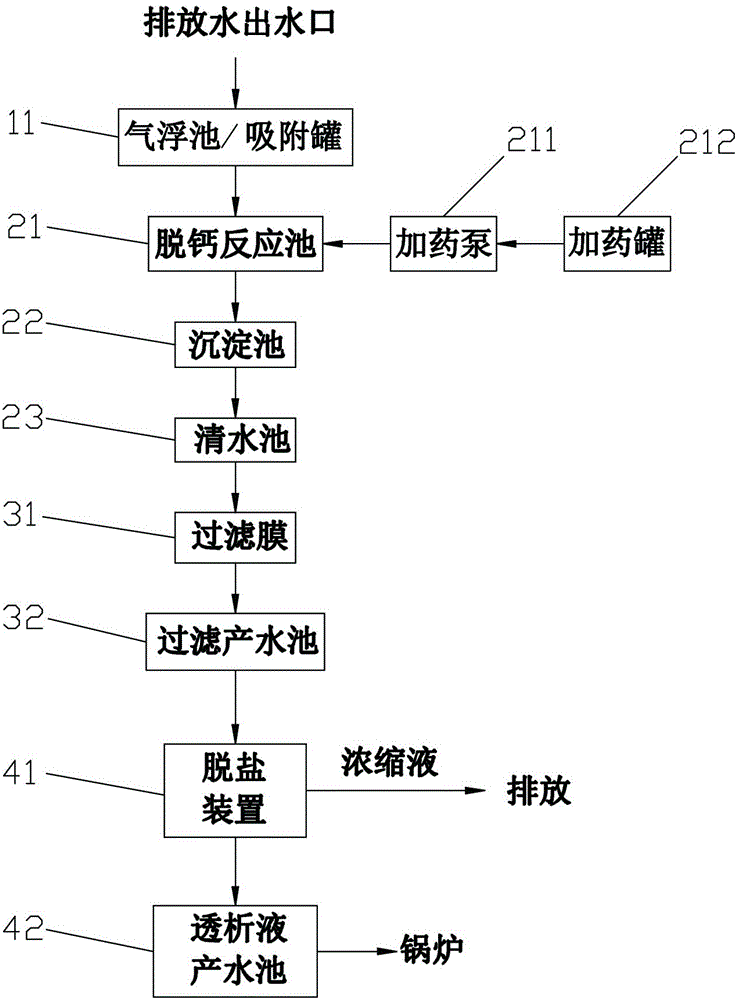

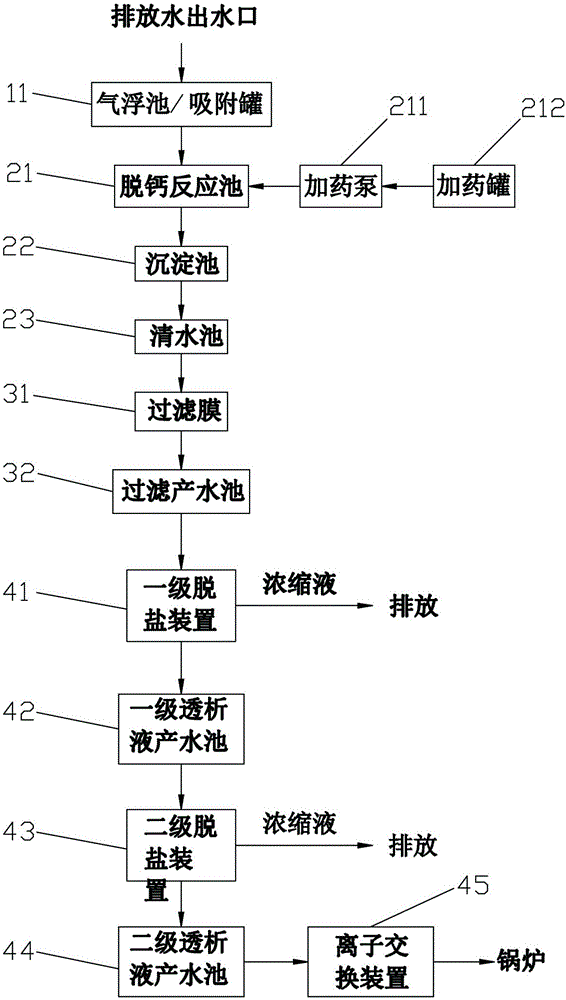

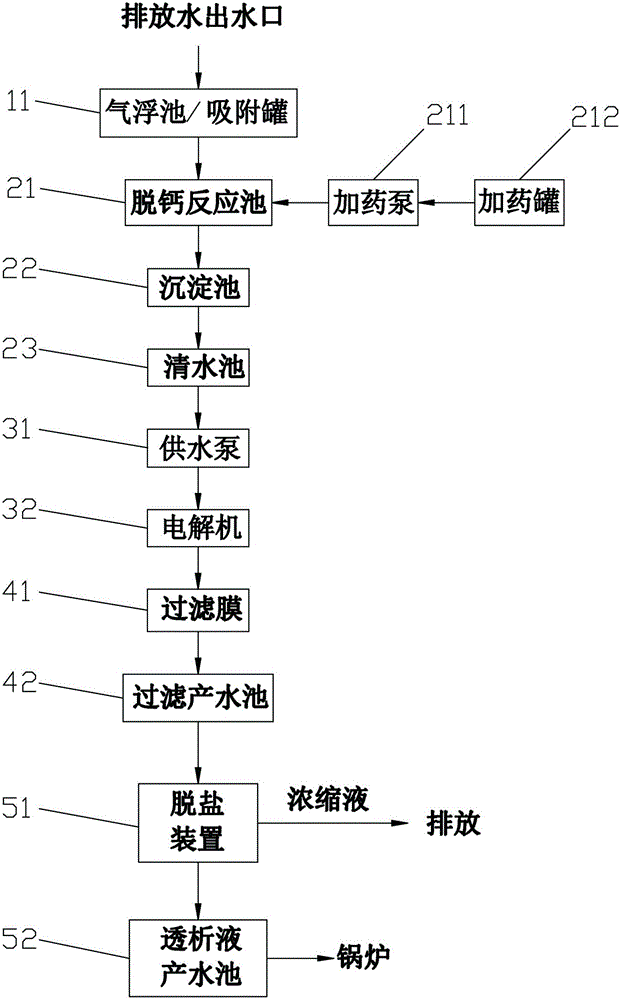

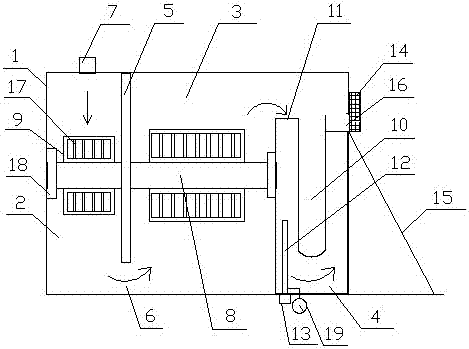

Oil-field wastewater treating and recycling device

InactiveCN105000727AEffective degreasingReduce CODcrWaste water treatment from quariesMultistage water/sewage treatmentFiltrationDesalination

An oil-field wastewater treating and recycling device comprises an oil removing system, a chemical decalcification system, a membrane filtration system and a desalting system; the oil removing system comprises an air floatation tank and an adsorption tank, the chemical decalcification system comprises a decalcification reaction tank, a sedimentation tank and a clean water tank, the membrane filtration system comprises a filtering membrane and a filtering water producing tank, the desalting system comprises a desalting device, a concentrated solution outlet of the desalting device is used for directly discharging, and a dialysis solution outlet of the desalting device is connected to a boiler. According to the device provided by the invention, through air floatation, the oil can be effectively removed, the CODcr is reduced, the calcification of the membrane is eliminated, the blockage of the membrane is avoided, the indexes, such as SS and turbidity, of waste water are reduced, the metal ions in water are removed, the salt content is reduced, and the recovery rate of 50 to 65 percent of oil-field wastewater is realized.

Owner:BOYING XIAMEN SCI & TECH

Degreasing method for animal hairs

The invention relates to a degreasing method for animal hairs and belongs to the technical field of natural fiber processing. The method comprises the steps of: 1) removing skin, flesh and dust attached to the animal hairs; 2) soaking the animal hairs with a composite degreasing agent in a weak-alkaline solution to perform initial degreasing; 3) performing initial washing to the animal hairs withhot water; 4) soaking the animal hairs in a weak-acid solution with bio-enzyme to perform secondary degreasing; and 5) performing secondary washing to the animal hairs with hot water, and drying the animal hairs to obtain degreased animal hairs. The method is simple in processes, has good degreasing effect, and is low in threat on environment.

Owner:黄桂凤

Multipurpose fabric washing and protecting liquid

InactiveCN108531304AEffective degreasingEffective decontaminationNon-ionic surface-active compoundsOrganic detergent compounding agentsChemical reactionLaundry

The invention relates to a multipurpose fabric washing and protecting liquid. At present, material washing in laundries and laundry factories is complex, and multiple kinds of washing agents and stainremoving agents are used. The chemical reactions of different washing agents and stain removing agents on different fabrics are different, which damages the fabrics and color and causes high incidence of washing accidents. Therefore, the multipurpose fabric washing and protecting liquid is invented. The multipurpose fabric washing and protecting liquid has a wide range of adaptation, has a good removing effect for most stains, do not damage the fabrics of clothing and the colors, and greatly reduces the washing accident rate of the laundries and the laundry factories.

