Patents

Literature

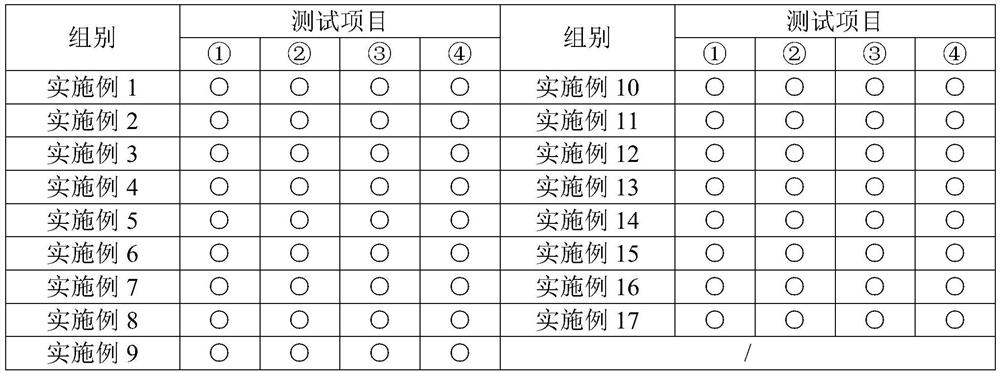

38results about How to "Improve fluffing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

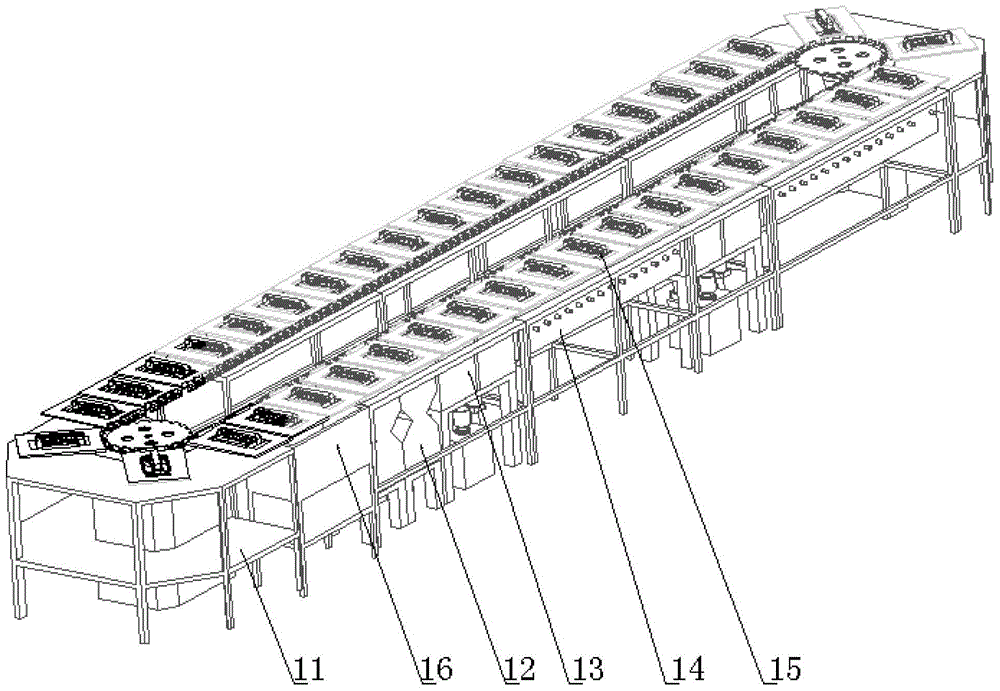

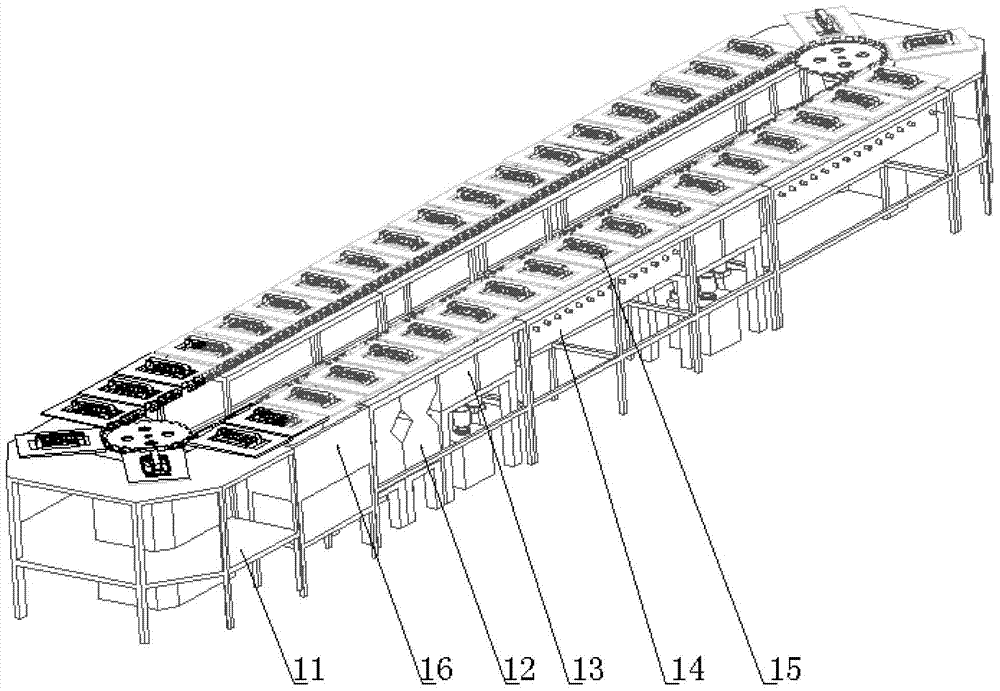

Multi-station full-automatic combined processing system and processing technology for cement shoes

The invention relates to a multi-station full-automatic combined processing system and processing technology for cement shoes. The processing steps are: (1) starting the system, and synchronously installing to-be-processed shoe soles and uppers; (2) performing sandblasting and fluffing, performing fluffing processing on the uppers which enter the system, performing polishing processing on the shoe soles which enter the system; (3) spraying glue, including upper glue spraying and shoe sole glue spraying; (4) drying, that is, after glue spraying is completed, an annular transmission mechanism driving the uppers and the shoe soles to go through a plurality of drying mechanisms in sequence; (5) bonding, that is, taking off the uppers and the shoe soles which complete drying, assembling and matching and fastening the uppers and the shoe soles which complete drying by manual work, to complete a cold bonding process. The system and the technology thoroughly change shoemaking production technology for cement shoes in market, and the system is high in automation degree, workers are librated from heavy and dangerous work. The whole process is completed under control of program of an electrical control system, and the system creates safe, convenient, environmentally-friendly, energy-saving, labor-saving, and perfect work.

Owner:马士通安全设备(天津)有限公司

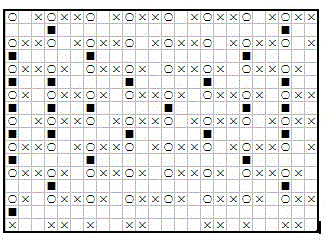

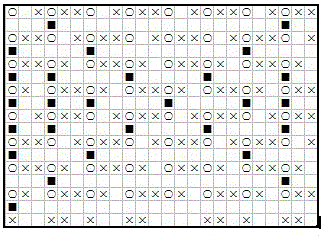

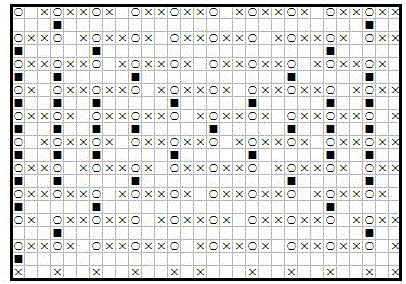

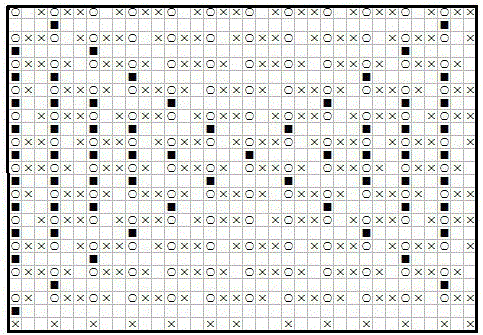

Binding two-layer Waffle fabric

The invention discloses a binding two-layer Waffle fabric, which is formed by interweaving two groups of pure cotton warp yarns and one group of pure cotton weft yarns, wherein warp float long threads and weft float long threads at the front side of the fabric are gradually transited from long ones to short ones or from short ones to long ones, a concave-convex quadrangle with the high edge and the low middle is formed, the opposite side of the fabric is a pile fabric, and the binding two-layer tissue weaving is adopted during the weaving. The binding two-layer Waffle fabric has the advantages that the binding two-layer tissue bound by adopting binding picks is adopted, an air layer inside the fabric is thickened, and the fabric is light and thin and achieves the effects of ventilation and heat insulation; the front side of the fabric adopts honeycomb tissues, the float long threads are long, the fabric structure is floppy, and the hand feeling elasticity of the fabric is enhanced; the opposite side of the fabric has a suede effect, the hand feeling softness degree of the fabric is improved, and when the fabric is in contact with a human body, the comfort is good; the float long threads at the opposite side of the fabric are short, the warp density is greater, the fabric structure is very compact, and the dimensional stability of the fabric is favorably realized; the float long threads at the opposite side of the fabric are short, and the use inconvenience caused by too-long float long threads of the fabric is avoided.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

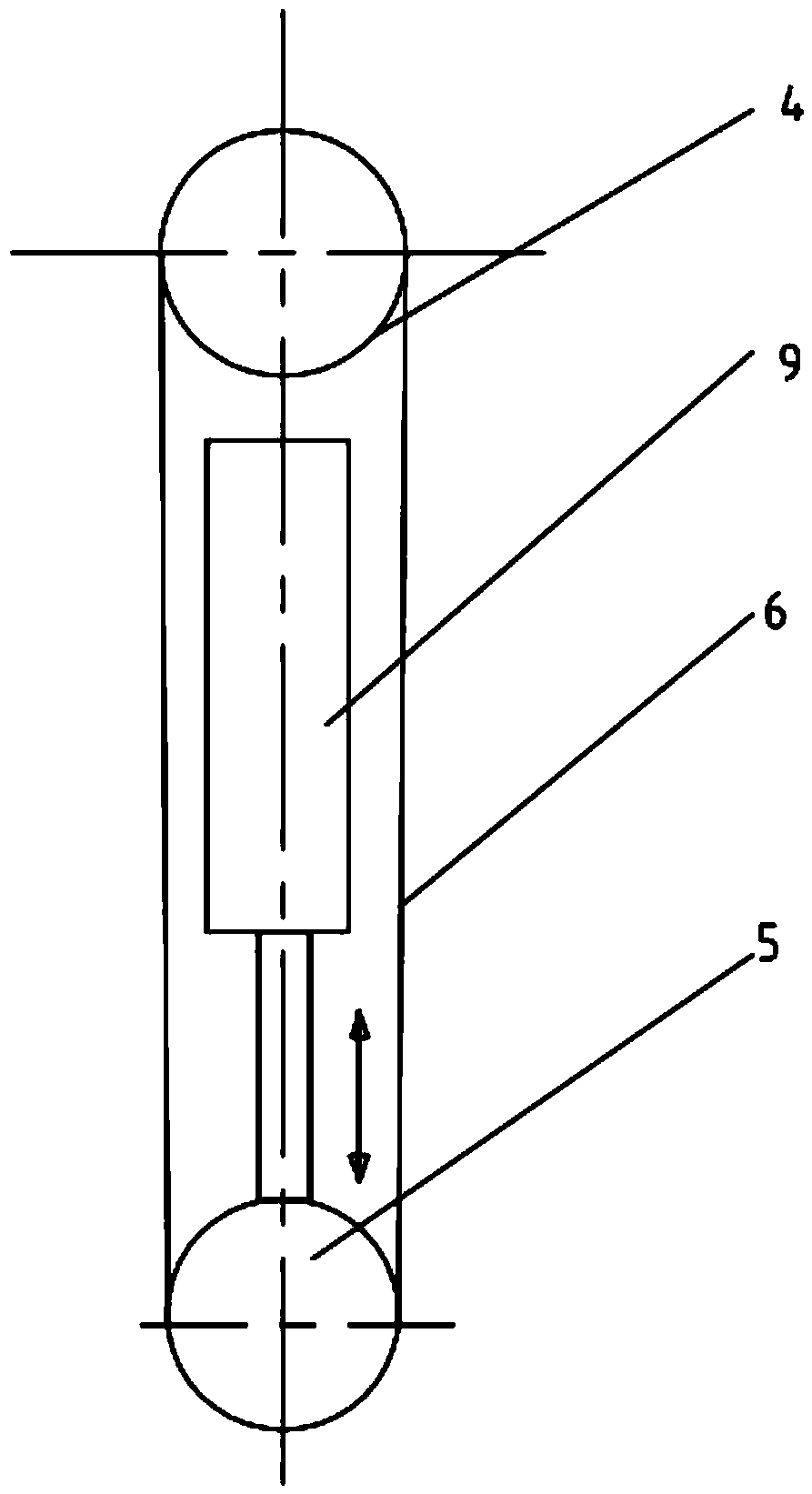

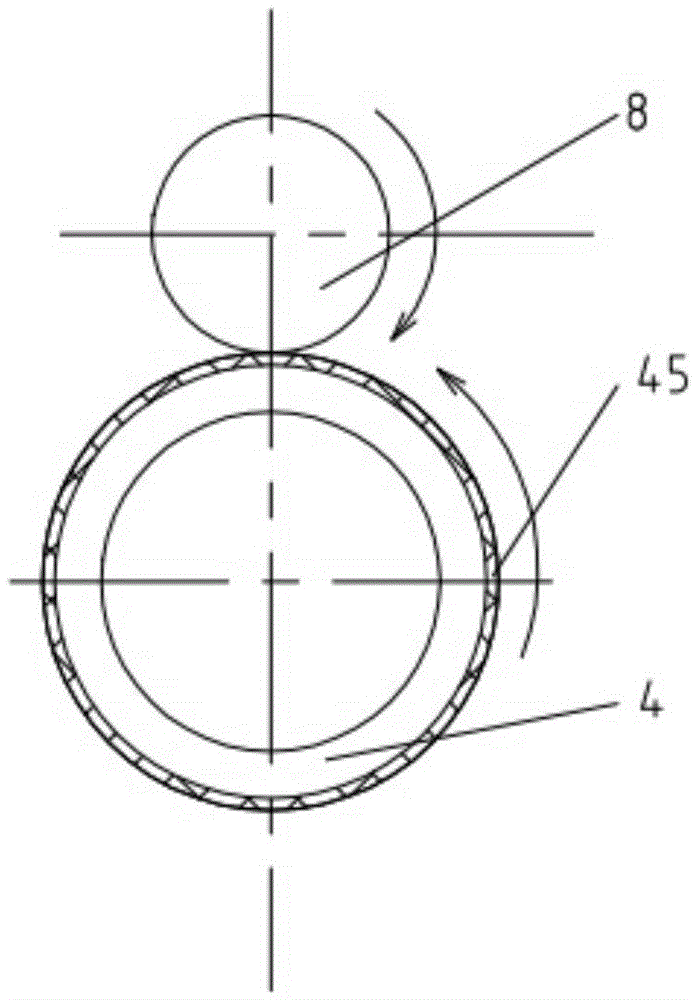

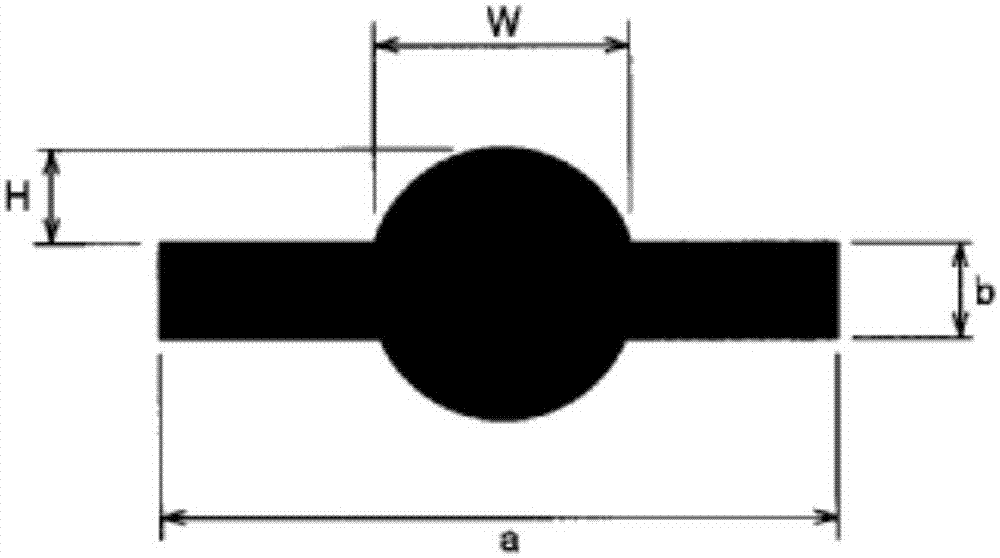

Double-roller frame yarn fluffing device

The invention discloses a double-roller frame yarn fluffing device, comprising a control box, a machine frame, a supporting shaft, an upper roller, a lower roller, a driving mechanism and a reciprocating transmission mechanism, wherein the supporting shaft is arranged on the machine frame; the upper roller is rotatably supported on the supporting shaft; the driving mechanism is movably connected with the upper roller so as to drive the upper roller to rotate relative to the supporting shaft; the upper roller and the lower roller are matched for sleeving two ends of frame yarns; the reciprocating transmission mechanism is movably connected with the lower roller so as to drive the lower roller to perform reciprocating movement relative to the upper roller; the control box is respectively connected with the driving mechanism and the reciprocating transmission mechanism in a controlling manner. The double-roller frame yarn fluffing device can achieve the effect of well combing the frame yarns.

