Patents

Literature

41results about How to "Excellent compression recovery performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

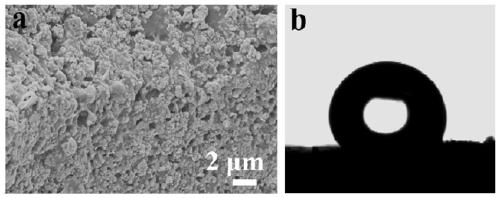

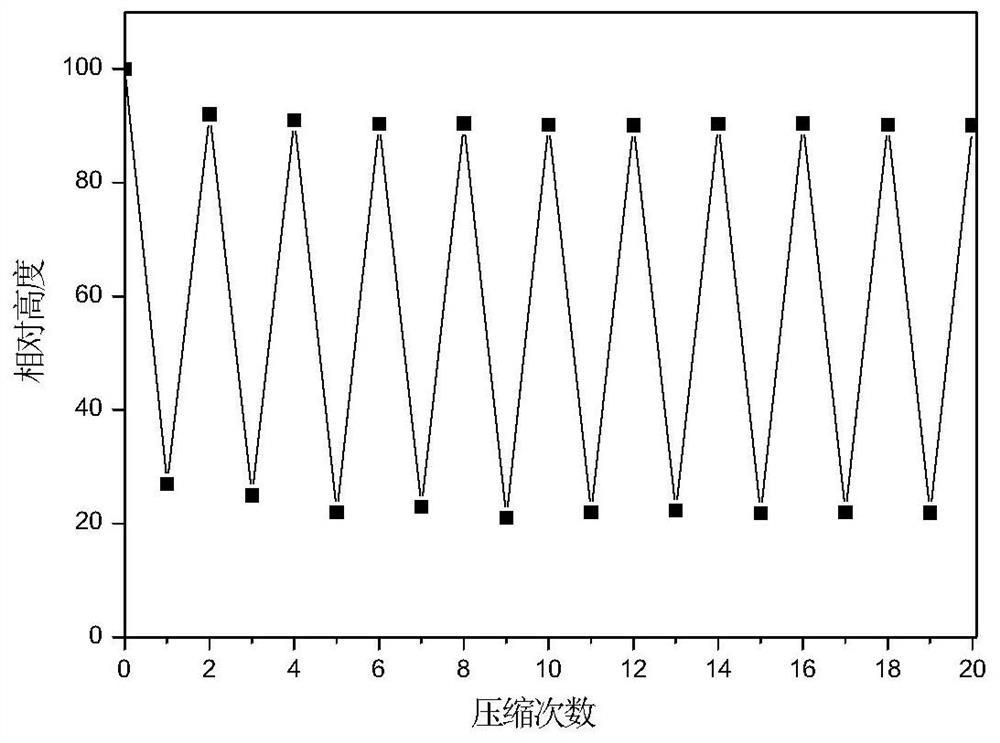

Biology base polymer aerogel oil absorption material and preparation method thereof

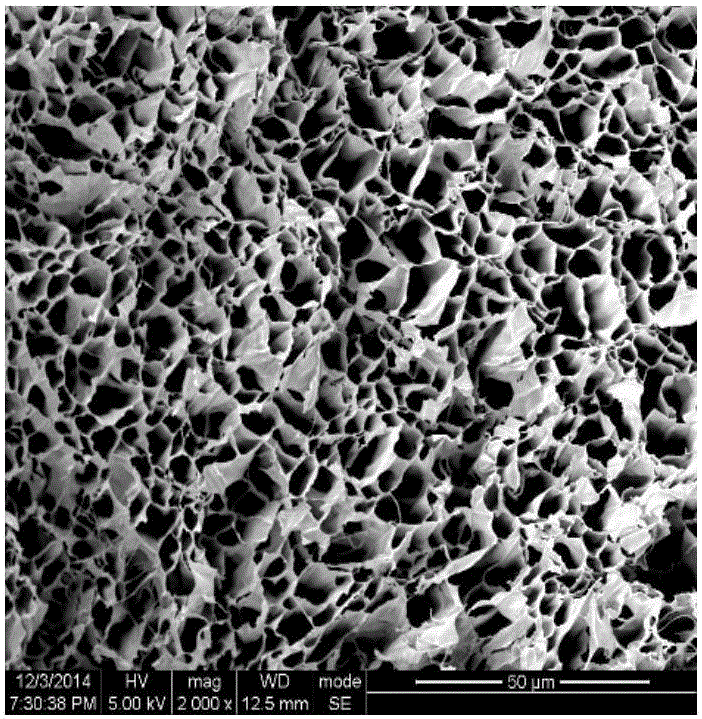

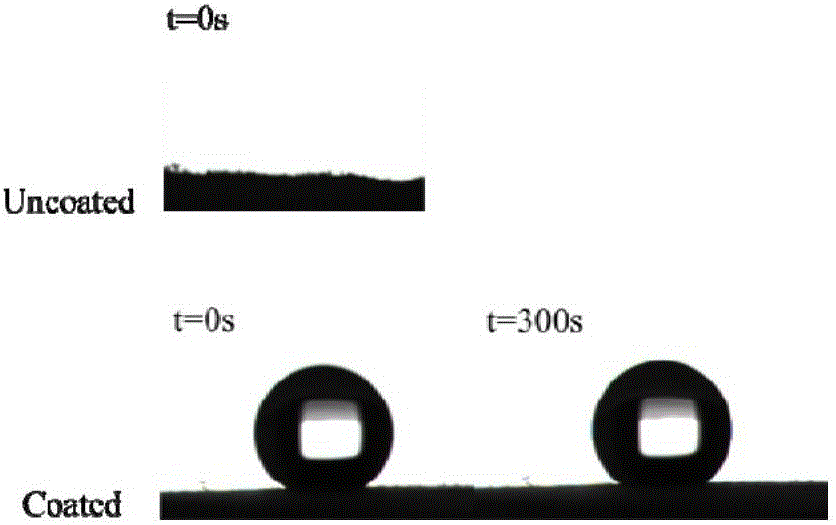

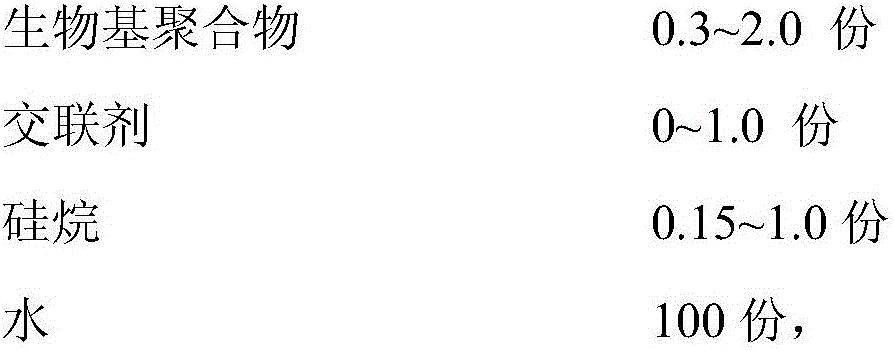

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

Foam

ActiveUS20090012194A1High closed cell contentHigh expansion ratioFoundry mouldsAbsorbent padsPolyolefinPolystyrene

The present invention provides a foam comprising (a) a polylactic acid resin, (b) at least one thermoplastic resin selected from a polyolefin resin and a polystyrene resin, and (c) a block copolymer of a vinyl aromatic compound and a conjugated diene, wherein a ratio of (a) to (b) by weight (a / b) is 80 / 20 to 20 / 80, and the foam comprises 0.5 to 20 parts by weight of (c) with respect to 100 parts by weight of (a) and (b) in total.

Owner:ASAHI KASEI CHEM CORP

Polylactic acid foam

A polylactic acid foam obtained from a resin composition comprising polylactic acid (A), a polyolefin resin (B), and a polyolefin resin copolymer (C), characterized in that the ratio of the weight of the polylactic acid (A) to the total weight of the polyolefin resin (B) and the polyolefin resin copolymer (C), (A) / {(B)+(C, in the resin composition is 0.2-6. The polylactic acid foam is a foam made from a polylactic acid resin, which burdens the environment little, and excellent in heat resistance, moldability, and compression recovery. This polylactic acid foam is suitable for use in various applications where polyolefin resin foams are used at present, such as automotive applications, bases for heat insulators, cushioning materials, packing materials, pressure-sensitive adhesive tapes, etc., and joint filling materials.

Owner:TORAY IND INC

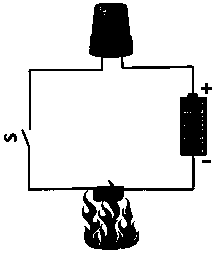

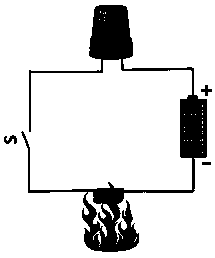

Resistance type fire detection/early-warning sensor and application

ActiveCN108109317AEasy to prepareCheap and easy to getFire alarm electric actuationFire riskLow voltage

The invention relates to the field of functional materials. In order to solve the deficiencies and defects of the traditional infrared fire alarms and smoke alarms in the using process at present, theinvention provides a novel resistance type fire detection / early-warning sensor, which is formed by connecting a low-voltage power supply, a warning lamp, a fire early-warning composite material and aplurality of lead wires in sequence, wherein the fire early-warning composite material is prepared from, by weight, 25-45 parts of melamine foam, 8-40 parts of graphene oxide and 15-67 parts of silicon-containing additive. The process is simple and efficient, and the raw material is low in cost. The invention further provides an application of the resistance type fire detection / early-warning sensor. The resistance type fire detection / early-warning sensor is used for monitoring and preventing various types of combustible materials in a high fire risk region, reducing or even avoiding the occurrence of fires and loss caused by the fires.

Owner:HANGZHOU NORMAL UNIVERSITY

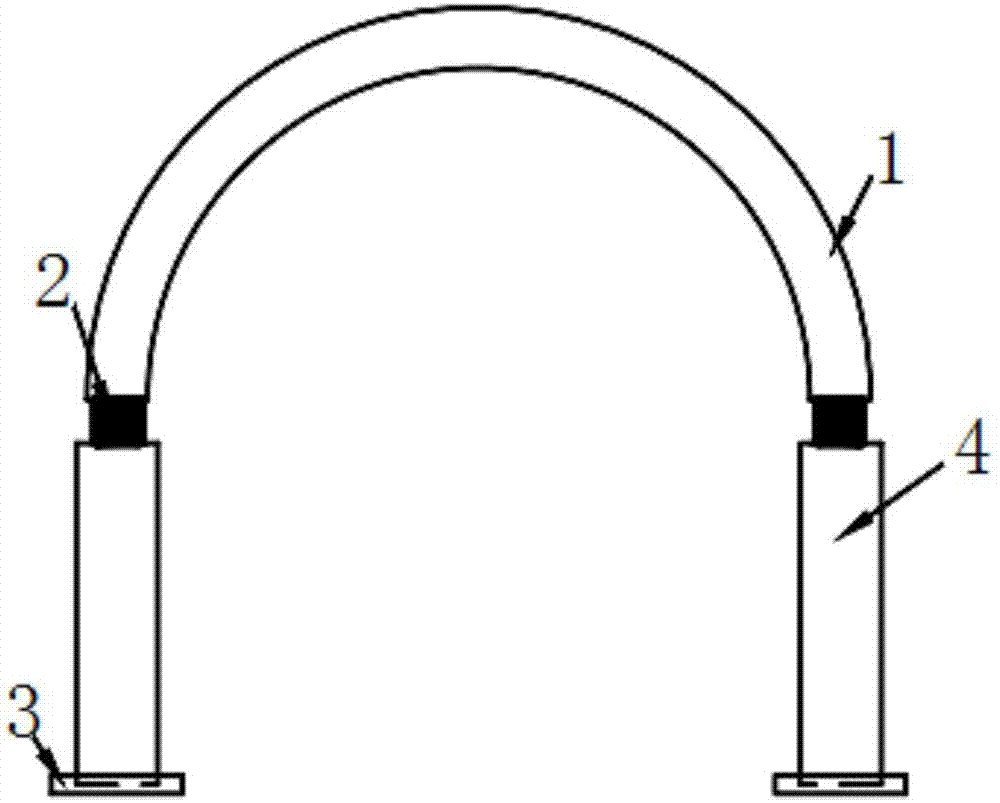

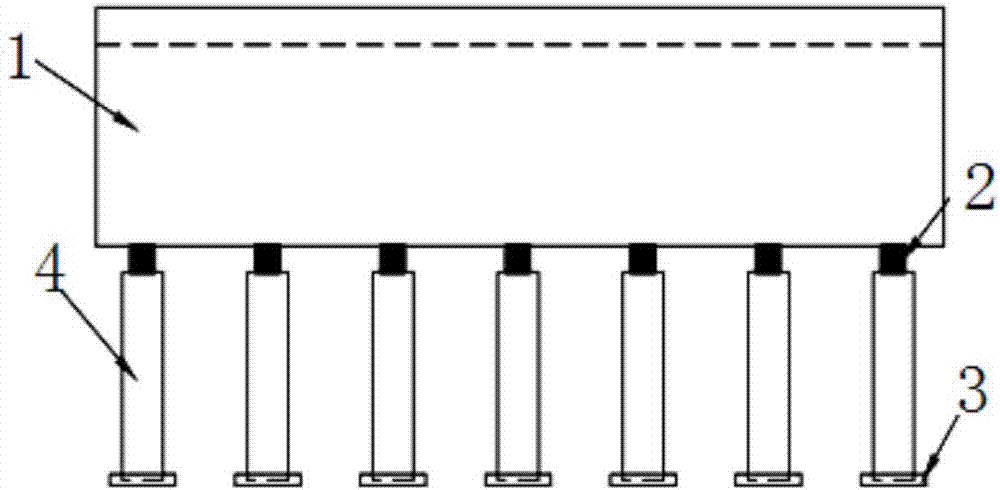

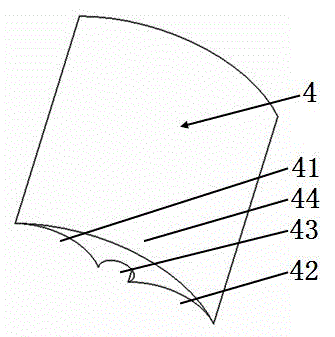

Tunnel portal dangerous rock falling multi-stage protection method and structure body thereof

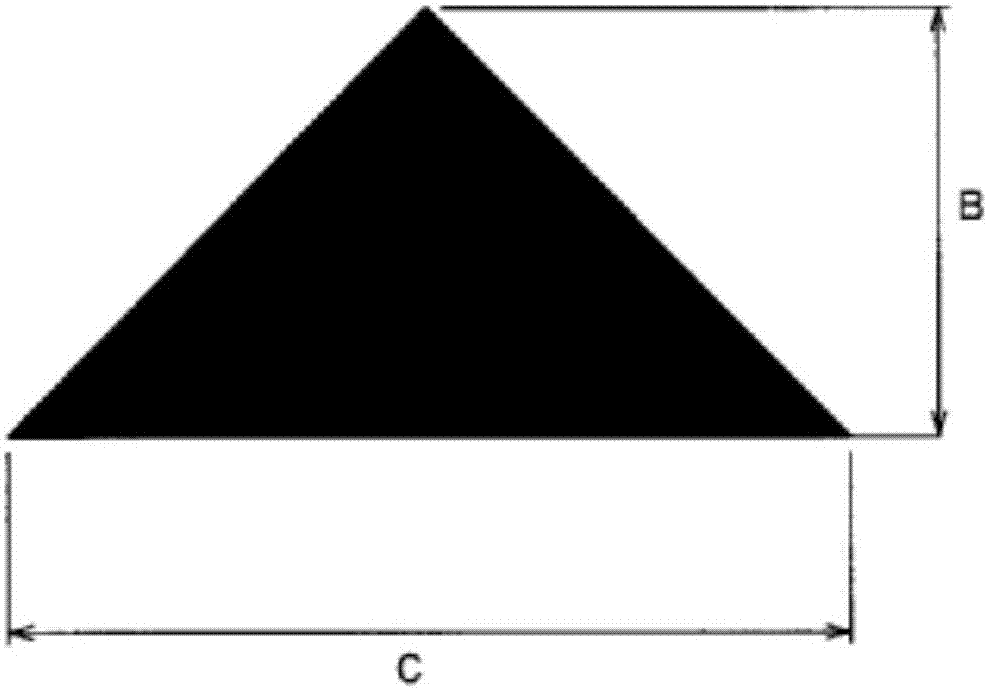

InactiveCN107044094AAvoid destructionEnsure Structural IntegrityProtective constructionHigh intensityUltimate tensile strength

The invention discloses a tunnel portal dangerous rock falling multi-stage protection method and a structure body thereof. The tunnel portal dangerous rock falling multi-stage protection method concretely comprises the following steps: step I, when rockfall impact energy is small, a high-strength rigid ceiling guides falling rocks to the two sides of a traffic line; step II, when the rockfall impact energy is medium, the high-strength rigid ceiling transfers the impact energy to a shock absorption and energy dissipation device and guides the falling rocks to the two sides of the traffic line at the same time; and step III, when the rockfall impact energy is large, the high-strength rigid ceiling carries out light plastic deformation and transfers the energy to the shock absorption and energy dissipation device at the same time, and the shock absorption and energy dissipation device carries out compressive deformation to realize the protection action. The structure body of the tunnel portal dangerous rock falling multi-stage protection method comprises the high-strength rigid ceiling, the shock absorption and energy dissipation device, a supporting structure and a permanent anchoring base. The tunnel portal dangerous rock falling multi-stage protection method and the structure body thereof realize multi-stage protection in a mode with the synergistic effect of avoidance, energy dissipation and guide and have the characteristics of obvious flexibility, applicability, economy and environmental protection property.

