Micro-nanofiber membrane as well as preparation method and application thereof

A micro-nano fiber and nano-fiber technology, applied in the field of filter materials, can solve the problem that the filtering effect needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

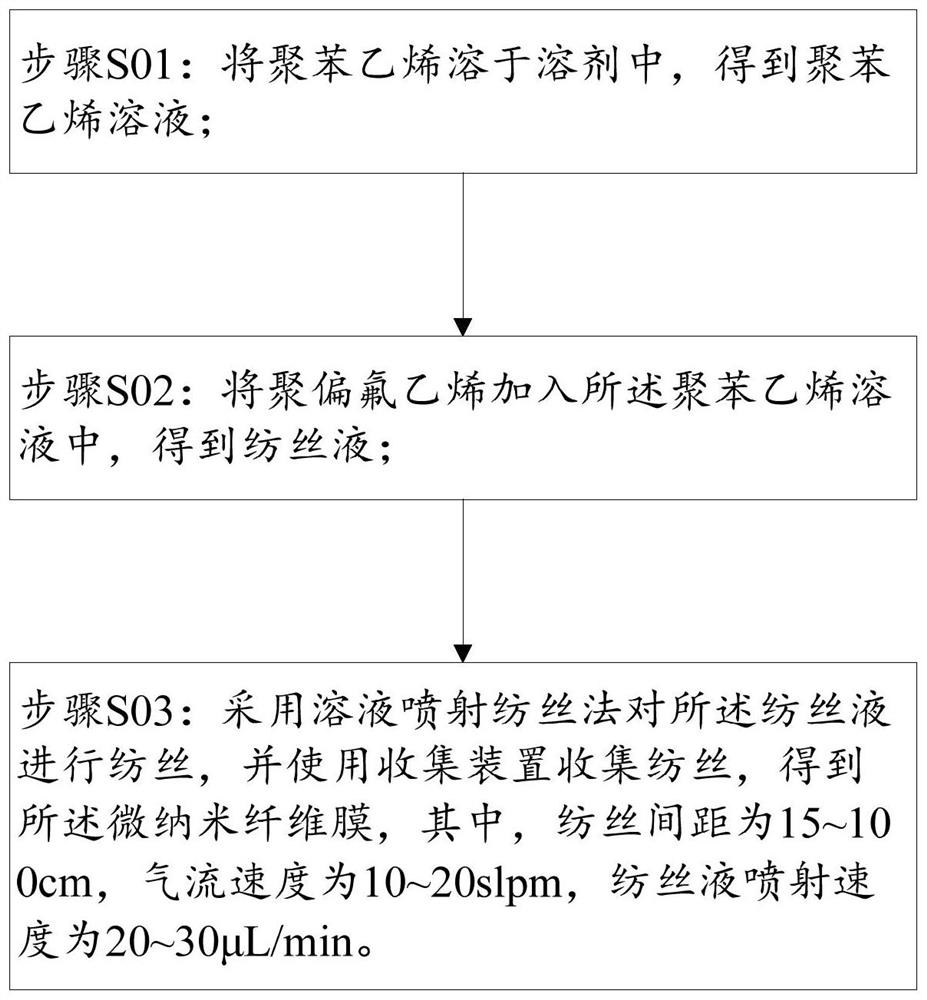

[0032] see figure 1 , the embodiment of the present application also provides a preparation method of a micro-nano fiber membrane, comprising the following steps:

[0033] Step S01: dissolving polystyrene in a solvent to obtain a polystyrene solution;

[0034] Step S02: adding polyvinylidene fluoride to the polystyrene solution to obtain a spinning solution;

[0035] Step S03: Spinning the spinning solution by using a solution jet spinning method, and collecting the spinning using a collecting device to obtain the micro-nano fiber membrane, wherein the spinning distance is 15-100 cm, and the air velocity is 10-100 cm. 20slpm, the spinning solution jet speed is 20~30μL / min.

[0036] In the step S01:

[0037] The solvent may be selected from, but not limited to, N,N-dimethylformamide (DMF), dimethylsulfoxide (DMSO), dimethylacetamide (DMAC), N-methylpyrrolidone (NMP), phosphoric acid At least one of triethyl ester (TEP) and acetone.

[0038] In some embodiments, after disso...

Embodiment 1

[0049] Dissolve 0.5 g of polystyrene in a mixed solution of 3 g of acetone and 7 g of DMF, and stir at room temperature for 1 h at a rotational speed of 800 rpm to obtain a polystyrene solution;

[0050] Add 1 g of polyvinylidene fluoride to the polystyrene solution, and stir at 800 rpm for 6 hours at 60° C. to obtain a spinning solution;

[0051] The spinning solution is spun by a solution jet spinning method, and the spinning is collected and spun using a roller to obtain a micro-nanofiber membrane, wherein the spinning spacing is 30 cm, the air velocity is 15 slpm, and the spinning solution jet velocity is 20 μL / min.

Embodiment 2

[0053] Dissolve 0.5 g of polystyrene in a mixed solution of 2 g of acetone and 8 g of DMF, and stir at room temperature for 1.5 h at a rotational speed of 850 rpm to obtain a polystyrene solution;

[0054] Add 1 g of polyvinylidene fluoride into the polystyrene solution, and stir at 850 rpm for 6.5 hours at 60° C. to obtain a spinning solution;

[0055] The spinning solution is spun by a solution jet spinning method, and the spinning solution is collected and spun using a collecting device to obtain the micro-nanofiber membrane, wherein the spinning distance is 25 cm, the air velocity is 15 slpm, and the spinning solution jetting speed is 25 cm. 20 μL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com