Owner:CHANGZHOU TEXTILE GARMENT INST

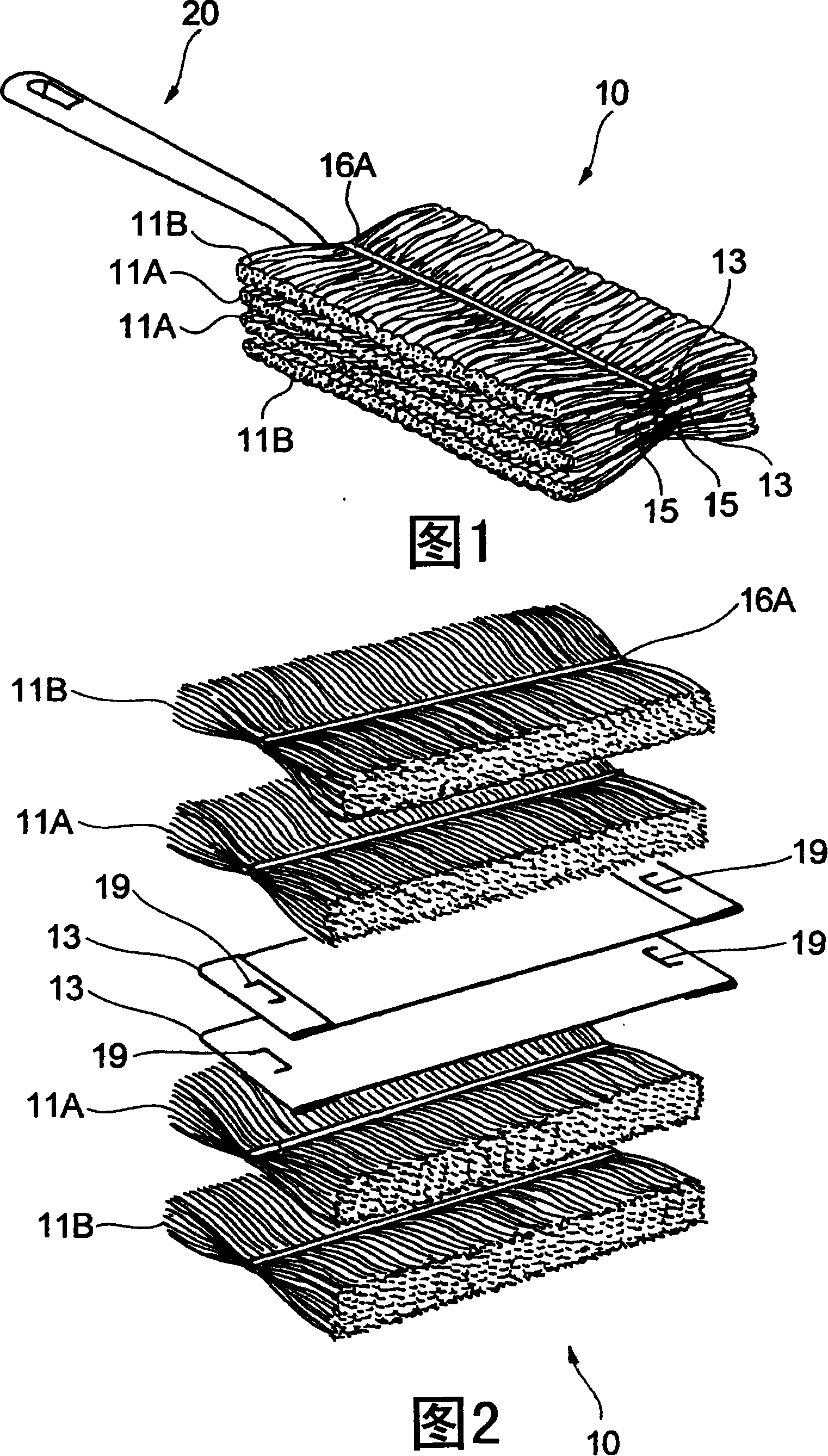

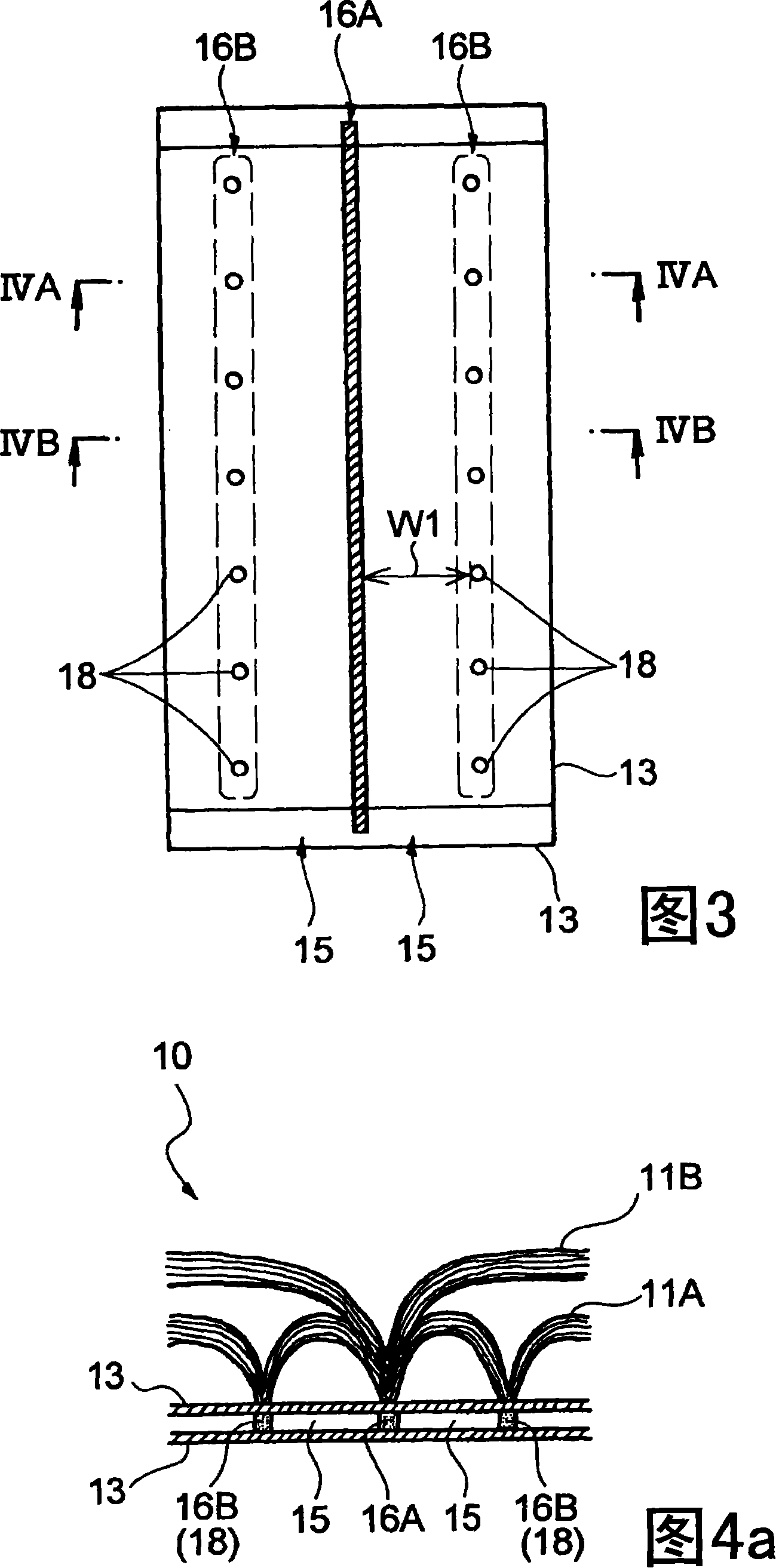

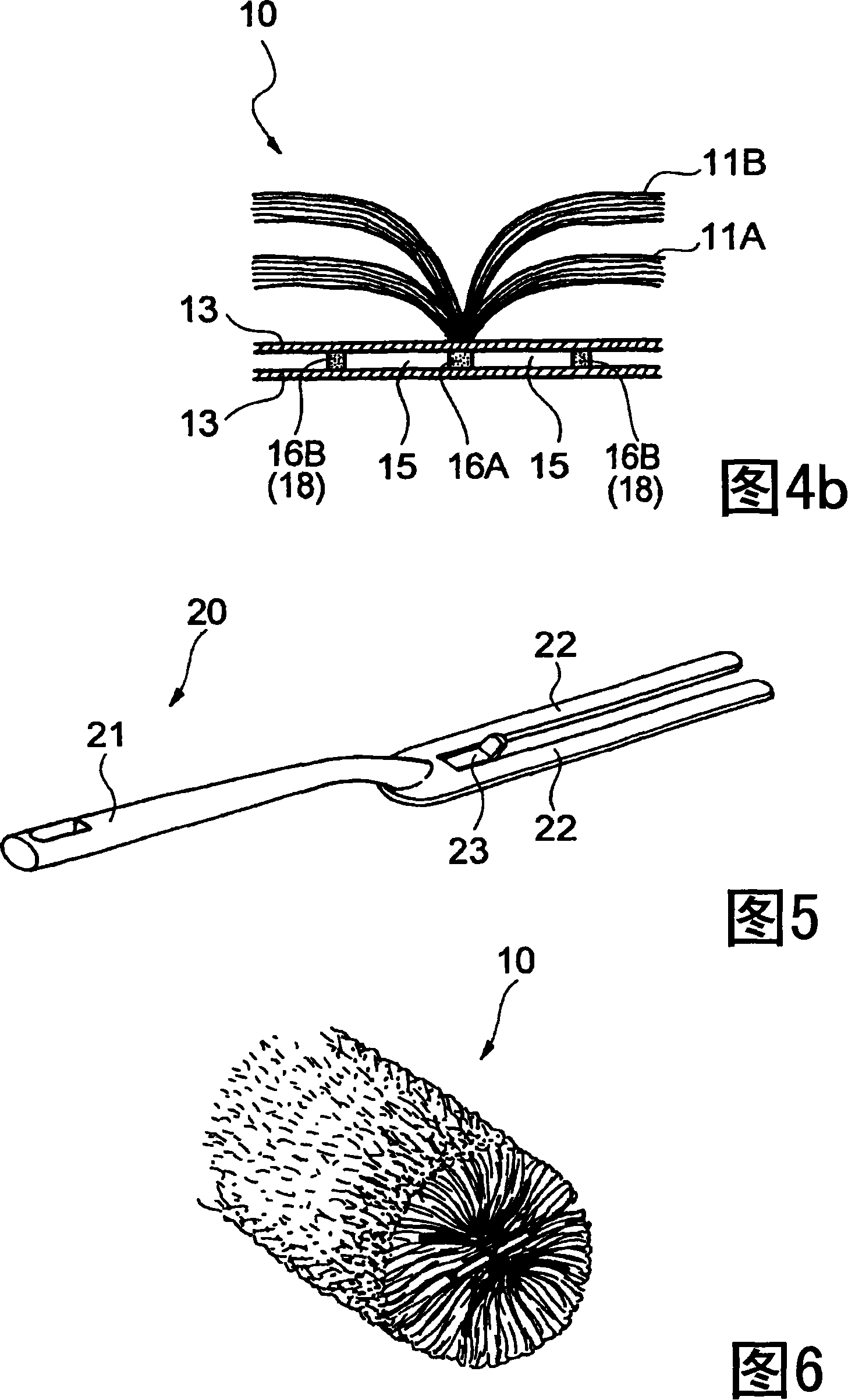

Cleaning article, method of fluffing cleaning article, and method of producing cleaning article

ActiveCN101115430AImprove fluffing effectExcellent compression recovery performanceCarpet cleanersFloor cleanersFiber bundleMechanical engineering

The invention provides a cleaning article (10), which has a flat cylindrical handle insertion part (15), and the handle can be inserted and installed in the handle insertion part (15). The insertion portion forming sheet (13) is joined and formed; on the upper surface and the lower surface of the handle insertion portion (15) on the handle insertion portion forming sheet (13), one or more fiber layers composed of fiber bundles are respectively provided (11A, 11B); the first fiber layer (11A) of the fiber layer (11A, 11B) closest to the handle insertion portion forming sheet (13) side is continuously sealed in the center portion in the width direction by a center extending continuously in the length direction The line (16A) is joined to the handle insertion portion forming sheet (13), at a position separated from the central continuous sealing line (16A) to at least one side outside in the width direction, passing through a side non-continuously extending longitudinally. A continuous seal (16B) is bonded to the handle insert forming sheet (13).

Owner:KAO CORP

Anti-fluffing finishing agent for embroidery and use method thereof

The invention discloses an anti-fluffing finishing agent for embroidery and a use method thereof. The anti-fluffing finishing agent comprises a copolymer, fibroin powder, a surface active agent and deionized water, wherein the copolymer consists of a methacrylamide monomer, a methacrylate monomer, a butyl acrylate monomer and an acrylic-2-hydroxyethyl methacrylate monomer. The use method comprises the following steps of: selecting a writing brush with a proper size to dip a proper amount of anti-fluffing finishing agent for embroidery, uniformly brushing along embroidery patterns multiple times, each in a small amount, till the embroidery patterns are fully wet so as to prevent the finishing agent from permeating to substrates outside the embroidery patterns, then drying the embroidery product by hot air with the temperature of 50-80 DEG C, finally baking the dried embroidery product for 3-5 minutes by using hot air with the temperature of 120-150 DEG C, and after treatment is finished, ironing by using an iron. The anti-fluffing finishing agent and the use method thereof disclosed by the invention have the advantages that after anti-fluffing finishing is carried out on an embroidery product, the fluffing performance of the embroidery product can be greatly improved, and the durability and the quality of the embroidery product can be improved.