Owner:陕西中咨土木工程检测有限公司

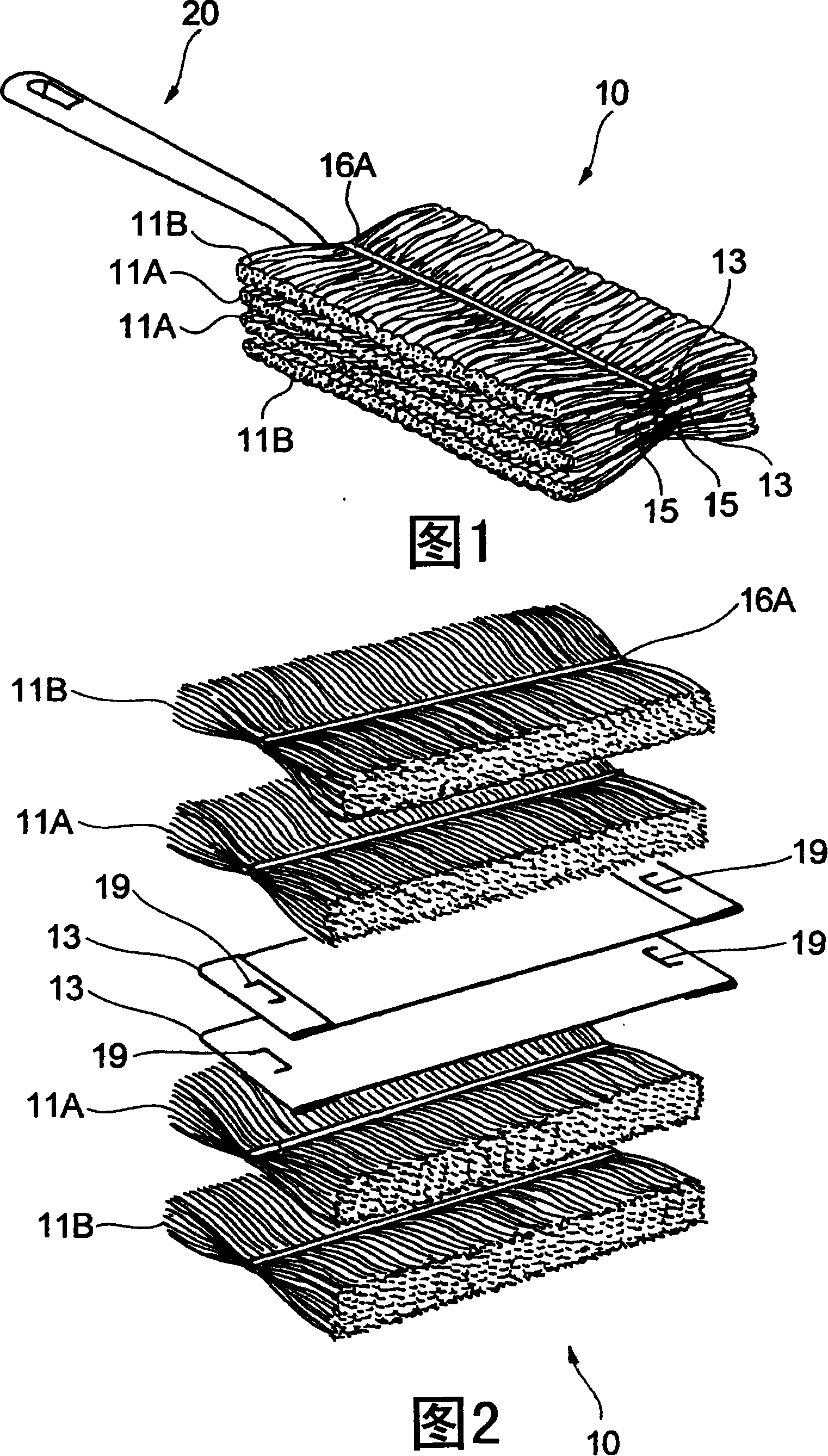

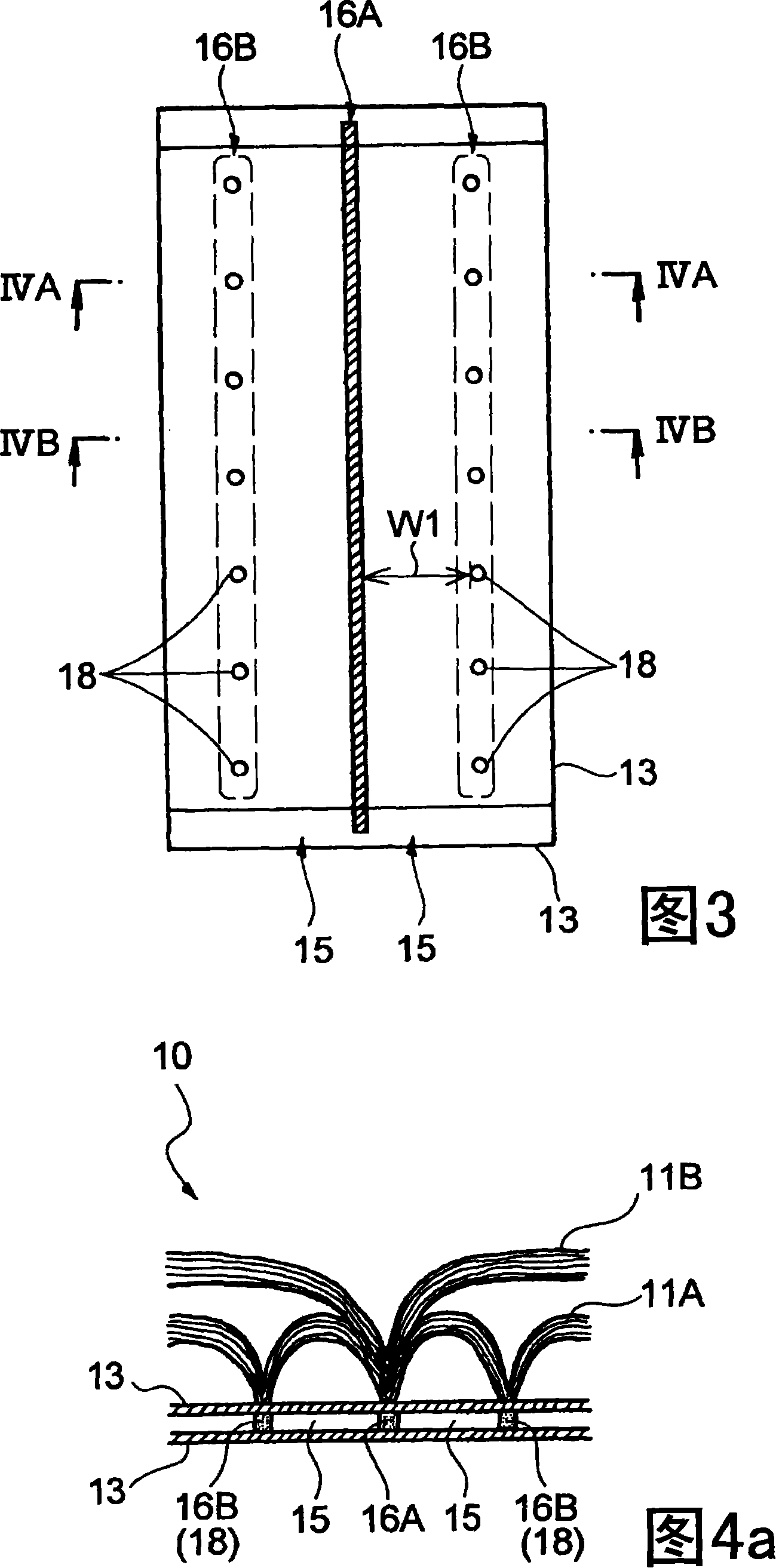

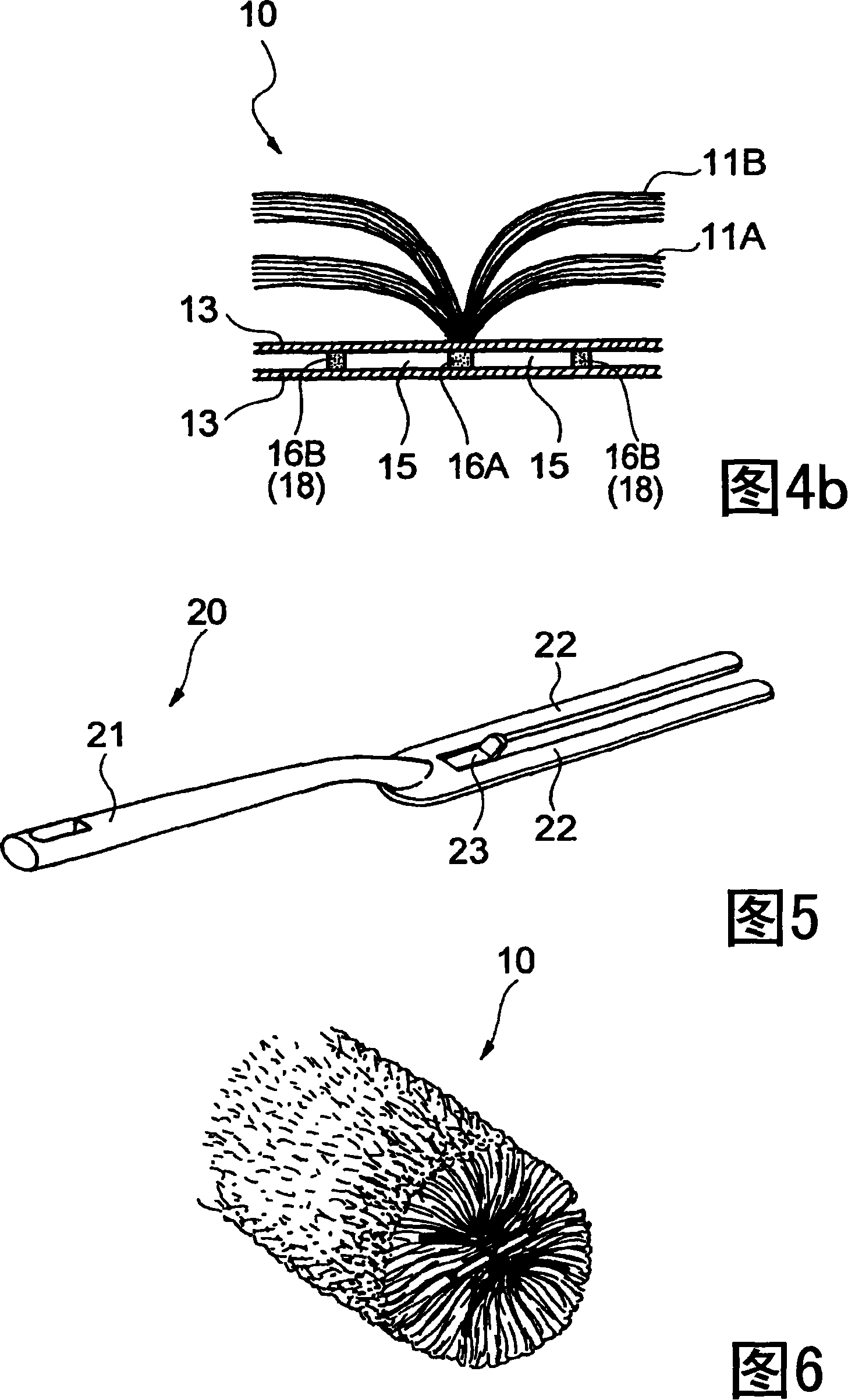

Cleaning article, method of fluffing cleaning article, and method of producing cleaning article

ActiveCN101115430AImprove fluffing effectExcellent compression recovery performanceCarpet cleanersFloor cleanersFiber bundleMechanical engineering

The invention provides a cleaning article (10), which has a flat cylindrical handle insertion part (15), and the handle can be inserted and installed in the handle insertion part (15). The insertion portion forming sheet (13) is joined and formed; on the upper surface and the lower surface of the handle insertion portion (15) on the handle insertion portion forming sheet (13), one or more fiber layers composed of fiber bundles are respectively provided (11A, 11B); the first fiber layer (11A) of the fiber layer (11A, 11B) closest to the handle insertion portion forming sheet (13) side is continuously sealed in the center portion in the width direction by a center extending continuously in the length direction The line (16A) is joined to the handle insertion portion forming sheet (13), at a position separated from the central continuous sealing line (16A) to at least one side outside in the width direction, passing through a side non-continuously extending longitudinally. A continuous seal (16B) is bonded to the handle insert forming sheet (13).

Owner:KAO CORP

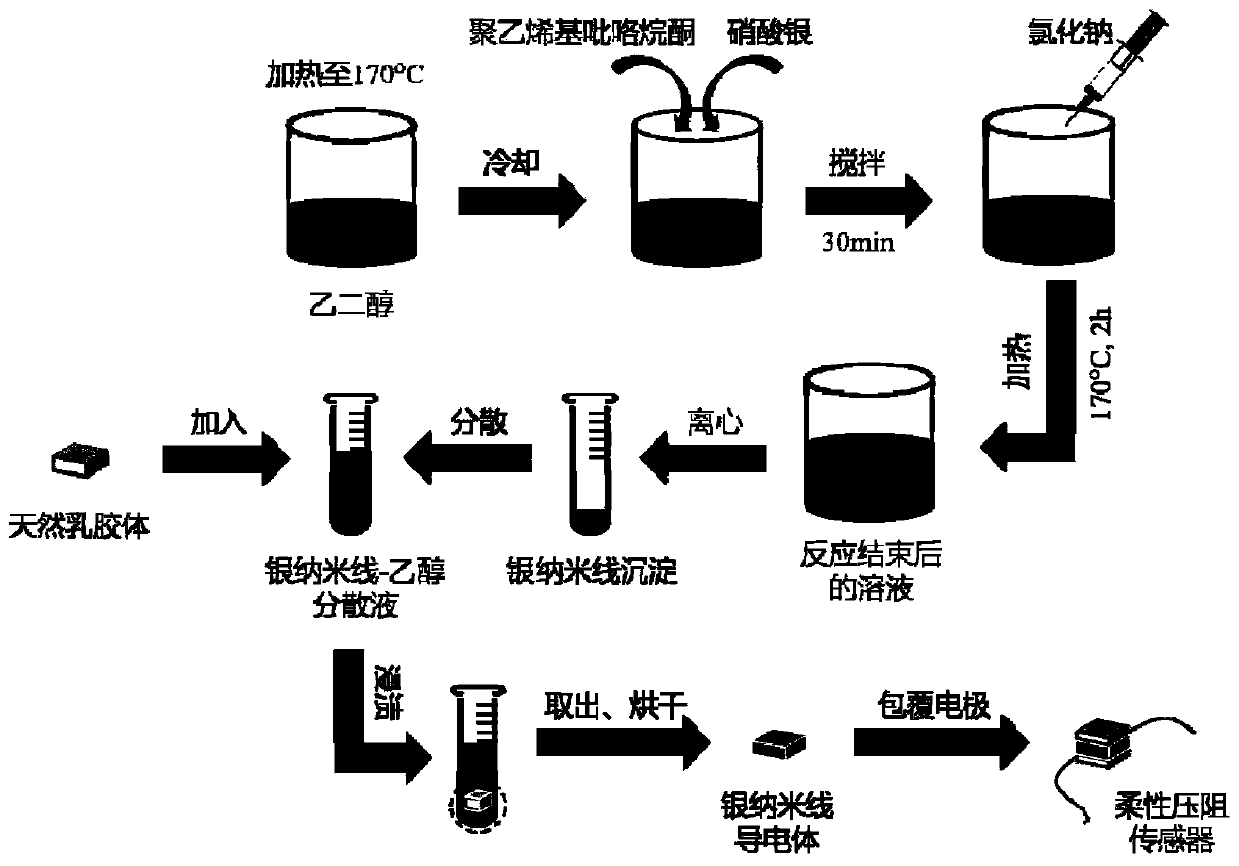

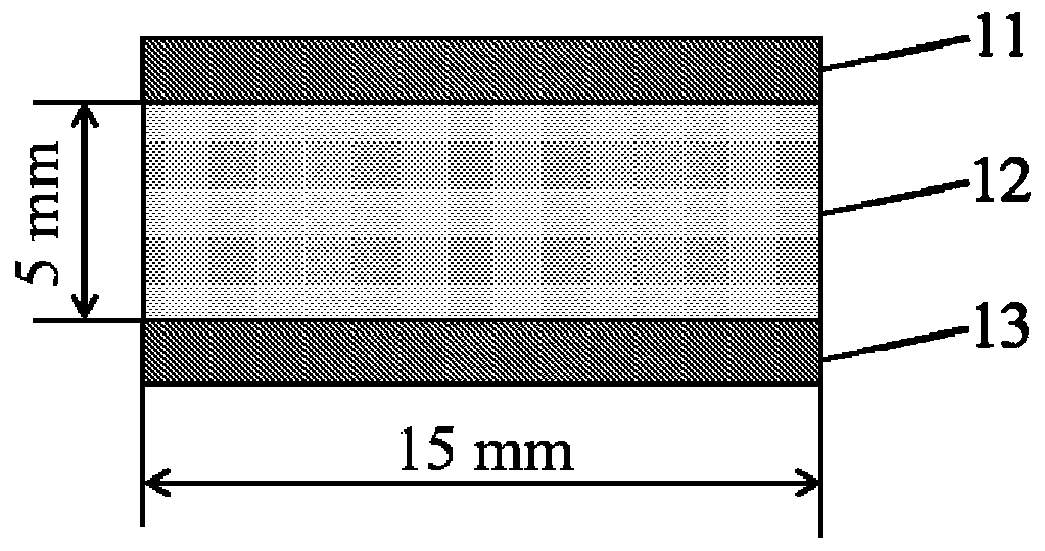

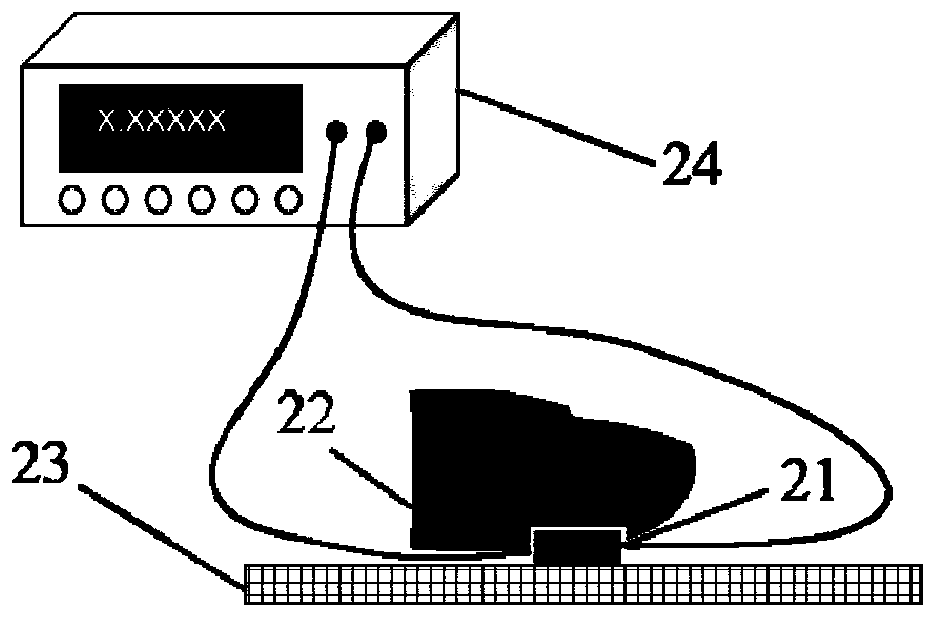

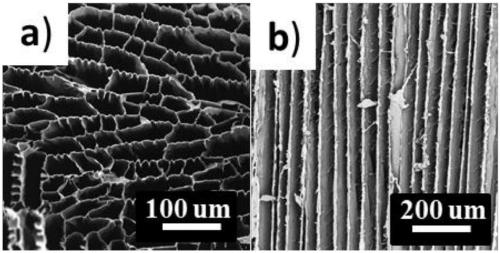

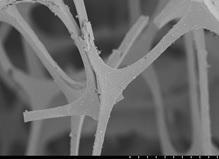

High-sensitivity flexible piezoresistive transducer as well as preparation method and application thereof

