A kind of dyeing process of imitation leather fleece

A technology of imitation leather and technology, which is applied in the field of dyeing technology of imitation leather, can solve the problems of uneven dyeing, light color, and poor dyeing effect, so as to improve the uniformity of dyeing, optimize the process, and improve dyeing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

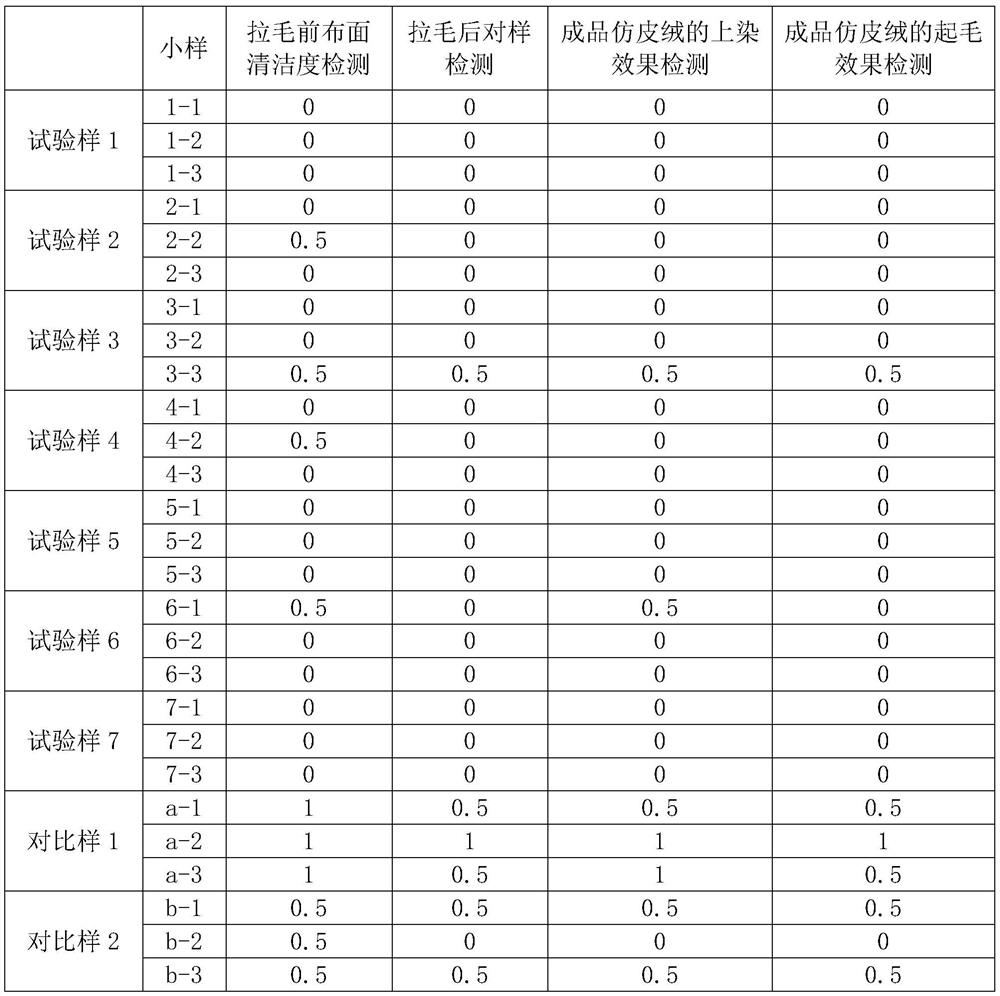

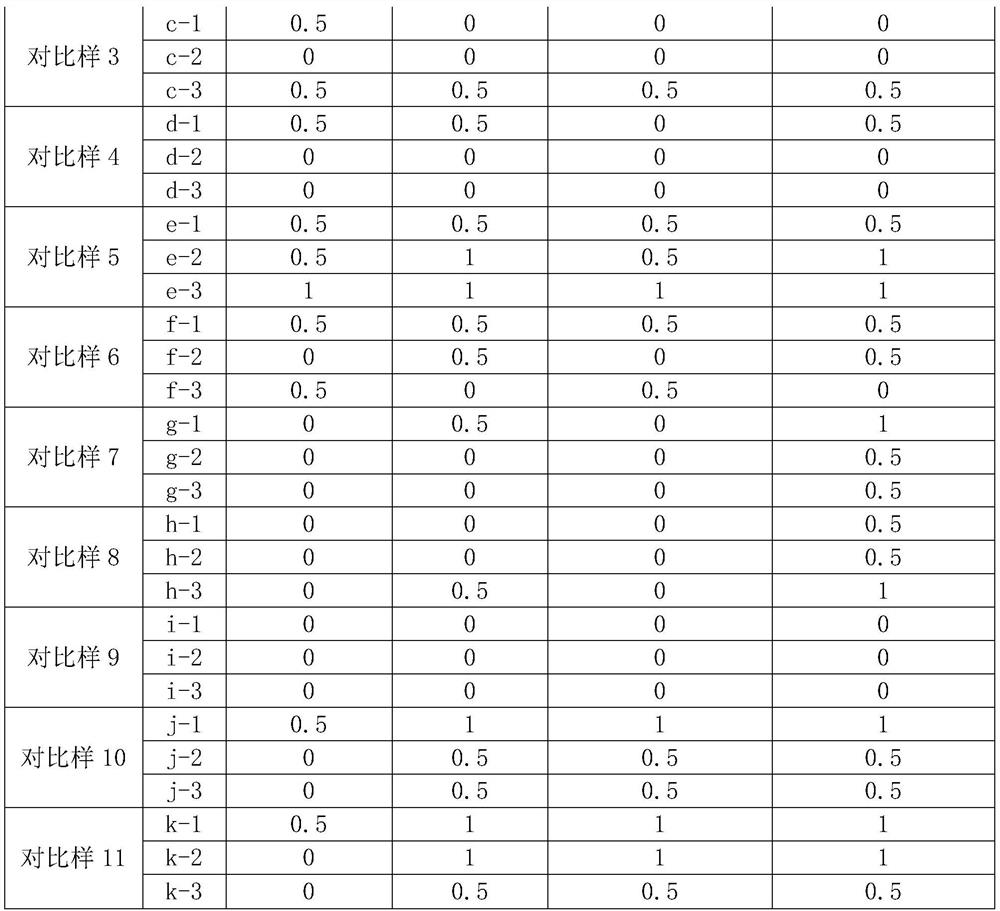

Examples

Embodiment 1

[0046] A dyeing process for imitation leather, comprising the following steps:

[0047] Step S1, unwinding the gray cloth through a KT-TJ-1800A unwinding machine.

[0048] Step S2, cleaning: add 3 tons of clear water, 2 kg of high-temperature degreaser (i.e. high-temperature degreaser JS-202) and 2 Mix 1 kg of deoiling spirit (that is, special effect deoiling spirit SXY-123), and then put the unrolled gray fabric into the overflow dyeing machine through the cloth guide frame, raise the temperature to 130°C, and keep it warm for 20 minutes for cleaning.

[0049] Step S3, decontamination and rinsing: lower the temperature to 100°C, discharge the water in the overflow dyeing machine under normal pressure, control the temperature of the clean water at 30-40°C, and then add clean water to rinse for 3 times.

[0050] Step S4, the gray cloth is exported from the overflow dyeing machine, and transferred to the drier for dehydration and drying for 20 minutes, and then opened by a TB-T...

Embodiment 2

[0059] A kind of dyeing process of imitation leather, and the difference of embodiment 1 is: in step S5, at first add 100 kilograms of clear waters, 1 kilograms of softening agent and 4 kilograms of fluffing agents in the tank and mix evenly, then at normal temperature will The gray cloth obtained in step S4 is put into the above-mentioned water tank for pretreatment, and then dried with a roller, and then put into an oven for drying treatment at a speed of 25-28m / min.

Embodiment 3

[0061] A dyeing process for imitation leather, the difference from Example 1 is: in step S7, after the overflow dyeing machine is cooled to 100°C, the overflow dyeing machine is first opened for sample processing, when the imitation leather When the dyeing of the velvet is consistent with the standard sample, add water to the overflow dyeing machine and rinse it 3 times, and get the imitation leather velvet after removing the water;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com