Owner:苏州秀艳天下刺绣工艺有限公司

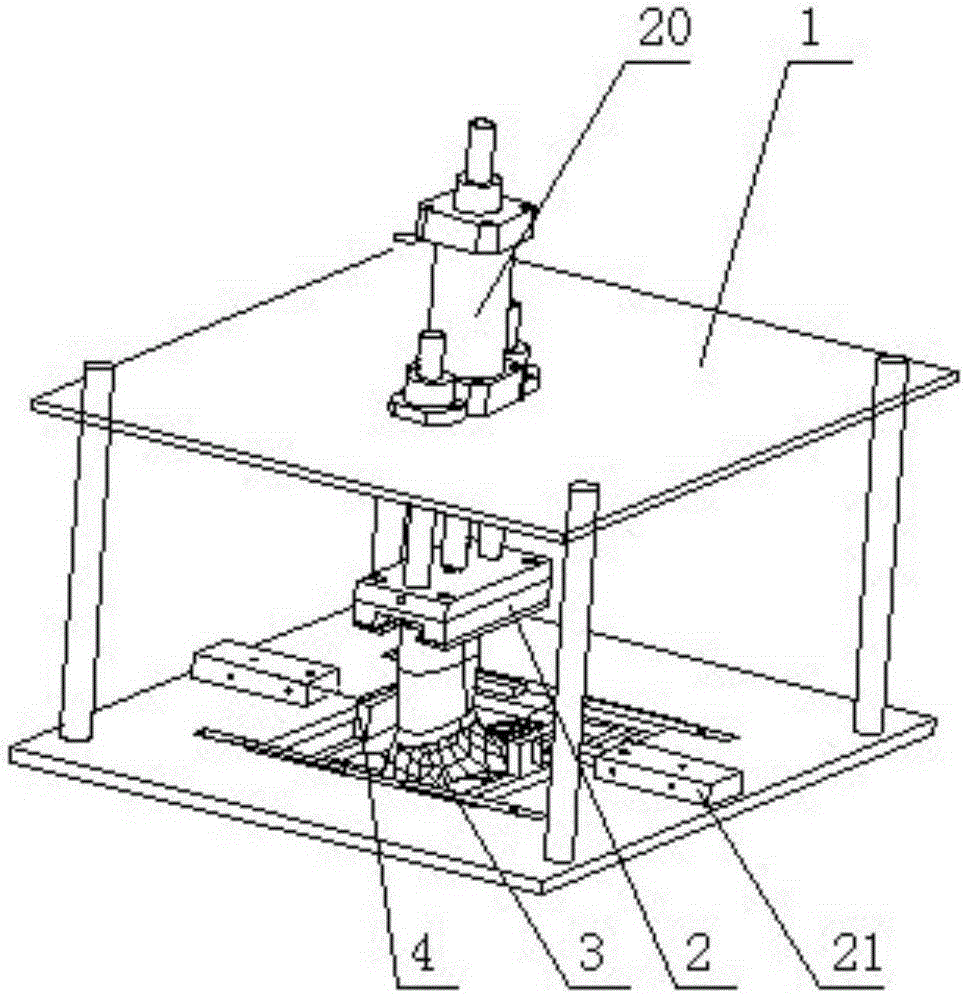

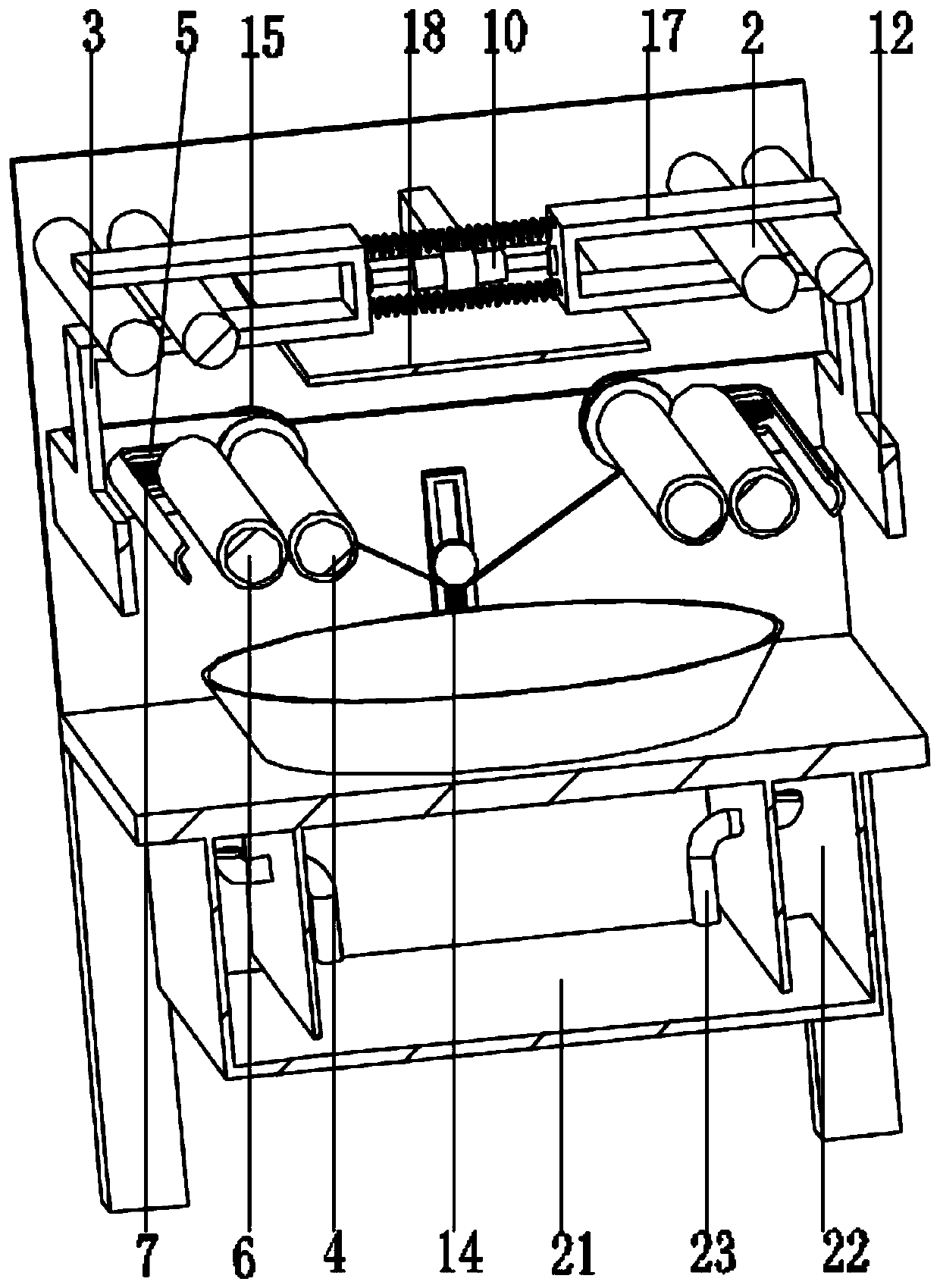

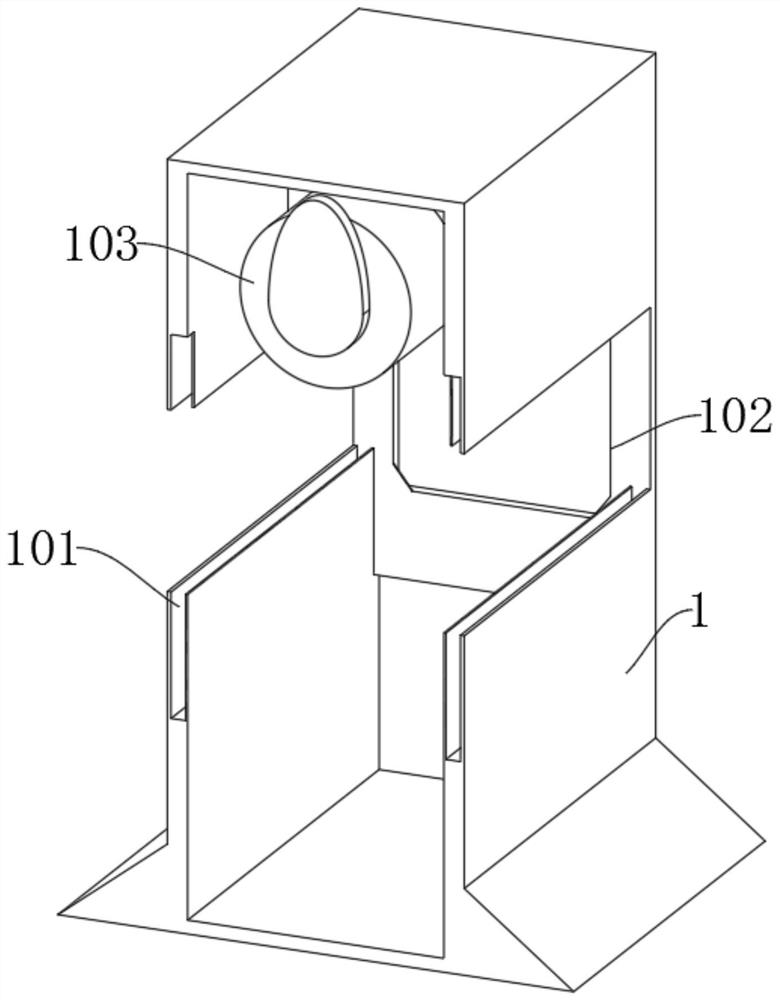

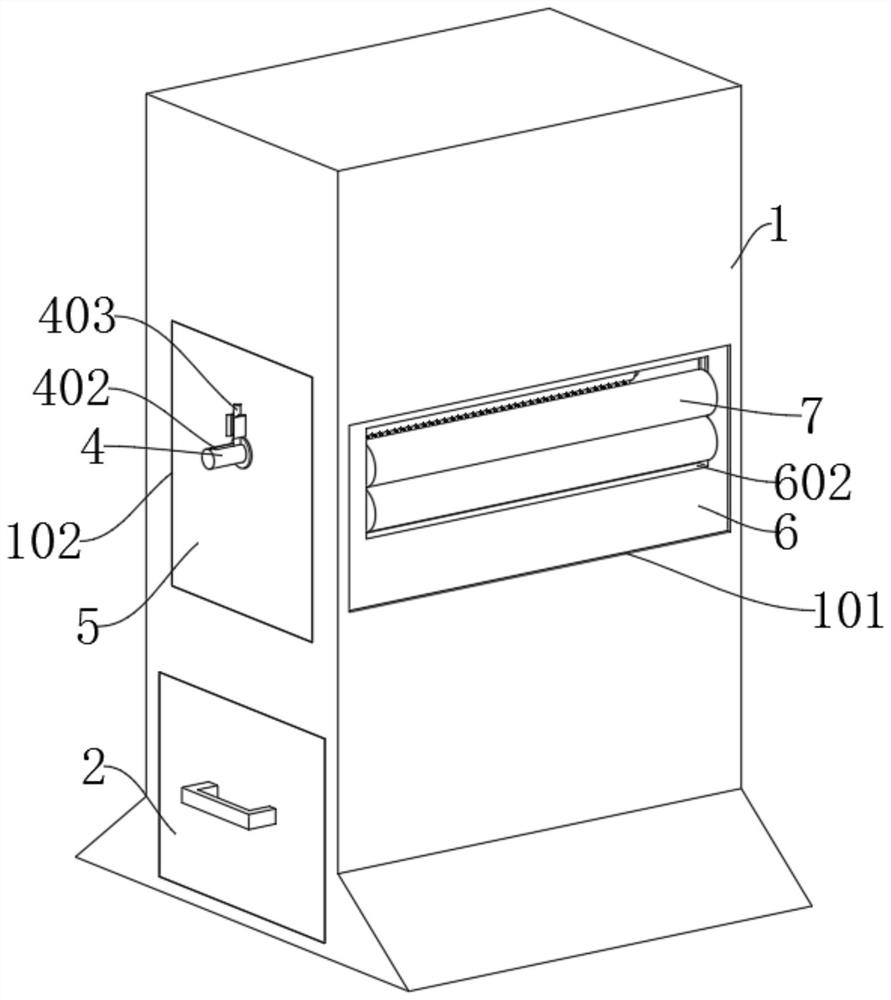

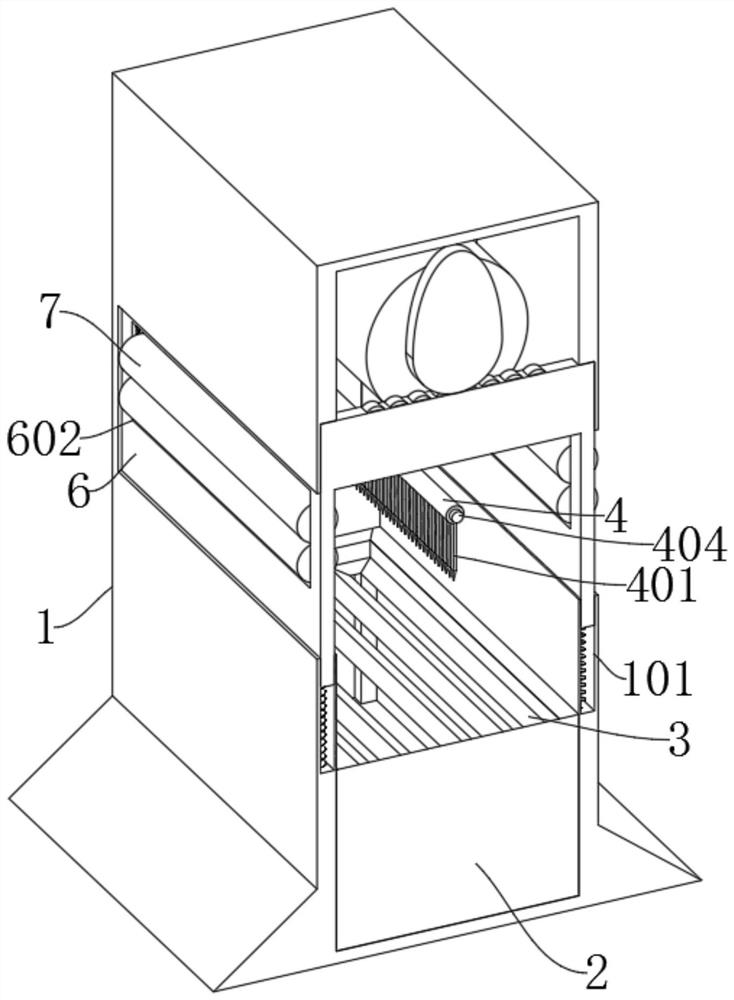

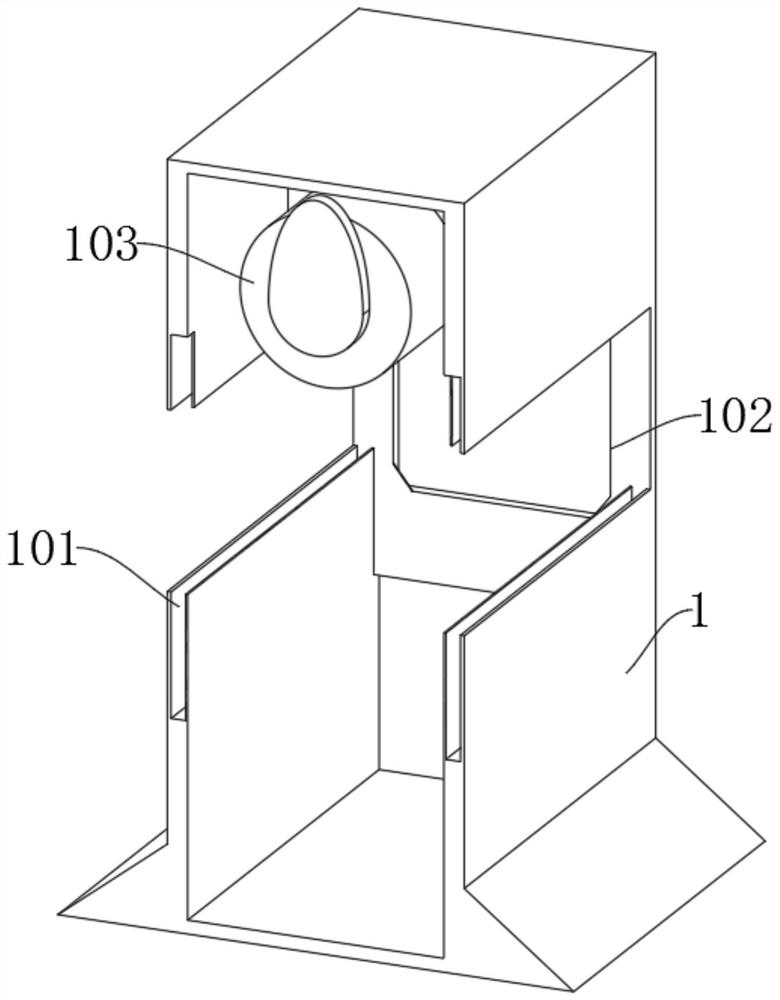

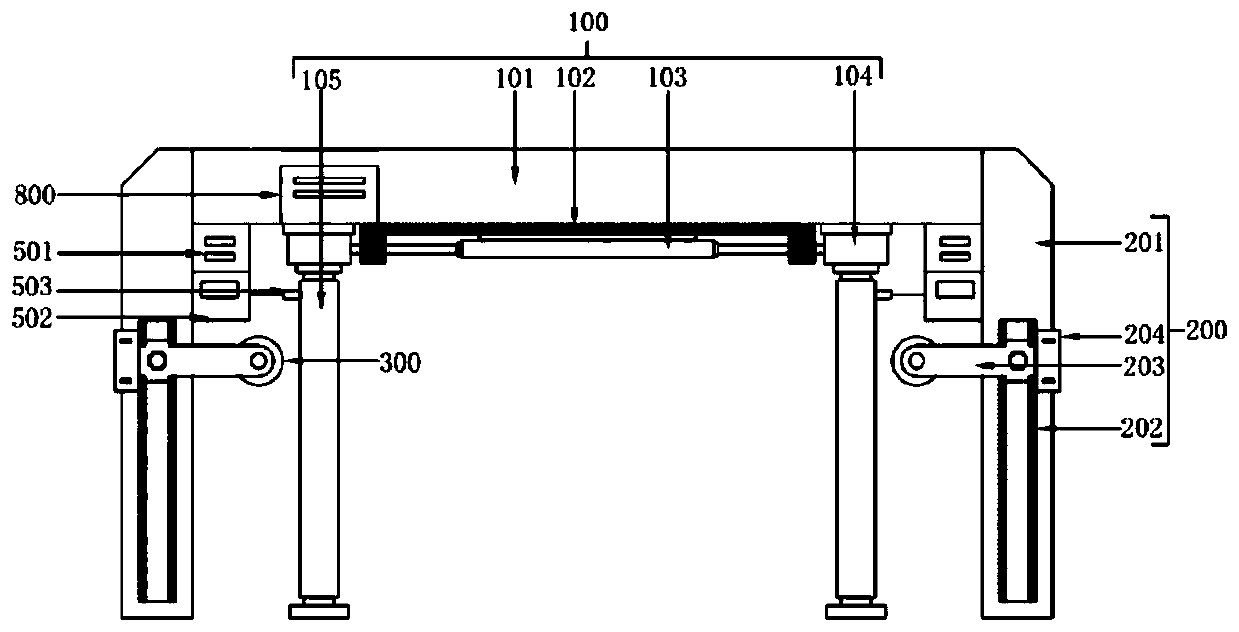

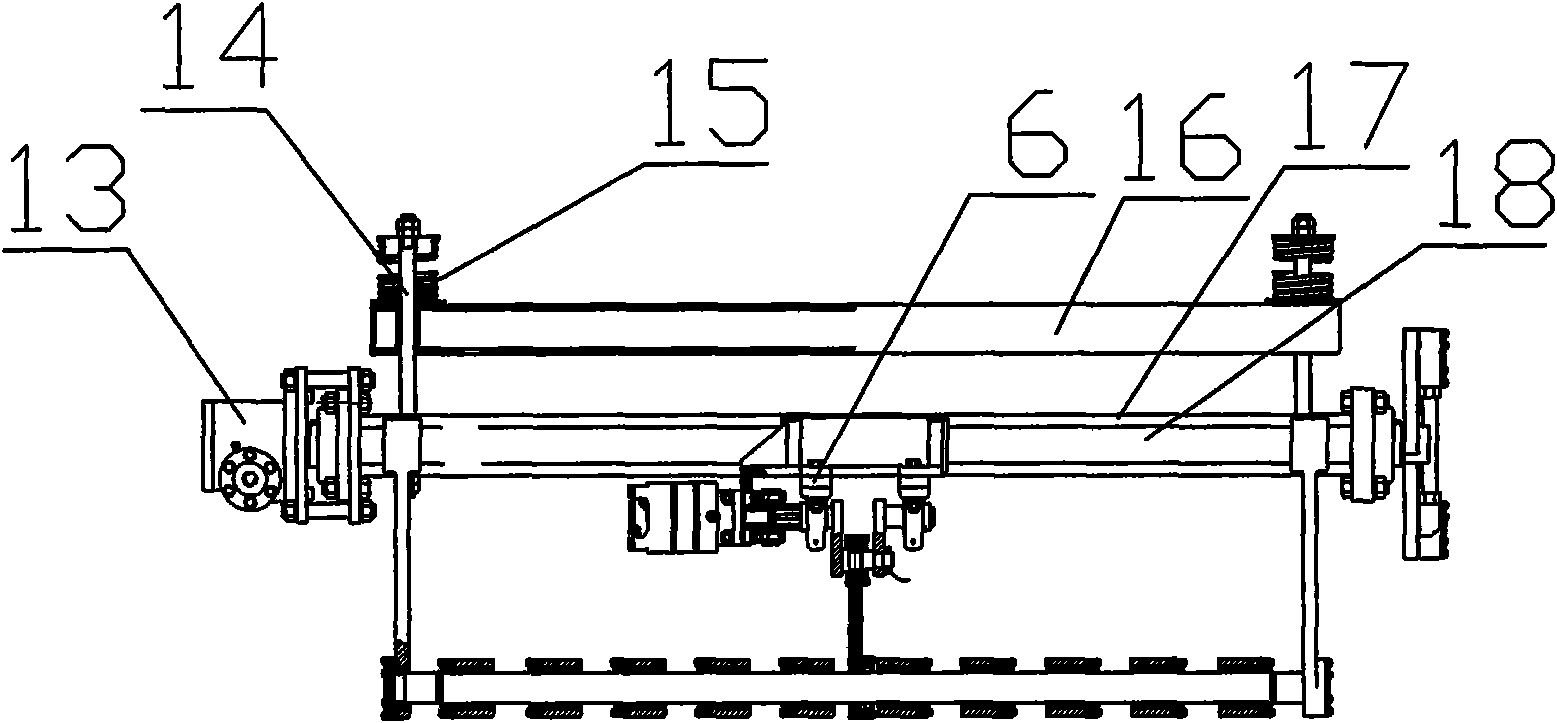

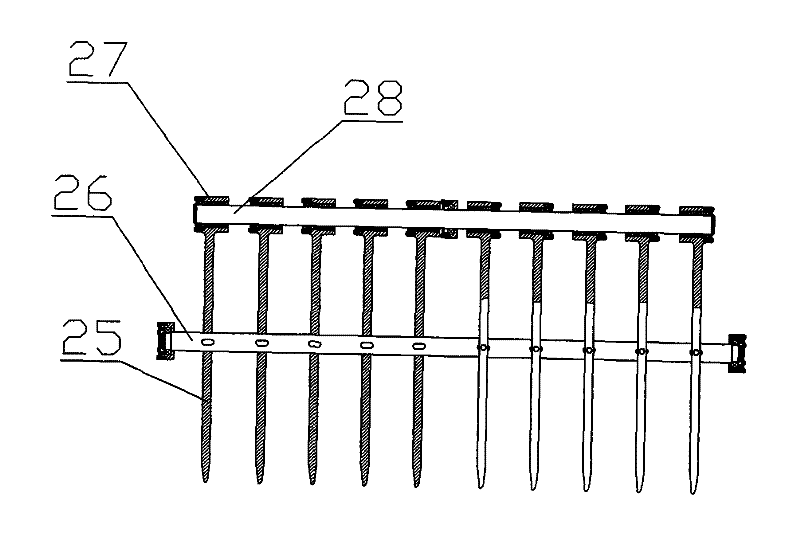

Sandblasting raising machine and sandblasting fluffing technology for upper of leather shoes

The invention relates to a sandblasting fluffing technology for uppers of leather shoes. The specific steps comprise: (1) preparing, firstly, inserting shoe trees which are sleeved with uppers into clamping grooves of a shoe tree support; (2) starting, the support holding the shoe trees moving downward and entering a fluffing seal box; (3) performing sandblasting and fluffing, a spray gun in the fluffing seal box starting to sandblasting and fluffing, in fluffing, high-pressure gas being sprayed out while sand grains of a sand box are pulled out, the sand grains being sprayed out with the high-pressure gas to uniformly hit the periphery of the uppers which are exposed out of the fluffing seal box, the skin of the uppers falling off and fibers of leather being exposed caused by uninterrupted high-speed jet friction of the sand grains applied on the surfaces of the uppers; (4) completing fluffing, the uppers which complete fluffing processing moving upward with the shoe trees to return to initial positions, and taking off the shoe trees. The sandblasting raising machine is rational in structure, and has high-quality and is efficient, saves manual work, and is high in automation degree. The machine and the technology effectively improve processing efficiency and processing quality of products, and the products are reliable and durable.

Owner:马士通安全设备(天津)有限公司

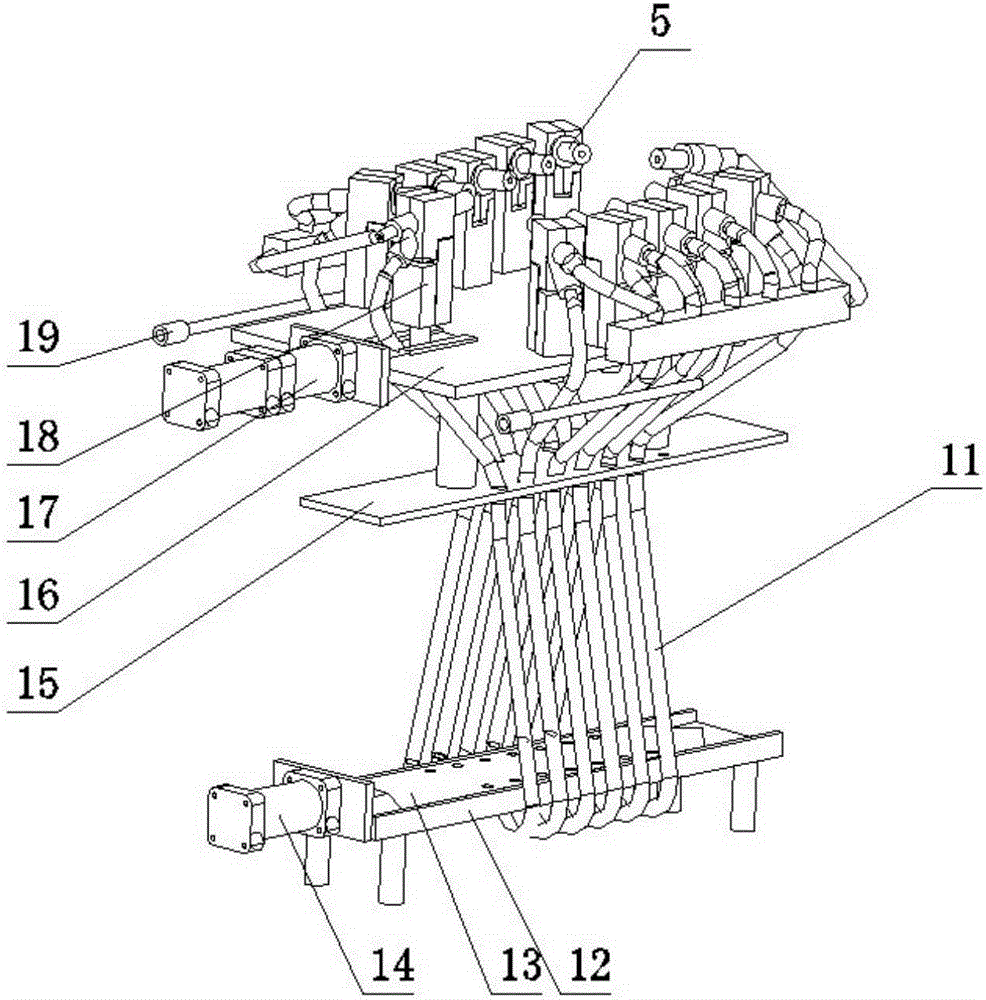

Horizontal hank yarn fluffing device

The invention discloses a horizontal hank yarn fluffing device in the technical field of textile machinery. The horizontal hank yarn fluffing device comprises a carding box, wherein a group of limiting pillars are fixedly connected to the inner wall of the carding box, shaking frames are glidingly connected to outer walls of the limiting pillars, shaking rolls are rotationally connected to the middles of the shaking frames, sliding frames are fixedly connected to the inner walls of the shaking frames, elastic rolls are glidingly connected to the middles of the sliding frames, compression springs are fixedly connected between the elastic rolls and the sliding frames, the elastic rolls are tangent to the shaking rolls, synchronous chain wheels are fixedly connected to end parts of the shaking rolls, a tensioning chain wheel is glidingly connected to the inner wall of the carding box, a double-end cylinder is fixedly mounted in the middle of the carding box and located between the shakingframes and have two ends fixedly connected with the shaking frames, a dust discharging window is arranged at the bottom of the carding box, and a dust suction assembly is fixedly connected to the bottom of the dust discharging window. The mechanical equipment fluffs, the labor force is saved, the working efficiency is improved, the fluffing and carding effects are good, and the problem of breakage in following procedures can be effectively solved.

Owner:盐城恒峰空科技有限公司

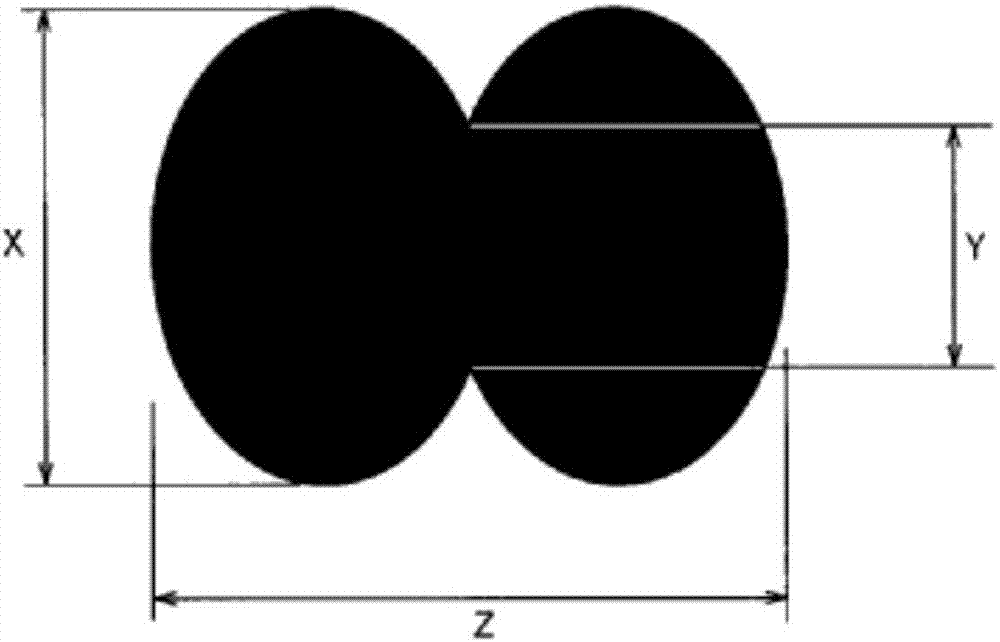

Double-roller type skein fluffing device based on textile processing

The invention provides a double-roller type skein fluffing device based on textile processing, relates to the technical field of textile processing, and aims to solve the problems that when an existing double-roller type skein fluffing device is used, yarn cannot be combed, redundant fine yarn ends and woolen yarn which are attached to the yarn cannot be cleaned and the device cannot assist in cleaning the yarn. The double-roller type skein fluffing device comprises a main body, a bottom piece and blocking pieces; the main body is of a rectangular structure; an inner cavity is formed in the main body; the main body is a skein fluffing device body; and the bottom piece is mounted in an inserting opening of the main body in an inserting manner. An adjusting rod is mounted in the main body, so that when the device is used, the yarn can pass through contact pieces at the bottom of the adjusting rod, the contact pieces can comb the yarn and remove the thread ends and the fine woolen yarn which are attached to the yarn, the removed thread ends or woolen yarn can be reused, and flying dust can be effectively avoided.