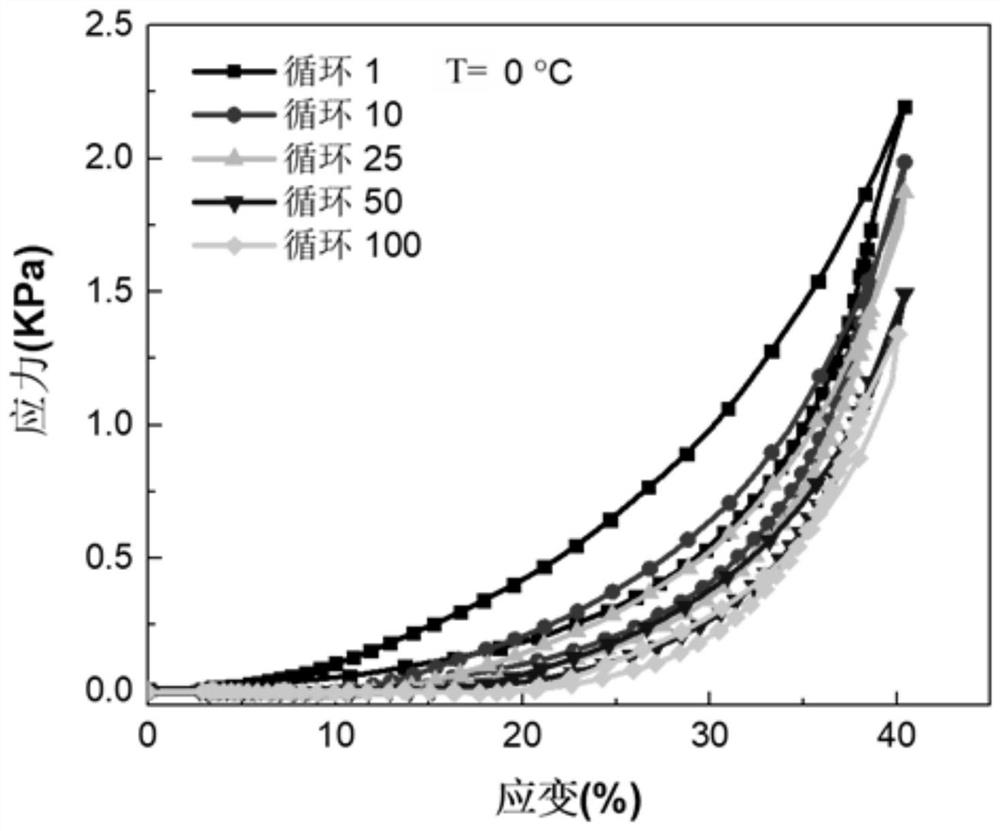

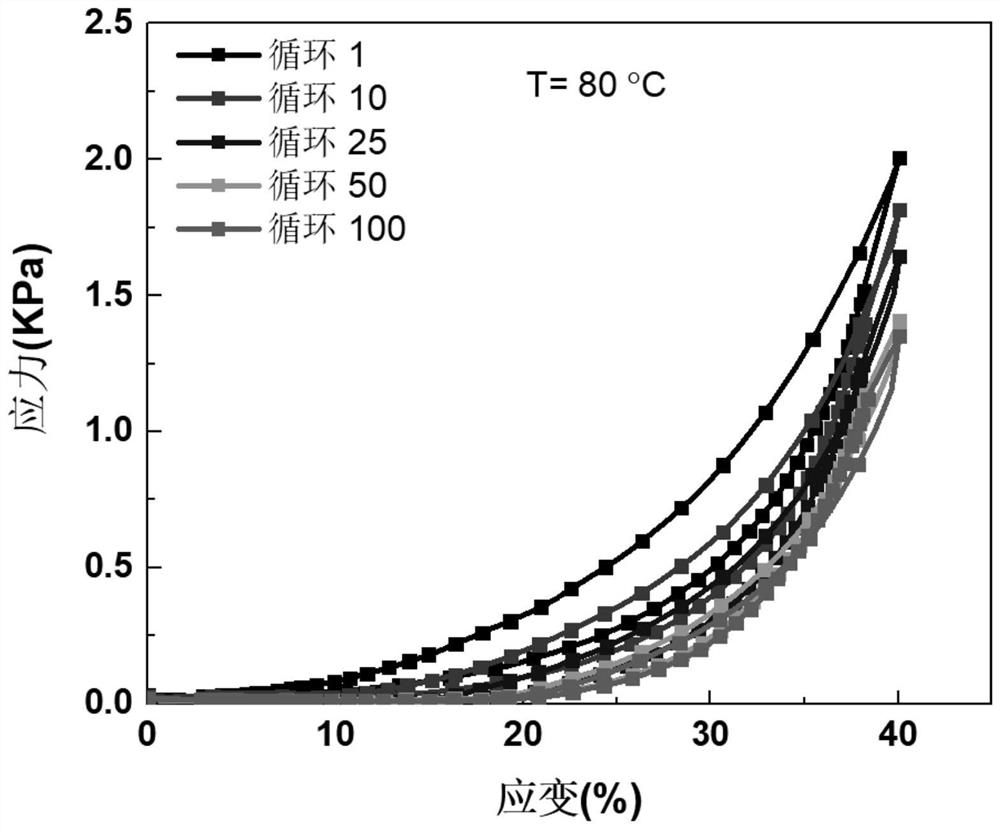

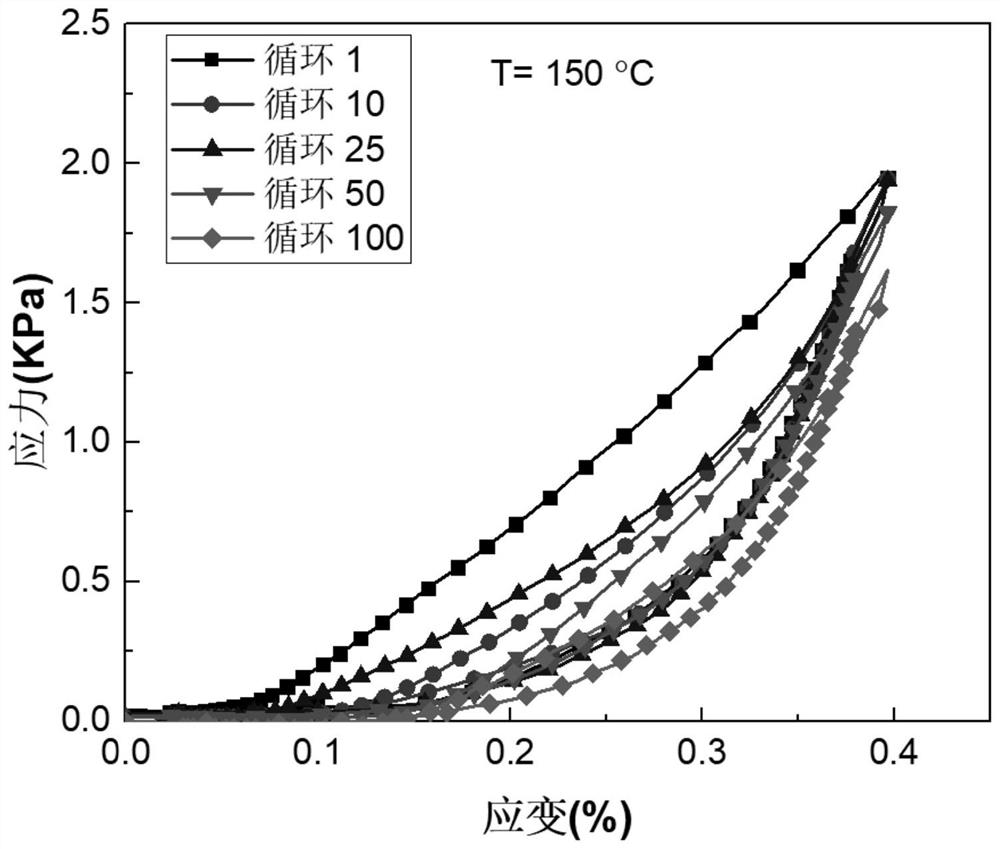

ActiveCN110411623ANarrow detection stress rangeLarge compressive strainForce measurementNanosensorsCross-linkEmulsion

The invention discloses a preparation method and application of a high-sensitivity flexible piezoresistive transducer based on low-dimensional narrow-distributed silver nanowires. The high-sensitivityflexible piezoresistive transducer based on the low-dimensional narrow-distributed silver nanowires is mainly formed by a two-stage structure, wherein the first-stage structure is of a skeleton structure, and a three-dimensional elastic nanoporous skeleton is formed by the natural emulsion colloid; and the second-stage structure is of a sensing structure, a three-dimensional cross-linked sensingstructure is formed by filling synthesized silver nanowires with the elastic emulsion colloid, and finally electrode layers are attached to the upper surface and the lower surface of a sensing part and a wire is led out to form the flexible piezoresistive transducer based on the low-dimensional narrow-distributed silver nanowires. The transducers all coat five fingers of a glove, an object is pressed by the glove on the hand, and electrical changes are generated, so that the mechanical property of each finger is monitored in real time. The preparation method disclosed by the invention is simple in processing technology, good in compression characteristic and high in sensitivity, and can be used for detecting human hand motion and grip strength state data.

Owner:DONGHUA UNIV

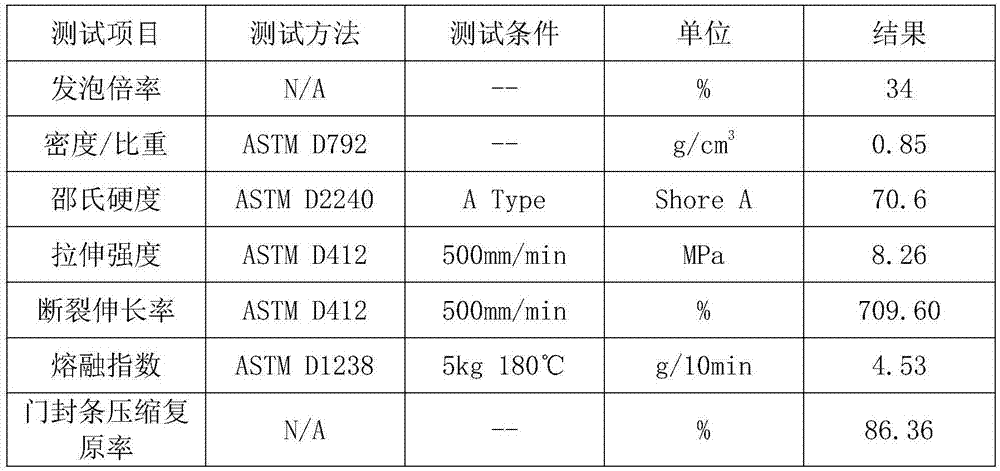

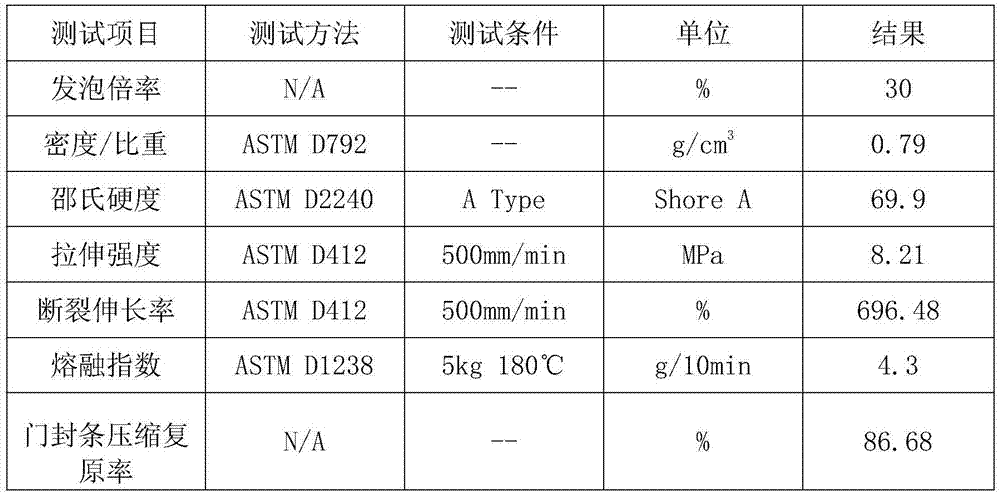

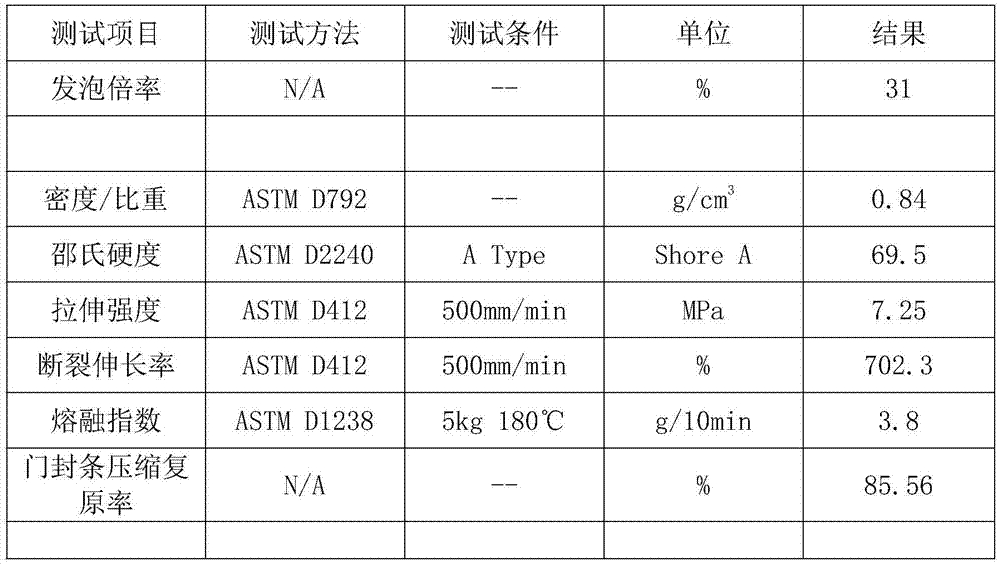

Thermoplastic elastomer foamed door seal strip and preparation method thereof

The invention discloses a thermoplastic elastomer foamed door seal strip and a preparation method thereof. The thermoplastic elastomer foamed door seal strip is characterized by being prepared from the following materials for preparation in parts by weight: 60 to 110 parts of styrene elastomer, 10 to 30 parts of high-density polyethylene, 10 to 40 parts of polypropylene, 60 to 110 parts of filling oil, 30 to 80 parts of mineral filler, 1 to 5 parts of lubricant, 1 to 5 parts of coupling agent, 0.1 to 2 parts of antioxidant, 0 to 5 parts of crosslinking agent and 1 to 8 parts of foaming agent. The preparation method is as follows: the styrene elastomer and the filling oil among the materials according to parts by weight are first sufficiently mixed for absorption, the other components are then added and uniformly mixed, the uniformly mixed materials are extruded by a double-screw extruder for pelletization, and the pelletized material is sent into a single-screw extruder and extruded out to be shaped. According to the preparation method, in the process of production, no wastewater and waste gas are produced, no solvents are discharged, halogen is not contained, scraps can be recycled, and a product has the advantages of good elasticity, high strength, good compressive resilience, low specific gravity, adjustable density, smooth surface and good welding effect.

Owner:ANHUI HIGASKET PLASTICS CO LTD

Foam

ActiveUS7947754B2Increase contentHigh expansionFoundry mouldsAbsorbent padsPolymer sciencePolyolefin

The present invention provides a foam comprising (a) a polylactic acid resin, (b) at least one thermoplastic resin selected from a polyolefin resin and a polystyrene resin, and (c) a block copolymer of a vinyl aromatic compound and a conjugated diene, wherein a ratio of (a) to (b) by weight (a / b) is 80 / 20 to 20 / 80, and the foam comprises 0.5 to 20 parts by weight of (c) with respect to 100 parts by weight of (a) and (b) in total.

