Sandblasting raising machine and sandblasting fluffing technology for upper of leather shoes

A technology for raising machine and shoe upper, which is applied to abrasive jet machine tools, shoe lasts, footwear, etc., can solve the problems of high manual technical requirements, low degree of process automation, separation of shoe uppers and soles, etc., to reduce labor intensity and technology. requirements, convenient operation, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

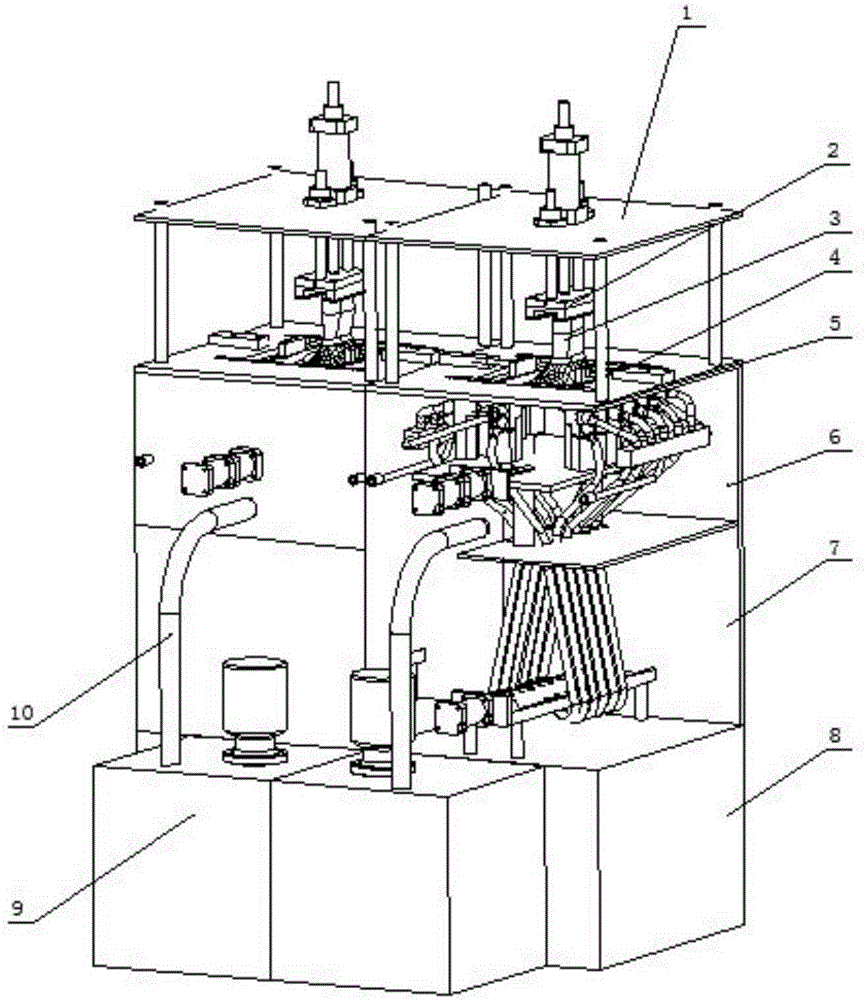

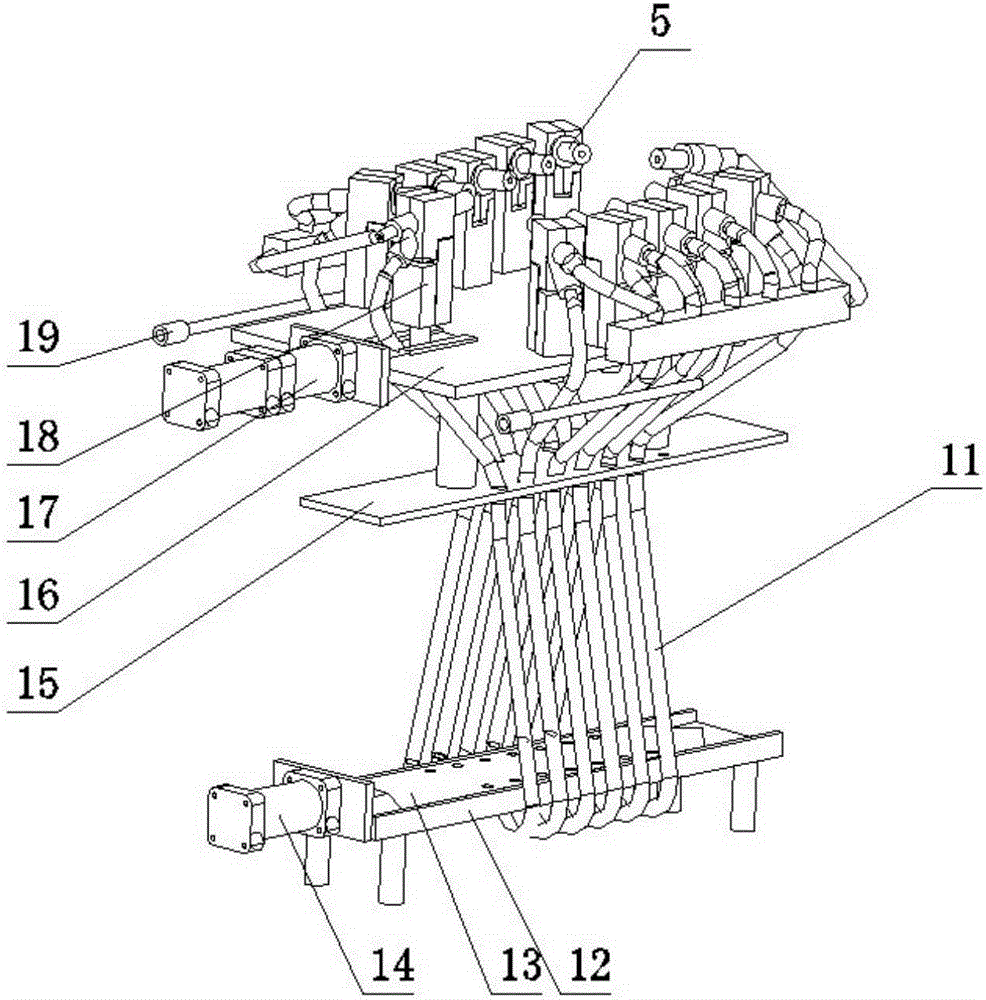

[0036] A sandblasting and raising machine for leather shoe uppers, comprising a frame 1, a shoe last support 