Owner:安徽省新远升针纺织有限公司

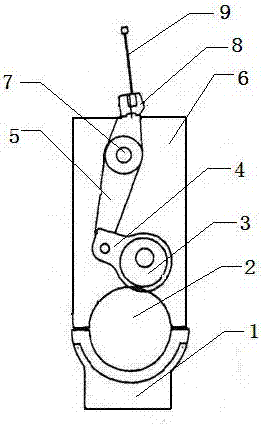

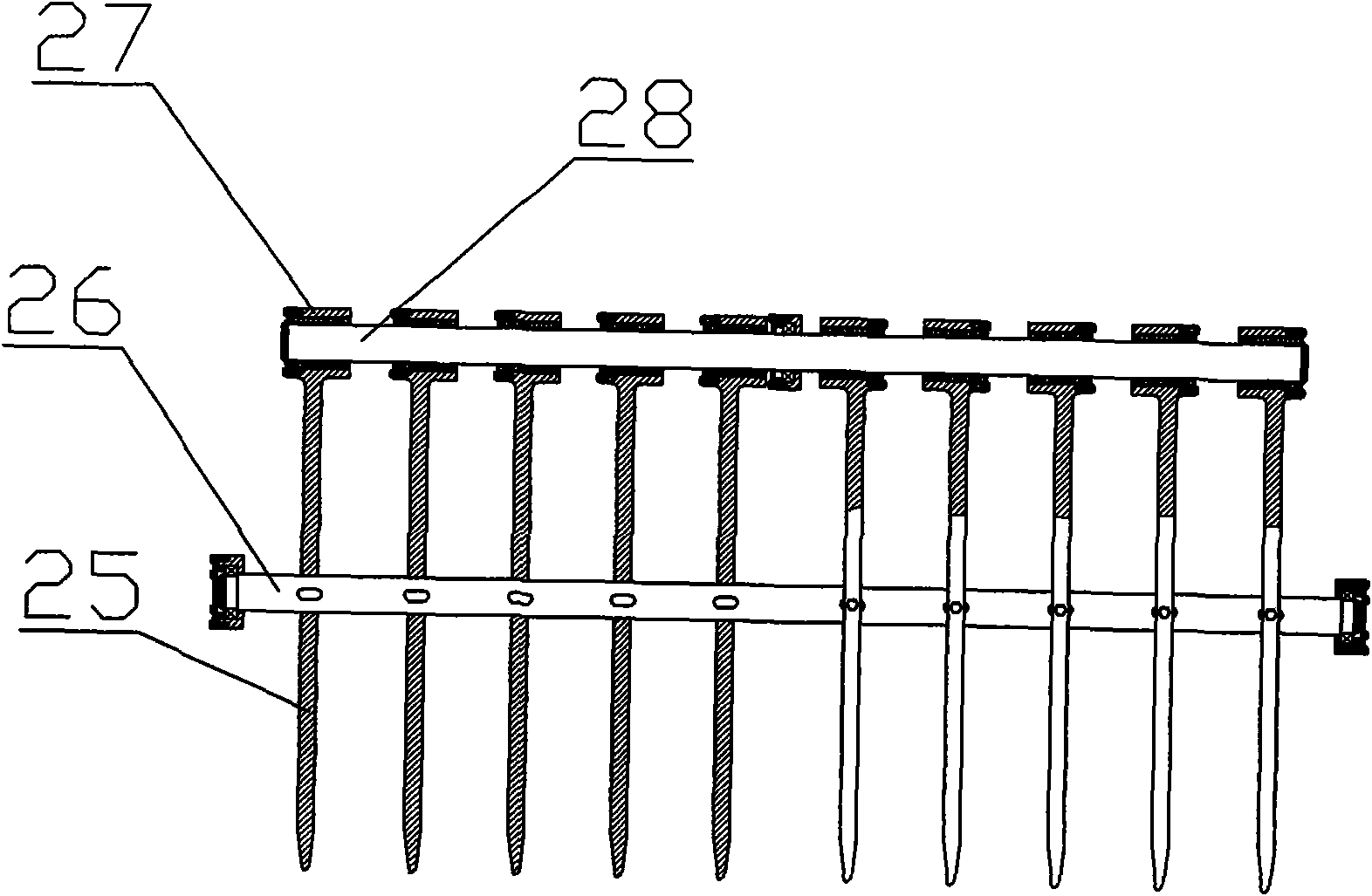

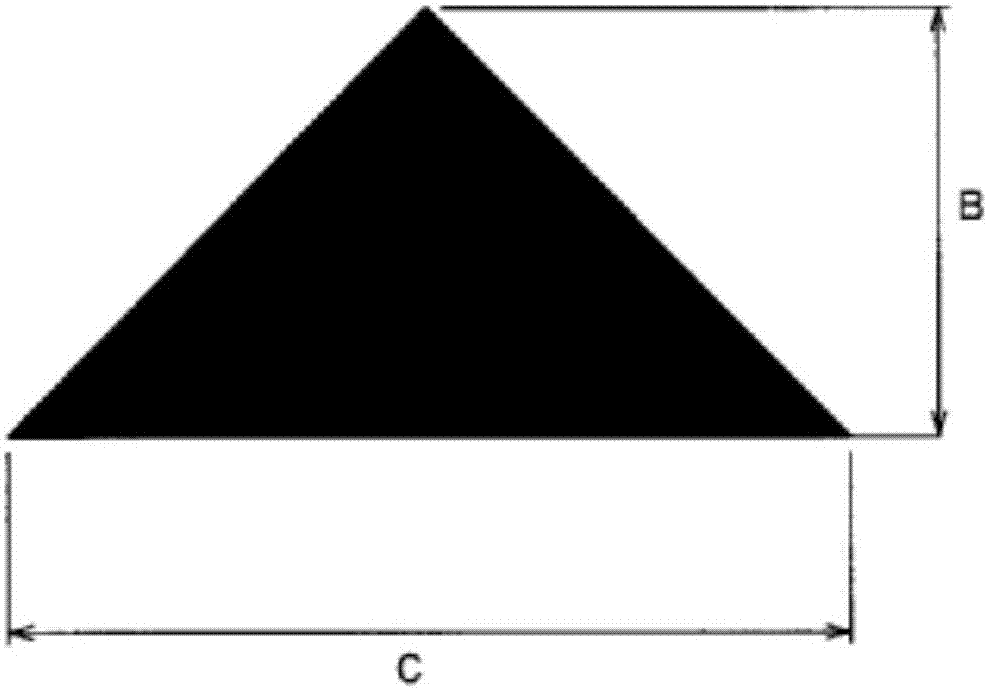

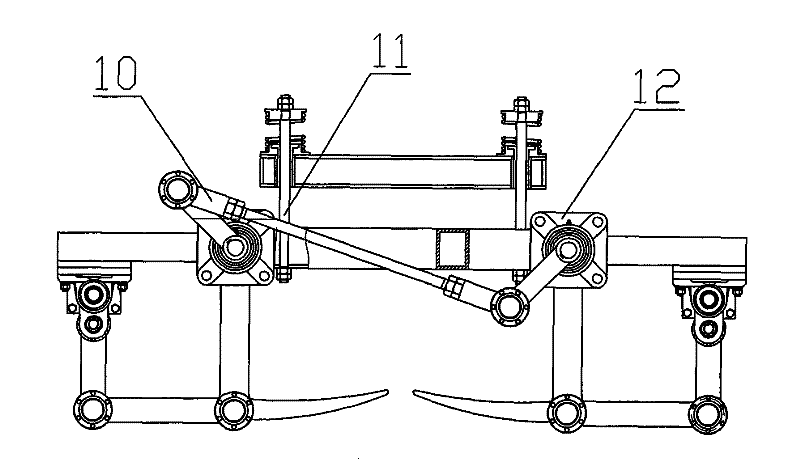

Rocker arm type fuzzing device

The invention provides a rocker arm fuzzing device. The rocker arm fuzzing device is characterized by comprising a rocking shaft base, a rocking shaft, an eccentric wheel, a connecting rod, a swing arm, a mounting base, a swing shaft, a fuzzing needle bed and fuzzing needles, wherein the rocking shaft is rotatably mounted on the rocking shaft base; the rocking shaft base is fixedly provided with the mounting base; the swing shaft is mounted on the mounting base and is in linkage with the mounting base; the connecting rod is arranged below and movably connected with the swing shaft via the swing arm; the other end of the connecting rod is provided and connected with the eccentric wheel; the eccentric wheel is externally tangent to the rocking shaft; the swing shaft is fixedly mounted on the fuzzing needle bed; the fuzzing needle bed is provided with a number of blocks of fuzzing needles. The rocker arm fuzzing device provided by the invention has the advantages of simple and reasonable structure, ingenious design, small occupied space, convenient installation and dismounting, saving of time and labor, low production cost, good fuzzing effect, formation of beautiful wool shapes of textiles, etc.

Owner:马红月

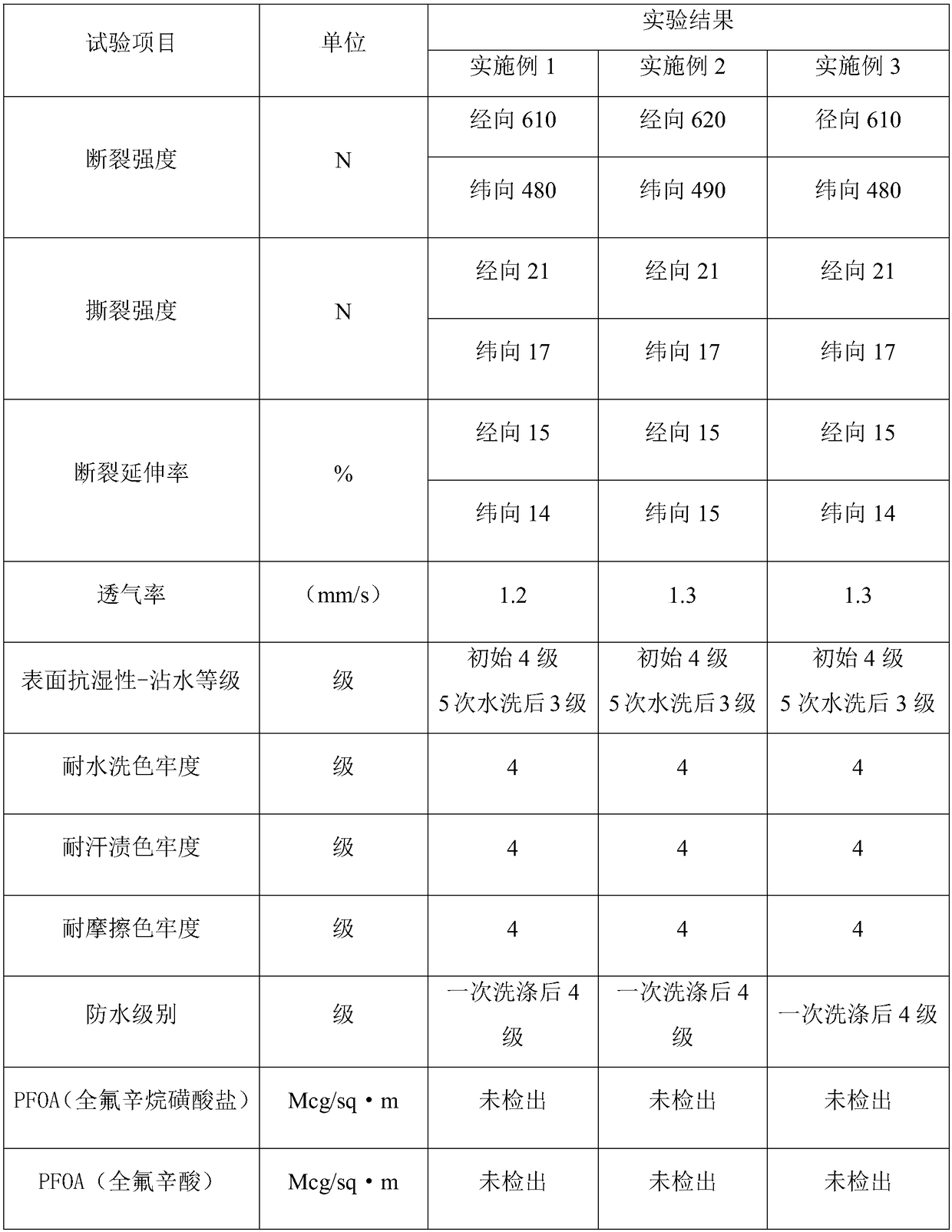

Preparation method of water-repellent polyester/cotton brushed fabric

ActiveCN108842445AAvoid damageShort fluffing timeTextile storage in superimposed formLiquid/gas/vapor removalPolyesterDyeing

The invention discloses a preparation method of water-repellent polyester / cotton brushed fabric, and belongs to the field of fabric. The preparation method of the water-repellent polyester / cotton brushed fabric comprises steps of grey cloth weaving, cold-batch, rinsing, carbon grinding, back boiling, dyeing, soaping, water repellent treatment, softening treatment, primary drying and secondary drying. The prepared water-repellent polyester / cotton brushed fabric has the advantages of high fiber strength, excellent waterproof performance, high color fastness and long service life.

Owner:石狮市展耀纺织科技有限公司

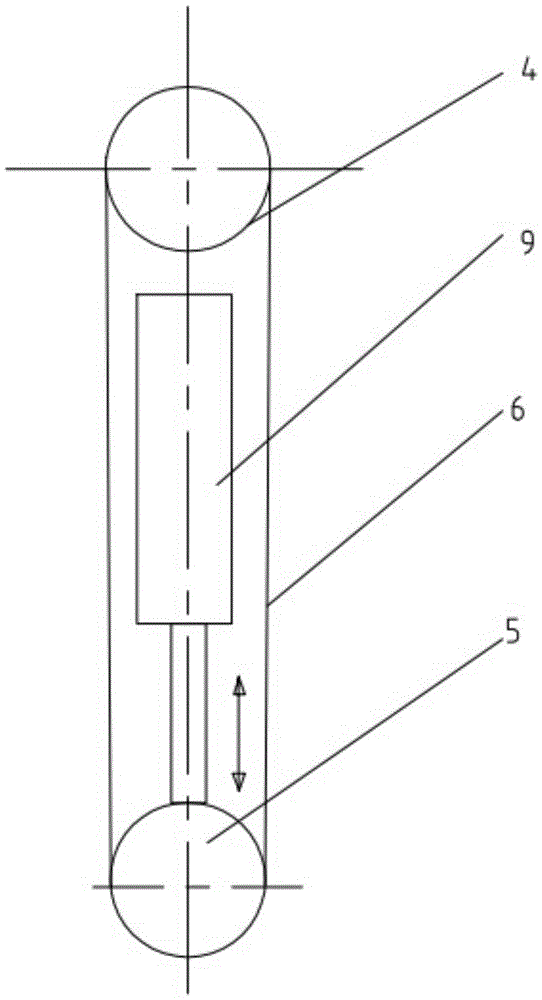

Double-roller hank fluttering device

InactiveCN104233538BImprove fluffingImprove fluffing effectTextiles and paperReciprocating motionAgricultural engineering

The invention discloses a double-roller skein fluffing device, which comprises a control box, a frame, a supporting shaft, an upper roller, a lower roller, a driving mechanism and a reciprocating transmission mechanism, the supporting shaft is installed on the frame, and the upper roller can be It is rotatably supported on the support shaft, the driving mechanism is movably connected with the upper roller to drive the upper roller to rotate relative to the support shaft, the upper roller and the lower roller are matched for the two ends of the skein, and the reciprocating transmission mechanism is movably connected with the lower roller In order to drive the lower roller to reciprocate relative to the upper roller, the control box is respectively connected with the driving mechanism and the reciprocating transmission mechanism. The invention can play a good carding effect on the skein.

Owner:CHANGZHOU TEXTILE GARMENT INST

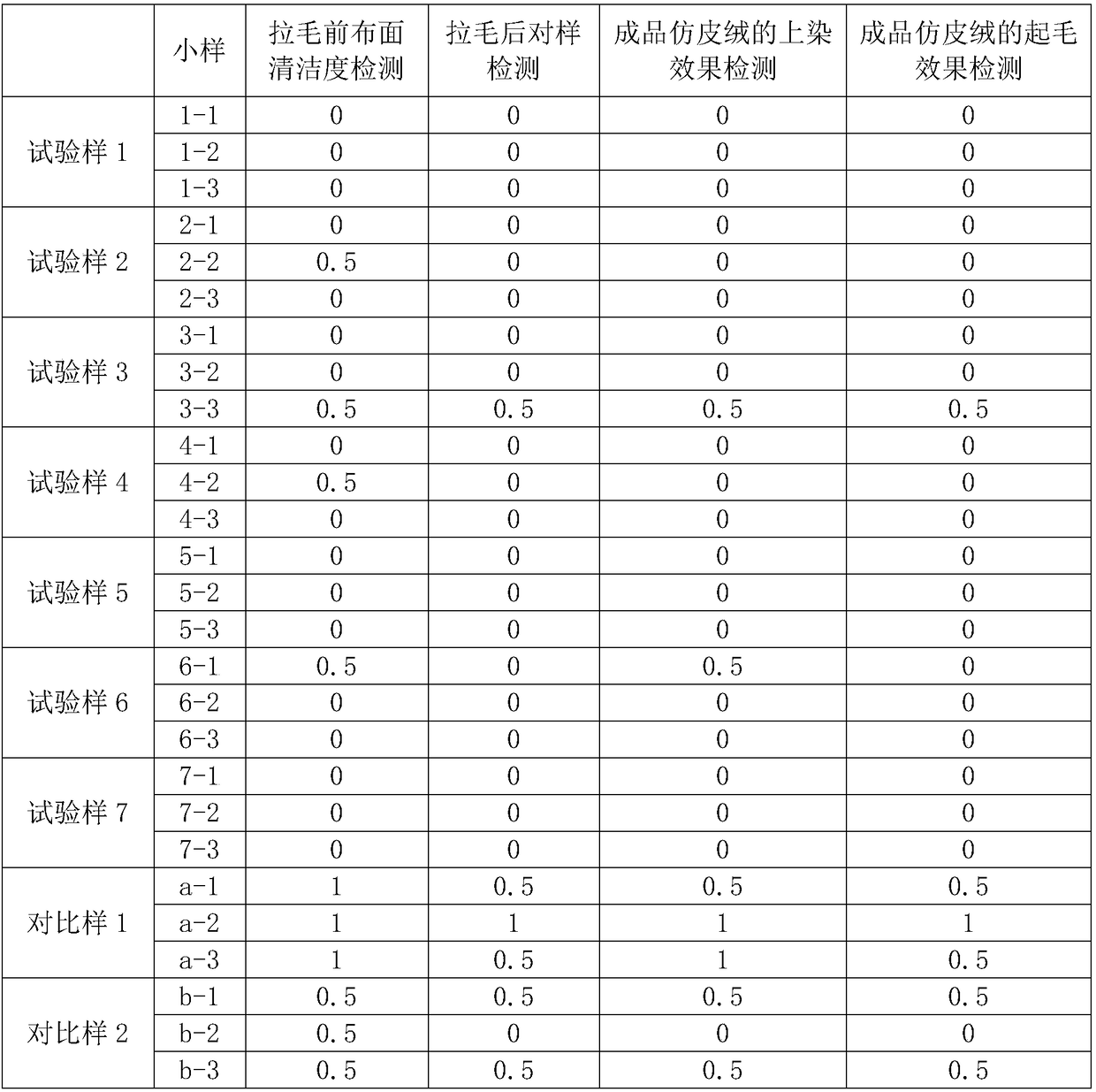

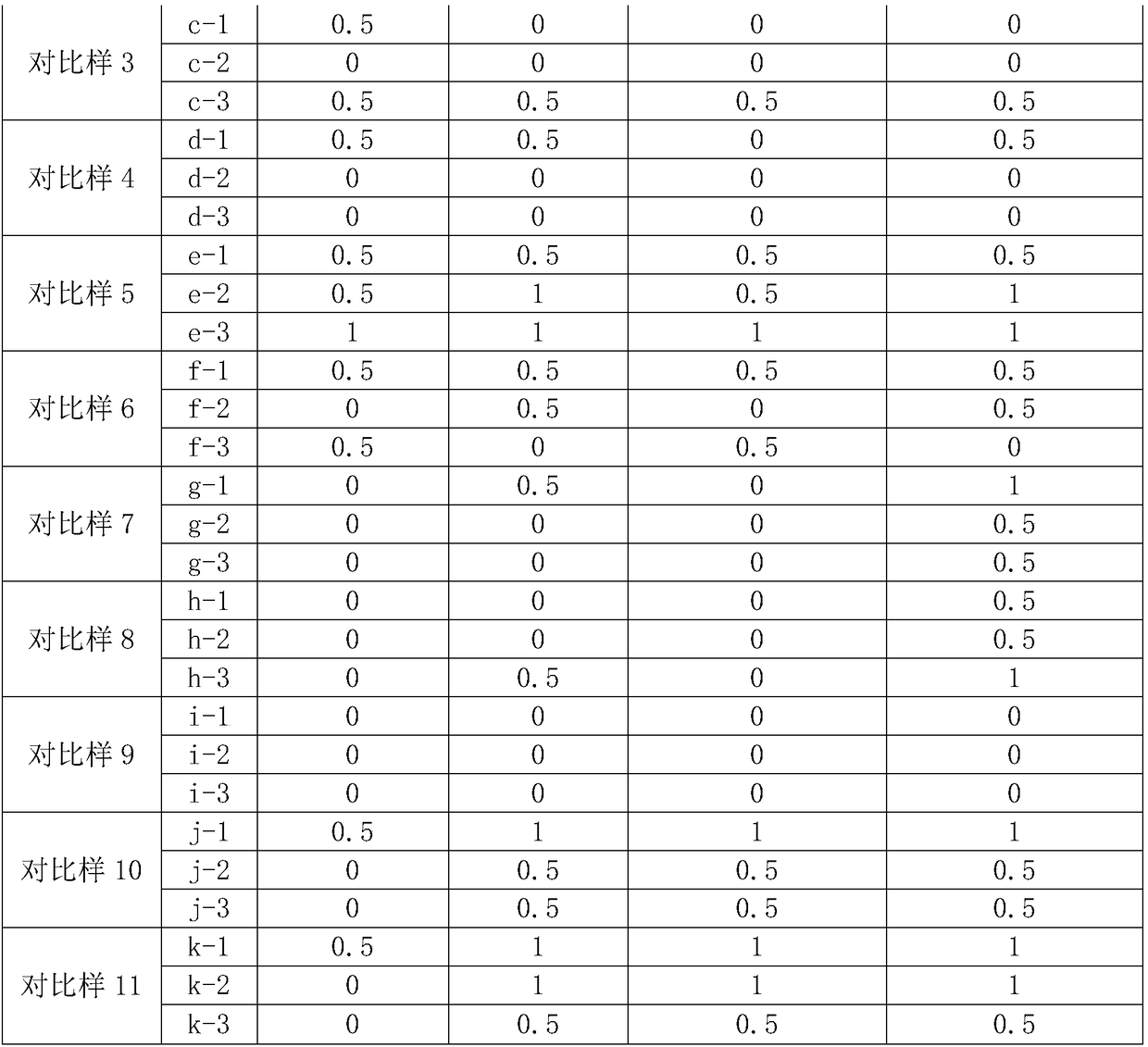

Imitation fur dyeing process

InactiveCN108532163AIncrease profitSave waterLiquid/gas/vapor removalHeating/cooling textile fabricsPulp and paper industryPre treatment

The invention discloses an imitation fur dyeing process, and belongs to the technical field of imitation fur processing. According to the technical scheme, the imitation fur dyeing process comprises the steps of grey fabric unreeling, cleaning, decontaminating and washing, dewatering and scutching, drying, napping, dyeing, dewatering and scutching, shaping and drying, cooling and shaping and thenreeling and storing to obtain finished imitation fur products. By adjustment of the sequence of the steps, the imitation fur dyeing effect and dyeing uniformity can be improved, furthermore, the process is optimized, and the efficiency is improved. Secondarily, by pretreatment through a fuzzy agent and a softening agent, the fuzzy effect of a grey fabric can be good in a later napping process, andmeanwhile, the softness of the grey fabric can be improved. In addition, the temperature is raised by step steps in drying and shaping, residual water in the imitation fur can be removed, moreover, an effect of adjusting the width of the imitation fur can further be achieved, and thus, the hair side of the imitation fur can be uniform and flat.

Owner:嘉兴市远大纺织印染有限公司

Dyeing process of fully dull fabric

InactiveCN111074458AImprove permeabilityGuaranteed matting effectSucessive textile treatmentsHeating/cooling textile fabricsPulp and paper industryScouring agent

The invention discloses a dyeing process for a fully dull fabric. The dyeing process includes the following steps that A, a grey fabric of a dull fabric is pre-treated to obtain a product A; B, the product A is dyed to obtain a product B; C, post finishing is carried out on the product B to obtain a product C; D, softening shaping treatment is carried out on the product C to obtain a product D; E,fuzzing treatment is carried out on the product D to obtain a product E; F, shaping is carried out on the product E to obtain a finished product; and the specific method of the pretreatment in the step A comprises the steps that the grey fabric of the dull fabric is subjected to scouring, a scouring agent and a degreasing agent are added during scouring, the scouring temperature is 85-95 DEG C, and the scouring time is 18-23min. The dyeing process has the characteristics of effectively improving the fuzzing effect.

