Preparation method of high-elasticity super-hydrophobic polystyrene-based porous material

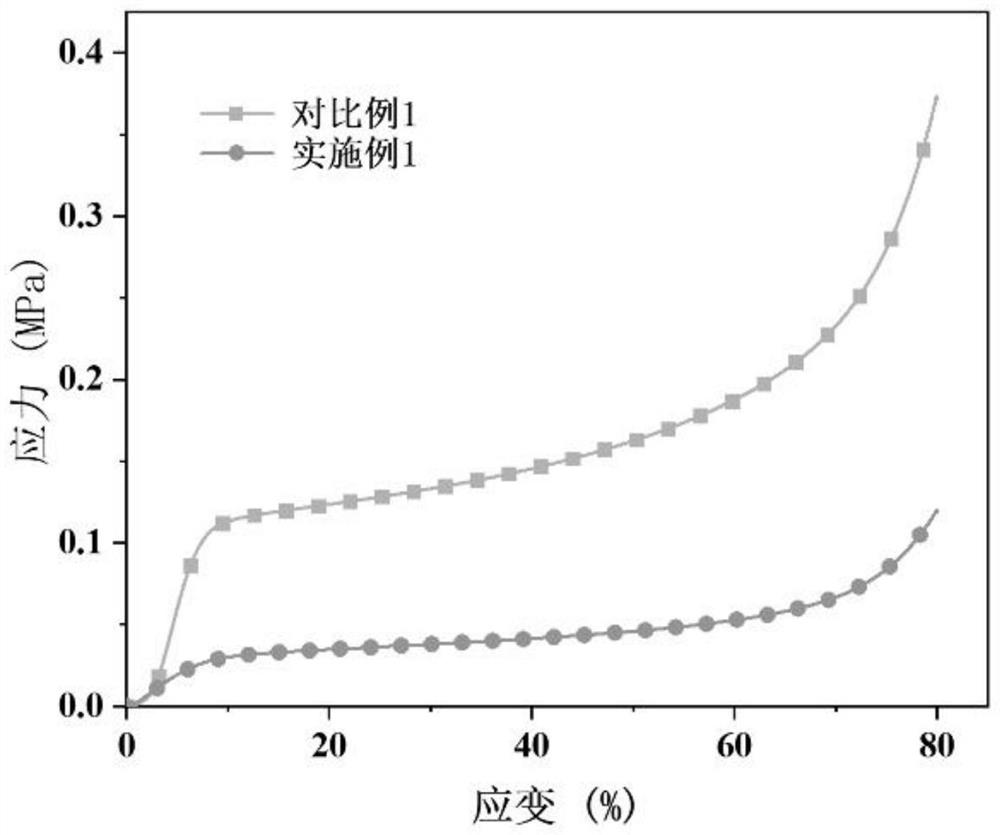

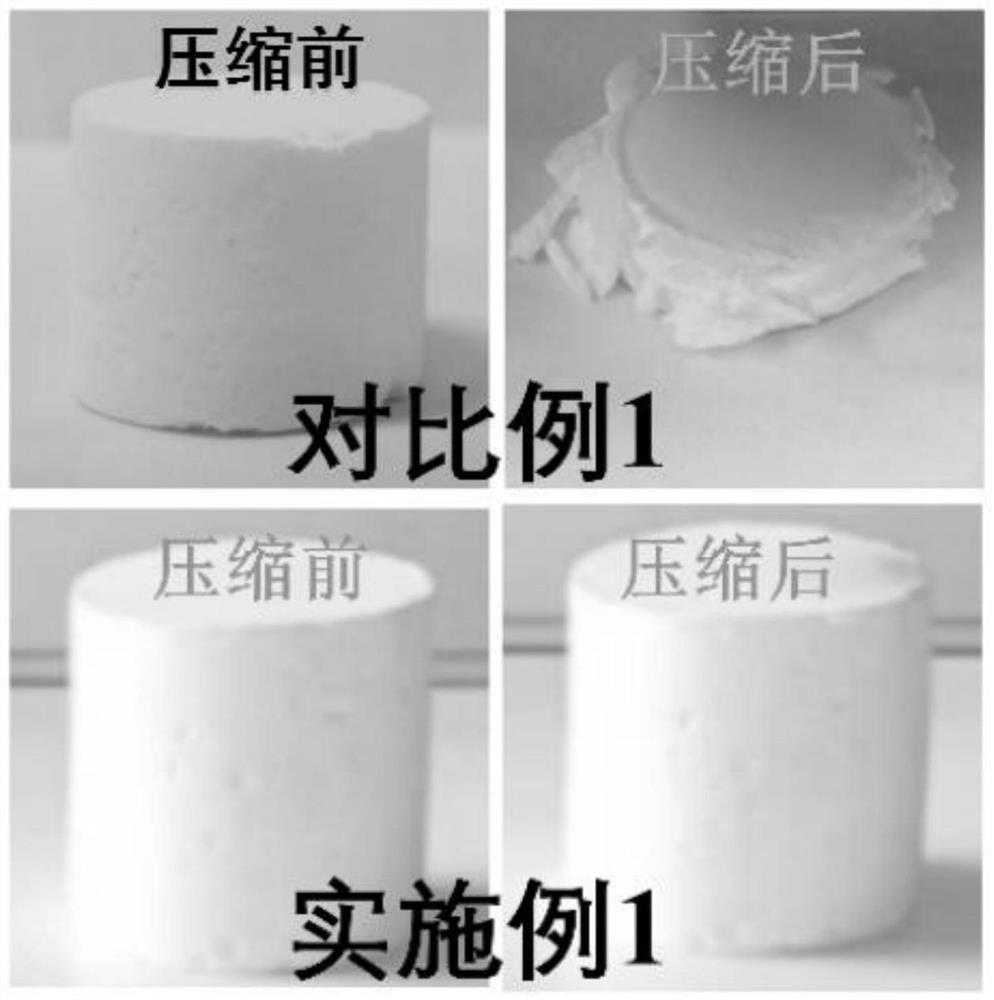

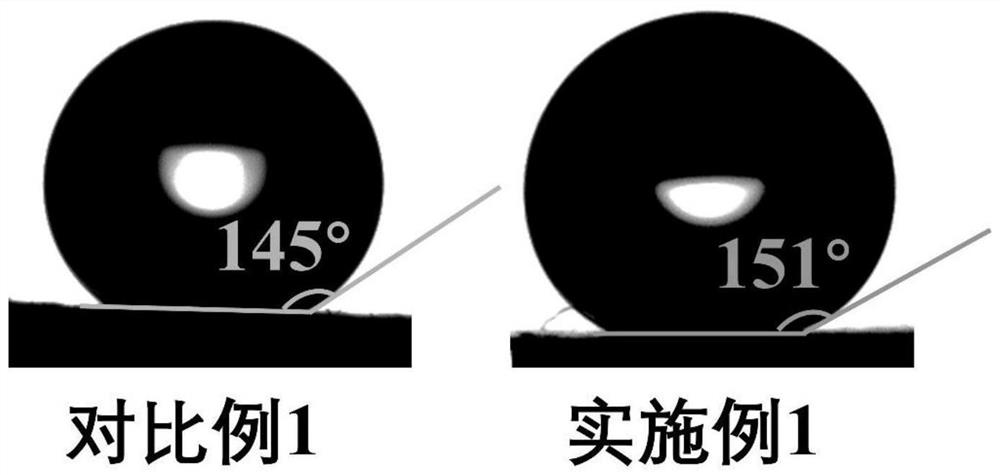

A polystyrene, super-hydrophobic technology, applied in the field of material preparation, can solve the problems of limited practical application and insignificant effect, and achieve the effect of excellent compression recovery performance, excellent mechanical performance, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of highly elastic superhydrophobic polystyrene-based porous material is prepared by the following steps: (1) 2 parts by weight of sodium persulfate are dispersed in 2000 parts by weight of deionized water to obtain solution A containing sodium persulfate; (2) 2002 Parts by weight of solution A was added to 20 parts by weight of styrene, 15 parts by weight of divinylbenzene, 5 parts by weight of trimethylolpropane triacrylate, 10 parts by weight of aminopropyl terminated polydimethylsiloxane and 15 parts by weight of In the mixed solution B that part Span80 lipophilic emulsifier is formed, in 200r / min mechanical agitation emulsification 20min, obtain pre-polymerization system; (3) the pre-polymerization system that step (2) obtains is reacted 8h at 65 ℃, and the product is used first After washing with absolute ethanol, air-dry at 50° C. for 10 h to obtain a highly elastic superhydrophobic polystyrene-based porous material.

Embodiment 2