2, a raising sealing box 6, a sand box 7 and a dust collection box 8, and a shoe last support that can move up and down is installed on the upper end of the frame, and the shoe last support A fuzzy sealing box is installed in the middle of the frame corresponding to the lower part. A sandbox is fixed at the lower end of the fuzzy sealing box, and a dust collection box is arranged on the outside of the sandbox. Falling dust.

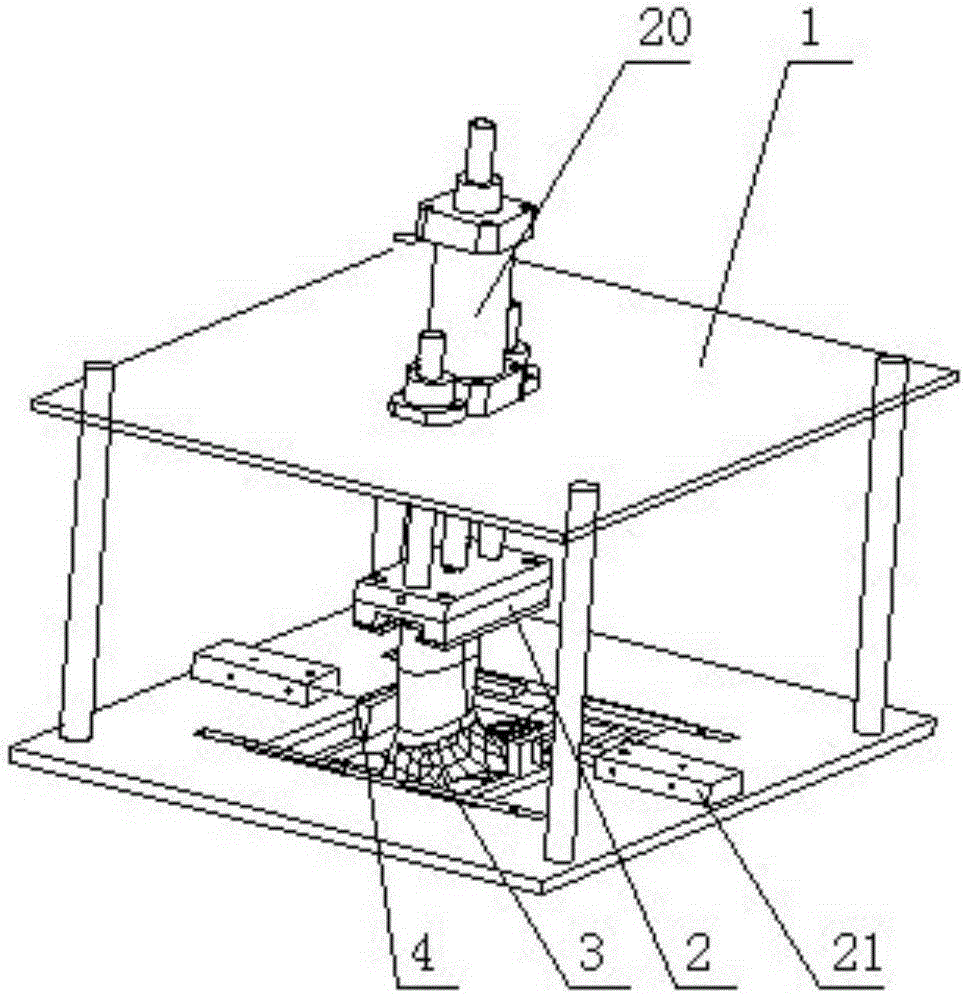

[0037] See attached figure 2 , a shoe last lifting cylinder 20 is vertically installed on the upper end of the frame, a shoe last bracket is coaxially installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com