Owner:ZHEJIANG CADY IND

Method for grinding card clothing for textile napping machines

The invention discloses a method for grinding card clothing for textile napping machines. The method is characterized in that a piled surface of upright pile fabric is horizontally and evenly coated with grinding slurry which is made of mixture of engine oil and grinding carborundum in mass ratio of 2:3; the grinding carborundum is 1000-meshed to 1300-meshed; the piled surface of the upright pile fabric is subjected to continuous napping on a textile napping machine so as to grind needle clothing; tension of the upright pile fabric is limited within the range of from 25newton to 30newton during napping; the pile surface of the upright pile fabric is finally coated with the grinding slurry once every two hours and is subjected to continuous napping for two days to complete grinding. The method has the advantages that grinding cycle is shortened greatly, replacing the upright pile fabric is not needed, manpower and material resources are saved greatly, and production cost is lowered.

Owner:宁波西田信染织有限公司

Frosted velvet fabric and post-treatment process thereof

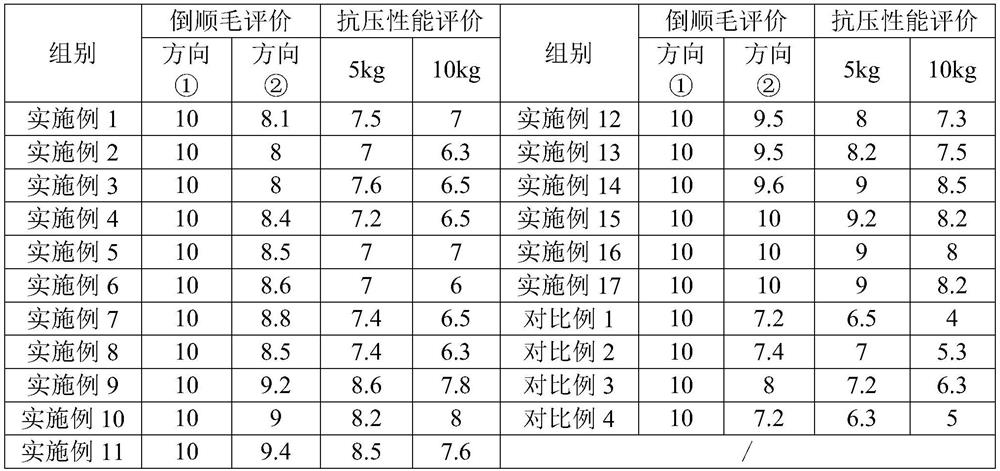

ActiveCN113279133AImprove fluffing effectWith strengthWarp knittingTextile/flexible product manufacturePolyesterYarn

The invention relates to the field of fabrics, and particularly discloses a frosted velvet fabric and a post-treatment process thereof. The frosted velvet fabric is formed by weaving a surface layer, a middle layer and a surface layer, wherein FDY polyester yarns 75D / 144F are adopted as raw materials of the surface layer, the number of head lines of the surface layer is 2500-3000 pieces / m, and the surface layer is of a 45 / 10 structure; the middle layer adopts FDY polyester yarns 45D / 24F as raw materials, the number of head lines of the middle layer is 2500-3000 / m, and the middle layer adopts a 12 / 10 structure; FDY polyester yarns 45D / 24F are adopted as raw materials of the bottom layer, the number of head lines of the bottom layer is 2500-3000 / m, and the bottom layer is of a 10 / 23 structure; the post-treatment process comprises the following steps of S1, primary shaping; S2, fuzzing; S3, dyeing and drying; S4, lustring; S5, fluff finishing; and S6, final setting. The frosted velvet fabric and the post-treatment process thereof have the advantages of reduction of reverse and smooth fluff, compression resistance, crease resistance and excellent hand feeling.