Owner:重庆众宜洗衣技术开发有限公司

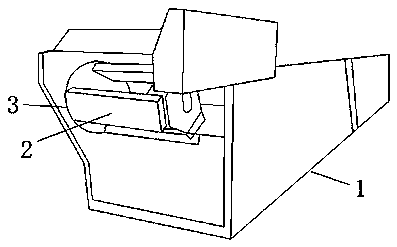

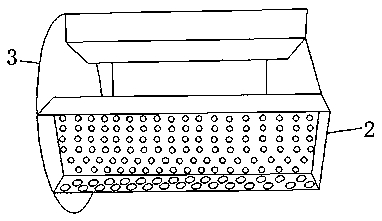

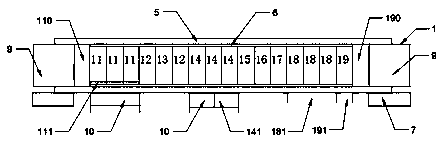

Battery shell discharge disc barrel plating device

InactiveCN105506722AEffective degreasingReduce generationElectrolysis componentsElectrical batteryAcid washing

The invention discloses a battery shell discharge disc barrel plating device. The device comprises a frame body and hangers; a degreasing tank, a water washing tank, an acid washing tank, a water washing tank, an electroplating tank, a bleaching tank, a neutralizing tank, a rust preventing tank, a drying tank and a cooling tank are formed in the middle part of the frame body in sequence; an ultrasonic processing device is arranged in the degreasing tank; external circulating filter devices are respectively arranged out of the degreasing tank and the electroplating tank; a roller is arranged on the frame body, adopts a mechanics symmetry structure, and is fixed with multiple net baskets; and the net basket s are connected with the hangers for placing battery shells. A battery shell discharge disc barrel plating process comprises the flows of: feeding-degreasing 1-degreasing 2-degreasing 3-water washing-acid washing-water washing-electroplating 1-electroplating 2-electroplating 3-bleaching-neutralizing-rust preventing-drying 1-drying 2-drying 3-cooling-discharge. The device improves the product quality when reducing the cost, reduces the sorting efficiency and the arrangement and container loading labors, and greatly improves the productivity.

Owner:上海金杨金属表面处理有限公司

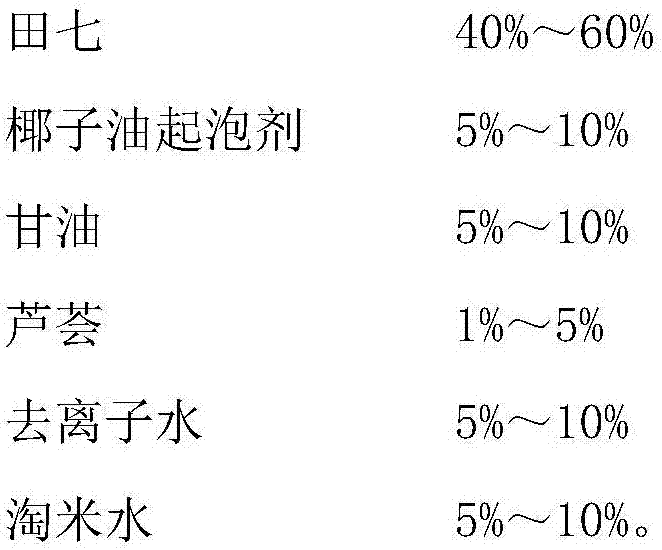

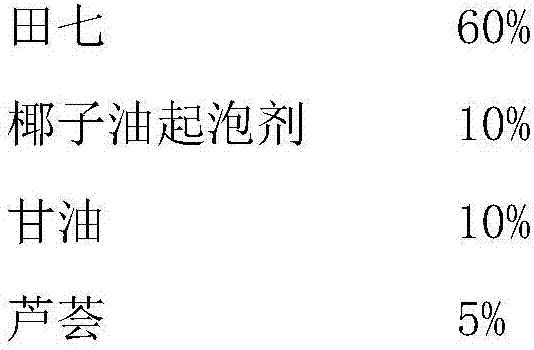

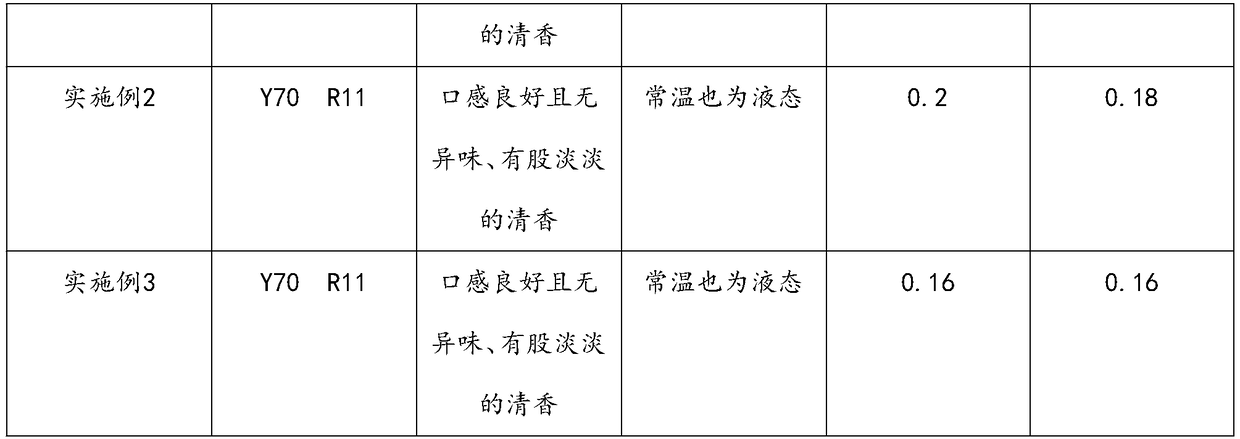

Manufacturing method of pseudo-ginseng shampoo

InactiveCN107019661ANo side effectsEffective dandruff removalCosmetic preparationsHair cosmeticsSide effectFoaming agent

The invention relates to a manufacturing method of a pseudo-ginseng shampoo. The formula of the pseudo-ginseng shampoo comprises the following components in percentages by weight: 40% to 60% of pseudo-ginseng, 5% to 10% of a coconut oil foaming agent, 5% to 10% of glycerinum, 1% to 5% of aloe, 5% to 10% of deionized water and 5% to 10% of rice washing water. According to the manufacturing method of the pseudo-ginseng shampoo disclosed by the invention, the pseudo-ginseng shampoo can be used for effectively removing dandruff and oil, relieving itching, preventing calvities and generating hair; compared with a traditional technology, the method is simple in technology and short in production period, the selected materials are safe and environmentally friendly, the product is anti-dangdruff for long time after being used, and the product is free of any side effect for human bodies, so that the product fills the market vacancy and also meets the requirement of people for health.

Owner:丛地召

Oil-control moisturizing hair conditioner

InactiveCN104546580AImprove dry and wet performanceImprove repair effectCosmetic preparationsHair cosmeticsGlycerolFatty alcohol

The invention discloses oil-control moisturizing hair conditioner which is characterized by comprising the following components in percentage by mass: 1-2% of aloe and ginger agents, 0.3-0.5% of fatty alcohol, 0.5-0.8% of stearamide propyl dimethyl tertiary amine, 1-2% of glycerol, 0.3-0.5% of polyoxyethylene ether, 1-1.5% of tea oil, 0.2-0.4% of hexadecyl trimethyl ammonium chloride, 1-2% of organic acid, 0.2-0.3% of dihydroxytoluene dimethyl hydantoin, 0.2-0.3% of essence, 0.2-0.4% of ethylenediamine tetraacetic acid disodium salt, 0.3-0.5% of tween -80, 0.5-0.8% of methyl parahydroxybenzoate, 0.5-0.8% of vinegar and 95-97% of deionized water. Stearamide propyl dimethyl tertiary amine performs the functions of brightening, softening and moisturizing hair under an acid condition and can obviously improve the moisture performance of hair. Tea oil and hexadecyl trimethyl ammonium chloride are compounded in use, which improves the effects of hair protection and nourishing, has effective antistatic performance, enables the hair to be smooth and slippery and easy to comb, and can effectively improve the hair quality after long-term use. The hair conditioner containing the aloe and ginger agents can effectively resist to dandruff, oil and itching, has a short cycle and obvious effects and works quickly.

Owner:罗鹏程

Regular filler degreasing process

ActiveCN109047168AEfficient removalEffective degreasingCleaning using liquidsComputer scienceUltrapure water

The invention discloses a regular filler degreasing process. The regular filler degreasing process comprises the steps of a) frame loading, b) primary flushing, c) primary cleaning, d) secondary cleaning, e) primary rinsing, f) secondary rinsing, g) ternary rinsing, h) secondary flushing, i) drying, j) detection and k) packing and warehousing. Regular fillers are firstly flushed, so that grease onthe regular fillers can be effectively removed, and the subsequent degreasing becomes more convenient and quicker; through multiple times of cleaning and multiple times of rinsing, the regular fillers can be effectively degreased to achieve excellent degreasing effect; and through application of electronic ultrapure water, the degreasing effect is more ideal.