Owner:ASAHI KASEI CHEM CORP

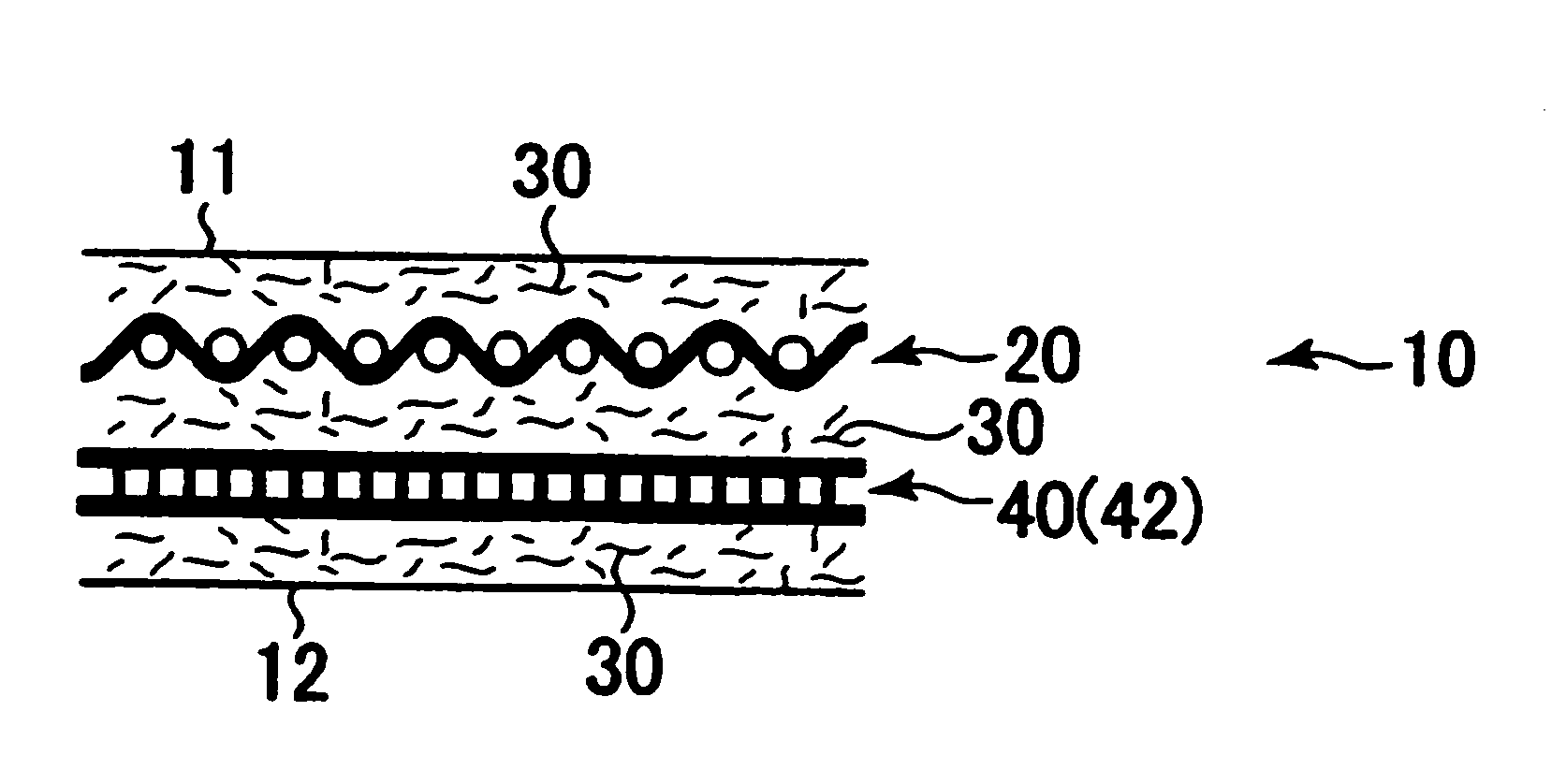

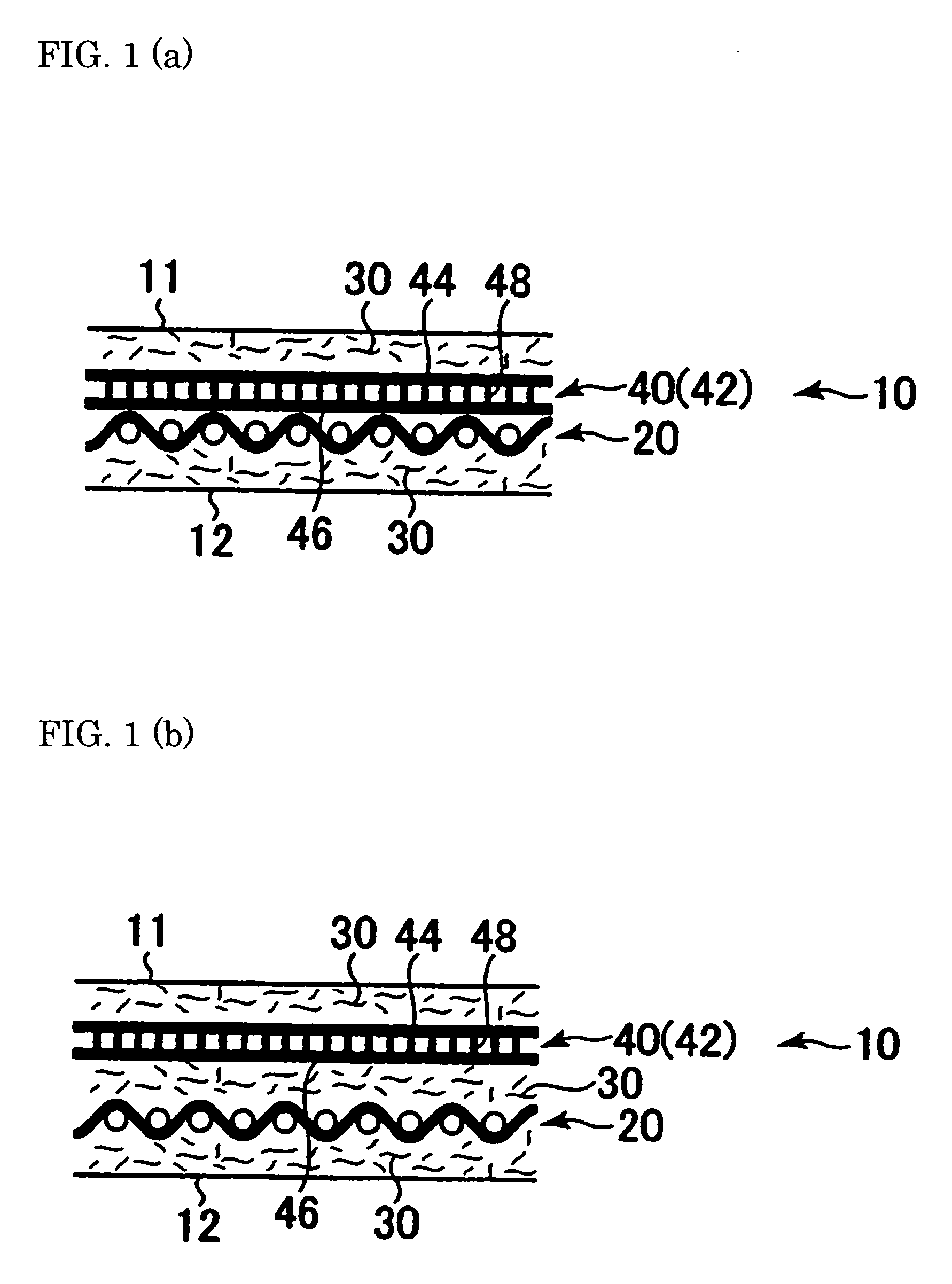

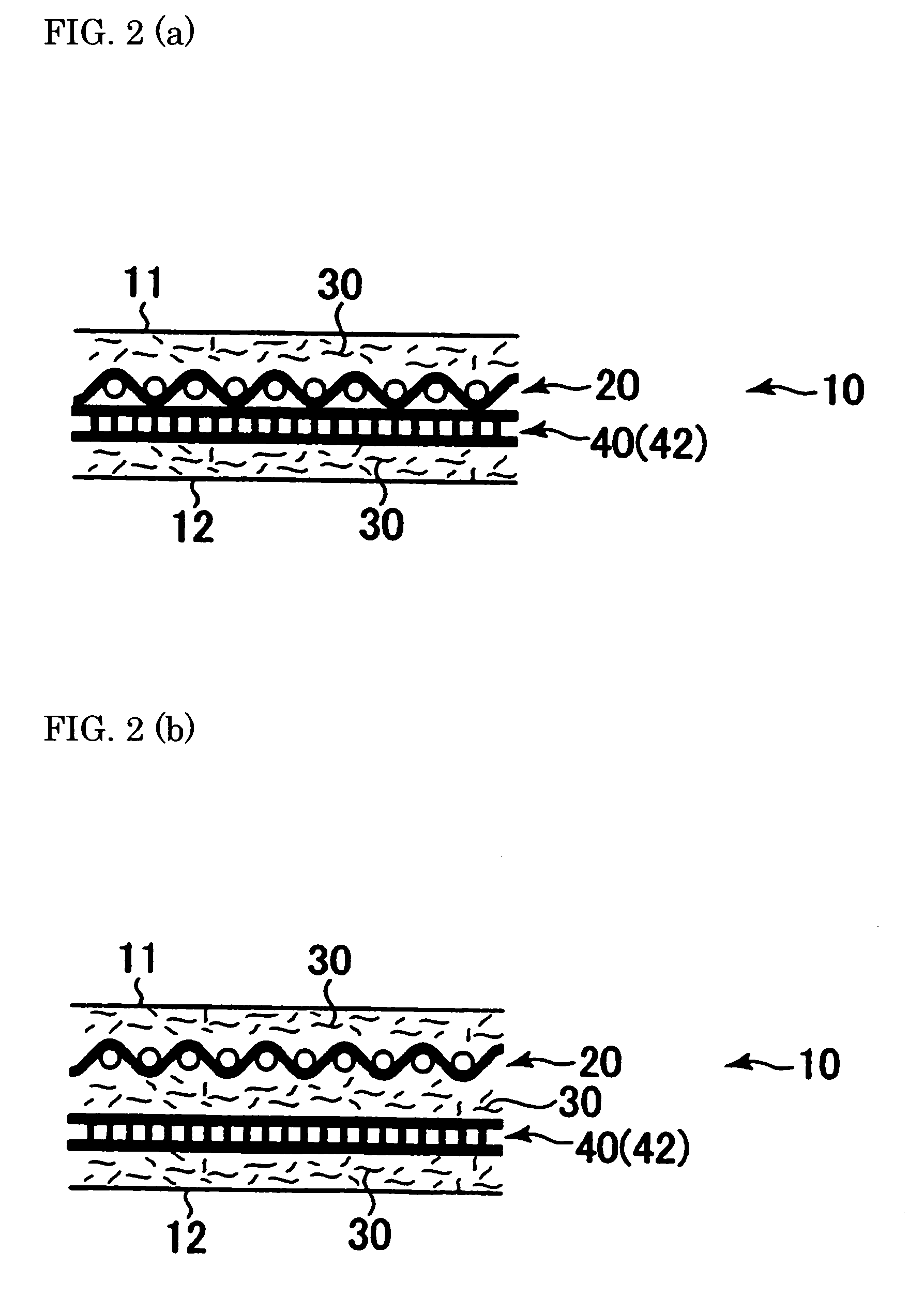

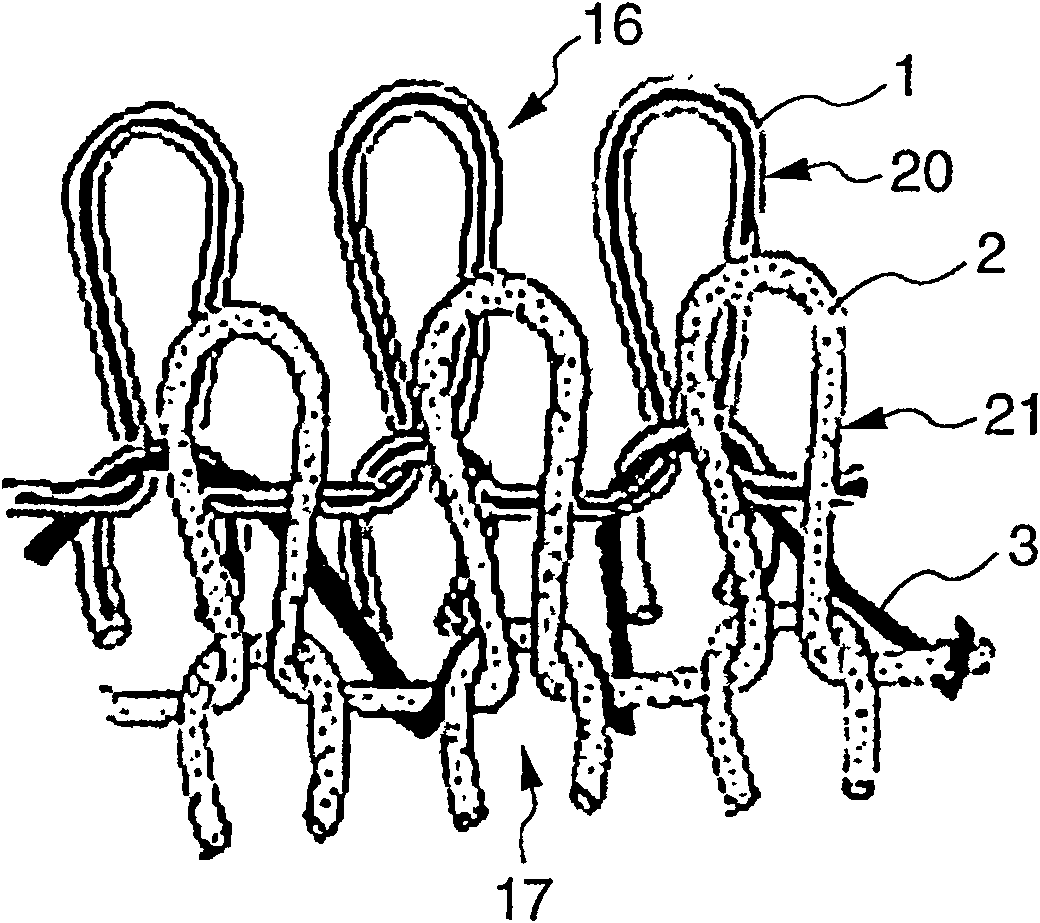

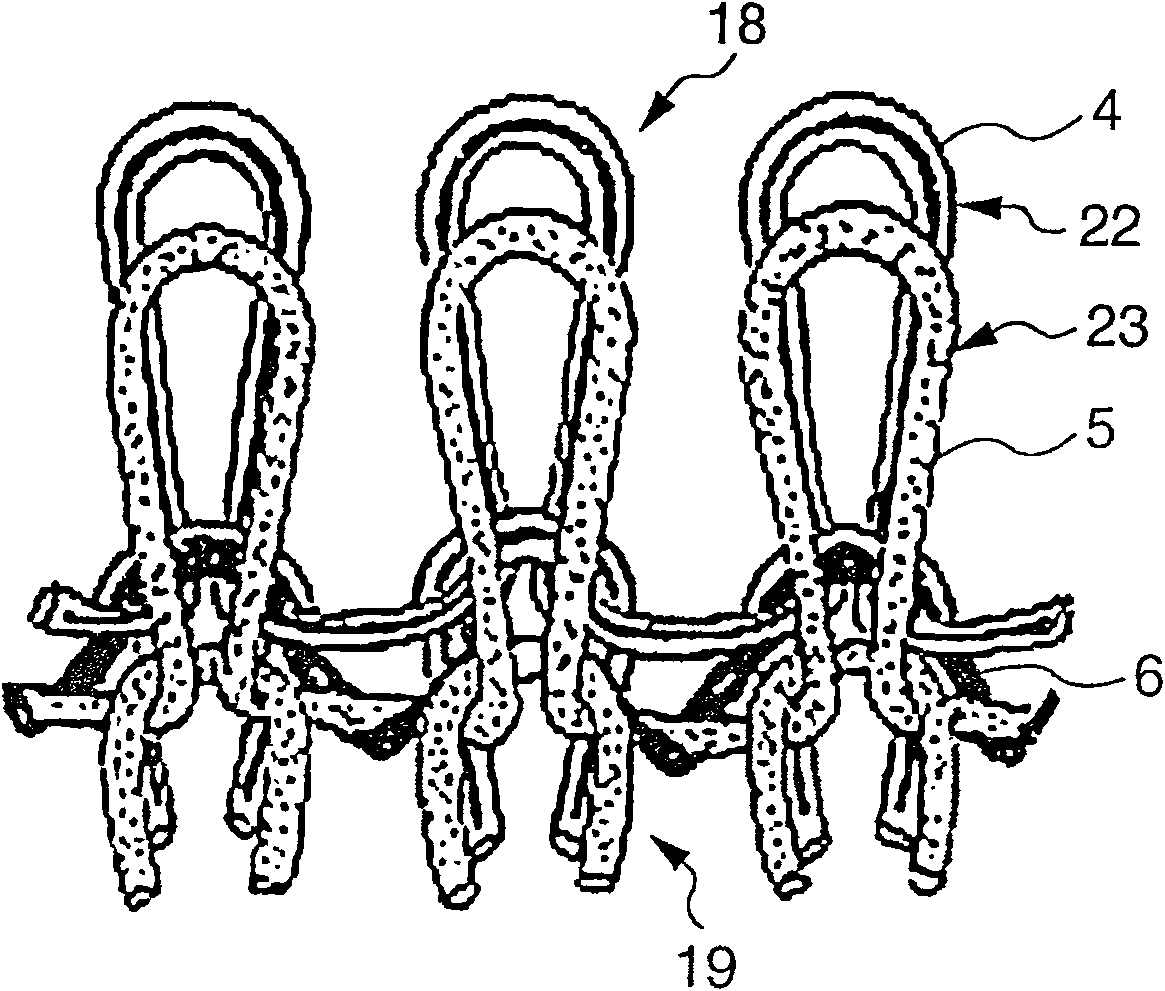

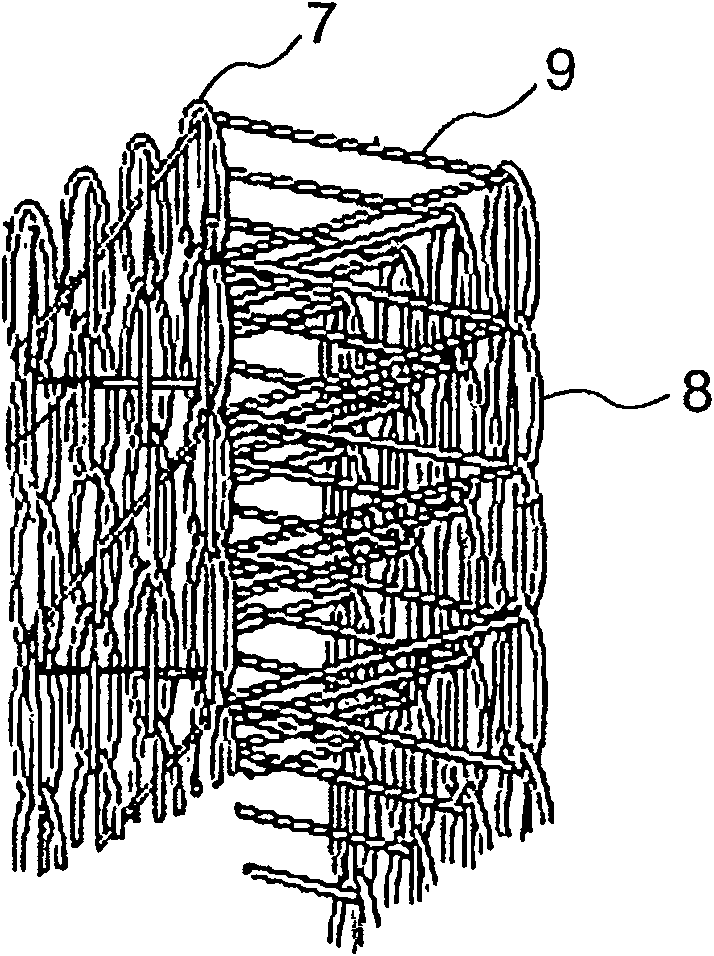

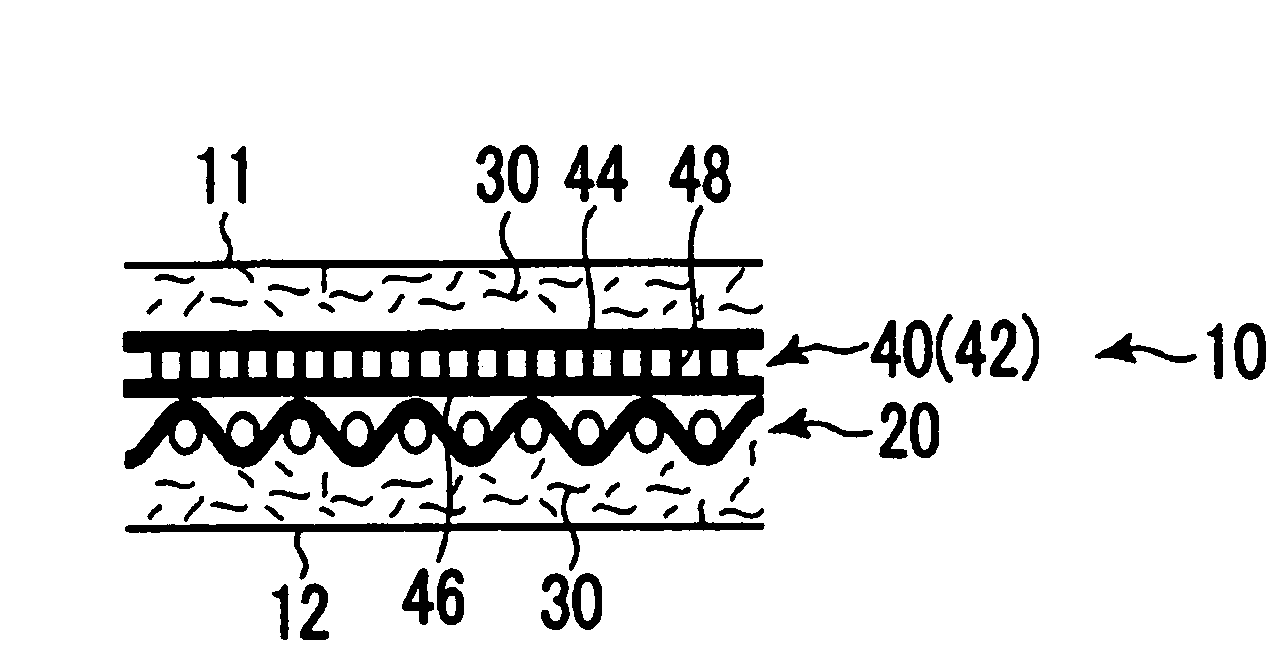

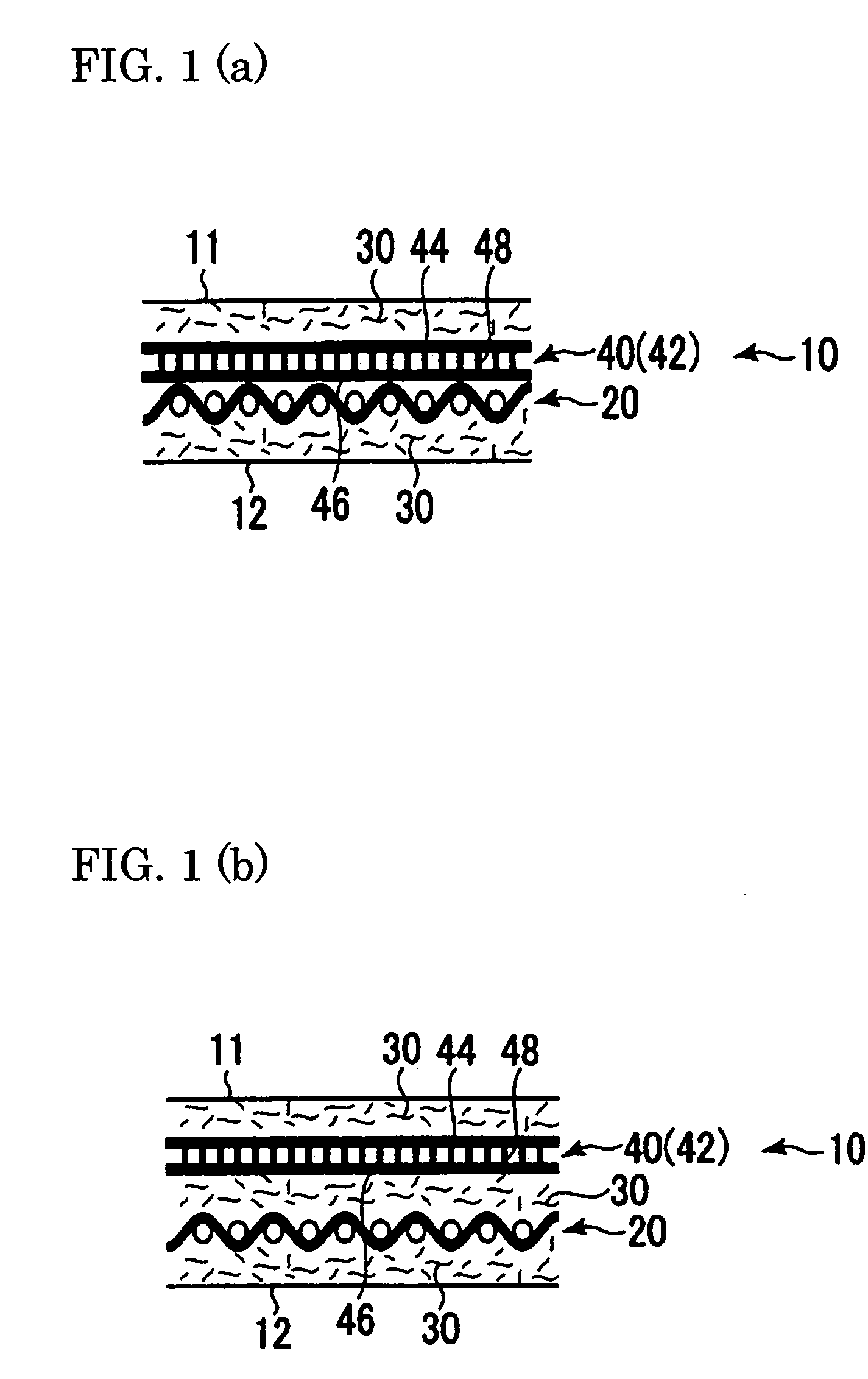

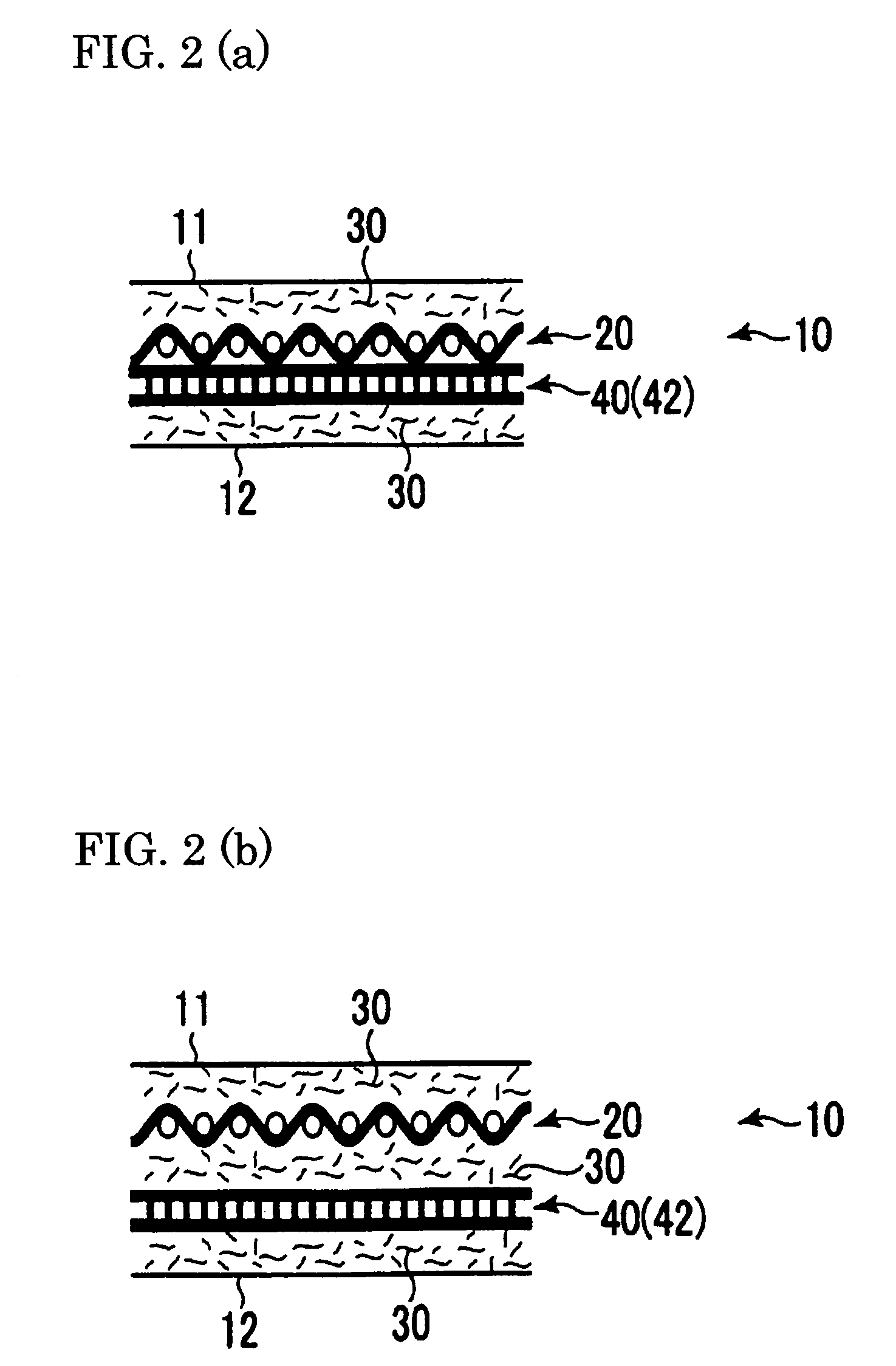

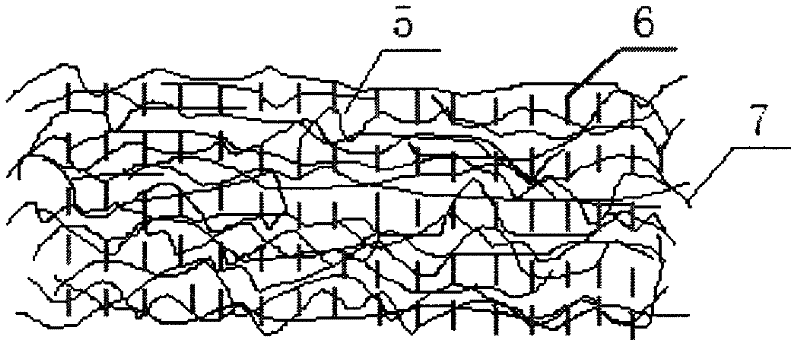

Press felt for papermaking and manufacturing method

InactiveUS7105077B2Improve adhesionExcellent compression recovery performanceLayered productsPaper/cardboardPulp and paper industry

A press felt for papermaking comprises a base body, a fibrous assembly, and a three-dimensional knitted fabric within the interior of the felt. The base body and the knitted fabric may be in contact, or, for improved adhesion between the base body and the knitted fabric, a fibrous assembly may be disposed between the base body and the knitted fabric. Excellent compression recoverability and sustainability may be obtained.

Owner:ICHIKAWA ELECTRIC CO LTD +1

Elastic knitting fabric having multilayer structure and method for producing the fabric

InactiveCN100570030CImprove tensile propertiesImproved shape stabilityWeft knittingOrnamental textile articlesFiberPolymer science

Owner:ASAHI KASEI KK

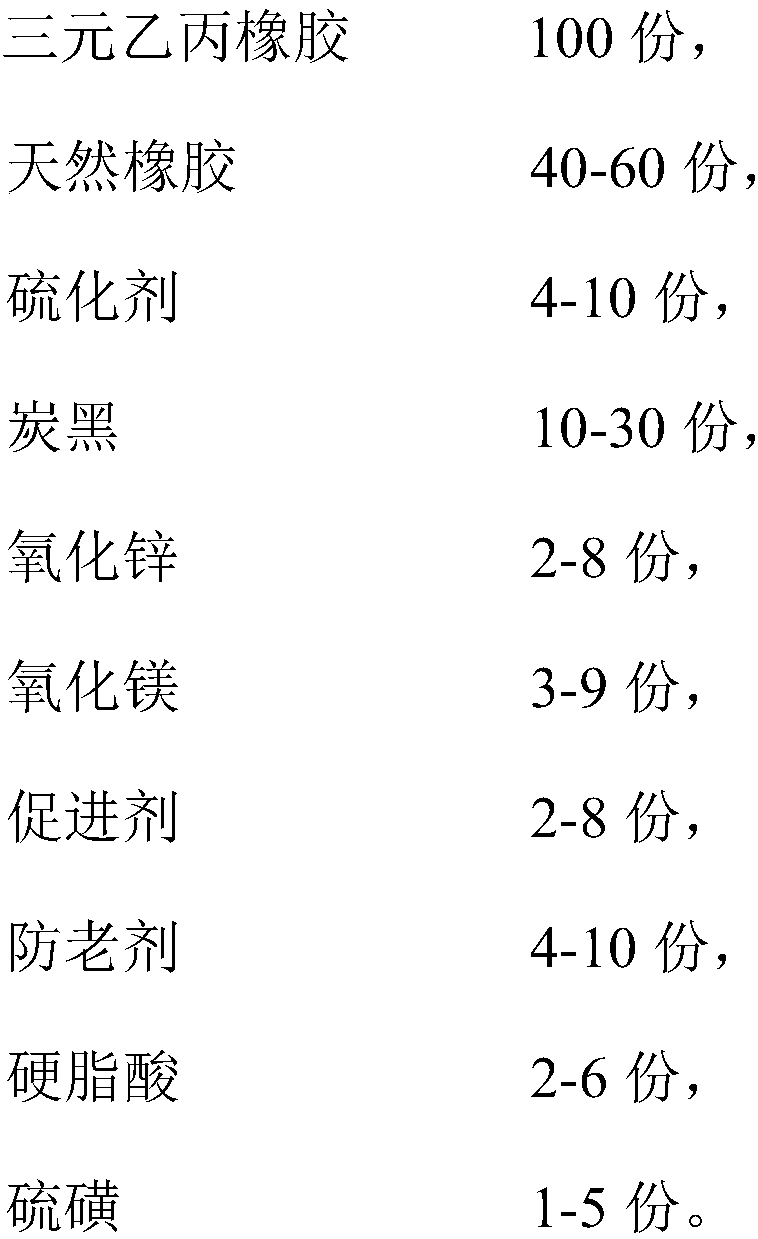

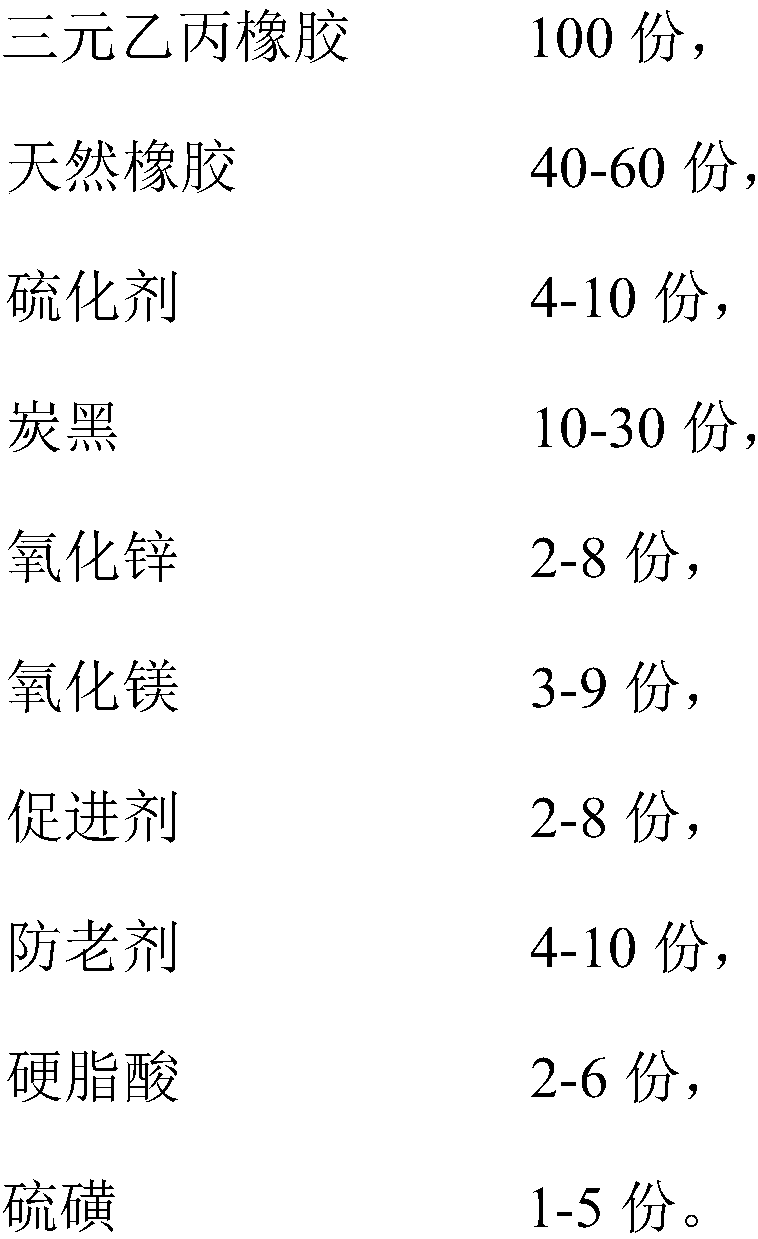

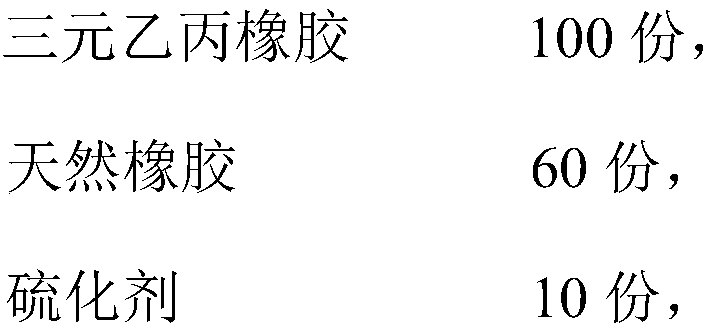

EPDM/ natural rubber combined ageing-resistant rubber and preparation method thereof

InactiveCN108841090AExcellent compression recovery performanceReduce surface tensionBulk chemical productionVulcanizationPolymer science

The invention discloses an EPDM / natural rubber combined ageing-resistant rubber and a preparation method thereof. The method comprises the following steps: (1) preparing EPDM masterbatch; (2) preparing natural masterbatch; (3) mixing EPDM / natural rubber; and (4) vulcanizing the rubber compound and a vulcanizing agent for 20-60min in a vulcanizing machine in order to form to obtain the ageing-resistant rubber. According to the method, a supercritical carbon