Intelligent fuzzing wheel

A kind of fluffing wheel, intelligent technology, applied in the direction of shoe soles, applications, footwear, etc., can solve the problems that the precision of fluffing is not up to the best effect, it is not suitable for large-scale production, and no public technology has been found, so as to improve the quality of grinding, Simple structure, good fluffing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

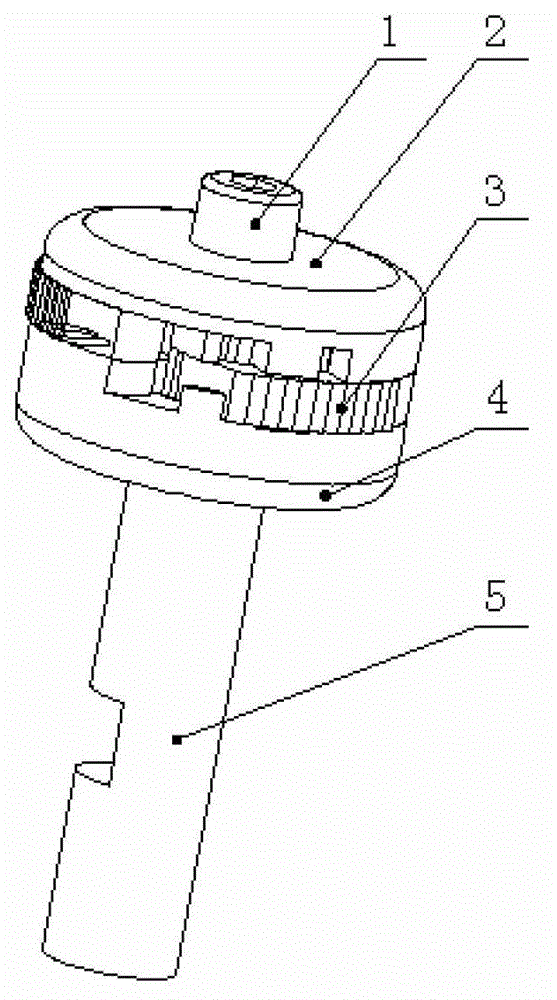

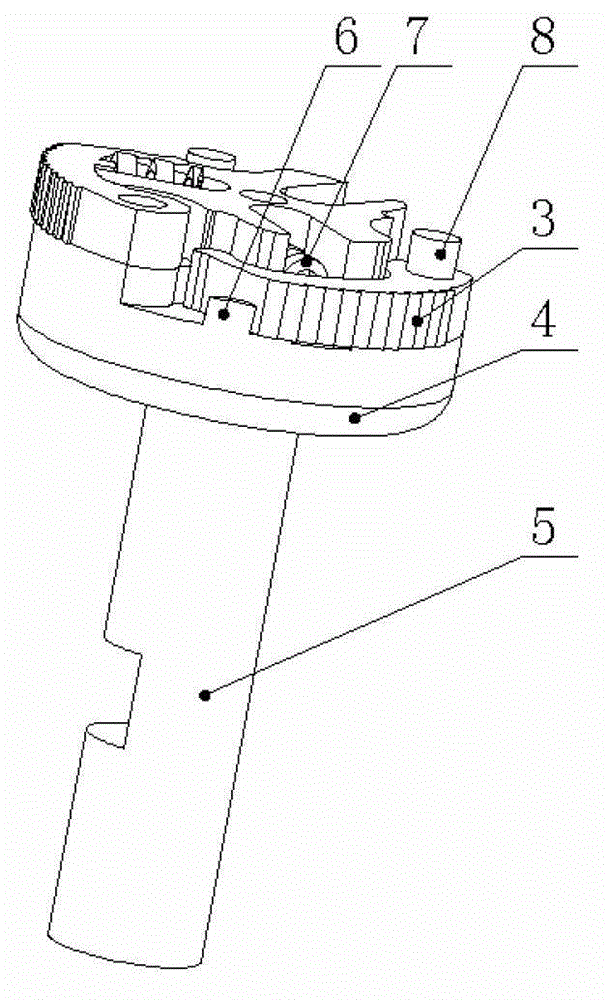

[0022] An intelligent raising wheel, comprising a rotating shaft 5, a base 4, a raising wheel group and a cover plate 2, the upper end of the rotating shaft is coaxially equipped with a base, and the raising wheel with adaptive elastic expansion and contraction is installed on the base Group, the upper end of the raising wheel group is coaxially installed with a cover plate by bolt 1, and the cover plate is the same as the diameter of the raising wheel.

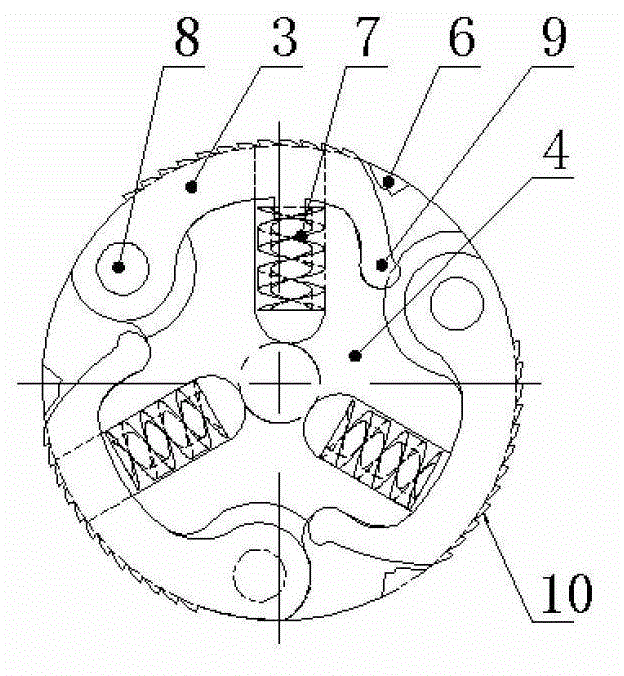

[0023] Described fluffing wheel group comprises alloy tooth block 3, pendulum shaft 8, elastic compression spring 7 and block 6, as Figure 2 to Figure 5 As shown, the plurality of alloy tooth blocks are radially hinged on the base through correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com