Owner:HAIYAN DESHENG CHEM EQUIP

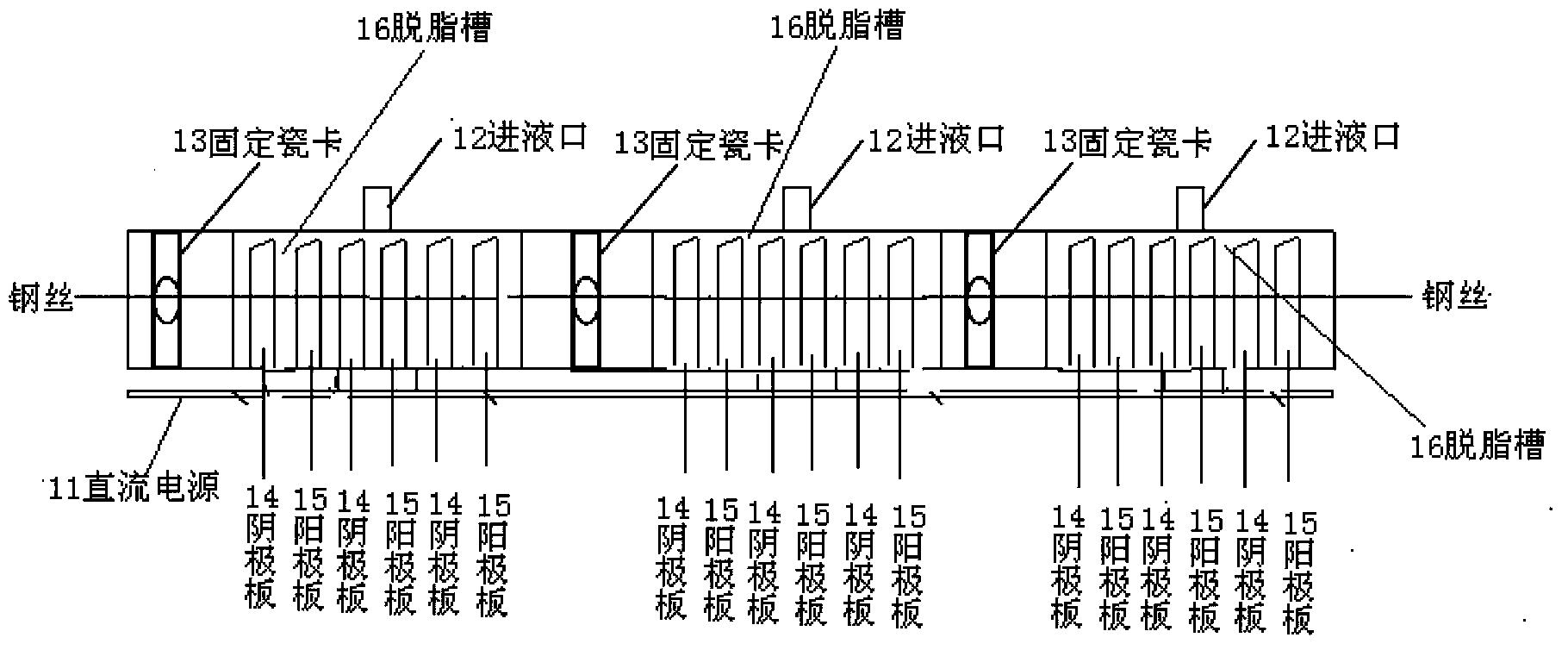

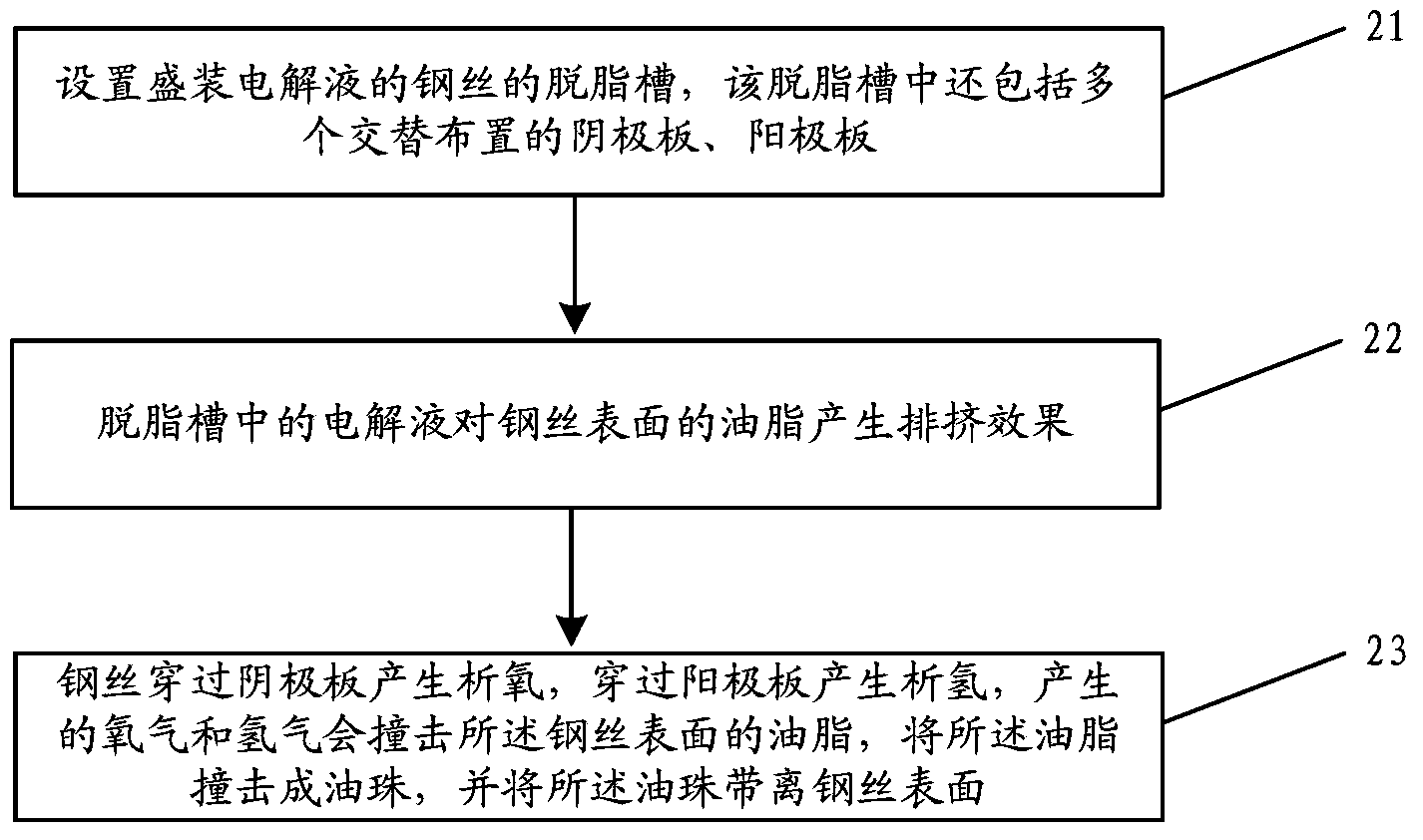

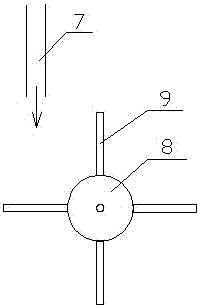

Method and device for performing degreasing treatment on steel wire

The invention provides a method and a device for performing degreasing treatment on a steel wire. The method mainly comprises the following steps of: holding an electrolyte in a degreasing tank for the steel wire, supplying power to the electrolyte by using a direct-current power source, and arranging a negative plate and a positive plate in the degreasing tank, wherein when the steel wire penetrates through the hollow part of the negative plate, the negative plate causes the steel wire to have an oxidization reaction through electromagnetic induction so that oxygen is generated on the surface of the steel wire; when the steel wire penetrates through the hollow part of the positive plate, the positive plate causes the steel wire to have a reduction reaction through electromagnetic induction so that hydrogen is generated on the surface of the steel wire. The oxygen and the hydrogen are capable of hitting against grease on the surface of the steel wire so that the grease forms oil droplets and the oil droplets are removed from the surface of the steel wire. The method and the device provided by the embodiment of the invention have the advantage that the negative plate and the positive plate are arranged in the degreasing tank, so that effective degreasing treatment can be performed on steel wires such as a tire bead steel wire through electromagnetic induction between the negative plate and the steel wire and between the positive plate and the steel wire.

Owner:ZHANGJIAGANG SHENGDA STEEL ROPE

Method for removing cross-colors and marking-off colors

InactiveCN108531305AReduce health impactEffective degreasingOrganic detergent compounding agentsNon-ionic surface-active compoundsAlcoholPreservative

The invention relates to a method for removing cross-colors and marking-off colors. A solution includes the following main parts, by mass: 23-32 parts of a surfactant, 2-8 parts of an alcohol ether solvent, 1-5 parts of a chelating agent, 0.2-0.8 part of a biological enzyme, 0.5-1 part of an anti-deposition agent, and 0.1-0.5 part of a preservative. The solution has a plurality of functions such as fabric oil removing, stain removing, color stain removing, color protection, safety, and environmental protection. Oil stains on fabrics are removed by smearing raw liquor on oil stains and then normally washing.