dioxide technology is carried out, the PEDM / natural rubber mixed rubber is subjected to supercritical treatment before vulcanizing, so that the compatibility and the co-vulcanization performance of the two-phase rubbers can be extremely improved, and the vulcanizing rate of the rubber compound is effectively increased; and the obtained rubber realizes the effective combination of the outstanding performances of the EPDM / natural rubber; the prepared rubber is outstanding in ageing resistance and mechanical performance and meets the performance demand of various special environments to a sealing material.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

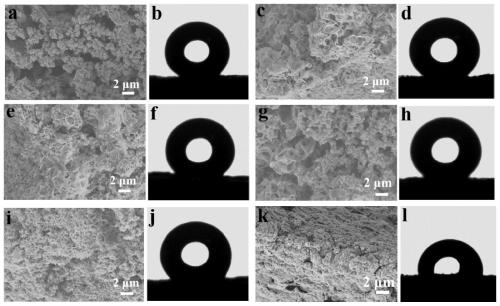

Flexible high flame retardant biologic aerogel material and preparation method thereof

ActiveCN109485910AAnisotropicImprove mechanical propertiesCoatingsPolymer scienceLimiting oxygen index

The invention discloses a preparation method of a flexible high flame retardant biologic aerogel material. The preparation method comprises the following steps: preparing a biomass macromolecular solution; uniformly mixing the biomass macromolecular solution with a synthesized resin precursor solution to obtain a mixed solution, then quickly placing the mixed solution at -20 to -200 DEG C to be cooled in a single direction and freezing the mixed solution to a solid; and finally, freezing and drying the solid in a freeze dryer to obtain a biologic aerogel and crosslinking the biologic aerogel in a dried vacuum environment or a dried alkaline vacuum environment at 150-200 DEG C for 0.5-50 h to obtain the flexible high flame retardant biologic aerogel material. The material has anisotropic mechanical property, has high axial strength and has rebound resilience radially. The pore wall of the material has a porous structure, and the aerogel prepared by the porous material has an ultralow heat conductivity coefficient which is 0.002-0.02W / (m.K). The density of the material is 16-181 kg / m<3>, the extreme oxygen index is 24.0-39.0%, the peak heat release rate is 55.6-245.6 kW / m<2>, and thecontact angle of the aerogel is 60-148 degrees.