Owner:ZHEJIANG FAMOUS TEXTILE CO LTD

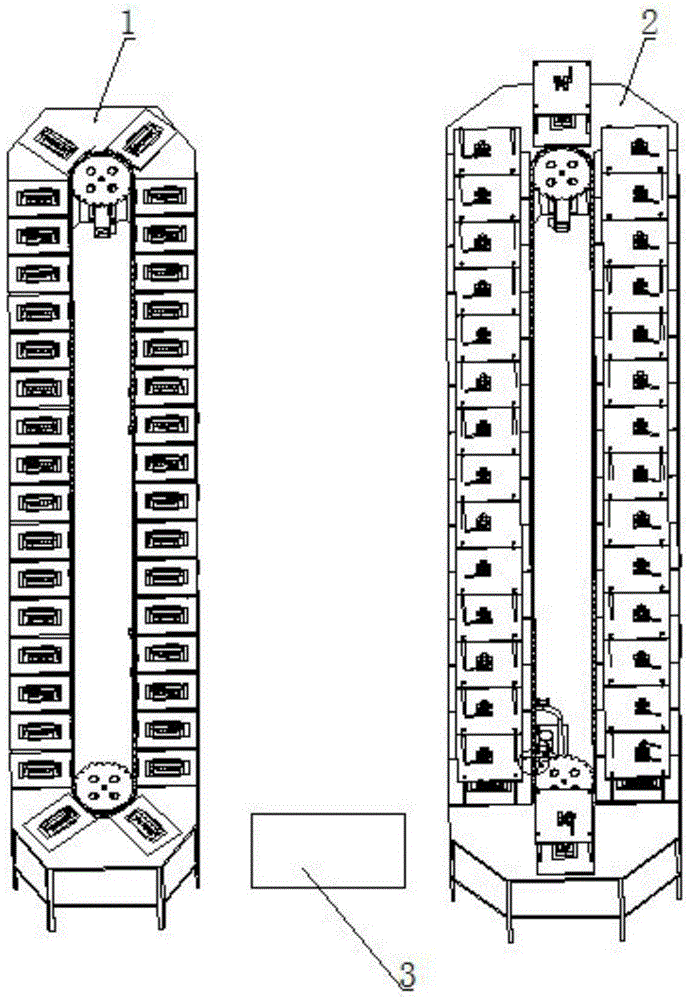

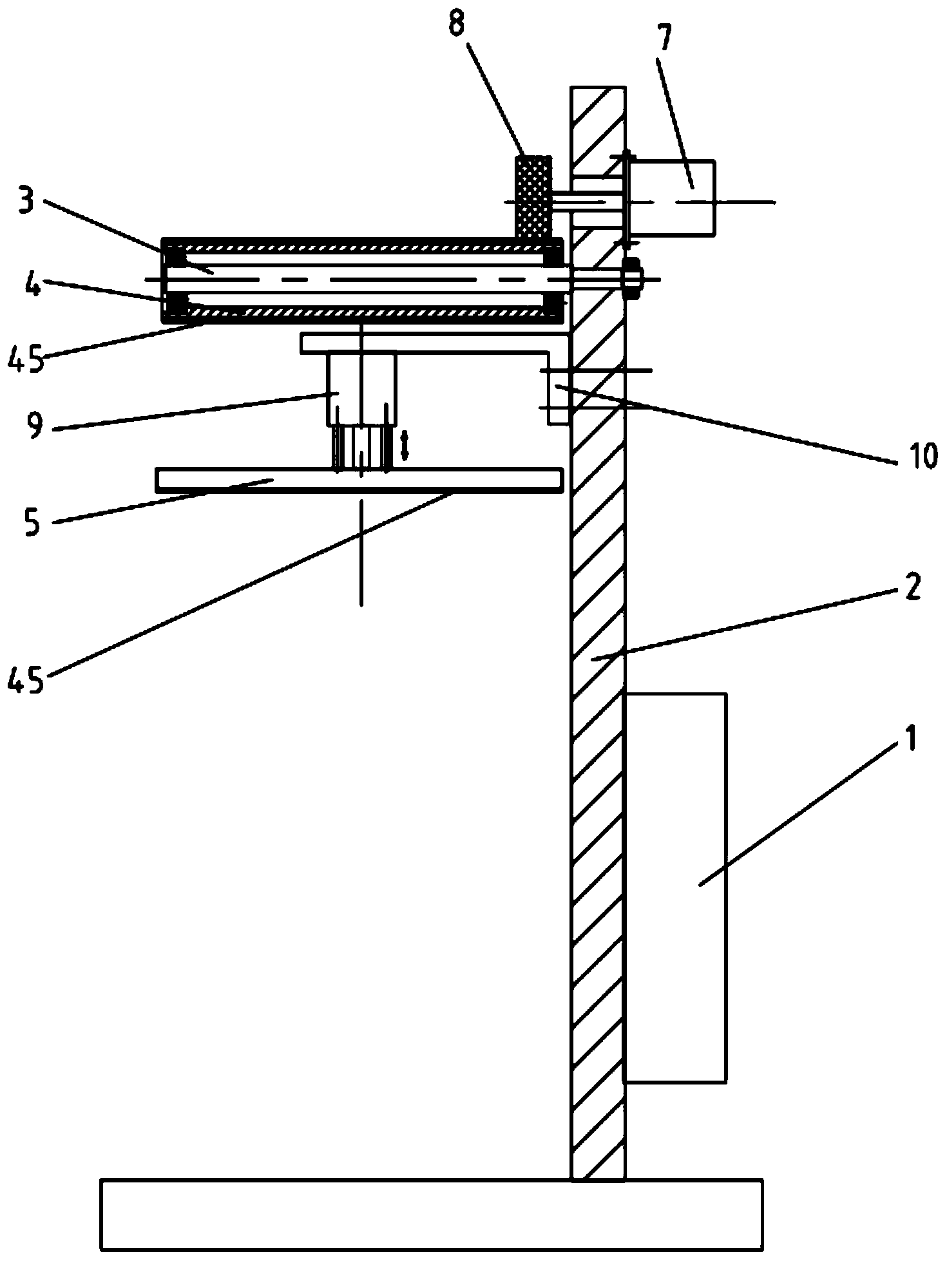

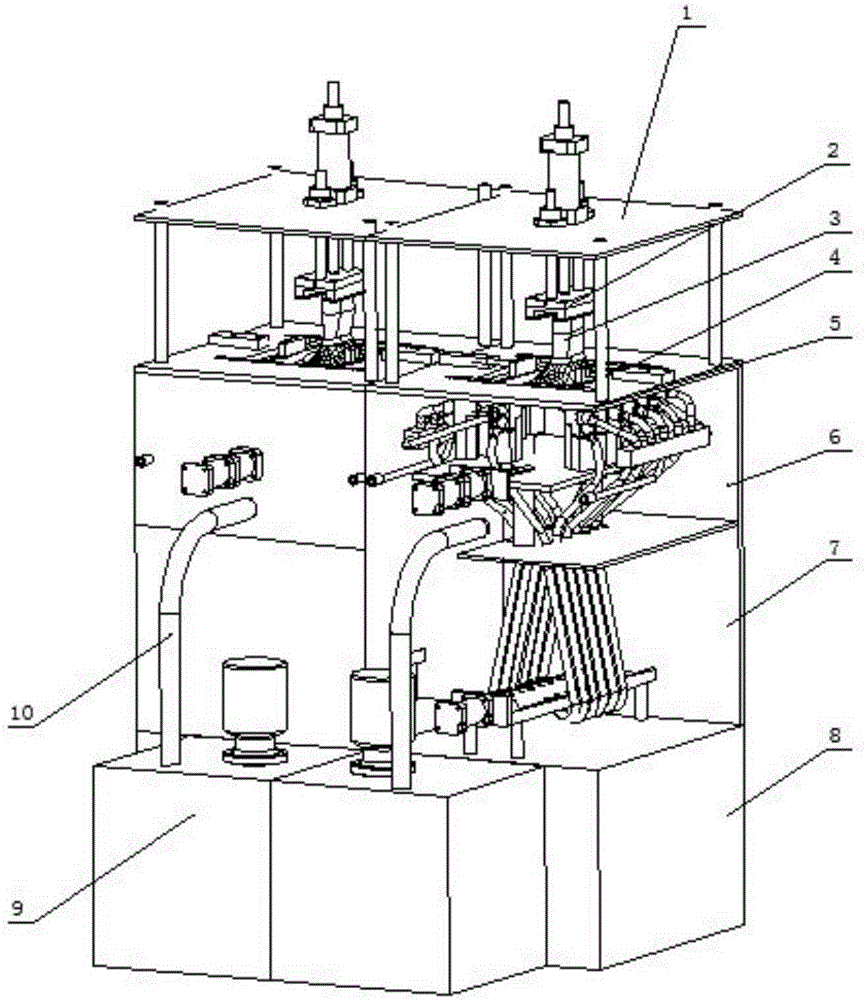

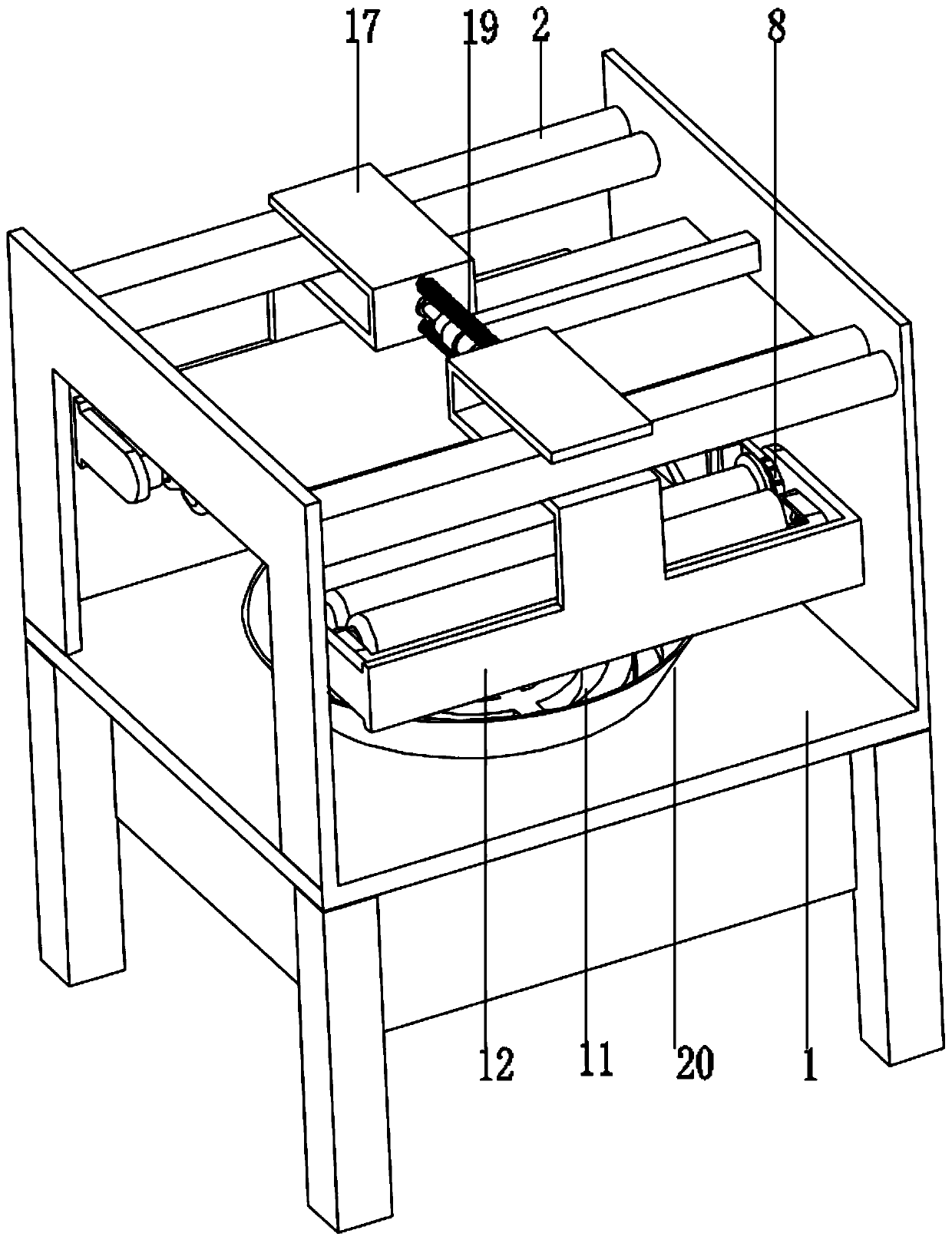

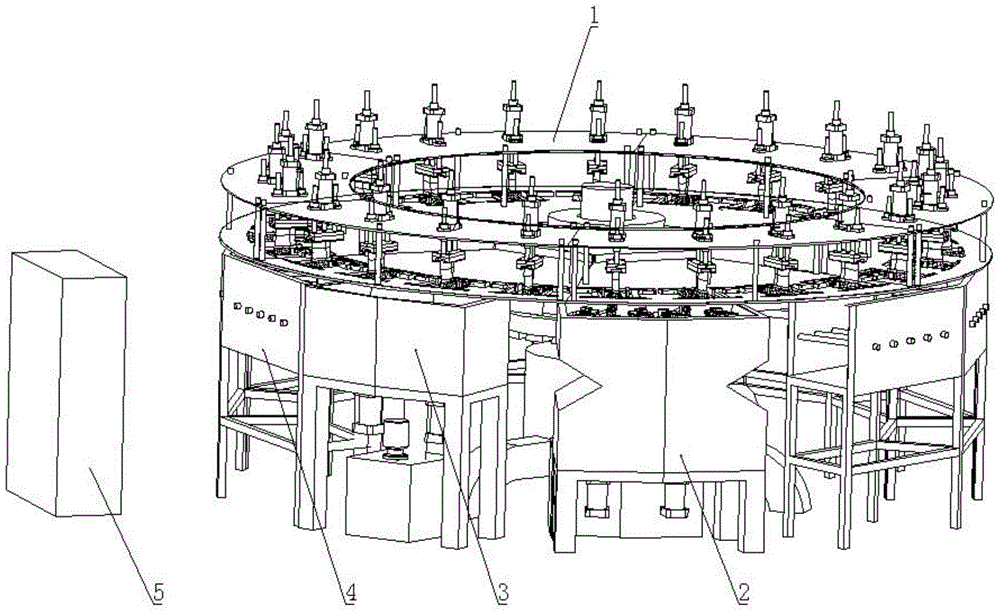

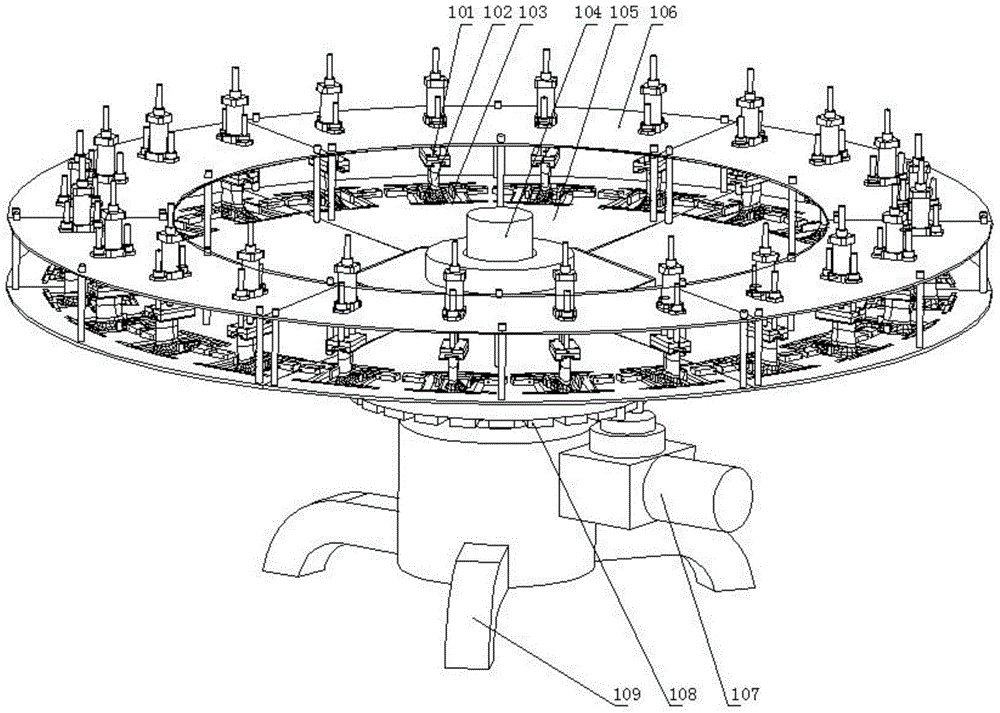

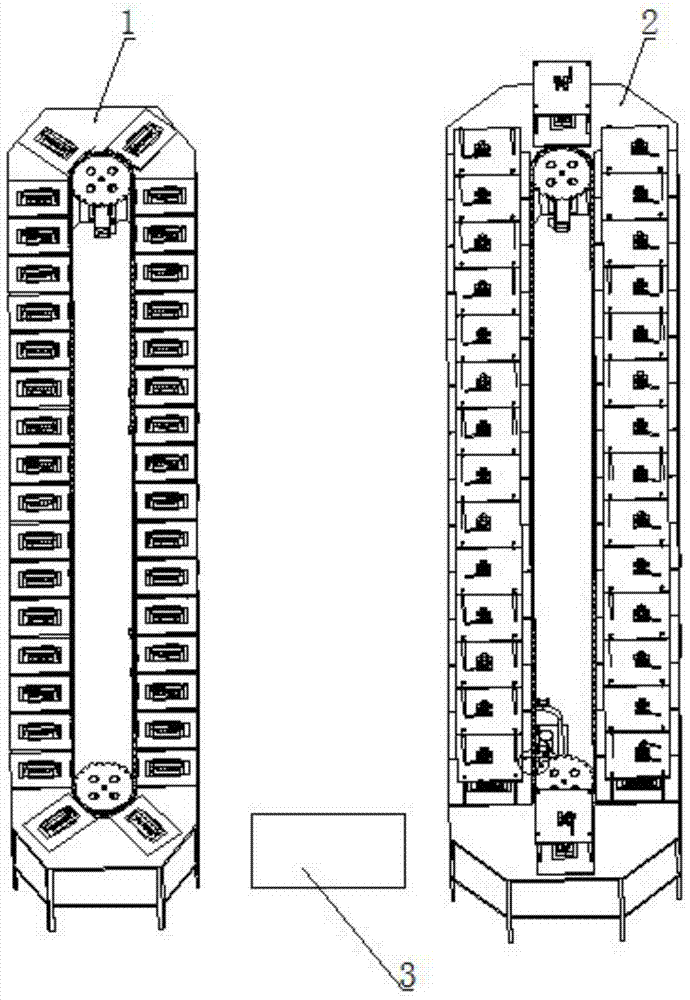

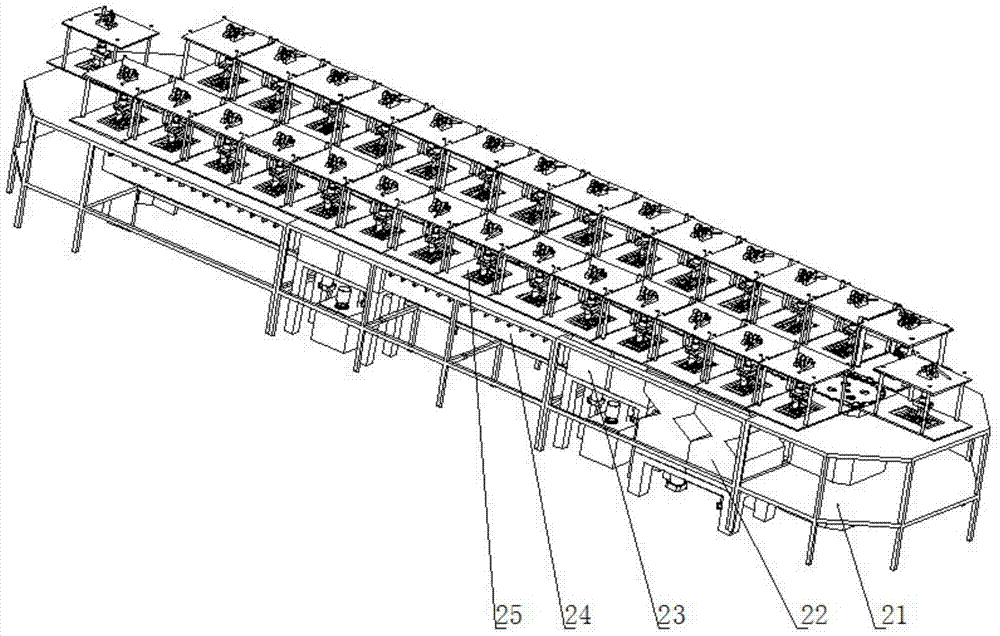

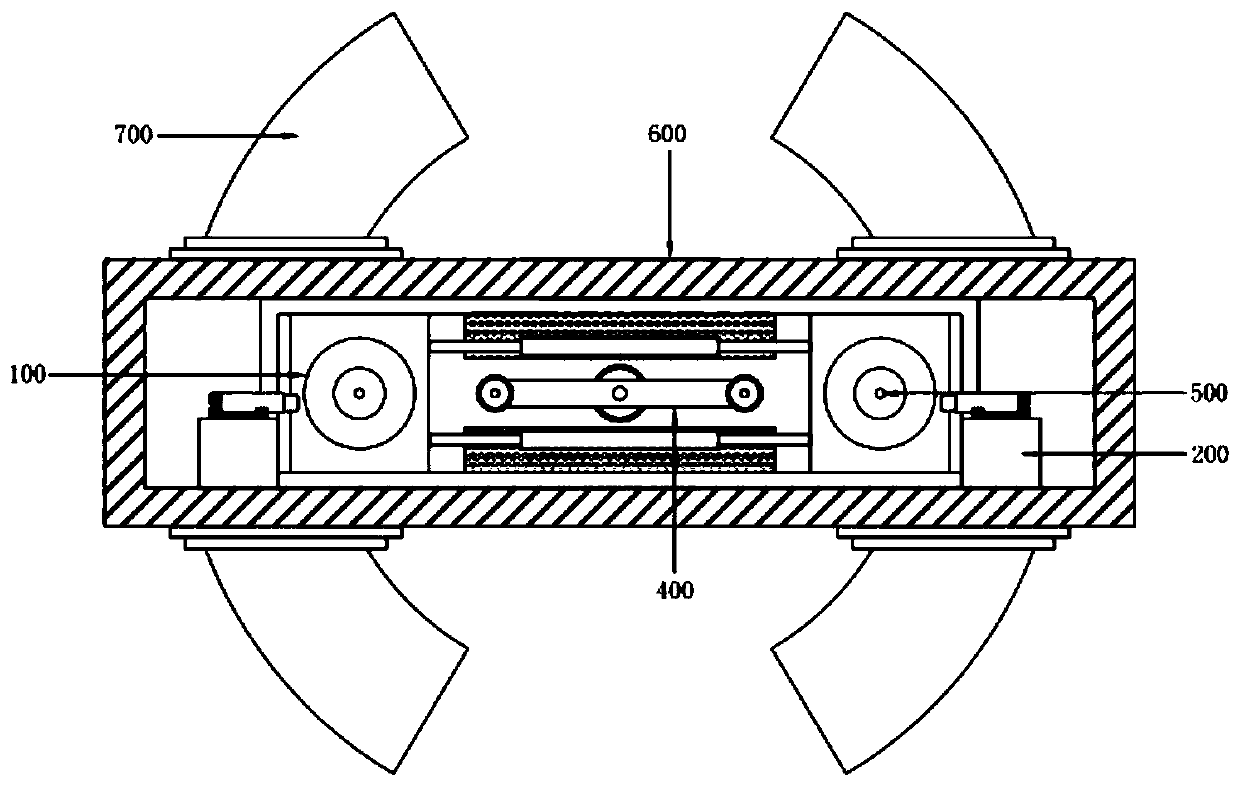

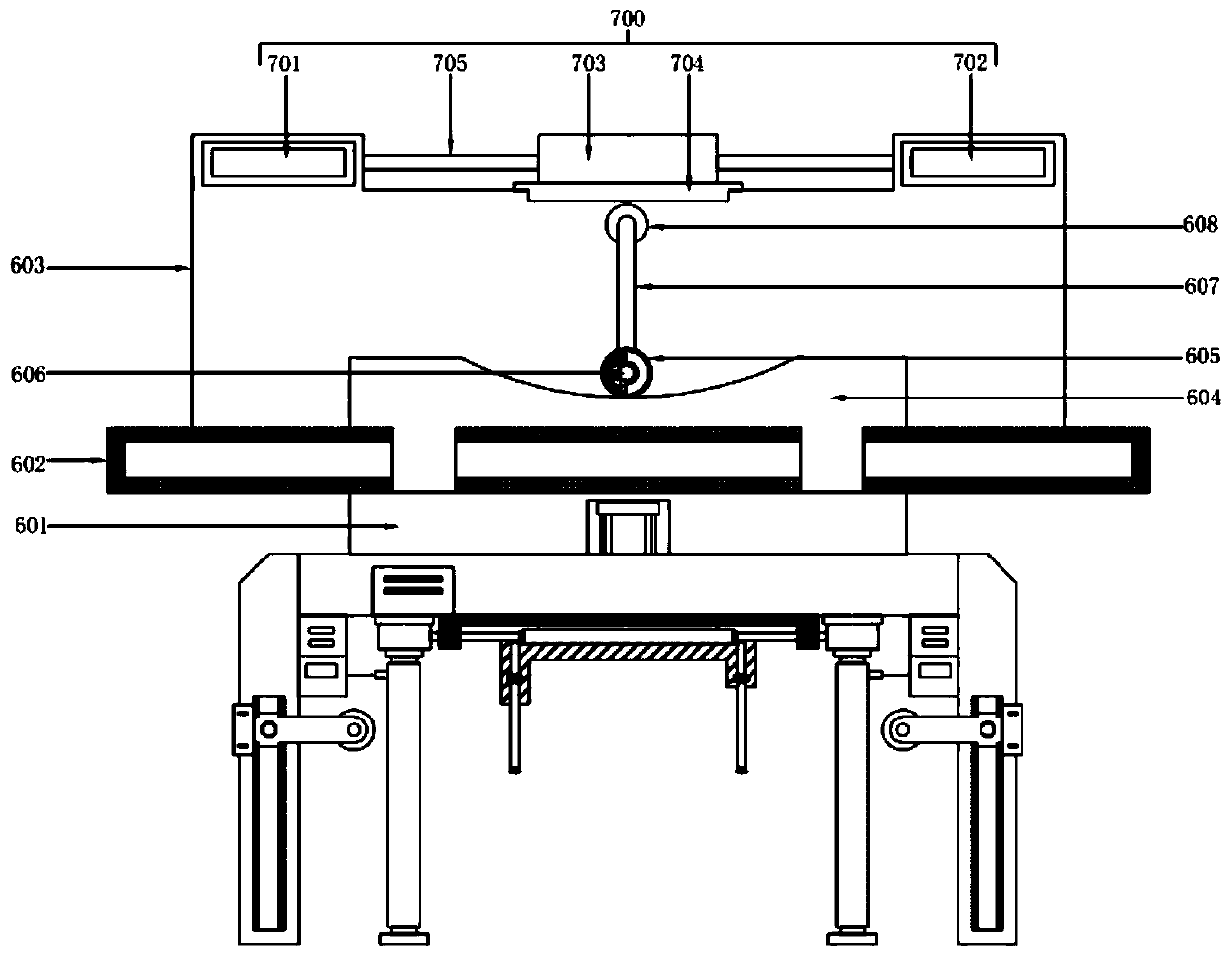

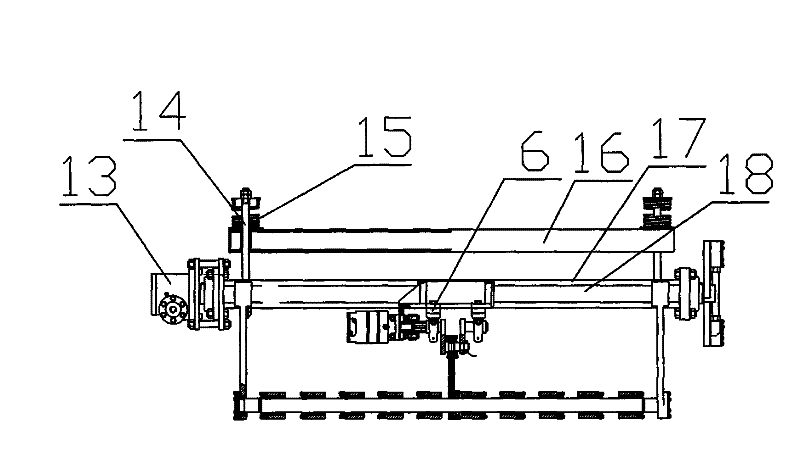

Multi-station multifunctional upper automatic sandblast fluffing glue-spraying disk machine

InactiveCN105212443AGood adhesionLarge fuzzy areaSolesAbrasive blasting machinesElectric controlProduct processing

The invention relates to a multi-station multifunctional upper automatic sandblast fluffing glue-spraying disk machine, comprising a disk mechanism, a fluffing mechanism, a glue-spraying mechanism, drying mechanisms, and an electric control cabinet. The radial direction of the periphery of the disk mechanism is uniformly distributed with a plurality of shoe tree supports. The corresponding lower part of the disk mechanism below the plurality of shoe tree supports is provided with the fluffing mechanism, the glue-spraying mechanism, and the plurality of drying mechanisms in sequence in an annular manner. The disk mechanism, the fluffing mechanism, the glue-spraying mechanism, and the plurality of drying mechanisms are respectively connected with the electric control cabinet. The disk machine thoroughly changes a cement shoe shoemaking production technology on market, and the technology is high in automation degree, production efficiency is obviously improved, and the number of labors is greatly reduced. The disk machine saves energy and protects environment, and effectively improves product processing efficiency and processing quality.

Owner:马士通安全设备(天津)有限公司

Embroidery anti-fuzzing treatment method

PendingCN113957713AImproved anti-pilling propertiesReduce slipBiochemical fibre treatmentGrip property fibresChemistryComposite material

The invention relates to the technical field of embroidery, in particular to an embroidery anti-fuzzing treatment method. The embroidery anti-fuzzing treatment method comprises the following steps that step 1, an anti-fuzzing treatment agent is prepared; step 2, an embroidery product is put into the anti-fuzzing treatment agent prepared in the step 1, and soaked for 5-8 hours; step 3, the embroidery product soaked in the step 2 is dried with hot air at 50-80 DEG C; step 4, the dried embroidery product is washed, and after the embroidery product is washed, a post-treatment agent is sprayed onto an embroidery pattern by using a hand press type sprayer; and step 5, the embroidery product in the step 4 is baked by using hot air at 120-150 DEG C, and ironed by using an iron after the treatment is finished. According to the embroidery anti-fuzzing treatment method, a method of soaking with the anti-fuzzing treatment agent is adopted, a layer of soft and tough film is formed on the surface of the embroidery product, slippage of the barbed threads in the embroidery product is reduced, plush is not prone to forming by friction during use, the fuzzing and pilling resistance of the embroidery product is effectively improved, and the use effect of a user is improved.

Owner:宝应县顺扬刺绣厂

Bonded double layer waffle fabric

The invention discloses a knotted double-layer waffle fabric, which is formed by interweaving two sets of pure cotton warp yarns and one set of pure cotton weft yarns. Transition, forming a concave-convex quadrilateral with high, medium and low sides, and the reverse side of the fabric is raised fabric, which is woven with a double-layer weave when weaving. The present invention adopts the double-layer weave of weft and weft, the air layer inside the fabric is thickened, the fabric is light, breathable, and warm; the front of the fabric adopts honeycomb structure, the floating length is long, the fabric structure is soft, and the hand feeling elasticity of the fabric is enhanced; The reverse side of the fabric has a suede effect, which improves the softness of the fabric. The fabric is in contact with the human body and has good comfort; Short, avoiding the inconvenience of using the fabric due to the long floating line.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

A twin-roller skein fluffing device based on textile processing

The invention provides a double-roller skein fluffing device based on textile processing, which relates to the technical field of textile processing, and solves the problem that the existing double-roller skein fluffing device cannot comb the yarn when it is in use, and cannot Unable to attach the yarn to excess fine thread ends and wool for cleaning, and unable to assist in cleaning the yarn, including the main body, bottom piece, and stopper; the main body is a rectangular structure, and the interior of the main body is provided with an inner cavity, and the main body is The main body of the skein fluffing device; the bottom part is installed inside the socket of the main body by inserting. The adjusting rod is used to be installed inside the main body, so that when the device is in use, the yarn can pass between the contact parts at the bottom of the adjusting rod, so that the contact parts can comb the yarn and attach it Thread ends and fine wool are removed, so that the cleaned thread ends or wool can be reused, and flying dust can also be effectively avoided.

Owner:安徽省新远升针纺织有限公司

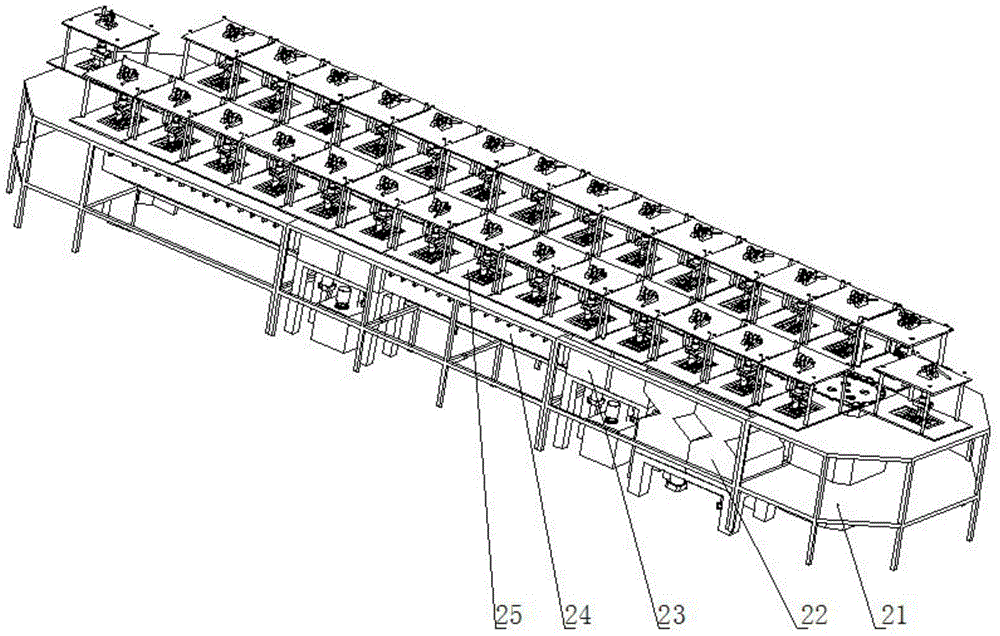

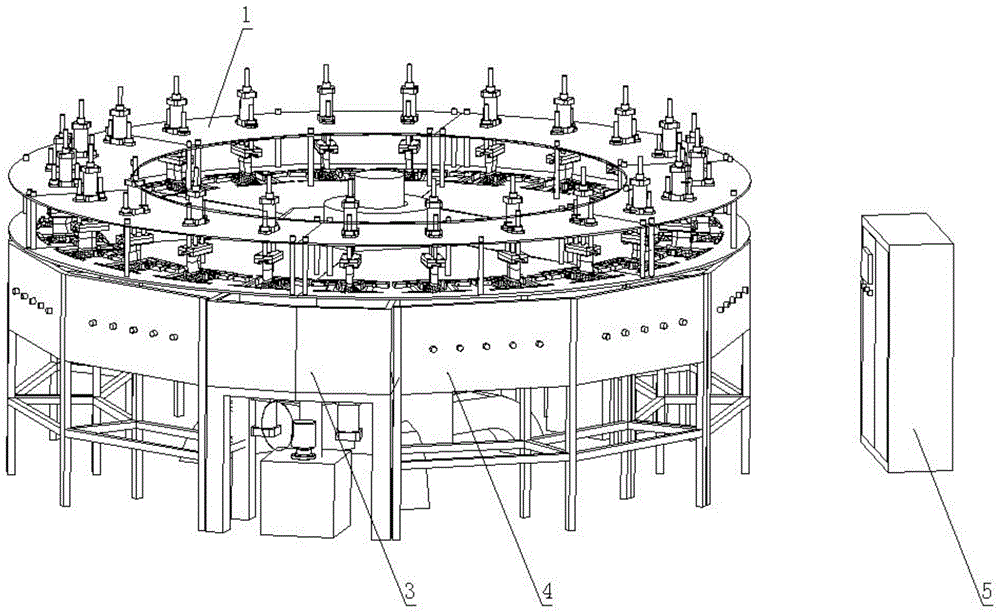

Multi-station automatic cold-bonded shoe compound processing system and processing technology

The invention relates to a multi-station fully automatic cold-bonding shoe composite processing system and processing technology. The processing steps are: (1) start the system, and simultaneously load the sole and the upper of the shoe to be processed; The upper of the system is fluffed, and at the same time, the sole that enters the system is polished; (3) spray glue, including spray glue on the upper and sole; (4) drying: after spraying glue, the ring transmission mechanism drives the upper and The soles pass through multiple drying mechanisms in sequence; (5) Bonding, remove the dried uppers and soles, and manually pair and fasten the dried uppers and soles to complete the cold bonding process. The present invention has completely changed the production process of cold-bonded shoes currently on the market. It has a high degree of automation and liberates workers from heavy and dangerous work. The entire process is completed under the program control of the electrical control system, creating a safe and fast , environmental protection, energy saving, labor saving, perfect work.

Owner:马士通安全设备(天津)有限公司

An anti-hair finishing agent for embroidery and its application method

ActiveCN106906661BImprove fluffing effectIncreased durabilityFibre treatmentAfter treatmentSurface-active agents

The invention discloses an anti-fluffing finishing agent for embroidery and a use method thereof. The anti-fluffing finishing agent comprises a copolymer, fibroin powder, a surface active agent and deionized water, wherein the copolymer consists of a methacrylamide monomer, a methacrylate monomer, a butyl acrylate monomer and an acrylic-2-hydroxyethyl methacrylate monomer. The use method comprises the following steps of: selecting a writing brush with a proper size to dip a proper amount of anti-fluffing finishing agent for embroidery, uniformly brushing along embroidery patterns multiple times, each in a small amount, till the embroidery patterns are fully wet so as to prevent the finishing agent from permeating to substrates outside the embroidery patterns, then drying the embroidery product by hot air with the temperature of 50-80 DEG C, finally baking the dried embroidery product for 3-5 minutes by using hot air with the temperature of 120-150 DEG C, and after treatment is finished, ironing by using an iron. The anti-fluffing finishing agent and the use method thereof disclosed by the invention have the advantages that after anti-fluffing finishing is carried out on an embroidery product, the fluffing performance of the embroidery product can be greatly improved, and the durability and the quality of the embroidery product can be improved.