Owner:重庆众宜洗衣技术开发有限公司

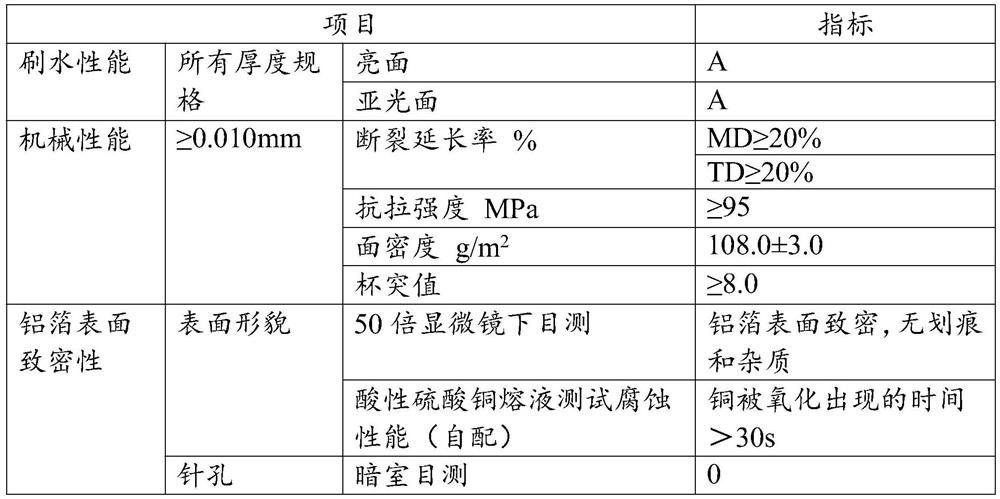

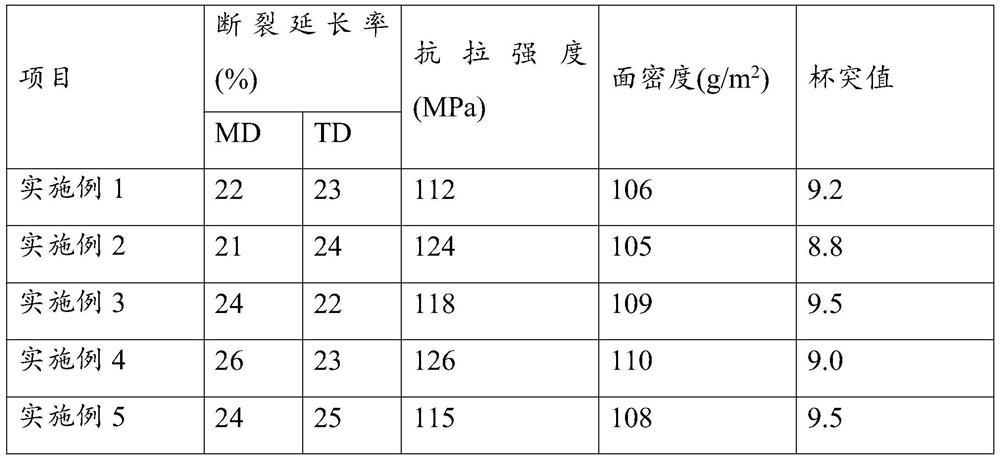

Processing method for power battery aluminum-plastic film aluminum foil

ActiveCN112126821AHigh elongationImprove ductilityMetal rolling arrangementsPower batteryIngot casting

The invention discloses a processing method for a power battery aluminum-plastic film aluminum foil. The method comprises the steps that an aluminum alloy plate and a metal additive material are placed into a smelting furnace for smelting, metal zirconium powder is added, and secondary smelting is carried out to obtain an aluminum melt; silicon oxide is added into the aluminum melt, cast rolling is carried out by using a cast rolling machine after uniform stirring, and a cast rolling roller is used for performing cast rolling on the melt to form a cast-rolled coil; reciprocating multi-pass cold rolling is performed on the cast-rolled coil by adopting a multi-roll reversible rolling mill; intermediate annealing is performed on a cold-rolled coil; and after annealing, and multi-pass finish rolling is carried out to prepare an aluminum foil coil. According to the method, the aluminum foil is prepared by adjusting the proportional relation of all elements in an alloy and through two timesof smelting, cast rolling, cold rolling, annealing and finish rolling processes, the prepared aluminum foil is good in ductility, meanwhile, the thickness uniformity and the surface compactness of thealuminum foil can be effectively controlled, meanwhile, a cast rolling method is adopted for processing, complex technological processes such as ingot casting and hot rolling compounding in a conventional production process can be omitted, and energy conservation and consumption reduction are achieved.

Owner:GUANGDONG ANDELI NEW MATERIALS CO LTD +1

Softening, nourishing, hair-blacking and oil-removing paste shampoo and preparation method thereof

PendingCN113576997AEasy to cleanMild performanceCosmetic preparationsHair cosmeticsJackfruitsNaCl - Sodium chloride

The invention provides softening, nourishing, hair-blacking and oil-removing paste shampoo and a preparation method thereof. The shampoo is prepared from the following raw materials: a bletilla striata extracting solution, a Chinese yam extracting solution, a green tea extracting solution, a red date extracting solution, a kiwi fruit extracting solution, a mango extracting solution, an aloe extracting solution, a grapefruit extracting solution, a pear extracting solution, a walnut kernel extracting solution, a pea extracting solution, a black rice grinding solution, an oat extracting solution, a white poria extract, a jackfruit seed extracting solution, a lemon extracting solution, a gingko extracting solution, a mint extracting solution, beer, sodium chloride, vitamin E, white vinegar, polyethylene glycol 6000 distearate, carbomer 941, an ice crystal forming agent AVC, a wire drawing agent PEG-90M, an amino acid foaming agent MS-11, lauryl sodium sulfate, a 30% triethanolamine solution, 1, 2-propylene glycol, ethylparaben and distilled water. Compared with the prior art, the shampoo disclosed by the invention can nourish hair, enables the hair to be smooth and glossy, and has a good curative effect on premature graying, dry and unflourishing hair, deoiling and alopecia prevention.

Owner:WANNAN MEDICAL COLLEGE

Preparation method for instant sweet corn kernels

InactiveCN104920982AExtended shelf lifeReduce greasy feelingFood preparationFood processingPerilla seed oil

The invention discloses a preparation method for instant sweet corn kernels, and belongs to the technical field of food processing. The method comprises the steps: 1) screening of raw material; 2) brine soaking boiling and slaking; 3) vacuum deep-frying; 4) baking deoiling; and 5), cooling and packaging, wherein a brine in the step 2) is north salted vegetable water, and in the deep-frying process of the step 3), one of perilla seed oil, castor oil and rapeseed oil is adopted. The instant sweet corn kernels prepared by the steps have the advantages of exquisite taste, unique flavor, and long shelf life.

Owner:冒玉兰

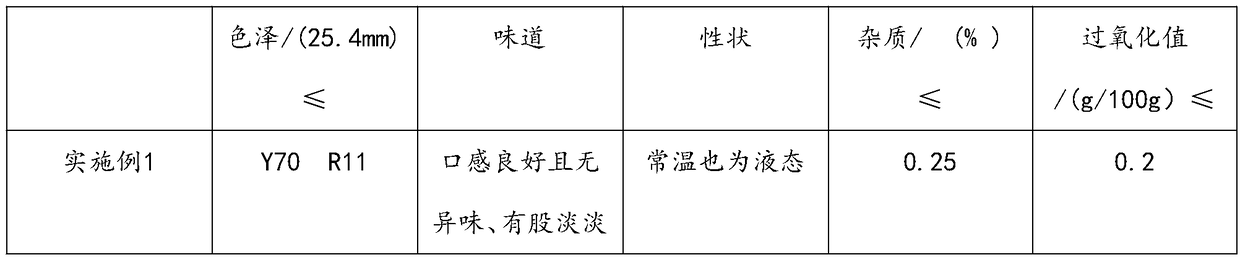

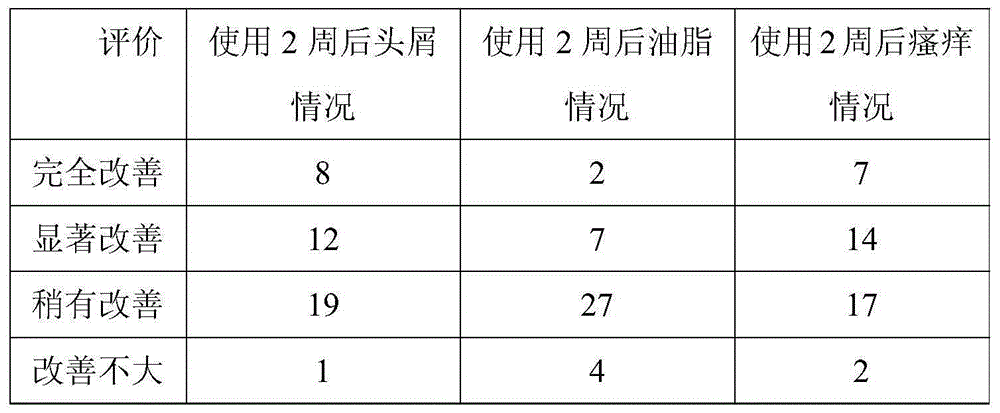

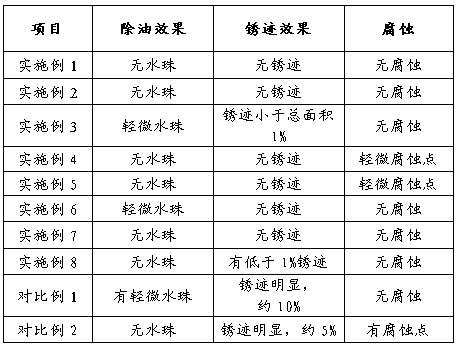

Cold blending oil and preparation method thereof

The invention relates to cold blending oil, which relates to the technical field of processing of blending oil. The cold blending oil is characterized by being prepared from the following materials inparts by weight: 50 to 60 parts of flaxseed oil, 90 to 100 parts of thick sesame oil, 10 to 20 parts of tea seed oil, 30 to 40 parts of peanut oil, 5 to 10 parts of walnut oil, 5 to 10 parts of camellia oil, 5 to 10 parts of olive oil, 1 to 5 parts of neutralizing agent, and 1 to 5 parts of auxotropy agent. The cold blending oil is reasonable in method, convenient in processing, rich in nutritionand free from grease sense.