Owner:SICHUAN UNIV

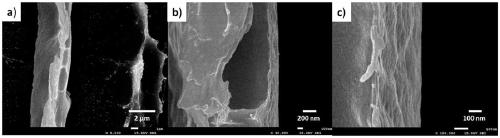

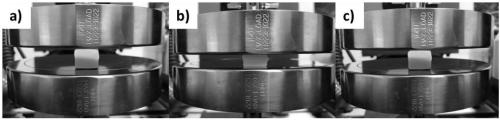

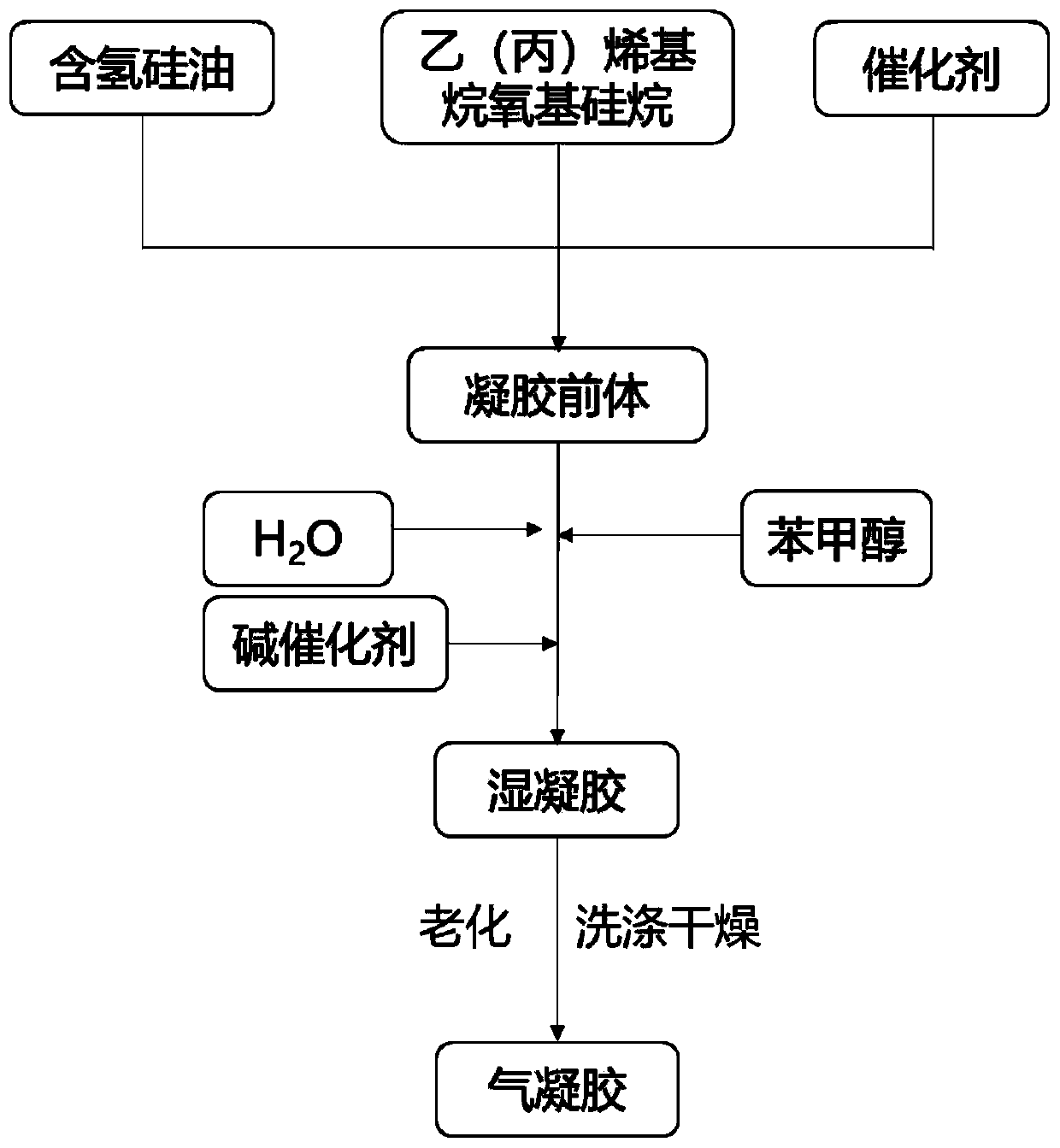

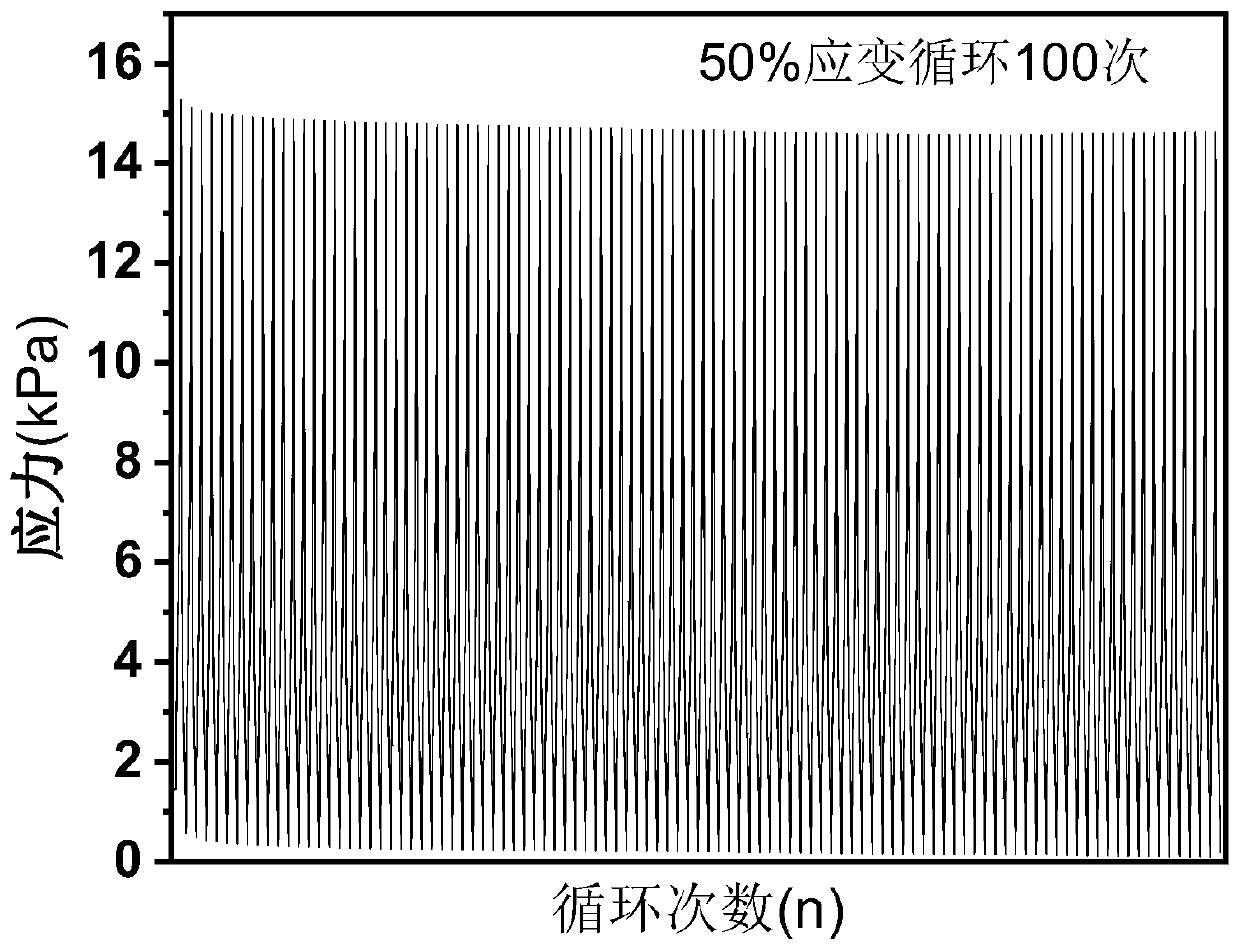

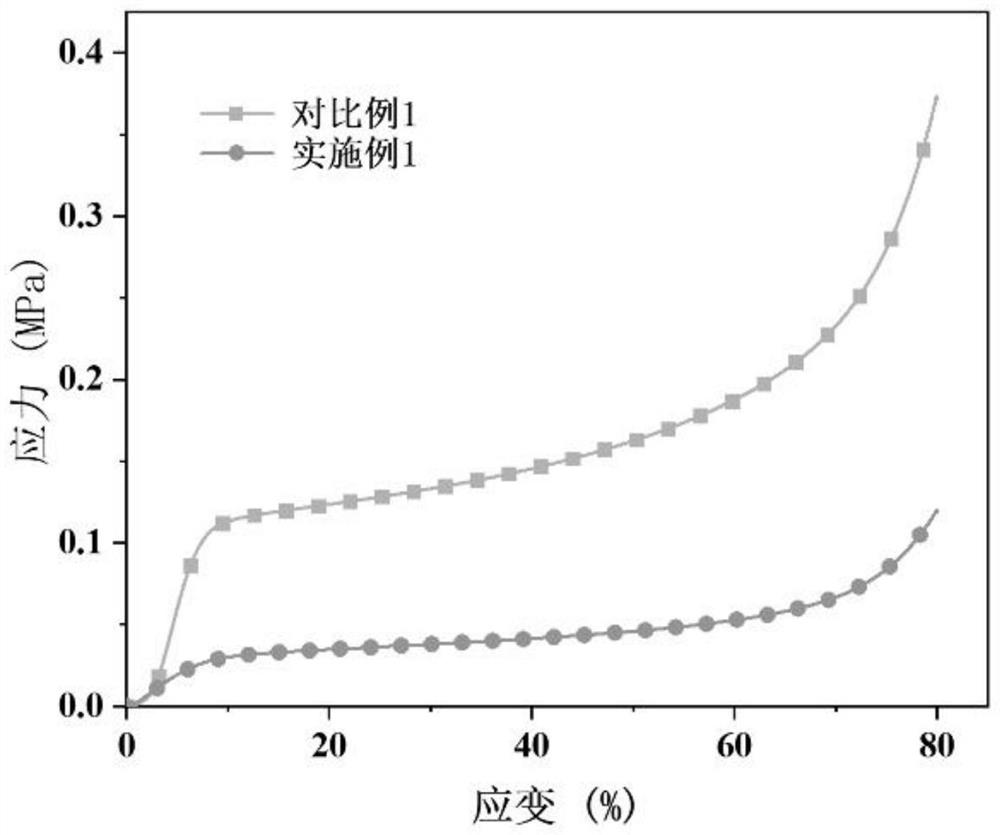

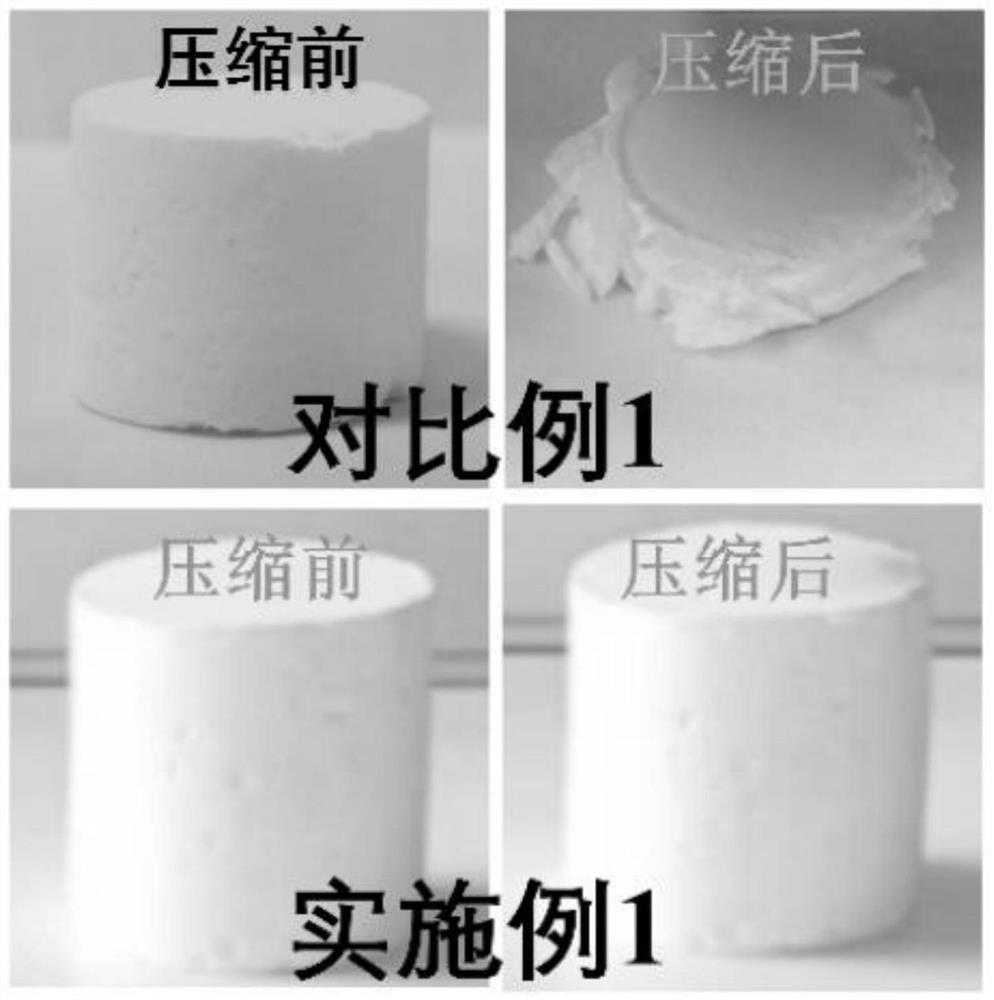

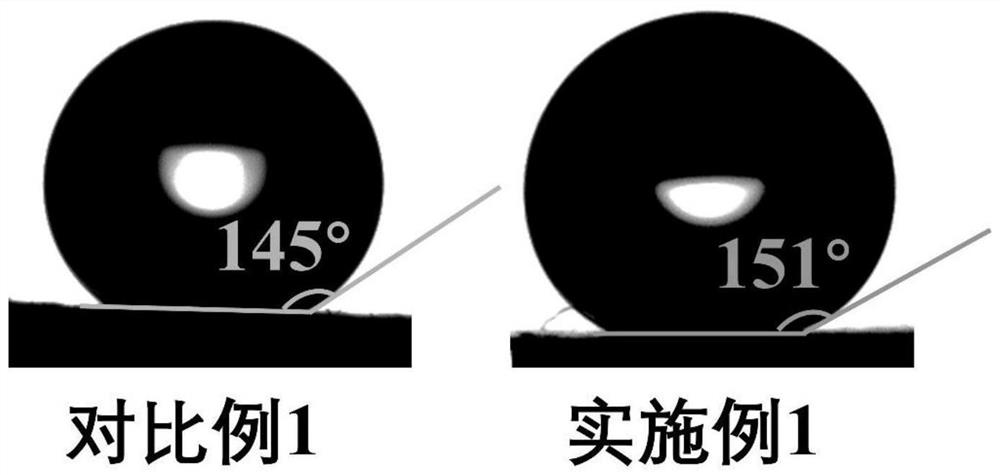

Super-hydrophobic organic silicon aerogel as well as normal-temperature and normal-pressure drying preparation method and application thereof

The invention discloses a normal-temperature and normal-pressure drying preparation method of super-hydrophobic organic silicon aerogel. The method comprises the following steps: (1) mixing hydrogen-containing silicone oil, a component A and a catalyst, and keeping the temperature at 40-70 DEG C to obtain a gel precursor; wherein the component A is vinyl alkoxy silane and / or allyl alkoxy silane; (2) adding an organic solvent, water and an alkali catalyst into the gel precursor, uniformly stirring, and keeping the temperature at 70-90 DEG C to obtain wet gel; and (3) washing the wet gel by using a washing solvent, removing the original solvent and unreacted molecules, then washing the wet gel again by using a low-surface-energy solvent, and finally drying at normal temperature and normal pressure to obtain the super-hydrophobic organic silicon aerogel. The invention also discloses the super-hydrophobic organic silicon aerogel prepared by the preparation method and an application of thesuper-hydrophobic organic silicon aerogel in oil-water separation. The preparation method is simple, high in operability and low in energy consumption, and the obtained aerogel has excellent super-hydrophobic oleophylic performance, low density, excellent compression resilience and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of MXene-based composite aerogel

ActiveCN113101877AWith superelastic mechanical propertiesImprove electrochemical performanceCarbon compoundsNitrogen-metal/silicon/boron binary compoundsFreeze-dryingElectrochemistry

The invention discloses a preparation method of MXene-based composite aerogel. The preparation method comprises the following steps: adding MXene into deionized water, and carrying out ultrasonic treatment and stirring to obtain MXene dispersion liquid; adding functionalized nano cellulose crystals into the MXene dispersion liquid, performing stirring, carrying out molecular self-assembly, adding polyurethane, continuously stirring and carrying out chemical crosslinking; and after the reaction is finished, carrying out liquid nitrogen freezing and ice crystal volatilization to obtain the MXene-based composite aerogel. The preparation method is characterized by taking the functionalized nano cellulose crystals as an assembling agent and a template, carrying out phase separation and self-assembly on the functionalized nano cellulose crystals and MXene two-dimensional nanosheets, then carrying out chemical crosslinking reaction with waterborne polyurethane, and then carrying out directional freeze-drying operation to obtain the MXene-based composite aerogel material with a three-dimensional directional internal pore channel structure. The MXene-based composite aerogel material not only has a super-elastic mechanical property, but also has an excellent electrochemical property.

