Cold blending oil and preparation method thereof

A technology of blending oil and sesame oil, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of not particularly good taste, disrupted nutritional balance, greasy nutrition, etc., and achieve light taste, balanced fatty acid content, and no nutrition. greasy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

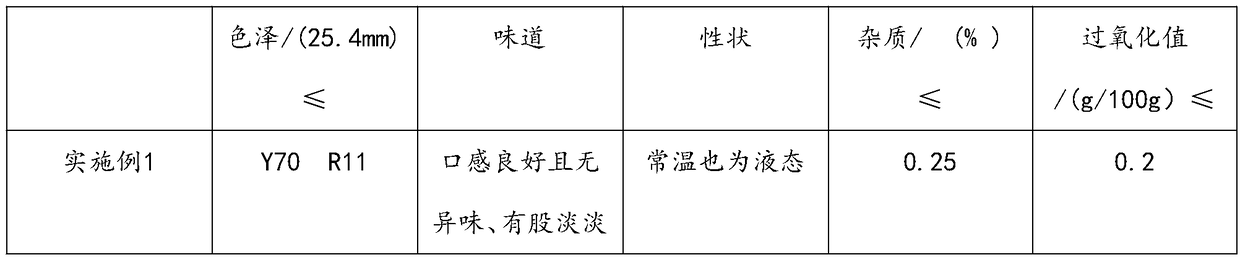

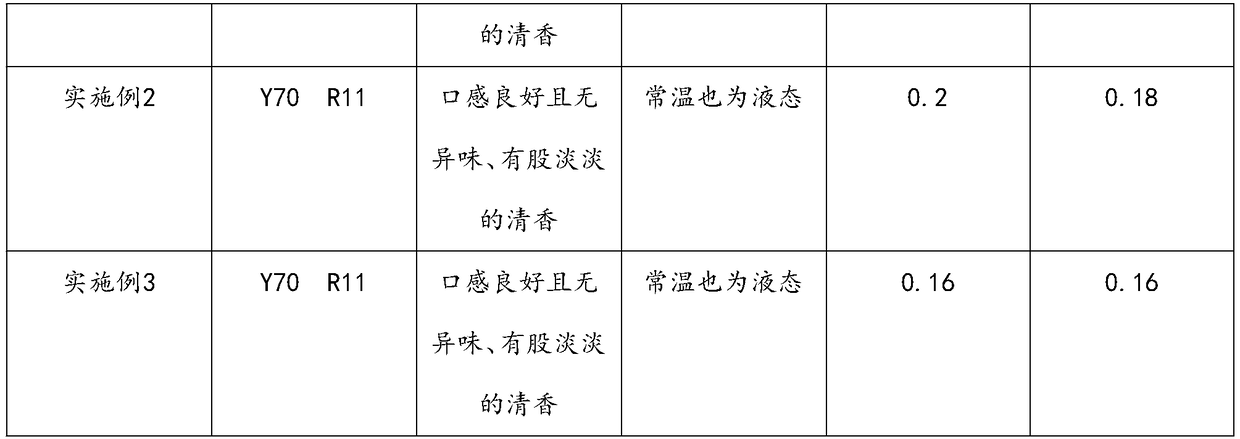

Examples

Embodiment 1

[0029] Embodiment 1 is a cold dressing oil, characterized in that: it is made of the following materials by weight,

[0030] 50-60 parts of linseed oil, 90-100 parts of strong sesame oil, 10-20 parts of tea seed oil, 30-40 parts of peanut oil, 5-10 parts of walnut oil, 5-10 parts of camellia oil, 5-10 parts of olive oil , 1-5 parts of neutralizing agent, 1-5 parts of nourishing agent;

[0031] The nourishing agent is made of the following materials by weight,

[0032] 5 parts of passion fruit, 4 parts of mangosteen, 4 parts of watermelon, 1 part of bayberry, 4 parts of grape, 3 parts of mango, 3 parts of kiwi, 2 parts of cherry, 3 parts of papaya, and 3 parts of apple;

[0033] Preparation method:

[0034] ⅠPeel the above-mentioned materials to get the pulp, then put 22 parts by weight of pure water into the juice extractor and squeeze the juice, then filter the residue and leave the pure juice;

[0035] Ⅱ Add 3 parts by weight of calcium gluconate and 5 parts by weight of ...

Embodiment 2

[0047] A cold blending oil is characterized in that: it is made of the following materials by weight,

[0048] 52-58 parts of linseed oil, 92-97 parts of strong sesame oil, 13-18 parts of tea seed oil, 31-37 parts of peanut oil, 6-9 parts of walnut oil, 6-9 parts of camellia oil, 6-9 parts of olive oil , 1-4 parts of neutralizing agent, 2-5 parts of nourishing agent;

[0049] The nourishing agent is made of the following materials by weight,

[0050] 5 parts of passion fruit, 4 parts of mangosteen, 4 parts of watermelon, 1 part of bayberry, 4 parts of grape, 3 parts of mango, 3 parts of kiwi, 2 parts of cherry, 3 parts of papaya, and 3 parts of apple;

[0051] Preparation method:

[0052] ⅠPeel the above-mentioned materials to get the pulp, then put 22 parts by weight of pure water into the juice extractor and squeeze the juice, then filter the residue and leave the pure juice;

[0053] Ⅱ Add 3 parts by weight of calcium gluconate and 5 parts by weight of zinc gluconate int...

Embodiment 3

[0065] A cold blending oil is characterized in that: it is made of the following materials by weight,

[0066] 55 parts of linseed oil, 96 parts of fragrant sesame oil, 17 parts of tea seed oil, 33 parts of peanut oil, 8 parts of walnut oil, 7 parts of camellia oil, 6 parts of olive oil, 2 parts of neutralizer, 4 parts of nourishing agent;

[0067] The nourishing agent is made of the following materials by weight,

[0068] 5 parts of passion fruit, 4 parts of mangosteen, 4 parts of watermelon, 1 part of bayberry, 4 parts of grape, 3 parts of mango, 3 parts of kiwi, 2 parts of cherry, 3 parts of papaya, and 3 parts of apple;

[0069] Preparation method:

[0070] ⅠPeel the above-mentioned materials to get the pulp, then put 22 parts by weight of pure water into the juice extractor and squeeze the juice, then filter the residue and leave the pure juice;

[0071] Ⅱ Add 3 parts by weight of calcium gluconate and 5 parts by weight of zinc gluconate into the fruit juice, then heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com