Owner:安徽新荣久农业科技有限公司

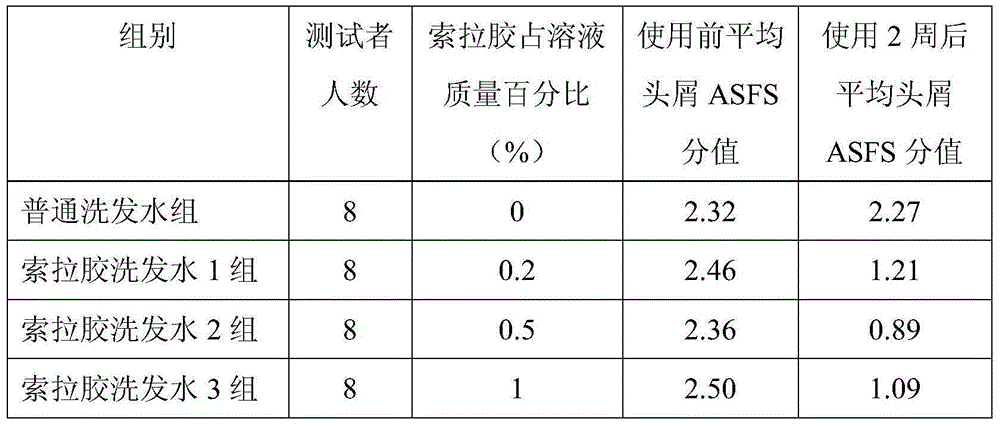

Application of soracan gum in hair washing and caring

InactiveCN105106032AEffective dandruff removalEffective degreasingCosmetic preparationsHair cosmeticsSide effectActive agent

The invention discloses application of soracan gum in hair washing and caring. In usage, the soracan gum has the effects of delaying cell apoptosis, resisting to fungi and repairing hurt to the scalp by surface active agents, is used for caring head hair or the scalp and can effectively remove scurf, degreasing, relieve itching and prevent hair loss, the period is short, speed is high, and the effect is remarkable; meanwhile, the soracan gum can improve the scalp ecology and promote hair growth fundamentally and is free of dependency and toxic and side effects and capable of remarkably improving wet combing performance of the hair and softness, brightness and smoothness of the dried hair.

Owner:NANJING UNIV OF SCI & TECH

Cleaning agent for metal surface, preparation method and method for cleaning metal surface

Owner:BYD CO LTD

Hair nutrient lotion and production process thereof

InactiveCN107773497ARemove toxins and impuritiesPromote growthCosmetic preparationsHair cosmeticsGINSENG EXTRACTNutrient solution

The invention discloses a hair nutrient lotion and a production process thereof. The hair nutrient lotion comprises the following raw materials in percentage by mass: 3-7% of a kochia scoparia extract, 1-5% of a tribulus terrestris extract, 1-5% of a sophora flavescens extract, 10-14% of a polygonum multiflorum extract, 10-14% of a mulberry leaf extract, 5-9% of a mulberry root extract, 2-6% of aYunnan paris polyphylla extract, 6-10% of a ginger extract, 11-15% of a radix salviae miltiorrhizae extract, 1-5% of a licorice root extract, 4-8% of a ginseng extract, 1-5% of a ligusticum wallichiiextract, 1-5% of an angelica sinensis extract, 1-5% of a lithospermum extract and the balance of a cacumen biotae extract. The production process comprises the following steps: mixing the raw materials, heating to 38-45 DEG C in the stirring process, continuously stirring for 25-35 minutes at the temperature so as to obtain a mixed material, after inspection qualification, filtering the mixed material, discharging, leaving to stand, inspecting, filling bottles, packaging, and storing in warehouses. The hair nutrient lotion is capable of removing oil, controlling oil, removing scurf, repairinghair, preventing bacteria and regulating sebum secretion and is applicable to people with poor hair such as excessive scurf, scalp itching, hair fragility and alopecia and hair reluster.

