High-shrinkage polyacrylonitrile fibers, yarns containing the fibers, and pile fabrics using the yarns with different pile heights

A technology of polyacrylonitrile fibers and plush fabrics, which is applied in the field of plush fabrics, can solve the problems of not mentioning shrinkage fibers, etc., and achieve the effect of excellent compression recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] "Example 1"

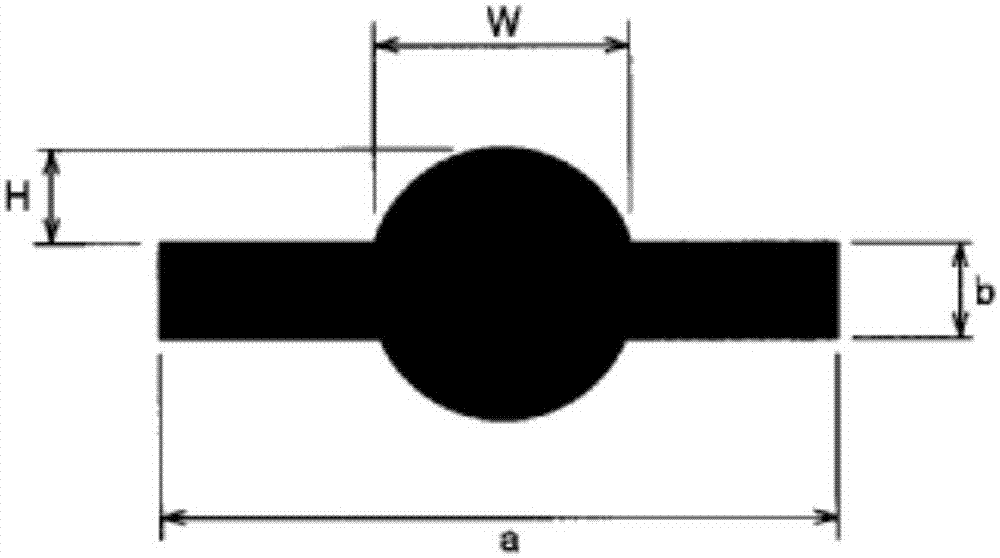

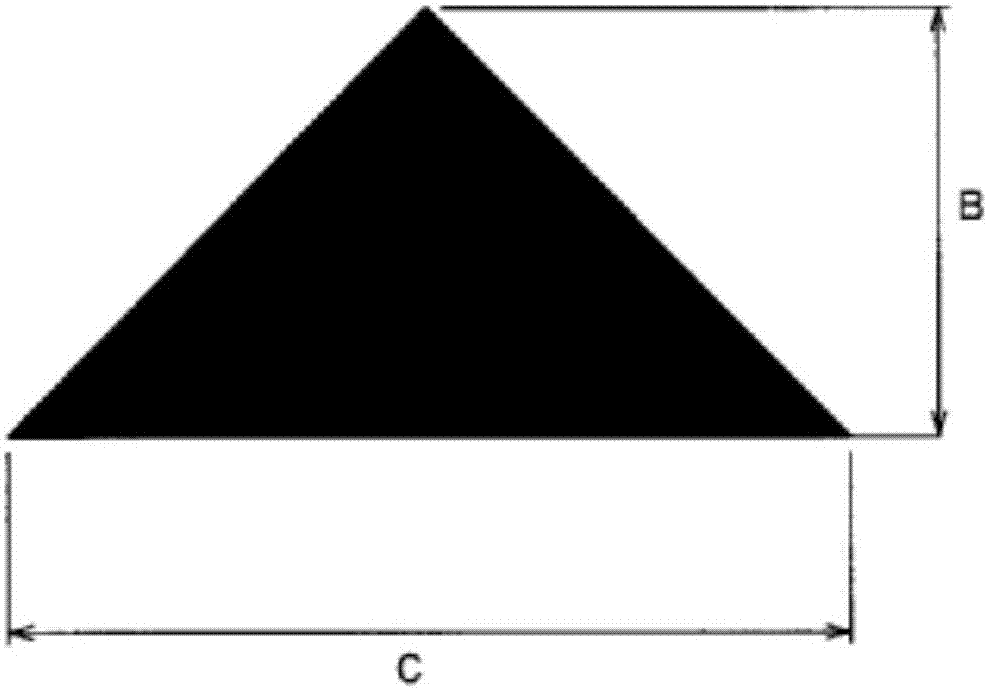

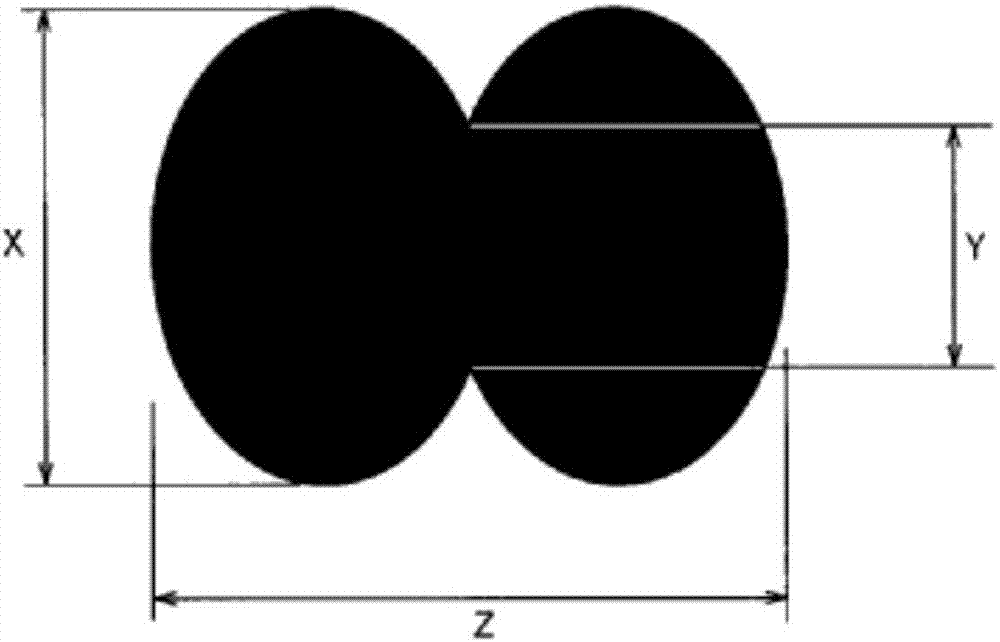

[0171] A copolymer composed of 90% by mass of acrylonitrile and 10% by mass of vinyl acetate was obtained by aqueous suspension polymerization. The polymer had a reduced viscosity of 2.0 in a 0.5% by mass dimethylformamide solution at 25°C. This polymer was dissolved in dimethylacetamide to prepare a spinning dope having a polymer concentration of 24% by mass. The above-mentioned spinning dope was discharged from a discharge hole of a spinning nozzle having a cross-sectional shape described in Table 1 in an aqueous solution of dimethylacetamide having a solvent concentration of 40% at a temperature of 40° C. to obtain coagulated fibers. Further, the above-mentioned coagulated fiber was stretched at a draw ratio of 5 times in hot water, washed, dried by a drying roll, and subjected to thermal relaxation treatment in a pressurized steam atmosphere, and then, in the steam stretching process Stretching was carried out to 2 times, and further mechanical crimp...

Embodiment 2~5

[0175] "Examples 2-5, Comparative Examples 1 and 2"

[0176] The polyacrylonitrile described in Table 1 and Table 2 was obtained in the same manner as in Example 1, except that the cross-sectional shape of the discharge hole of the spinning nozzle was changed so that the cross-sectional shape of the shrunk polyacrylonitrile fiber was as shown in Table 1. fiber.

[0177] In addition, with regard to the pile fabric having different pile heights, a pile fabric having different pile heights was obtained in the same manner as in Example 1 except that the fibers of the short pile portion were changed to the fibers described above.

[0178] The evaluation results of plush fabrics with different pile heights are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com