Owner:苏州秀艳天下刺绣工艺有限公司

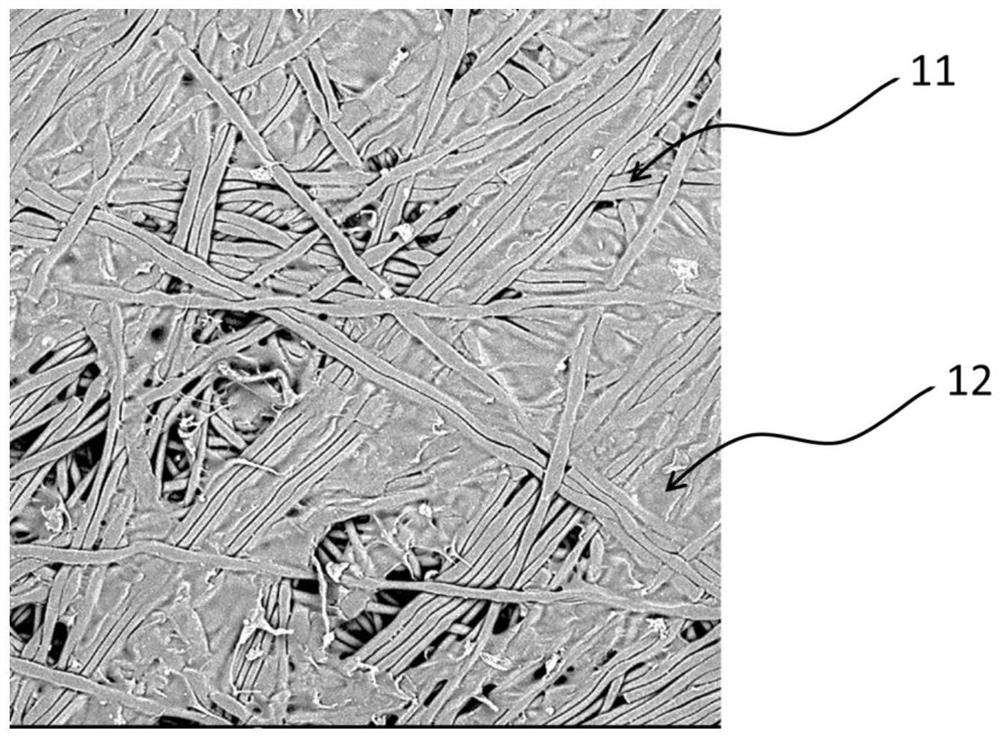

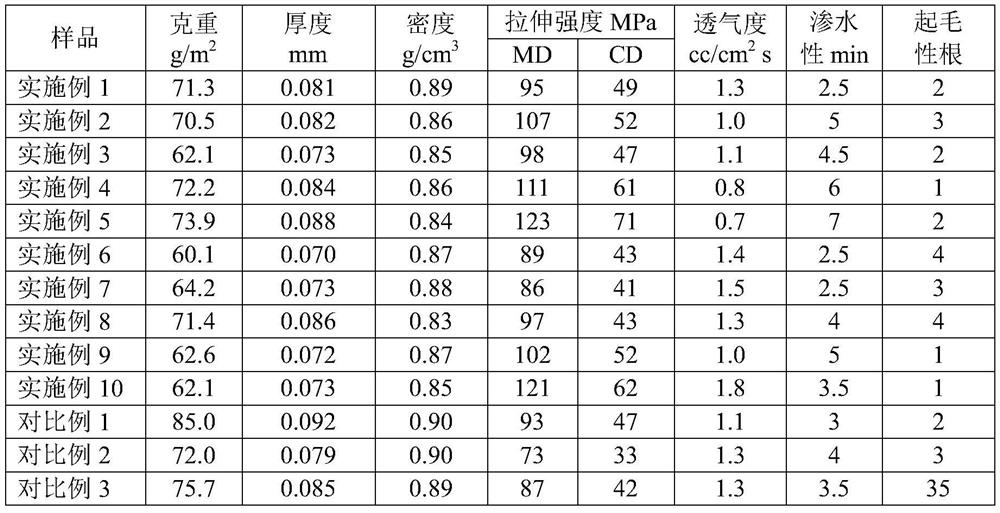

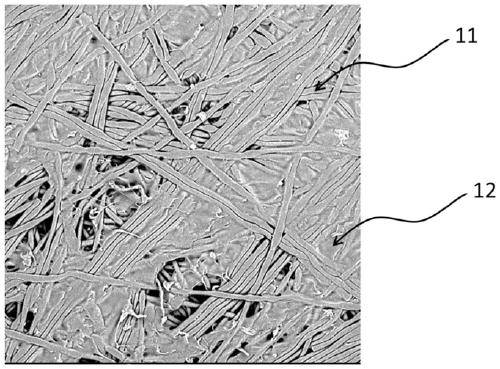

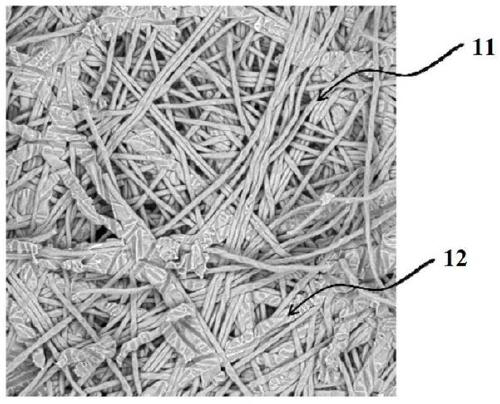

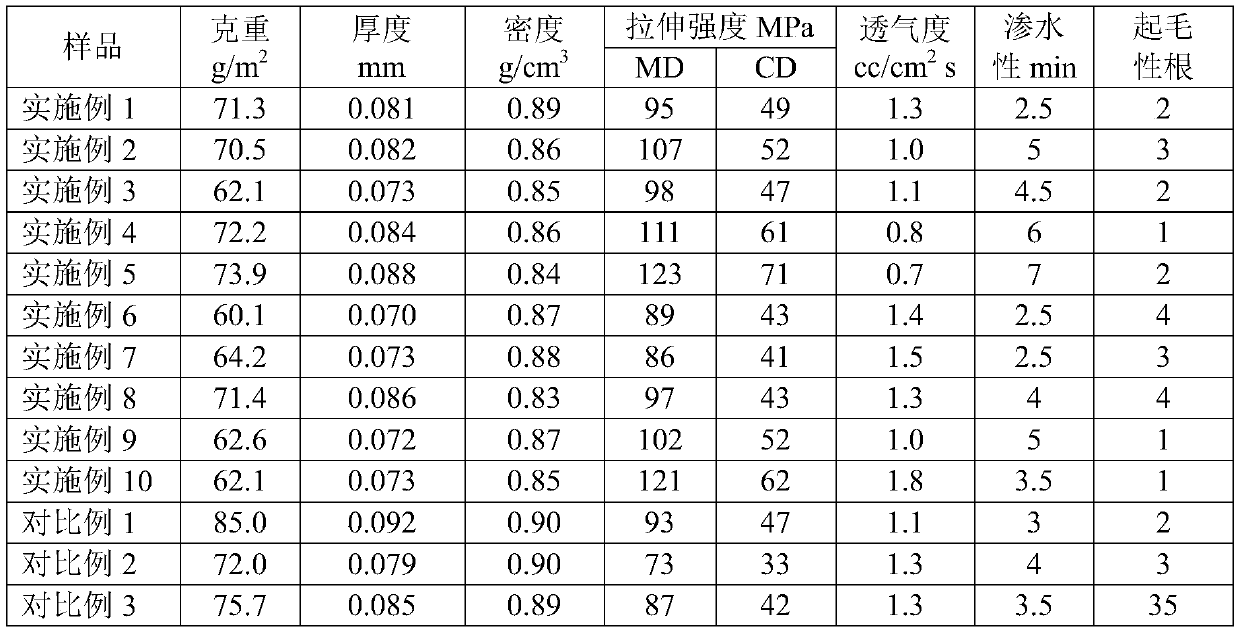

Support materials and semipermeable membrane composites

ActiveCN111530299BImprove breathabilityImprove filtering effectSemi-permeable membranesGeneral water supply conservationFiber diameterUltimate tensile strength

The invention provides a support material and a semipermeable membrane composite material. The support material includes main body fibers and binder fibers, the support material has two surface regions arranged in the thickness direction and an inner region, wherein the inner region is arranged between the two surface regions, and the thickness of each surface region is smaller than that of the support material 1 / 2 of the thickness, the first raw fiber diameter of the binder fiber used to form the surface area is R 1 , the diameter of the second raw fiber used to form the binder fiber of the inner region is R 2 , and R 1 greater than R 2 . When operating under the same pressure, the thickness of the support material can be further reduced, which not only enables the final membrane product to wrap a larger area of membrane material with the same appearance size, thereby achieving greater membrane flux, but also reduces the production cost. membrane cost. The surface area forms a denser surface structure, maintains sufficient smoothness and excellent fluff on the surface of the support material, and provides greater tensile strength.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

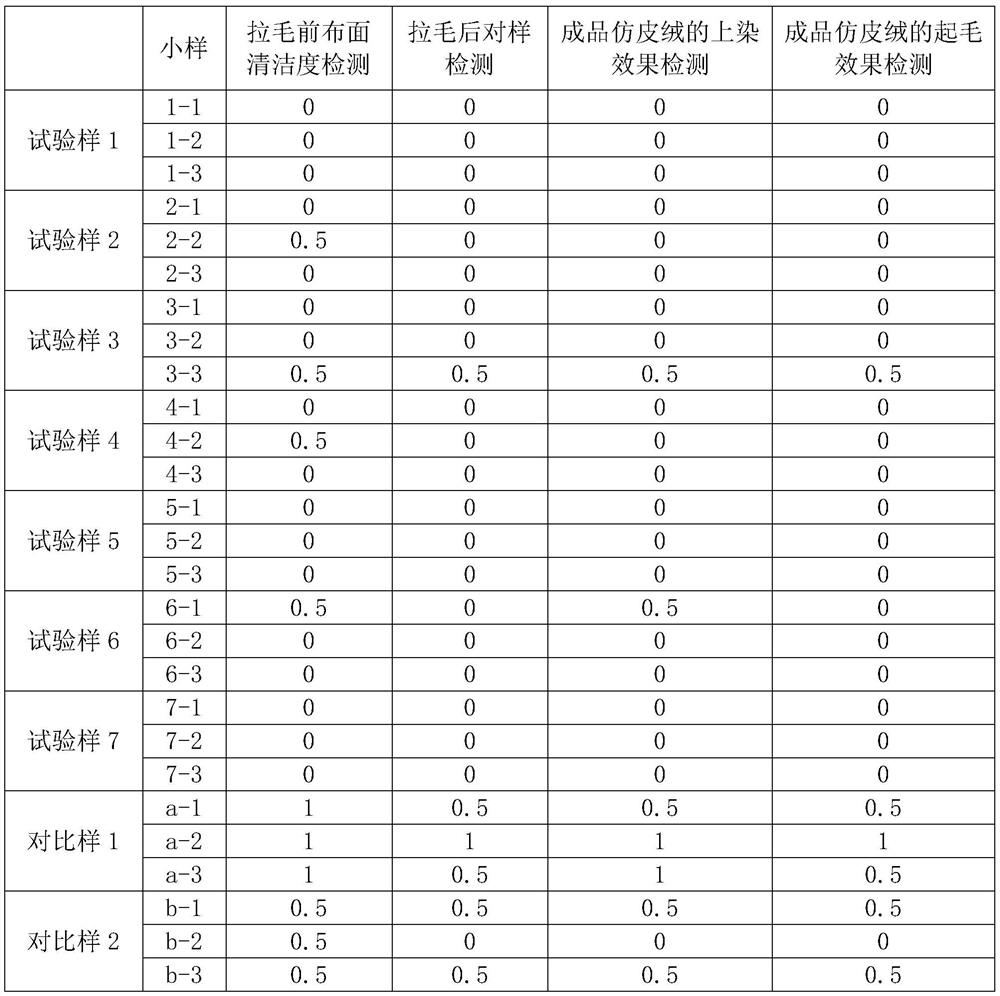

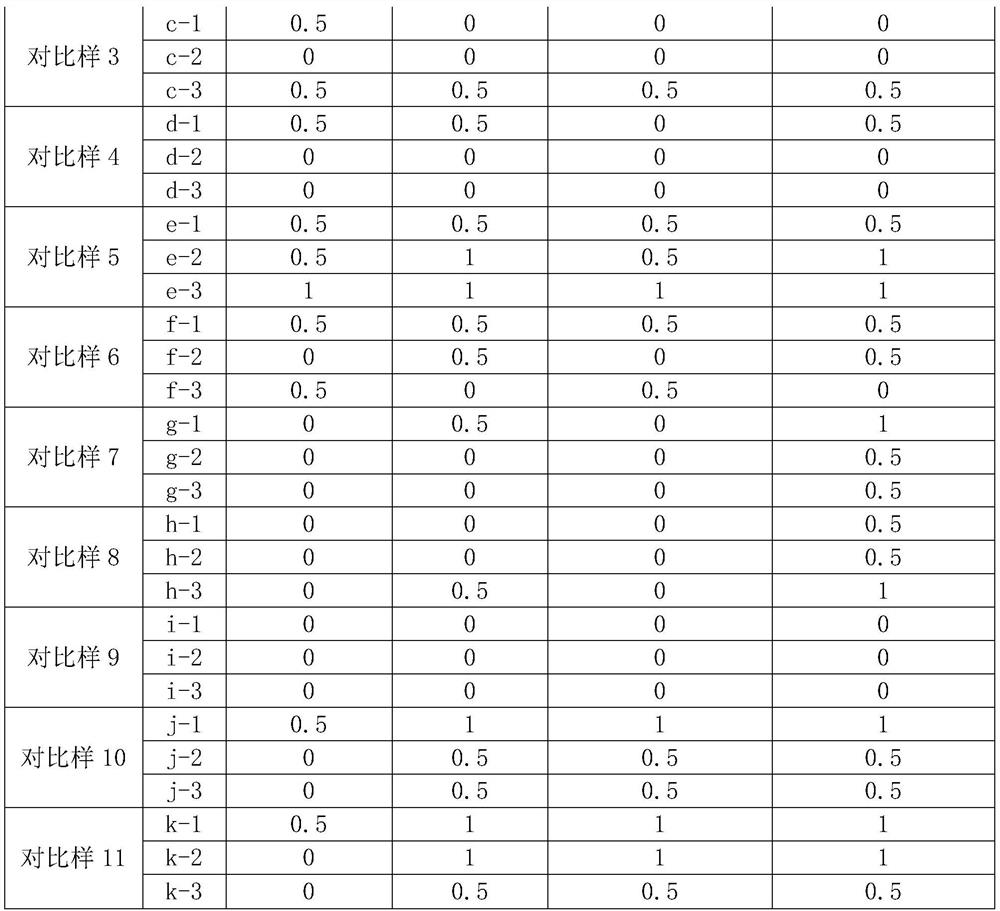

A kind of dyeing process of imitation leather fleece

InactiveCN108532163BImprove efficiencySimple processLiquid/gas/vapor removalHeating/cooling textile fabricsProcess engineeringIndustrial engineering

The invention discloses a dyeing process of imitation leather, which belongs to the technical field of imitation leather processing, and its technical points include gray cloth unwinding, cleaning, decontamination and rinsing, dehydration and opening, drying, napping, dyeing, dehydration and opening, and shaping After drying, cooling and shaping, and rolling into the warehouse, the finished imitation leather can be obtained. By adjusting the sequence of each step, the invention can not only improve the dyeing effect and dyeing uniformity of the imitation leather, but also further optimize the process and improve the efficiency. Secondly, the pretreatment of the fluffing agent and the softening agent can make the fluffing effect of the gray cloth better in the later process of napping, and at the same time increase the softness of the gray cloth. In addition, when drying and setting the temperature in two steps, not only can the excess water in the imitation leather be removed, but also the effect of adjusting the width of the imitation leather can be achieved, so that the hair surface of the imitation leather is more uniform and smooth.

Owner:嘉兴市远大纺织印染有限公司

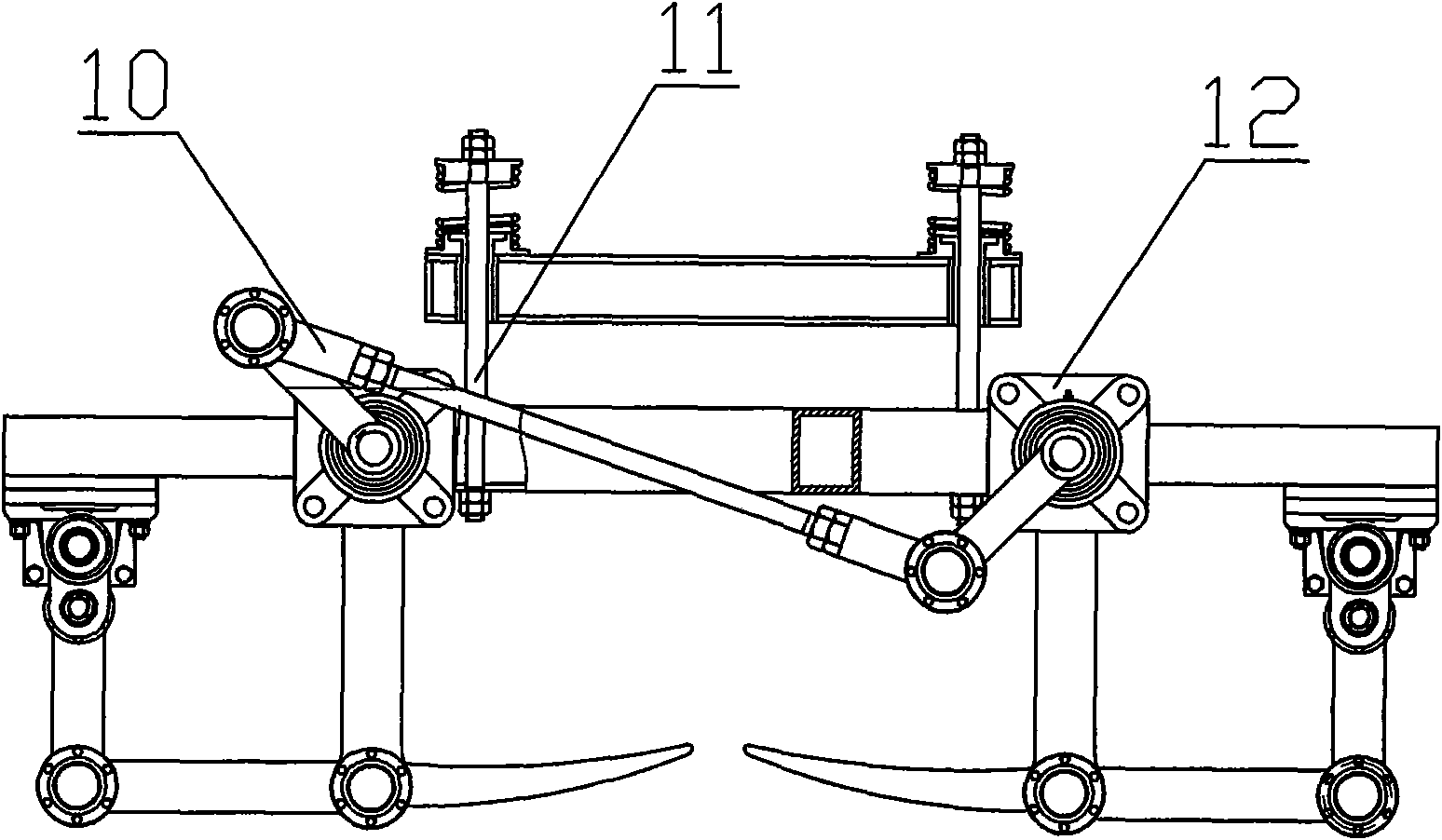

Double-roller type skein fluffing device and method

The invention discloses a double-roller type skein fluffing device and method, and belongs to the technical field of textiles. The double-roller type skein fluffing device comprises a double-roller assembly, moving assemblies are arranged on the two sides of the double-roller assembly, a shifting rod assembly is arranged on each moving assembly, and a stretching assembly is arranged on the front side of the double-roller assembly; and a vibration assembly is arranged on the side wall of each moving assembly, the double-roller assembly is movably installed on a transverse shaking assembly, thetransverse shaking assembly is movably installed on a vertical shaking assembly, and a control box is installed on the double-roller assembly. According to the device, operation is carried out throughalternate circulation of the transverse shaking assembly and the vertical shaking assembly, so that fluffing operation similar to manual operation on skein is achieved, manual labor intensity is reduced, and skein carding quality is improved; and overall tightness of skeins is reduced through the shifting rod assemblies and the vibration assemblies, the skeins are easier to shake and loosen, andskein carding efficiency is improved.