Owner:河南波斯坦生物科技有限公司

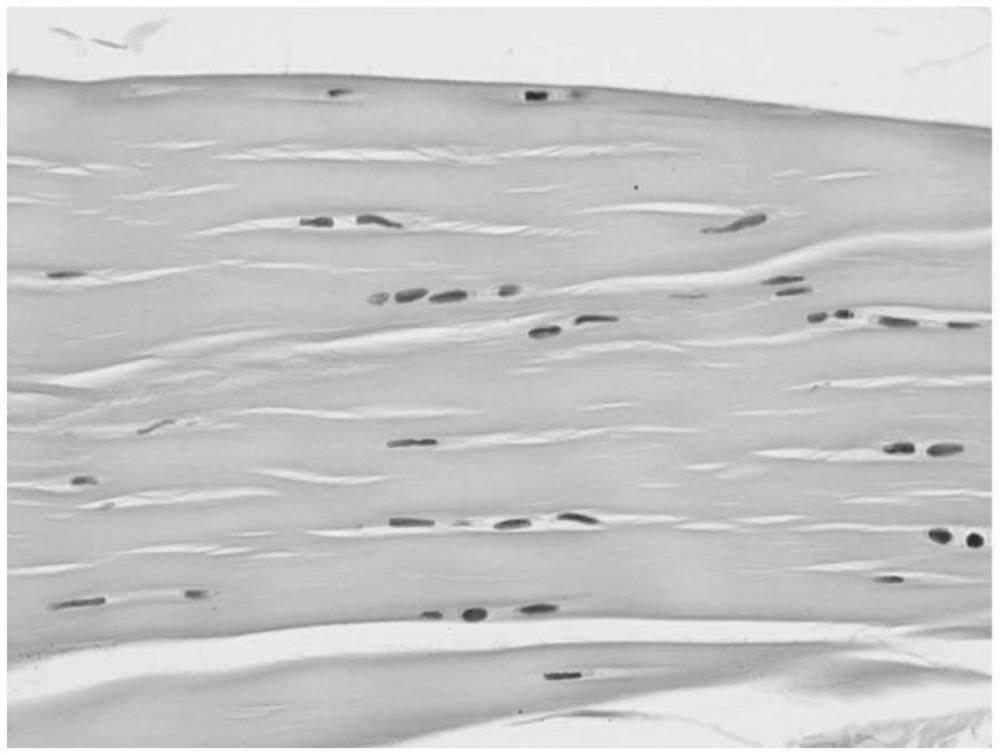

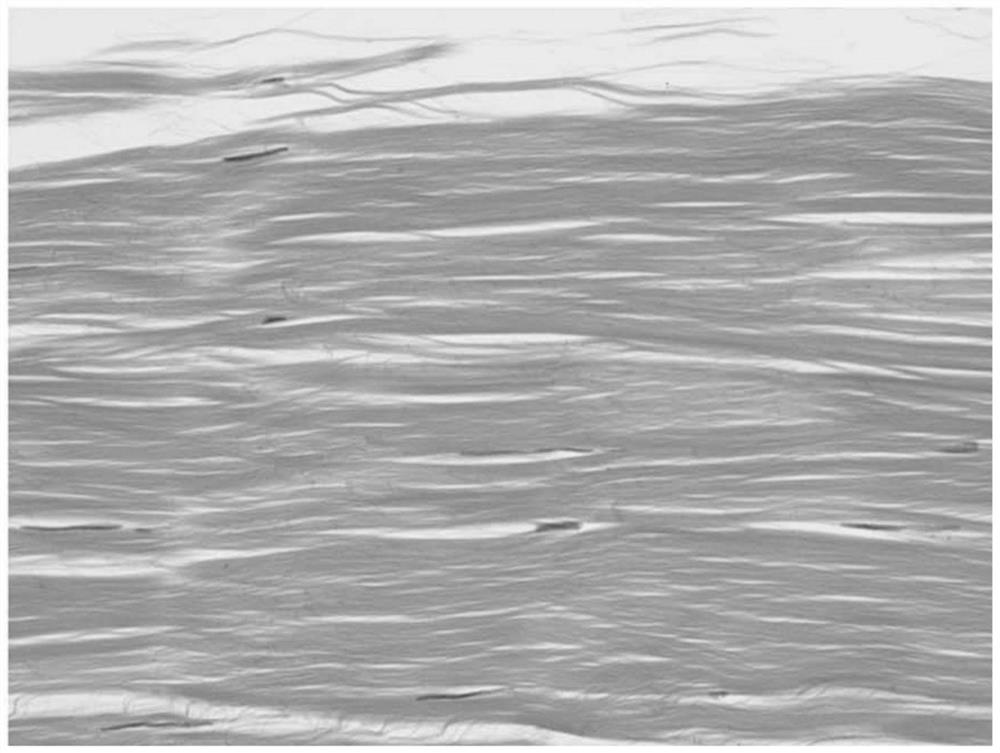

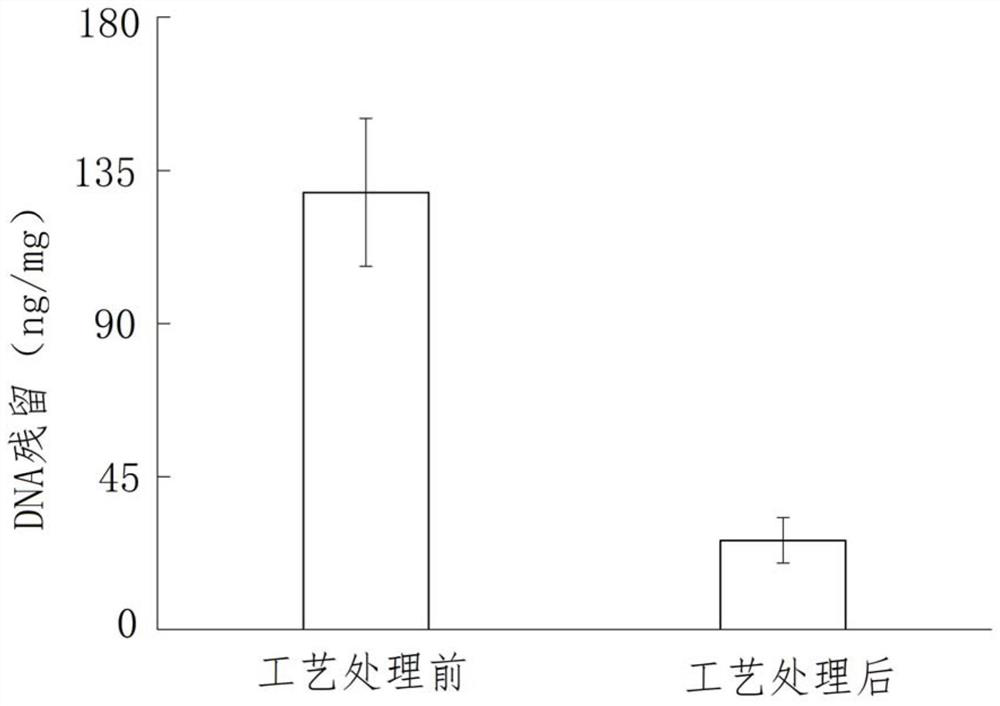

Preparation method of allogeneic or xenogeneic tendon and bone tendon complex

InactiveCN111686303AComplete structureIncrease lethalityTissue regenerationProsthesisBone tendon bonePlantaris tendon

The invention relates to a preparation method of an allogeneic or xenogeneic tendon and bone tendon complex. The preparation method comprises the following steps that: S1: an allogeneic or xenogeneictendon and bone tendon complex material is obtained, and bloodstains on the surfaces of the tendons are cleaned with purified water; S2, supercritical CO2 extraction equipment is started, and the cleaned tendons are put into the supercritical CO2 extraction equipment for extraction; S3, the extracted tendons are subjected to decellularization treatment and grease washing; S4, the purified water isadded into the tendons subjected to oscillation washing, and oscillation washing is carried out in a shaking table at room temperature; S5, the tendons subjected to oscillation washing are trimmed, water on the surfaces of the trimmed tendons is drained off, and vacuum packaging is carried out under aseptic conditions; and S6, the packaged tendons with cobalt-60 under the dosage of 10-30 kGy areirradiated, and sterilization again is carried out so as to obtain the tendons subjected to vacuum packaging. The preparation method has the advantages of convenient processing, high efficiency, environmental protection and safety.

Owner:上海亚朋生物技术有限公司

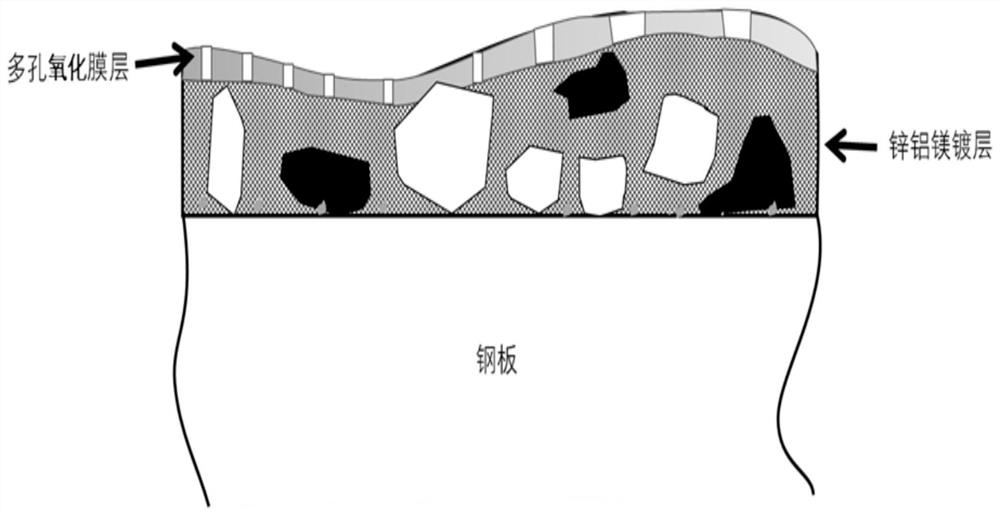

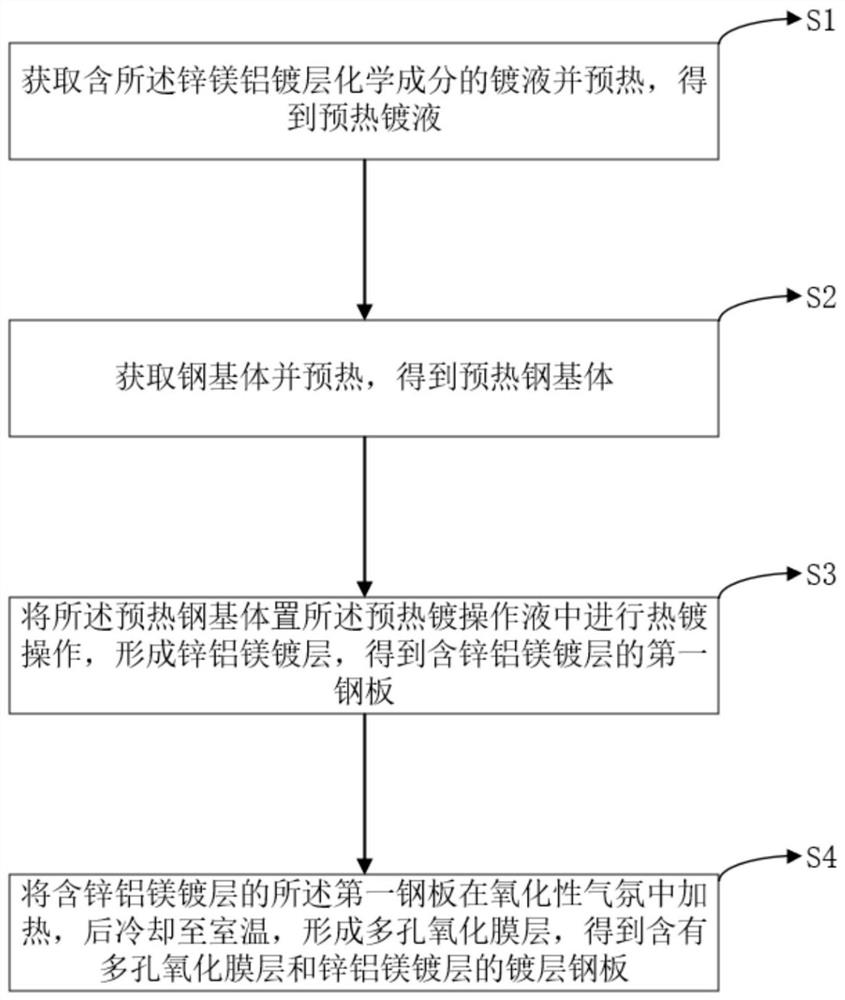

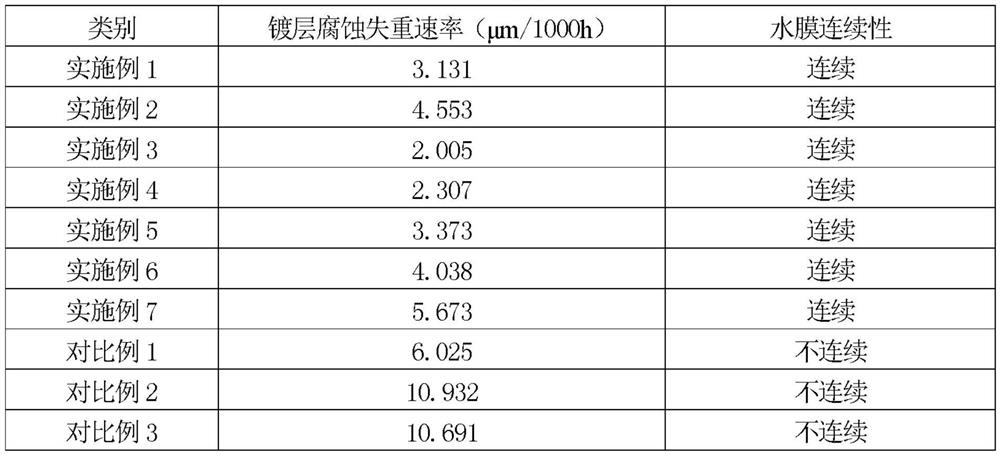

Easily degreased coated steel plate, preparation method thereof and painted steel plate

PendingCN114058996AEffective degreasingStrong degreasing performanceHot-dipping/immersion processesSolid state diffusion coatingAluminum coatingCorrosion

The invention belongs to the technical field of steel hot dipping treatment, and particularly relates to an easily degreased coated steel sheet, a preparation method thereof and the application thereof.The coated steel sheet comprises a steel substrate and a coating, the coating comprises a zinc-aluminum-magnesium coating and a porous oxidation film, the innermost layer of the coating is the zinc-aluminum-magnesium coating, and the outermost layer of the coating is the porous oxidation film layer; the porous oxidation film layer is an oxidation film layer of the zinc-aluminum-magnesium coating; the method comprises the steps that a plating solution containing chemical components of the zinc-magnesium-aluminum coating is obtained and preheated, and a preheated plating solution is obtained; a preheated steel base body is obtained; the preheated steel base body is placed in the preheated plating solution to be subjected to hot dipping treatment, and a first steel plate is obtained; the first steel plate is heated in an oxidizing atmosphere and then cooled to the room temperature, and a plated steel plate is obtained; according to the application, the coated steel plate is applied to production of vehicle parts and household appliances needing to be painted. By controlling the components of the zinc-aluminum-magnesium coating and the process conditions of the oxidizing atmosphere, the coated steel plate with good degreasing effect and high corrosion resistance can be obtained.