Owner:NANJING FORESTRY UNIV

Press felt for papermaking and manufacturing method

InactiveUS7381665B2Excellent compression recovery performanceImprove abilitiesLayered productsWarp knittingFiberPulp and paper industry

Owner:ICHIKAWA ELECTRIC CO LTD

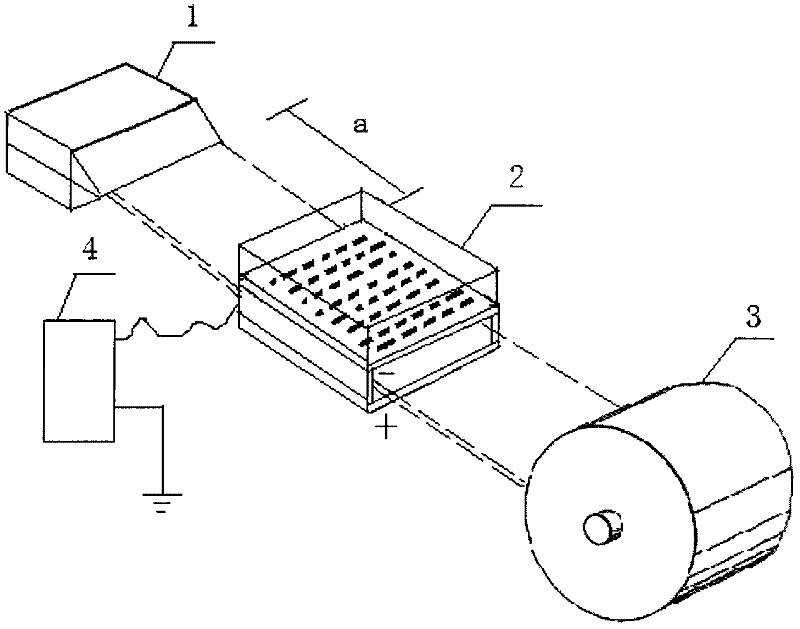

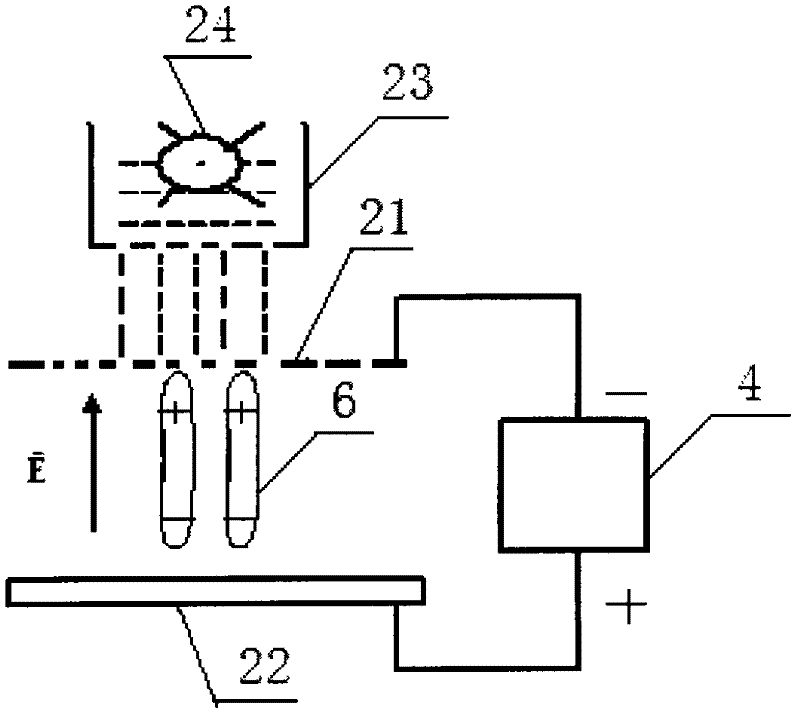

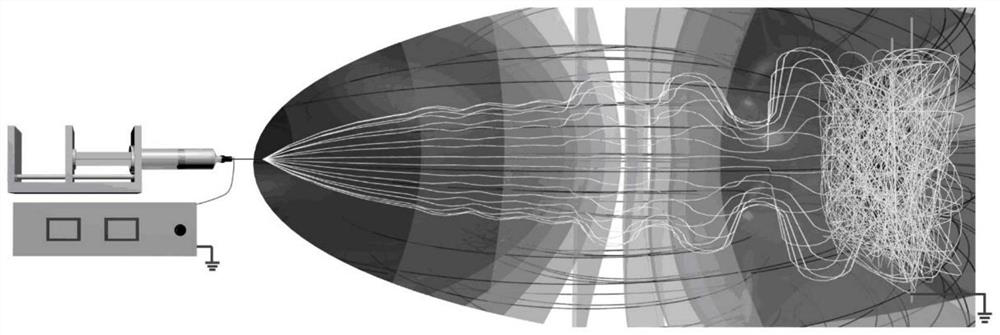

Production method of breathable melt-blown nonwoven fabrics

InactiveCN102517797AMature technologyGood warmth retentionNon-woven fabricsPolytetramethylene terephthalateMicrometer

The invention discloses a production method of breathable melt-blown nonwoven fabrics, which is used for producing polymer superfine fibers by means of well-known melt blowing. The method is characterized in that an electrostatic flocking box is arranged between a melt-blowing die head and a receiving device, superfine fibers pass through the electrostatic flocking box to be adhered with short fibers which perpendicularly fly down in the electrostatic flocking box under the action of an electrostatic field, and breathable melt-blown nonwoven fabrics are formed when the superfine fibers and the short fibers reach the receiving device. The polymer is one of polypropylene, polyester, polybutylene terephthalate, polytrimethylene terephthalate or mixture of the above materials. The short fibers are highly moisture absorbable, 2-20 micrometers in diameter and 3-15 micrometers in length, adding amount of the short fibers accounts for 5-30% of the total weight of the breathable melt-blown nonwoven fabric, and the short fibers are provided by a feeding mechanism. The flocking output voltage of the electrostatic flocking box ranges from 20KV to 60KV, the distance between the melt-blowing die head and the electrostatic flocking box ranges from 10cmm to 40cm, and the distance between an upper pole plate and a lower pole plate in the electrostatic flocking box ranges from 30cmm to 50cm.

Owner:TIANJIN POLYTECHNIC UNIV

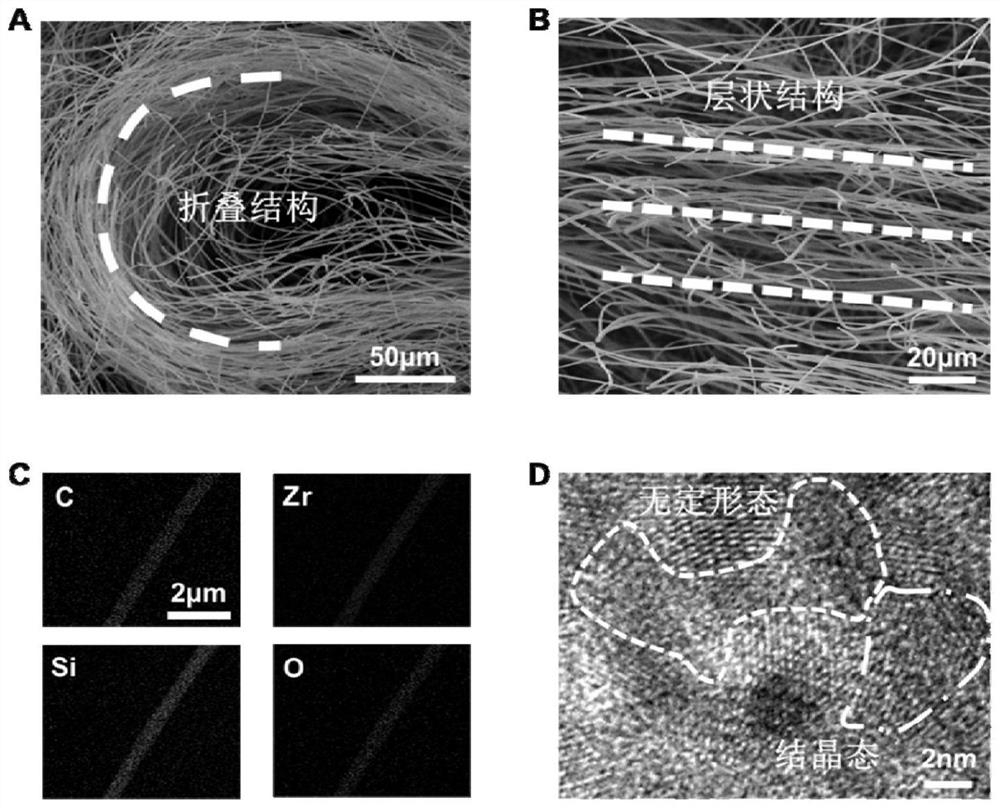

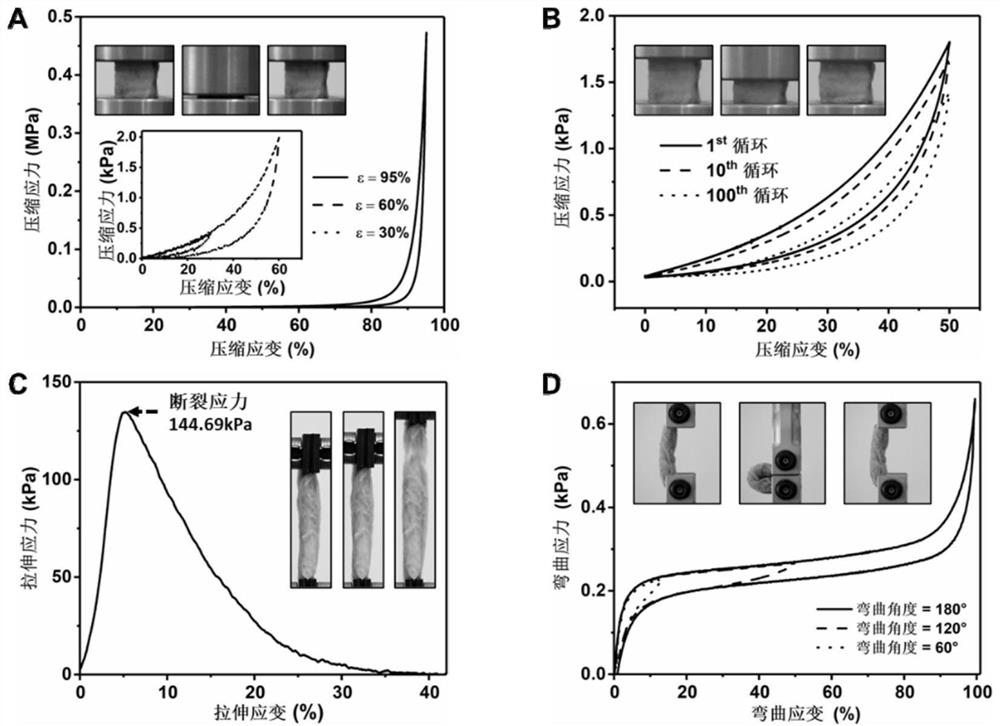

Three-dimensional carbon-rich nanofiber ceramic aerogel and preparation method thereof

ActiveCN113999037AHigh carbon contentGood high temperature insulation performanceCeramicwareSpinningCarbon nanofiber

The invention discloses a three-dimensional carbon-rich nanofiber ceramic aerogel and a preparation method thereof, and the preparation method is based on a far electric field-electrostatic spinning preparation method, and the method specifically comprises the following steps: after highly polymerized zirconium acetylacetonate powder is combined with a phase stabilizer yttrium element, introducing a silane coupling agent KH550 at the same time; co-dissolving macromolecular polyoxyethylene PEO in methanol to prepare a binary silicon-zirconium ceramic electrostatic spinning precursor with high spinnability, and then preparing and forming a binary silicon-zirconium nanofiber ceramic aerogel precursor with a three-dimensional layered structure through a far electric field-electrostatic spinning method; and finally, carrying out step-by-step high-temperature annealing crystallization heat treatment and chemical crosslinking to obtain the three-dimensional carbon-rich nanofiber ceramic aerogel with an intact shape structure. The preparation method provided by the invention has the advantages of low production cost and simple production process, and the prepared three-dimensional carbon-rich nanofiber ceramic aerogel material has high carbon content and excellent high-temperature heat insulation performance and mechanical performance.

Owner:HARBIN INST OF TECH

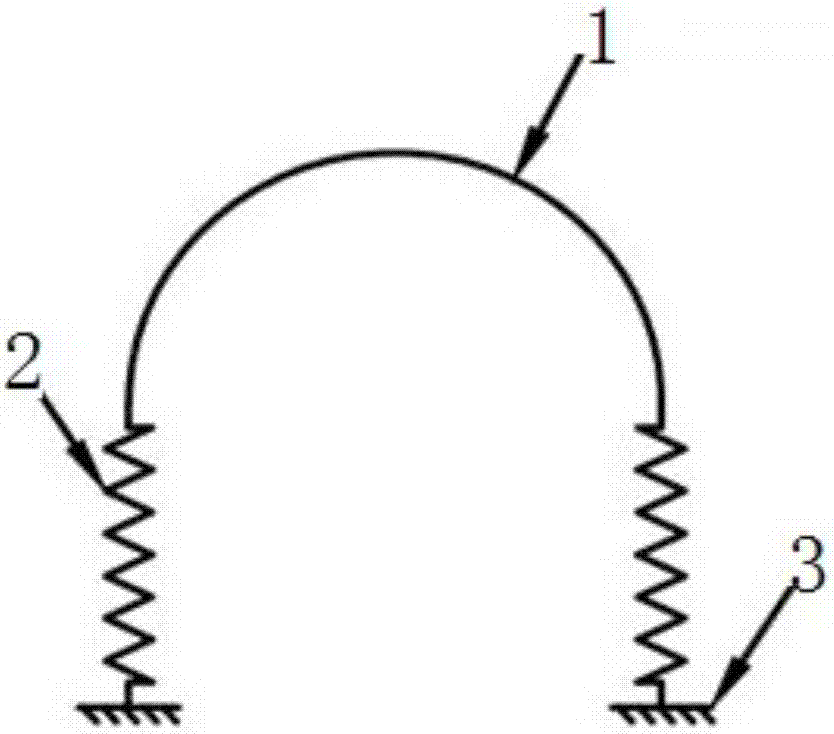

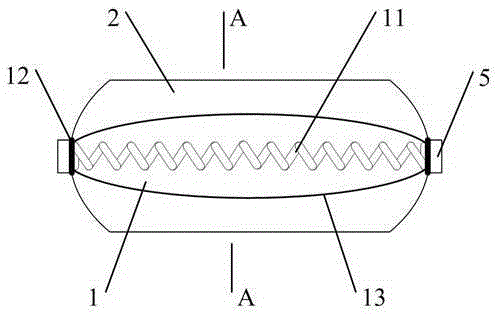

Elastic telescopic fender

InactiveCN105350495AImprove wear resistanceHigh strengthClimate change adaptationShipping equipmentEnergy absorptionEngineering

The invention provides an electric telescopic fender which comprises an electric telescopic shaft, an anti-abrasion layer, a reinforcing layer and a rubber foaming layer. The electric telescopic shaft, the reinforcing layer and the anti-abrasion layer are sequentially and coaxially arranged in a packaged manner from inside to outside. The portion between the reinforcing layer and the electric telescopic shaft is filled with a rubber foaming material, so that the rubber foaming layer is formed. Flange plates are installed at the two ends of the electric telescopic shaft. Compared with the prior art, the quay fender has the beneficial effects of being long in service life, large in compression distance, large in energy absorption capacity and the like.

Owner:JIANGSU SAIER RUBBER CO LTD

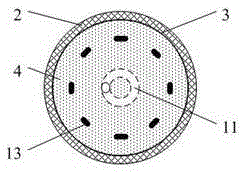

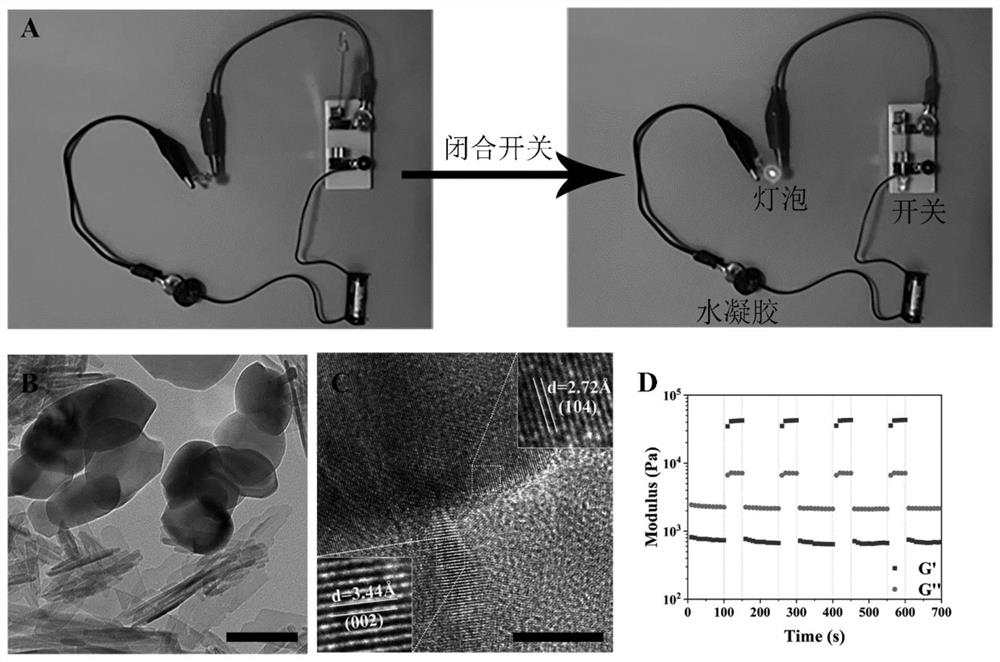

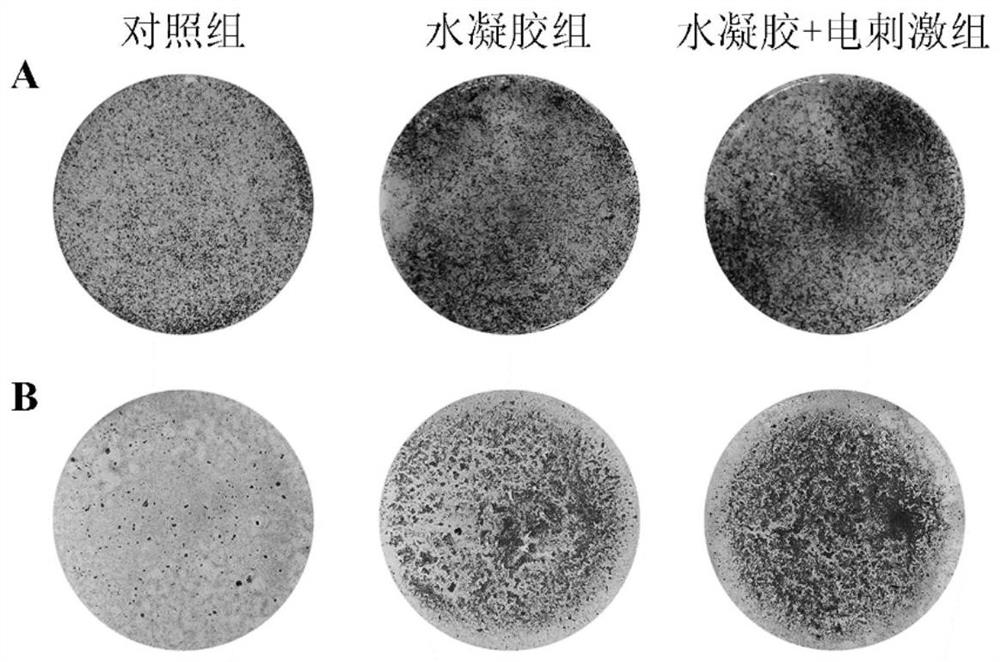

Electroactive perovskite hydrogel suitable for electrical stimulation bone regeneration as well as preparation and application of electroactive perovskite hydrogel

PendingCN114539559ASimple processOperating solutionTissue regenerationExternal electrodesPhotoinitiatorPolystyrene

The invention discloses an electroactive perovskite hydrogel suitable for electrical stimulation bone regeneration, a preparation method of the electroactive perovskite hydrogel and application of the electroactive perovskite hydrogel in preparation of drugs and stents for repairing bone defects. The preparation method comprises the following steps: dissolving sodium alginate powder in deionized water, adjusting the pH value to 7.4-8.0 by using a sodium hydroxide solution, dropwise adding a methacrylic anhydride solution, and stirring for reaction to obtain a methacrylic acid grafted sodium alginate solution marked as a solution A; dialyzing and drying the solution A to obtain methacrylic acid sodium alginate powder, and dissolving the methacrylic acid sodium alginate powder in deionized water to obtain a purified solution B; adding calcium phosphate, perovskite and poly (3, 4-ethylenedioxythiophene): poly (styrene sulfonate) into the solution B, and uniformly stirring to obtain a solution C; and dissolving a photoinitiator in the solution C, and carrying out a cross-linking reaction under ultraviolet irradiation to obtain the electroactive perovskite hydrogel suitable for electrical stimulation bone regeneration.