Owner:HEFEI C&P NONWOVEN PROD

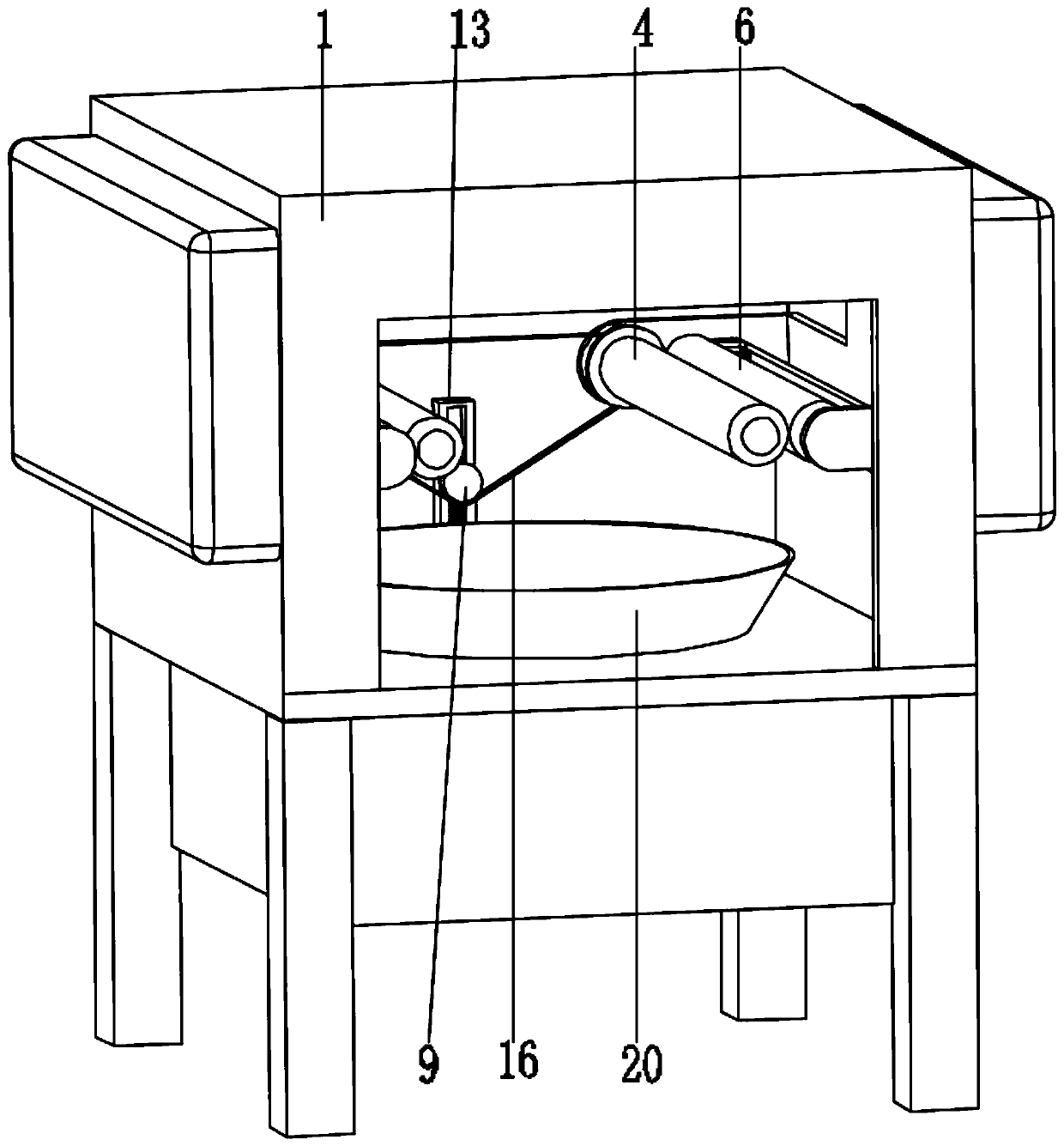

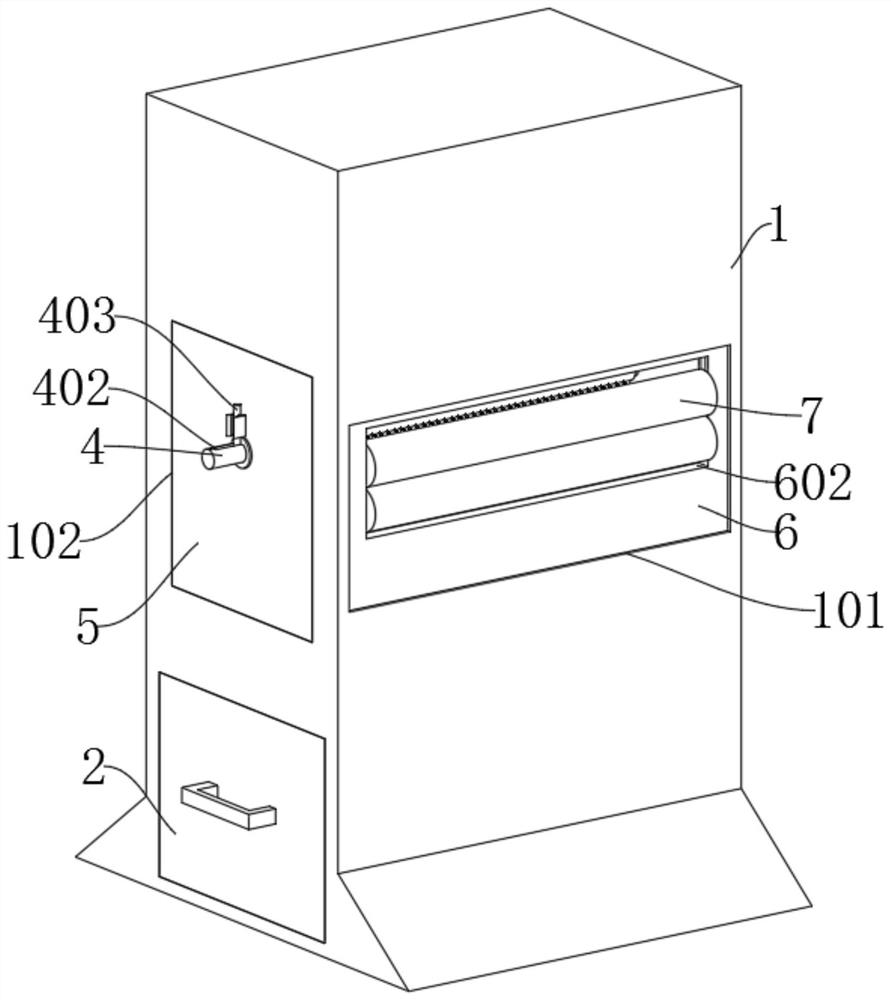

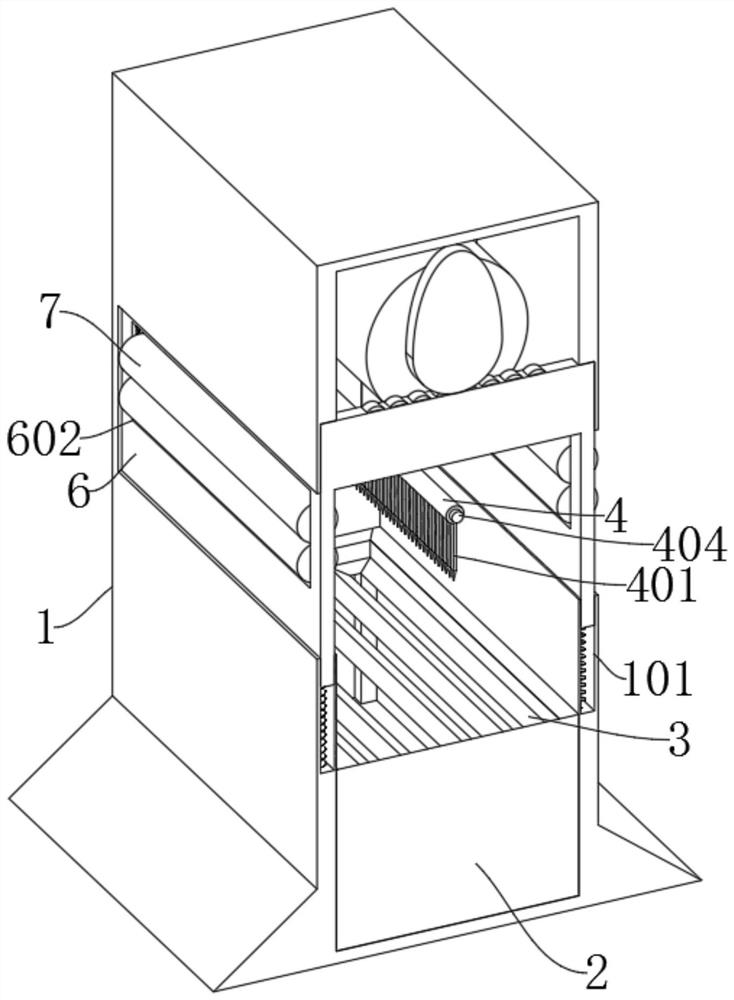

Full-automatic hemp fluffing machine

InactiveCN101994160ASolve the long-standing manual problem of looseningIncrease productivityMechanical treatmentEngineeringWorkload

The invention discloses a full-automatic hemp fluffing machine. The full-automatic hemp fluffing machine provided by the invention comprises a tooth fluffing assembly device, a fluffing connecting rod device, a crank fluffing device, a conveying device, a base and a support frame; and the devices work cooperatively, so that the problem of hemp fluffing is radically solved. The machine solves the problem that the hemp fluffing always depends on manual operation for a long time and greatly improves production efficiency; and the workload of 300 to 500 persons can be offset by one machine and the fluffing effect is far superior to that of manual fluffing.

Owner:六安金宇数控机床制造有限公司

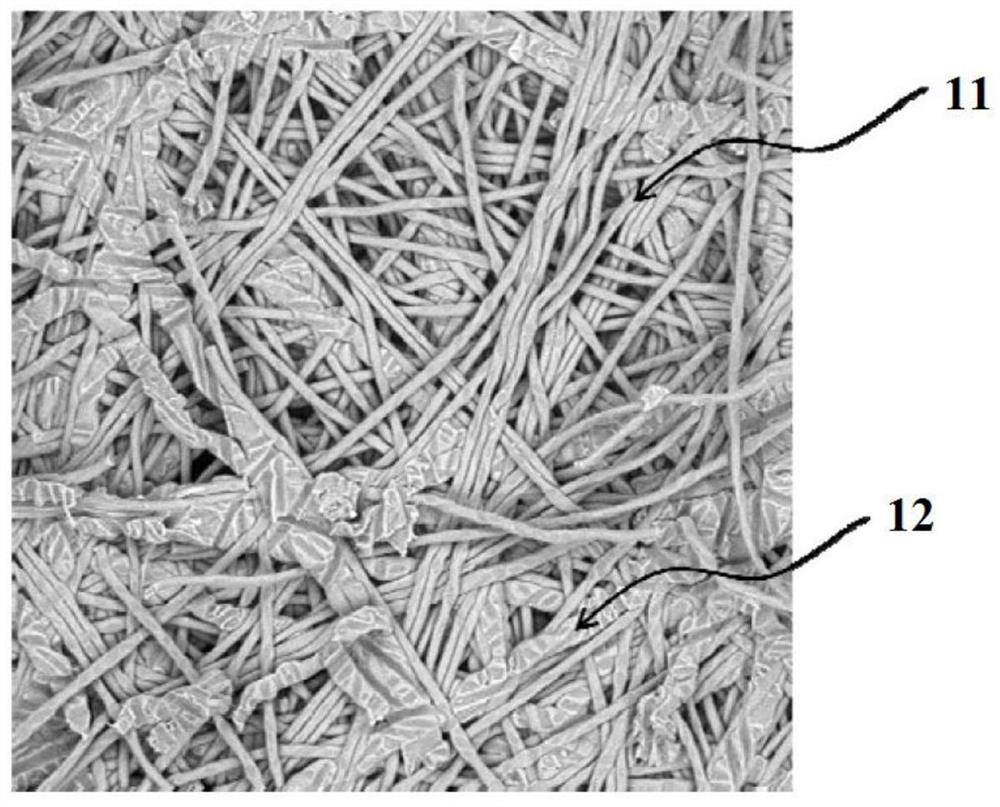

High-shrinkage polyacrylonitrile fibers, yarns containing the fibers, and pile fabrics using the yarns with different pile heights

ActiveCN105705687BImprove fluffing effectExcellent compression recovery performanceElectroconductive/antistatic filament manufactureArtificial filament washing/dryingYarnSingle fiber

The present application provides polyacrylonitrile fibers suitable for pile fabrics with different pile heights such as high pile cloth, yarns containing the fibers, and pile fabrics using the yarns. The polyacrylonitrile fiber is a highly shrinkable polyacrylonitrile fiber with a single fiber fineness of 1-7dtex, a shrinkage rate of 20-40%, and a shrinkage bulk of 0.19-0.30mm3 / g, or a single fiber fineness of 2- 7dtex, polyacrylonitrile fiber with elongation of 50-70% and bulkiness of 0.19-0.30mm3 / g.

Owner:MITSUBISHI CHEM CORP

Full-automatic hemp fluffing machine

InactiveCN101994160BSolve the long-standing manual problem of looseningIncrease productivityMechanical treatmentWorkloadMechanical engineering

The invention discloses a full-automatic hemp fluffing machine. The full-automatic hemp fluffing machine provided by the invention comprises a tooth fluffing assembly device, a fluffing connecting rod device, a crank fluffing device, a conveying device, a base and a support frame; and the devices work cooperatively, so that the problem of hemp fluffing is radically solved. The machine solves the problem that the hemp fluffing always depends on manual operation for a long time and greatly improves production efficiency; and the workload of 300 to 500 persons can be offset by one machine and the fluffing effect is far superior to that of manual fluffing.

Owner:六安金宇数控机床制造有限公司

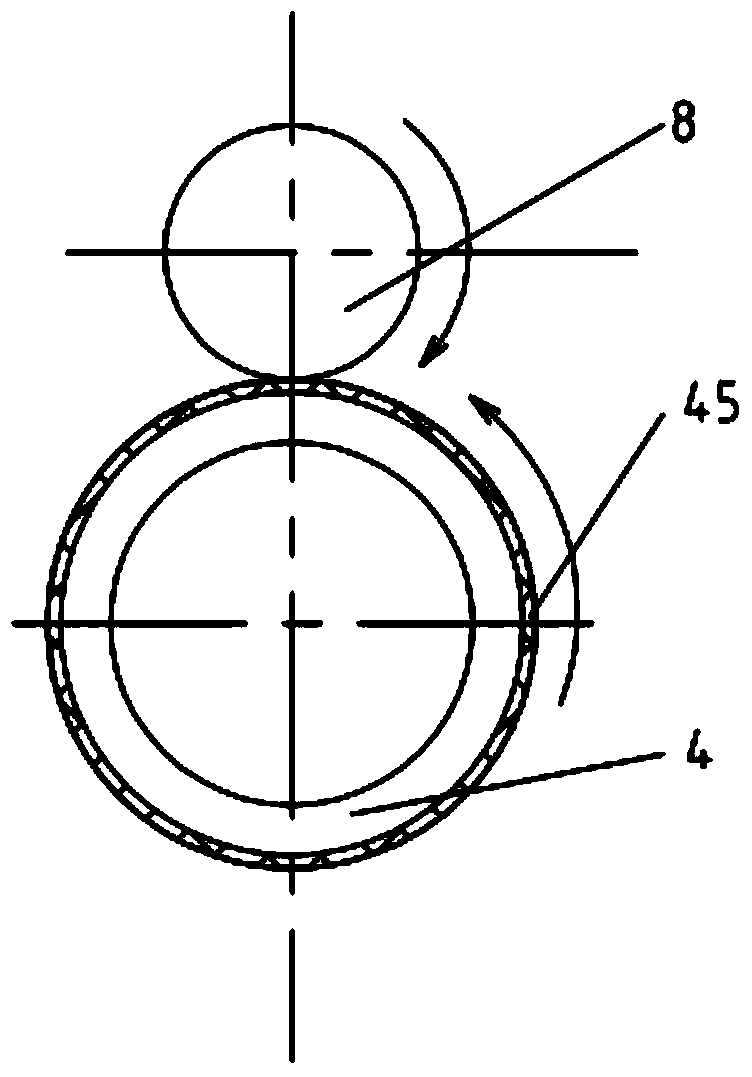

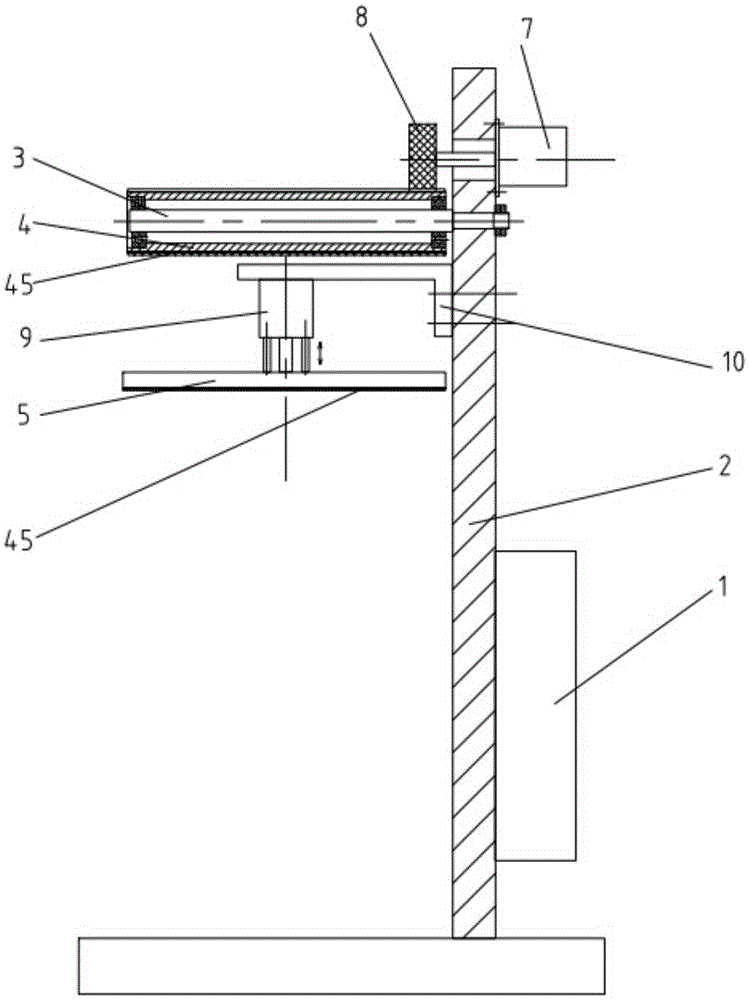

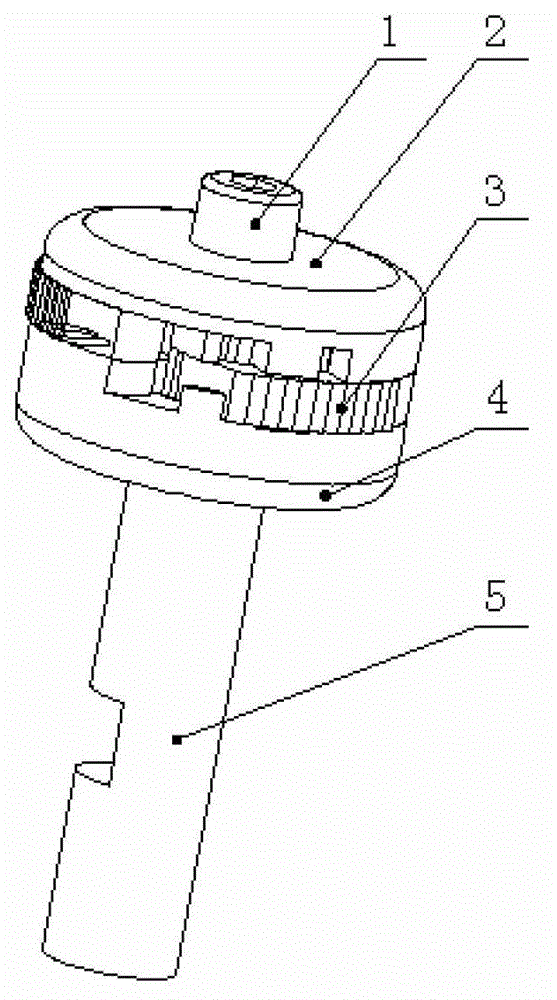

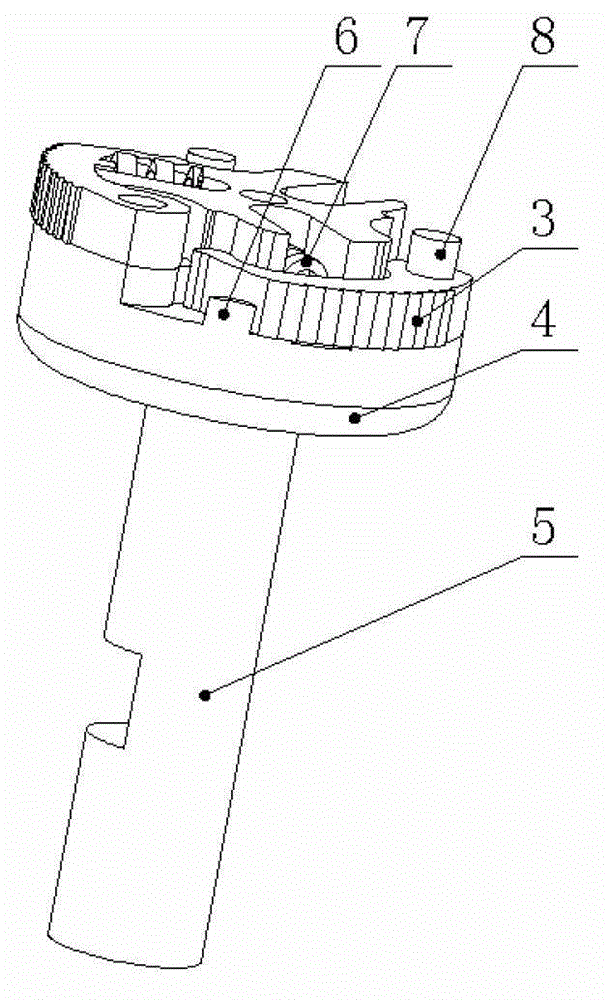

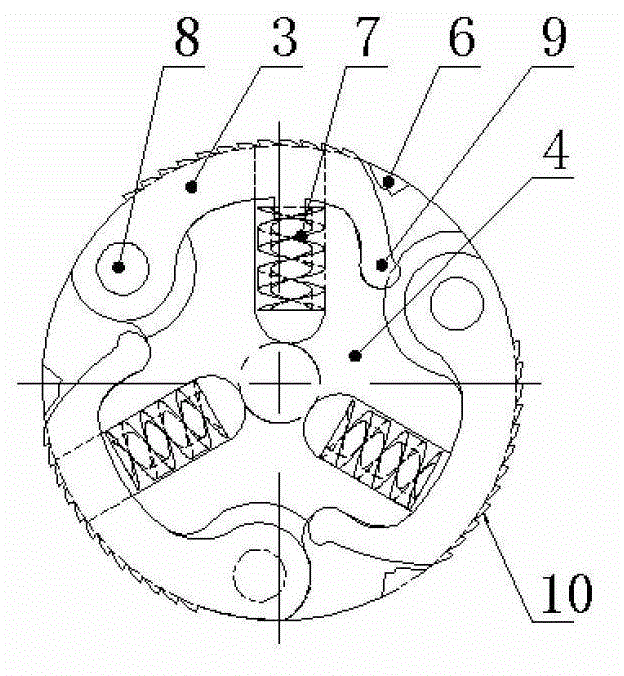

Intelligent fuzzing wheel

ActiveCN102960909BAutomatically adjust pop-up angleGood fluff qualitySolesMechanical engineeringStandardization

The invention relates to an intelligent fuzzing wheel which comprises a rotating shaft, a base, a fuzzing wheel set and a cover plate, wherein the base is mounted at the upper end of the rotating shaft coaxially; the fuzzing wheel set with a self-adapting elastic extension bulge is mounted on the base; and the cover plate is mounted at the upper end of the fuzzing wheel set coaxially. The intelligent fuzzing wheel is simple in structure, lower in cost and uniform in fuzzing, and can be applied to a shoemaking process and various polishing processes, the fuzzing force can be automatically regulated, the polishing force is automatically regulated, the polishing quality and the production efficiency are improved, and the product standardization is ensured.

Owner:马士通安全设备(天津)有限公司

Support material and semipermeable membrane composite material

ActiveCN111530299AImprove breathabilityImprove filtering effectSemi-permeable membranesGeneral water supply conservationCompositermesSemipermeable membranes

The invention provides a support material and a semipermeable membrane composite material. The support material comprises main body fibers and adhesive fibers, and the support material is provided with two surface areas and an inner area which are arranged in the thickness direction. The inner area is arranged between the two surface areas, the thickness of each surface area is smaller than 1 / 2 ofthe thickness of the support material, the diameter of the first raw material fiber used for forming the adhesive fibers of the surface areas is R1, the diameter of the second raw material fiber usedfor forming the adhesive fibers of the inner area is R2, and R1 is larger than R2. The thickness of the support material can be further reduced when the support material runs under the same pressure,so that a final membrane product can be wound with a larger area of membrane material under the same appearance size, a larger membrane flux is realized, and meanwhile, the membrane manufacturing cost is also reduced. A more compact surface structure is formed in the surface areas, enough smoothness and excellent fuzzing property of the surface of the support material are kept, and higher tensilestrength is provided.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

Preparation method for environmentally-friendly fuzzy agent

The invention provides a preparation method for an environmentally-friendly fuzzy agent. The preparation method comprises step (1) of taking all internal organs of a grass carp, and grinding the internal organs with a meat grinder; step (2) of taking the ground internal organs, and adding water and stirring; step (3) of adjusting pH to 7, adding papain, and stirring for enzymolysis at a temperature of 50 DEG C; step (4) of pouring enzymolysis liquid, performing centrifugation, and taking upper layer oil; step (5) of taking 4-5wt% of the upper layer oil, 8-10wt% of sodium dodecylbenzene sulfonate and 2-3wt% of CO40 high-efficiency solubilizing agent for mixing; step (6) of adding the balance water, continuing to stir for 10-20 min, and performing homogenization under high pressure at 70-80MPa; step (7) of adding melamine and thionyl chloride, transferring the product into a reaction kettle, and reacting at a temperature of 80-90 DEG C; step (8) of adding sodium stearyl lactate, and transferring to an emulsifier for emulsification. The prepared environmentally-friendly fuzzy agent can increase the tearing strength of a fiber and is good in fuzzing degree and more favorable for a subsequent fleece process.

Owner:SUZHOU TIANAO SPECIAL EMBROIDERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com