Owner:SHOUGANG CORPORATION

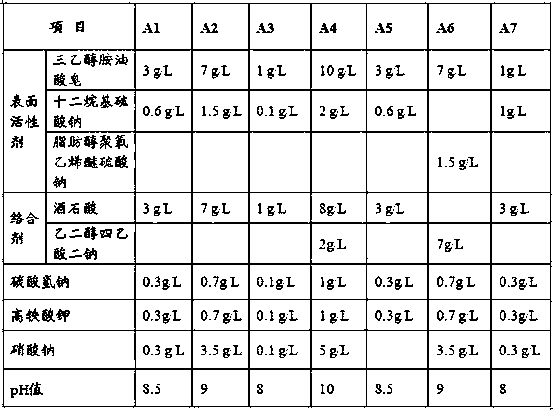

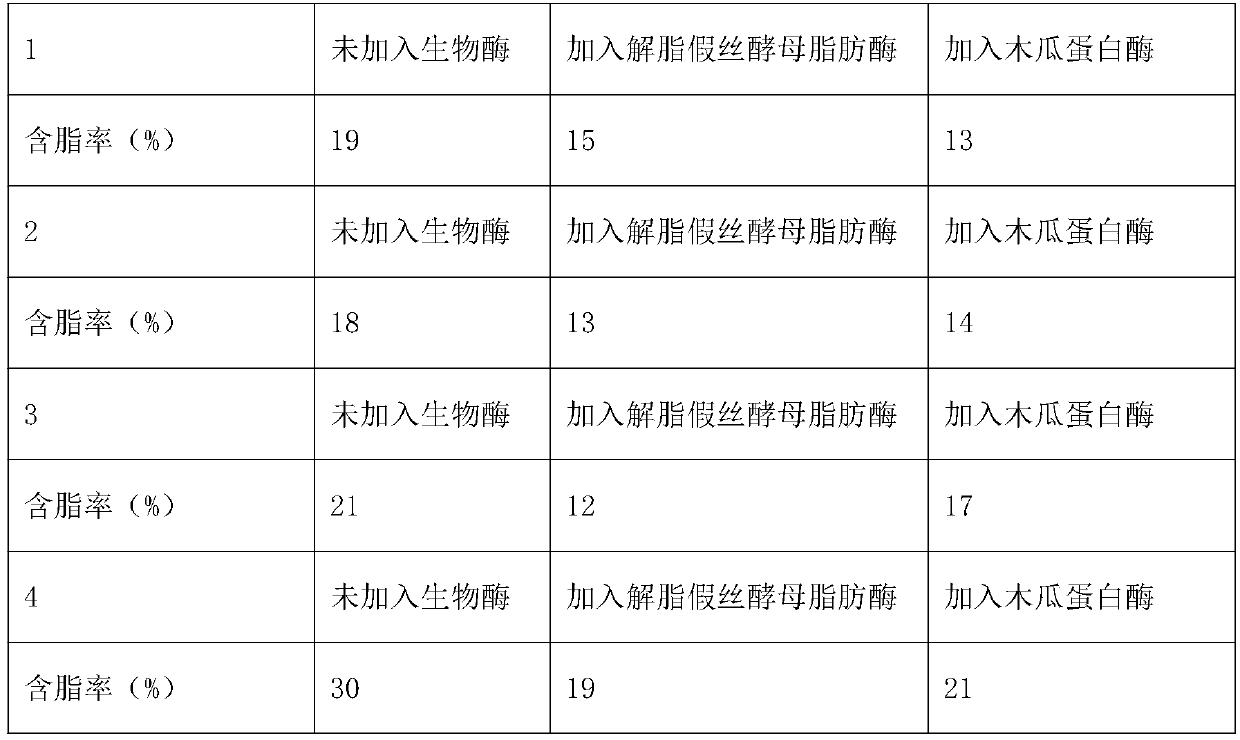

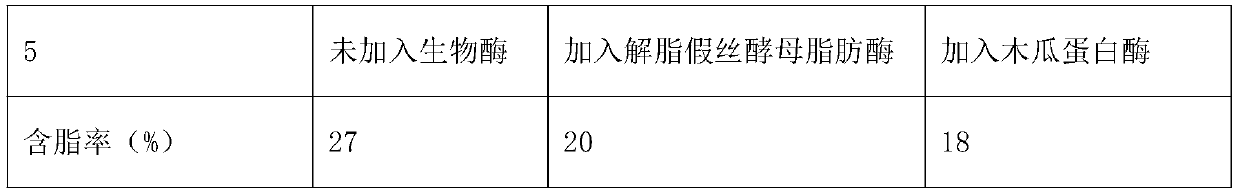

Natural cashmere degreasing method adopting biological enzyme process

InactiveCN109629238AReasonable designEasy to operateBiochemical treatment with enzymes/microorganismsAnimal fibresDegreasingPapain

The invention discloses a natural cashmere degreasing method adopting a biological enzyme process. The natural cashmere degreasing method comprises the following steps: 1, removing the flesh and dustattached to cashmere and adding the cashmere in clean water for soaking; 2, using a composite degreasing agent to soak the cashmere in a weak alkaline solution so as to execute primary degreasing; 3,flushing the cashmere once with hot water; 4, soaking the cashmere with a biological enzyme in a weakly acidic solution so as to execute secondary degreasing; 5, using hot water to conduct secondary flushing on the cashmere and executing drying to obtain degreased cashmere. The natural cashmere degreasing method adopting the biological enzyme process integrates degreasing with the inorganic composite degreasing agent and degreasing with the biological enzyme, the degreasing with the inorganic composite degreasing agent is executed under a higher-temperature alkaline condition, and effective degreasing can be achieved; by means of degreasing with the biological enzyme, the cashmere can be more deeply decreased by cooperatively using candida lipase and papain, and the degreasing effect is more optimized and thorough.

Owner:湖州世轩丝绸进出口有限公司

Oil dirt processing device for domestic wastewater

InactiveCN107226576AIncrease ascent speedChange collision chanceWater treatment parameter controlFatty/oily/floating substances removal devicesWastewaterSewage

The invention discloses an oil dirt processing device for domestic wastewater. The oil dirt processing device comprises a processing box, wherein a water inlet area, a coalescence area and a separation box are sequentially arranged in the processing box; a partition is arranged between the water inlet area and the coalescence area; a water running opening is formed below the partition; a water inlet I is formed above the water inlet area; a horizontal round shaft is arranged in the water inlet area and the coalescence area and penetrates the partition; stirring blades are arranged on the side surface of the round shaft; the water inlet I is aligned to the stirring blades; a groove in the vertical direction is formed in the middle above the separation box; a water inlet II is formed in the left side of the groove; a heating tube is arranged below the water inlet II; a water outlet is formed in the right side of the groove; an oil suction bag is arranged at the water outlet; and a fiber-ball filter is arranged in the oil suction bag. The oil dirt processing device is reasonable in structure, convenient to use, small in land occupation, low in cost, easy in oil-water separation and strong in oil dirt processing capability.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

A structured packing degreasing process

ActiveCN109047168BEfficient removalEffective degreasingCleaning using liquidsProcess engineeringMechanical engineering

The invention discloses a degreasing process for structured packing, which comprises the following steps: a) framing, b) washing once, c) washing once, d) washing twice, e) rinsing once, f) rinsing twice, g) three times Rinsing, h) secondary rinsing, i) drying, j) testing, k) packaging and storage. The present invention washes the structured packing first, so that the grease on the structured packing can be effectively removed, making the subsequent degreasing more convenient and fast; multiple cleaning and multiple rinsing settings enable the structured packing to be effectively degreased, The degreasing effect is good; the application of electronic grade ultrapure water makes the degreasing effect more ideal.

Owner:HAIYAN DESHENG CHEM EQUIP

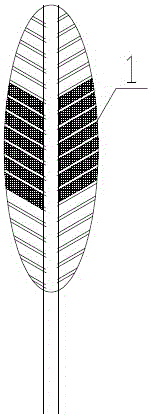

A kind of chicken neck hair brush and preparation method thereof

The invention relates to the field of writing brush manufacturing, and specifically relates to a chicken neck feather writing brush and a manufacturing method thereof. The chicken neck feather writing brush and the manufacturing method thereof are realized through the following technical scheme. The chicken neck feather writing brush comprises a pen point and a penholder. The pen point comprises a central feather batch region on the center of the pen point and a peripheral feather batch region on the periphery of the central feather batch region. The peripheral feather batch region comprises chicken neck feathers. The central feather batch region comprises chicken neck feathers and elastic feathers. An objective of the invention is to provide a chicken neck feather writing brush and a manufacturing method thereof. The writing brush which uses chicken neck feathers as main material is low in cost and waste is turned into treasure. The writing brush has relatively good soundness and elasticity, and is convenient in writing.