Owner:ZHEJIANG UNIV

Multifunctional super-hydrophobic conductive rubber composite material and preparation method thereof

The invention discloses a multifunctional super-hydrophobic conductive rubber composite material and a preparation method thereof. The method comprises the following steps: soaking rubber foam consisting of 40% of natural rubber and 60% of butadiene styrene rubber into a tetrahydrofuran solution of silver trifluoroacetate; and reducing the silver precursor, and carrying out phase separation on thepartially dissolved polymer matrix in a non-solvent in the reducing solution to obtain the super-hydrophobic conductive rubber foam / silver nanoparticle composite material. The composite material disclosed by the invention has tensile and compression response properties, can be used for detecting human motion by wearable electronic equipment, and is good in stability, excellent in cycle performance and wide in application range; and the material has super-hydrophobic, electric-heating and photo-thermal effects, so that the application of the material in severe environments is broadened.

Owner:YANGZHOU UNIV

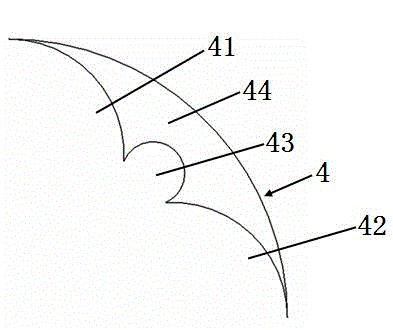

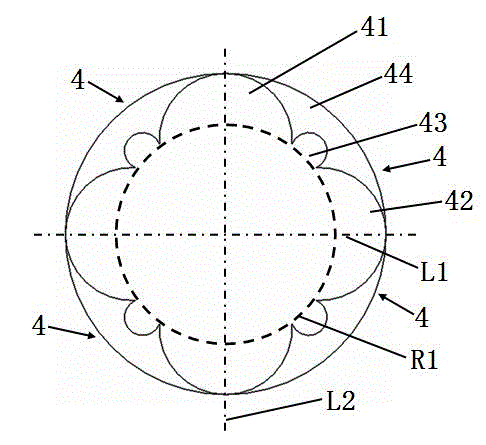

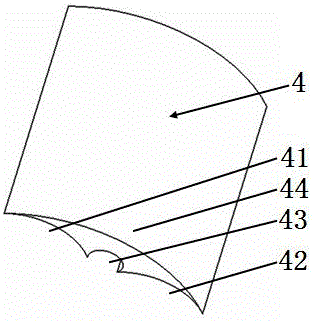

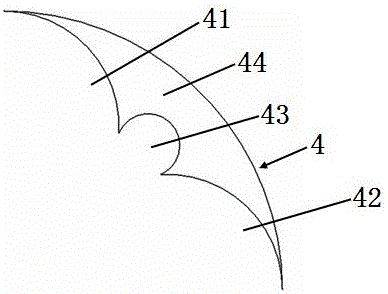

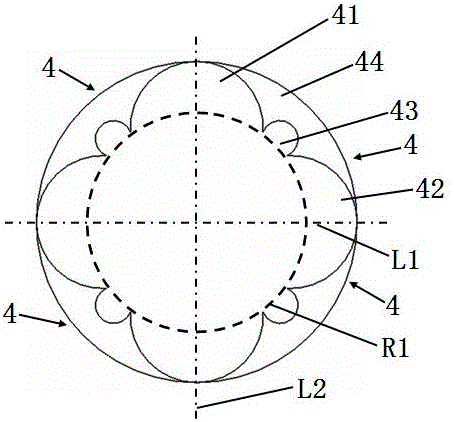

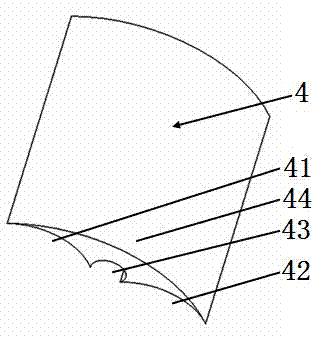

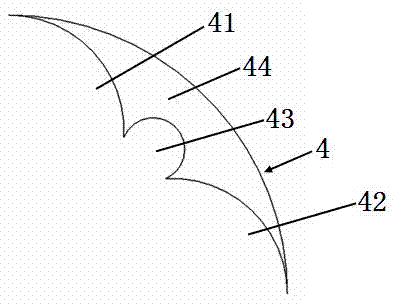

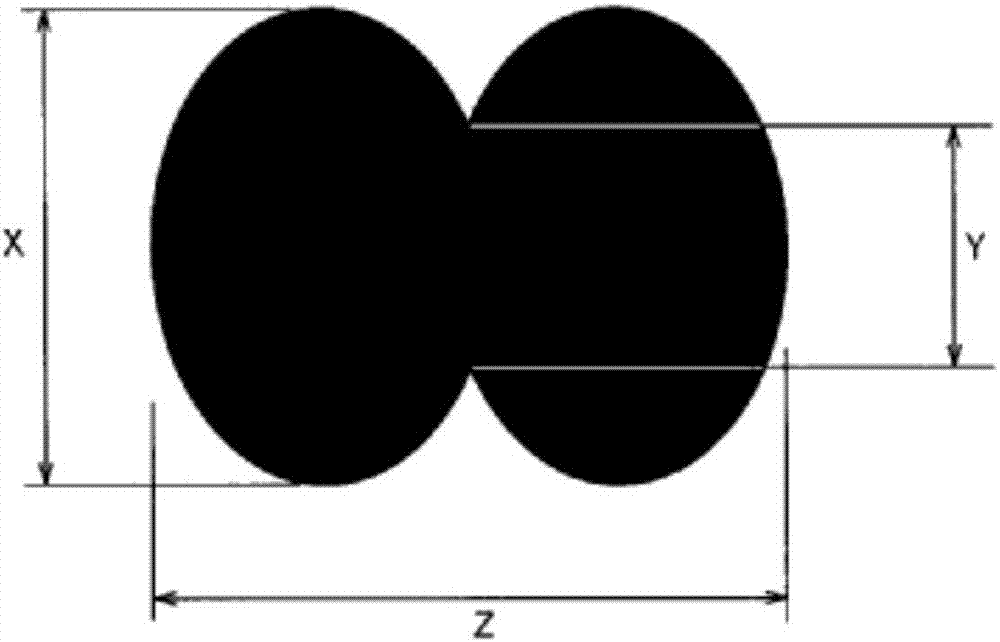

Abnormal-shape filling rope for optical cable, cable, photoelectric composite cable or photoelectric comprehensive cable

InactiveCN104700942ASimple structureEasy to manufactureInsulated cablesFibre mechanical structuresWire rodElectric cables

The invention belongs to the technical field of a wire material and relates to an abnormal-shape filling rope for an optical cable, a cable, a photoelectric composite cable or a photoelectric comprehensive cable. The abnormal-shape filling rope comprises a rope body, wherein the rope body is composed of four cylindrical arcs, the other end of a first cylindrical arc is connected with one end of a third cylindrical arc, the other end of the third cylindrical arc is connected with one end of a second cylindrical arc, one end of a fourth cylindrical arc is connected with one end of the first cylindrical arc, and the other end of the fourth cylindrical arc is connected with the other end of the second cylindrical arc; the first, second, third and fourth cylindrical arcs are bent along the same direction; the first / second cylindrical arc are equal in diameter and arc length; the arc length of the third cylindrical arc is no less than 2 / 3 of the circumference of the circle corresponding to the arc and no more than 4 / 5 of the circumference of the circle corresponding to the arc. The rope body is manufactured by a special method. The abnormal-shape filling rope is simple in structure, easy to manufacture and excellent in performance.

Owner:蒋菊生

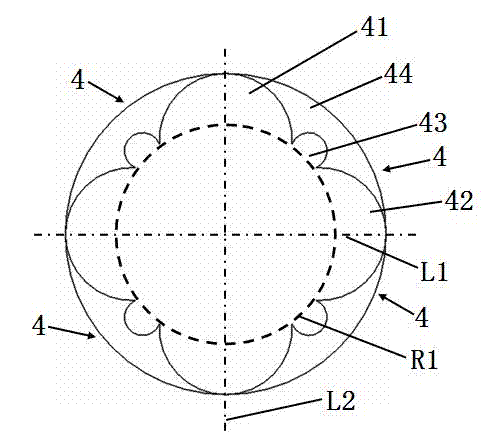

Photoelectric composite cable with special-shaped filling material

InactiveCN105788742ASimple structureEasy to manufactureCommunication cablesFibre mechanical structuresElectrical conductorEngineering

The invention belongs to the technical field of cables, and relates to a photoelectric composite cable with a special-shaped filling material. The cable comprises a reinforcing part, a plurality of power transmission conductors which are located at an outer side of the reinforcing part and sequentially tangential or slightly separated, optical fiber communication units located in gaps outside the adjacent power transmission conductors, a protection layer wrapping the power transmission conductors and the optical fiber communication units, and a sheath layer which covers the protection layer in an extruding manner. The cable is characterized in that the gaps outside the adjacent power transmission conductors are provided with special-shaped ropes; the special-shaped ropes are formed by the sequential jointing or one-time extrusion molding of a plurality of small-structure filling rope bodies; the outer edges of the small-structure filling rope bodies are respectively a complete cylindrical surface; the power transmission conductors respectively consists of a conductor and an insulating body; and the optical fiber communication units respectively consists of an optical fiber and a protection tube wrapping the optical fiber. The special-shaped ropes are made of materials with a special formula. The cable provided by the invention is simple in structure, is lower in cost, is better in performance, and is more convenient in construction.

Owner:蒋菊生

Photoelectric comprehensive cable with irregular filling ropes

ActiveCN104715852ASimple structureEasy to manufacturePlastic/resin/waxes insulatorsCommunication cablesFiber-optic communicationMechanical engineering

The invention belongs to the technical field of cables, and in particular relates to a photoelectric comprehensive cable with irregular filling ropes. The photoelectric comprehensive cable comprises a reinforcing part, a plurality of transmission conductors which are arranged at the outer side of the reinforcing part and are sequentially tangential to each other or arranged at small intervals, optical fiber communication units positioned in outer gaps between the adjacent transmission conductors, protecting layers for wrapping the transmission conductors and the optical fiber communication units, and protecting cover layers which wrap the protecting layers by extrusion molding. The photoelectric comprehensive cable is characterized in that the irregular filling ropes are arranged in the outer gaps between the adjacent transmission conductors; each optical fiber communication unit is clamped into the corresponding irregular filling rope. According to the photoelectric comprehensive cable with the irregular filling ropes, the irregular filling ropes are manufactured from special material; the photoelectric comprehensive cable has the beneficial technical effects of being simple in structure, low in cost, outstanding in performance, convenient to construct and the like.

Owner:河南圣源线缆有限公司

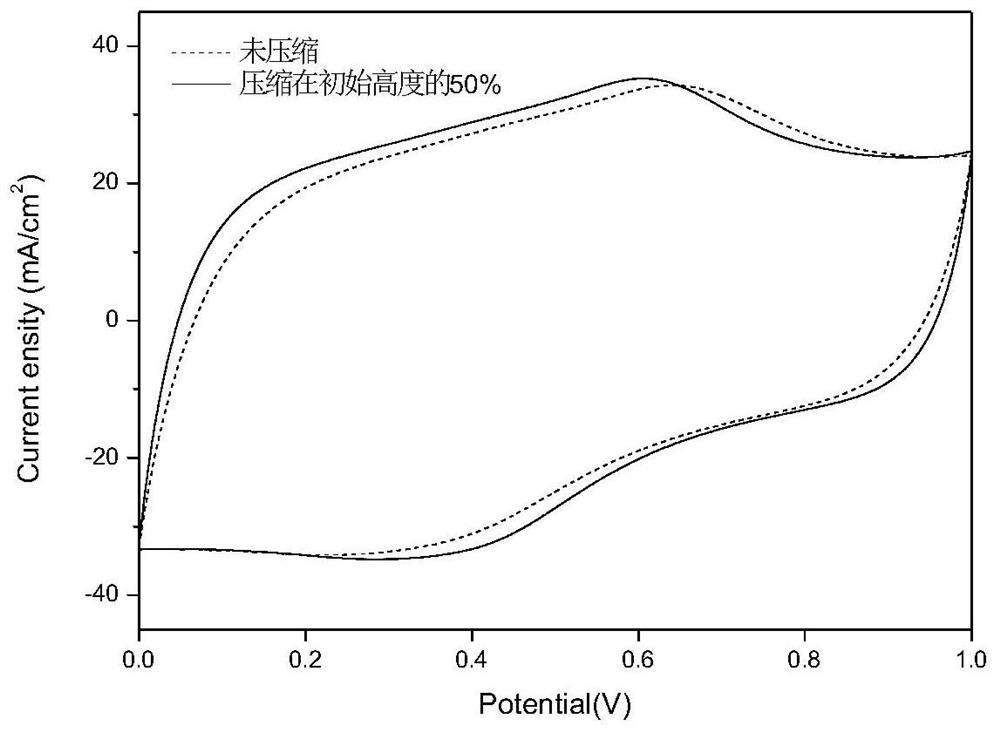

A kind of preparation method of polypyrrole-graphene-polyvinyl alcohol composite airgel

The invention discloses a preparation method of polypyrrole-graphene-polyvinyl alcohol composite aerogel. The preparation method comprises the following steps: (1) dispersing graphene oxide into a dispersing agent, to obtain graphene oxide dispersed liquid with a certain concentration; (2) adding pyrrole, a glutaraldehyde solution and a polyvinyl alcohol solution into the graphene oxide dispersed liquid obtained in the step (1) in sequence, uniformly stirring the components, and allowing the uniform mixture to stand still for a period of time; (3) cyclically freezing and defreezing a composite obtained in the step (2) at low temperature and normal temperature for multiple times, to obtain pyrrole-graphene oxide-polyvinyl alcohol composite aerogel; (4) putting the composite aerogel obtained in step (3) into an oxidant and hydrazine hydrate in sequence, to obtain the polypyrrole-graphene-polyvinyl alcohol composite aerogel. The preparation process of the preparation method is simple; the obtained composite aerogel is extremely high in electrochemical performance and compression resilience, and can be used for producing novel electronic devices such as a compressible supercapacitor.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A strong three-dimensional curly memory fiber and its manufacturing method

InactiveCN103590139BEasy to curlExcellent compression recovery performanceMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyethylene terephthalate glycol

The invention relates to a powerful three-dimensional curly memory fiber and a manufacturing method thereof. Raw materials include: poly(1,4-cyclohexanedimethanol terephthalate) referred to as PCT; propylene glycol terephthalate referred to as PTT; blended and spun through melting and kneading. The invention uses the homogeneously dispersed and stable blend melt formed by melting and blending of polymers to carry out spinning, drawing and other processes to obtain three-dimensional short fibers with excellent curling and memory properties. On the one hand, it is because PCT itself has very good curling and compression recovery properties. In addition, under the synergistic effect of PTT’s high elastic properties, PCT is easier to form multiple and dense curls, and PTT also has excellent memory properties, which can lock Holds the formed curl and always maintains the original curl state.

Owner:YANGZHOU GUANGTAI CHEM FIBER

A kind of polyaniline/graphene/polyvinyl alcohol composite gel and preparation method thereof

The invention discloses a polyaniline / graphene / polyvinyl alcohol composite gel. First, graphene oxide and p-phenylenediamine are dispersed and reacted to obtain aniline-containing graphene; aniline and aniline-containing graphene are subjected to water Thermal reaction to obtain polyaniline / graphene composite gel, which is then immersed in polyvinyl alcohol solution for cyclic freezing and thawing treatment. The present invention uses aniline as a reducing agent and a polymerization monomer at the same time, uses aniline to reduce graphene oxide in a hydrothermal reaction, and initiates the polymerization of aniline through the aniline group grafted on the graphene, and realizes the molecular level of polyaniline and graphene. Composite, and further use the hydrogen bond interaction between polyvinyl alcohol and polyaniline to enhance the mechanical properties of the resulting gel, so that the composite gel has good compression recovery performance, which can be used to prepare compressible supercapacitors, etc.; and the preparation method involved is simple , mild reaction conditions, adjustable composite gel components, suitable for popularization and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A resistance type fire detection/early warning sensor and its application

ActiveCN108109317BEasy to prepareCheap and easy to getFire alarm electric actuationLow voltageFire risk

The invention relates to the field of functional materials. In order to solve the deficiencies and defects of the traditional infrared fire alarms and smoke alarms in the using process at present, theinvention provides a novel resistance type fire detection / early-warning sensor, which is formed by connecting a low-voltage power supply, a warning lamp, a fire early-warning composite material and aplurality of lead wires in sequence, wherein the fire early-warning composite material is prepared from, by weight, 25-45 parts of melamine foam, 8-40 parts of graphene oxide and 15-67 parts of silicon-containing additive. The process is simple and efficient, and the raw material is low in cost. The invention further provides an application of the resistance type fire detection / early-warning sensor. The resistance type fire detection / early-warning sensor is used for monitoring and preventing various types of combustible materials in a high fire risk region, reducing or even avoiding the occurrence of fires and loss caused by the fires.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of high-elasticity super-hydrophobic polystyrene-based porous material

The invention discloses a preparation method of a high-elasticity super-hydrophobic polystyrene-based porous material, which is prepared by in-situ polymerization of styrene, a cross-linking agent A, a cross-linking agent B and an amino compound under the action of an initiator, water and a lipophilic emulsifier. The amino compound is one of 1, 12-diaminododecane, 1, 18-octadecane diamine, polyether amine, polyethyleneimine, aminopropyl terminated polydimethylsiloxane and ethidene diamine, and the amino compound is one of 1, 12-diaminododecane, 1, 18-octadecane diamine, polyether amine, polyethyleneimine, aminopropyl terminated polydimethylsiloxane and ethidene diamine; the cross-linking agent A is one of divinyl benzene, N, N-methylene bisacrylamide, glycidyl methacrylate, glycidyl acrylate and glycidyl ether; and the cross-linking agent B is one of triallyl isocyanurate, pentaerythritol triacrylate, trimethylolpropane triacrylate, ethylene glycol dimethacrylate and dipentaerythritol pentaacrylate. The porous material prepared by the preparation method disclosed by the invention has excellent hydrophobic / oleophylic performance and compression recoverable performance, and oil stain recovery and cyclic utilization of the porous material can be realized in an extrusion mode.

Owner:SOUTHWEST PETROLEUM UNIV

High-shrinkage polyacrylonitrile fibers, yarns containing the fibers, and pile fabrics using the yarns with different pile heights

ActiveCN105705687BImprove fluffing effectExcellent compression recovery performanceElectroconductive/antistatic filament manufactureArtificial filament washing/dryingYarnSingle fiber

The present application provides polyacrylonitrile fibers suitable for pile fabrics with different pile heights such as high pile cloth, yarns containing the fibers, and pile fabrics using the yarns. The polyacrylonitrile fiber is a highly shrinkable polyacrylonitrile fiber with a single fiber fineness of 1-7dtex, a shrinkage rate of 20-40%, and a shrinkage bulk of 0.19-0.30mm3 / g, or a single fiber fineness of 2- 7dtex, polyacrylonitrile fiber with elongation of 50-70% and bulkiness of 0.19-0.30mm3 / g.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com