[0037] A kind of highly elastic superhydrophobic polystyrene-based porous material is prepared by the following steps: (1) 20 parts by weight of ammonium persulfate are dispersed in 1000 parts by weight of deionized water to obtain solution A containing ammonium persulfate; (2) 1020 Parts by weight of solution A was added to 40 parts by weight of styrene, 15 parts by weight of glycidyl methacrylate, 20 parts by weight of pentaerythritol triacrylate, 40 parts by weight of polyether amine and 10 parts by weight of Span80 lipophilic emulsifier. (3) react the pre-polymerization system obtained in step (2) at 40°C for 24h, wash the product with absolute ethanol first, and then drum it at 80°C After air drying for 24 hours, a highly elastic superhydrophobic polystyrene-based porous material was obtained.

Embodiment 3

[0039] A kind of highly elastic superhydrophobic polystyrene-based porous material is prepared by the following steps: (1) 20 parts by weight of cumene hydroperoxide are dispersed in 2000 parts by weight of deionized water to obtain solution A containing cumene hydroperoxide . (2) Add 2020 parts by weight of solution A to 50 parts by weight of styrene, 20 parts by weight of N,N-methylenebisacrylamide, 10 parts by weight of ethylene glycol dimethacrylate, 30 parts by weight of 1,18- In the mixed solution B of octadecanediamine and 30 parts by weight of hydroxylated lanolin lipophilic emulsifier, emulsify at 600r / min mechanical stirring for 20min to obtain a prepolymerization system; (3) the prepolymerization system obtained by step (2) After reacting at 40°C for 24 hours, the product was first washed with absolute ethanol, and then air-dried at 80°C for 24 hours to obtain a highly elastic superhydrophobic polystyrene-based porous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com