Owner:湖州市善琏鑫利湖笔厂

Bacteriostatic detergent and preparation method thereof

InactiveCN113004979AThe process steps are simpleGood antibacterial effectOrganic detergent compounding agentsSurface-active detergent compositionsChemistryAntibacterial effect

The invention discloses a bacteriostatic detergent and a preparation method thereof. The bacteriostatic detergent is prepared from the following raw materials: lauramide diethanol, lauryl sodium sulfate, hydroxypropyl methyl cellulose, larch bark extract active ingredients and water. The detergent disclosed by the invention can effectively remove oil, can be stored for a long time and shows an excellent antibacterial effect.

Owner:合肥洞鉴新材料技术有限公司

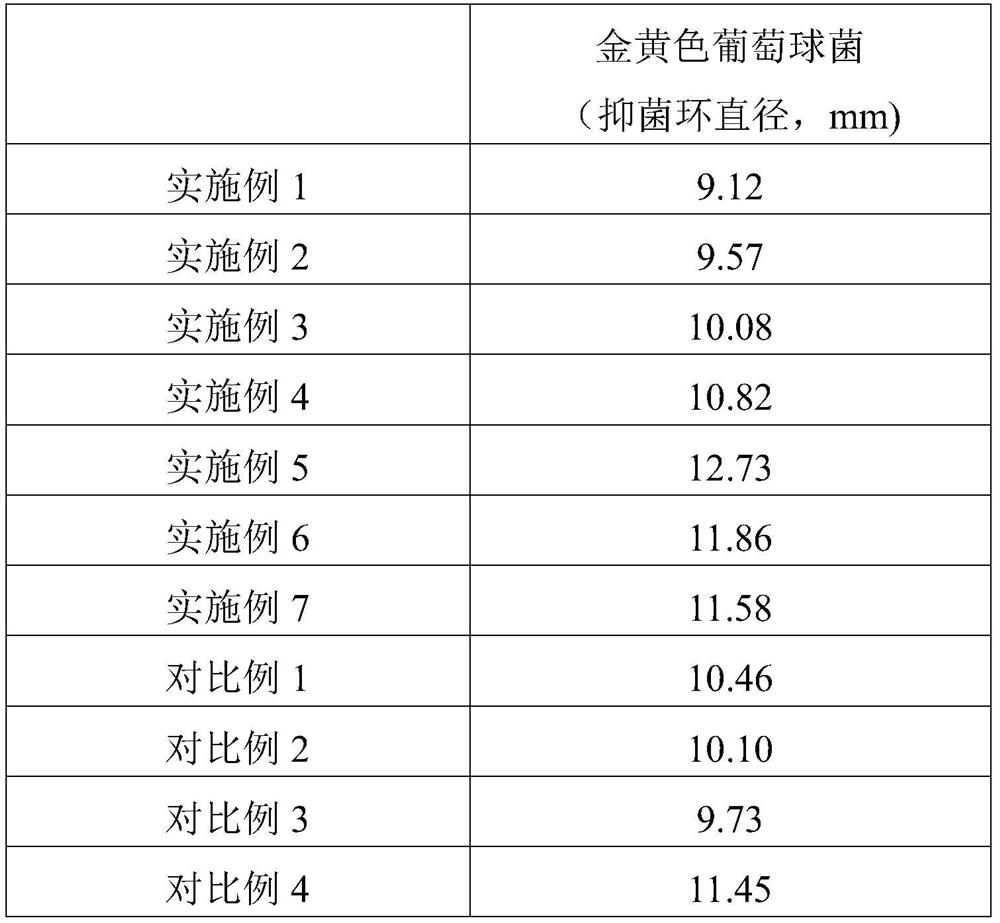

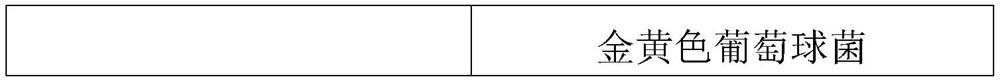

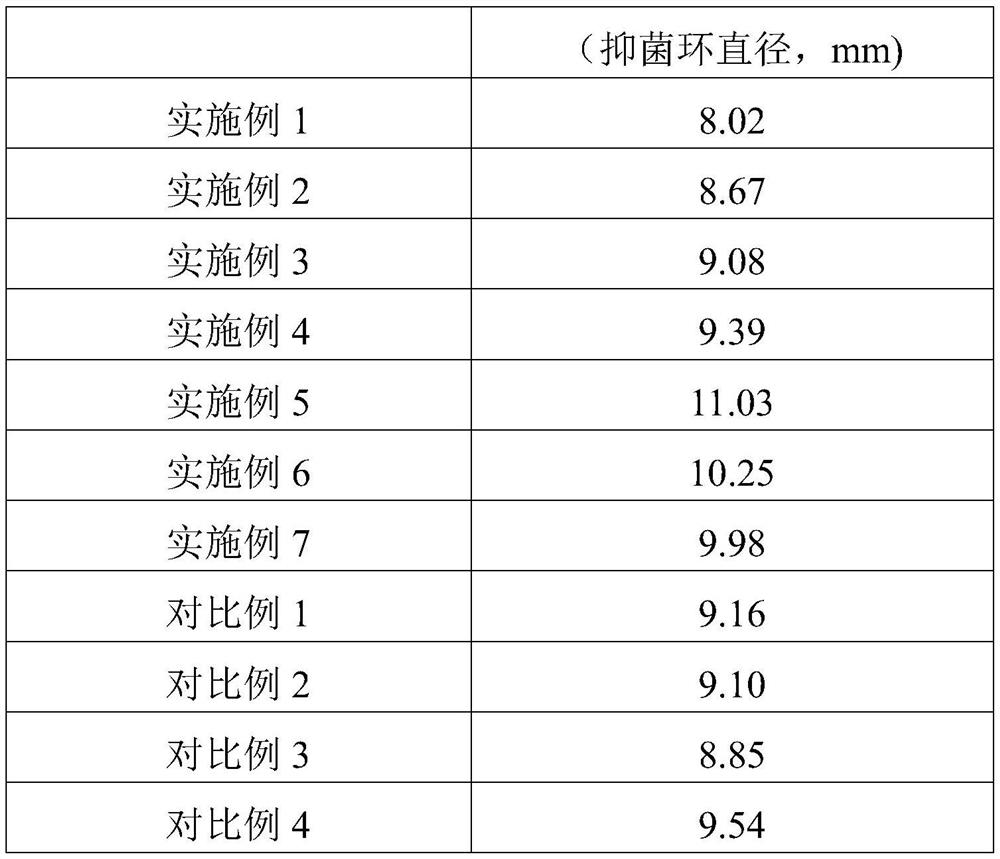

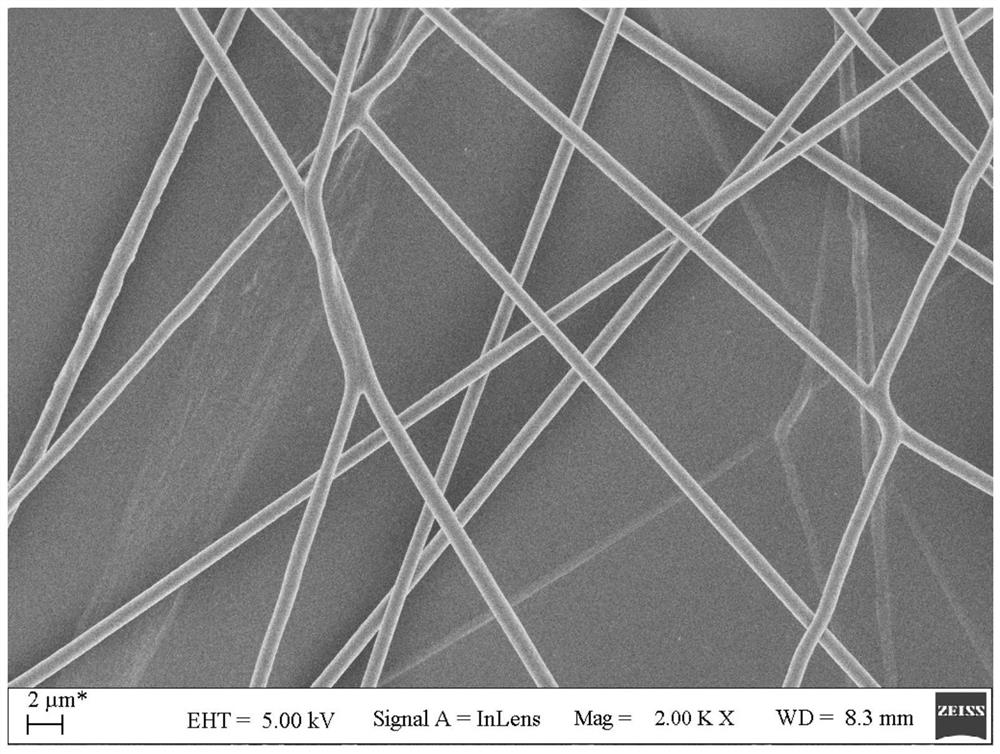

Micro-nanofiber membrane as well as preparation method and application thereof

PendingCN114713038AExcellent hydrophobic and lipophilic propertiesEffective degreasingMembranesSemi-permeable membranesFiberPolymer science

The invention discloses a micro-nanofiber membrane, the micro-nanofiber membrane is mainly composed of polymer nanofibers, polymers in the polymer nanofibers comprise polyvinylidene fluoride and polystyrene, and the micro-nanofiber membrane comprises nanoscale fibers and micron-sized fibers. The micro-nano fiber membrane provided by the invention has excellent hydrophobic and oleophylic characteristics, can effectively remove oil from oil-containing water, and can also filter and remove solid particles in an oil-water mixture. In addition, the invention further discloses a preparation method and application of the micro-nanofiber membrane.

Owner:深圳维度新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com