Multi-station automatic cold-bonded shoe compound processing system and processing technology

A kind of processing technology, fully automatic technology, applied in the direction of footwear, soles, adhesive shoe parts, etc., can solve the problems of lack of automatic production system, non-compliance with environmental protection requirements, fire hazards, etc., to improve product processing efficiency and processing quality , The effect of reducing labor intensity and technical requirements, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

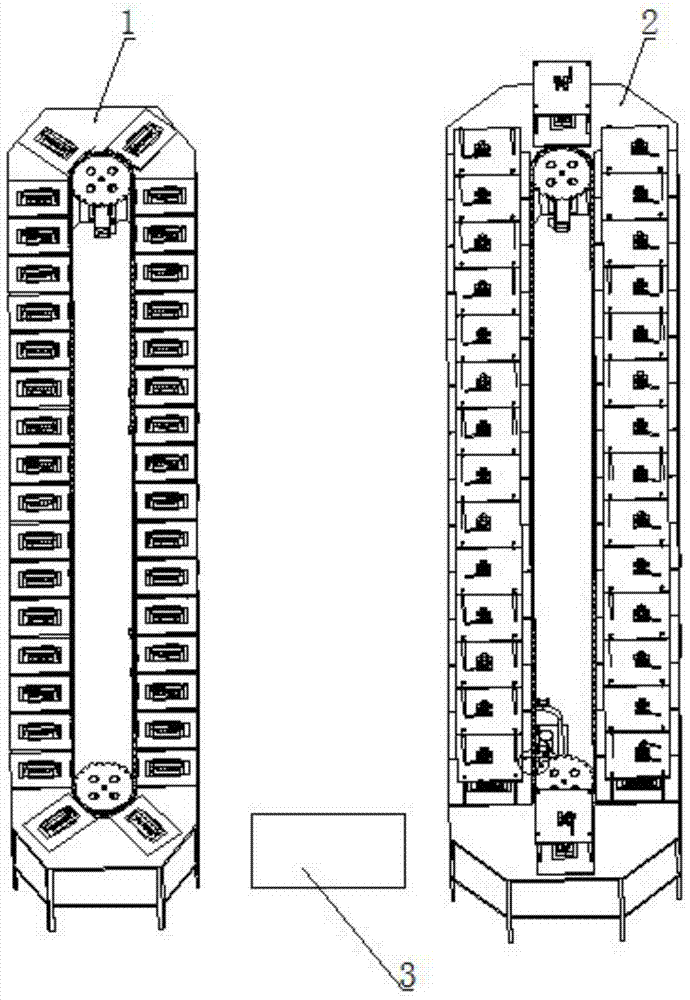

[0072] A multi-station full-automatic cold-bonding shoe composite processing system is composed of a sole processing line 1, an upper processing line 2 and a cold-bonding workbench 3. For ease of description, this embodiment is attached figure 1 The horizontal and vertical directions in the directions shown are explained. The sole processing line and the upper processing line are arranged horizontally and longitudinally at intervals. A cold bonding workbench is provided between the upper processing lines of the sole processing line. The cold bonding workbench corresponds to the sole processing line. The position corresponding to the outlet of the shoe upper processing line;

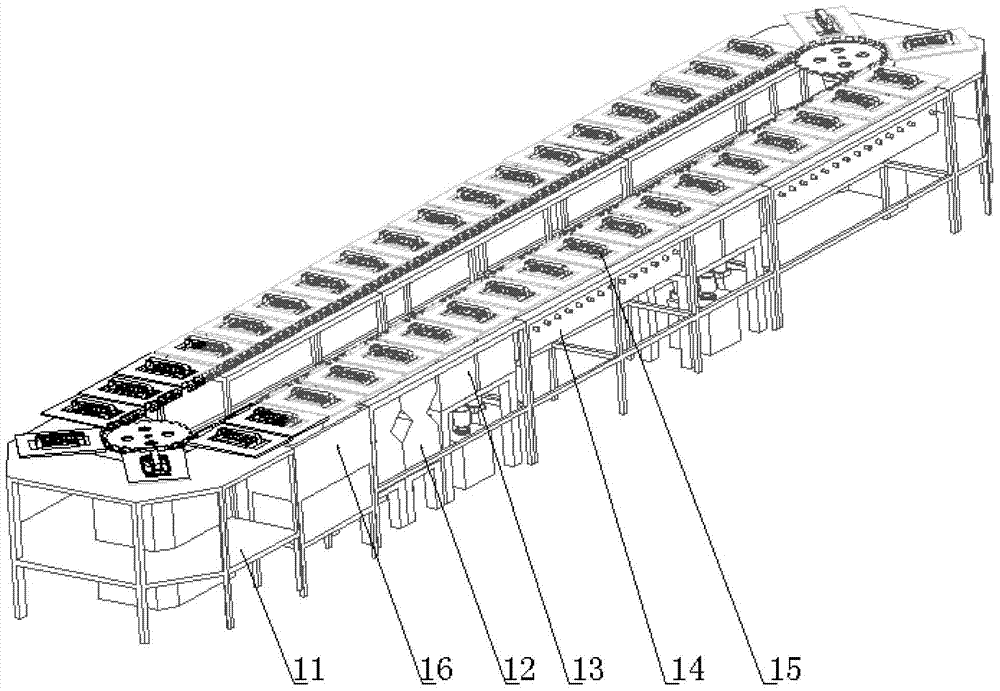

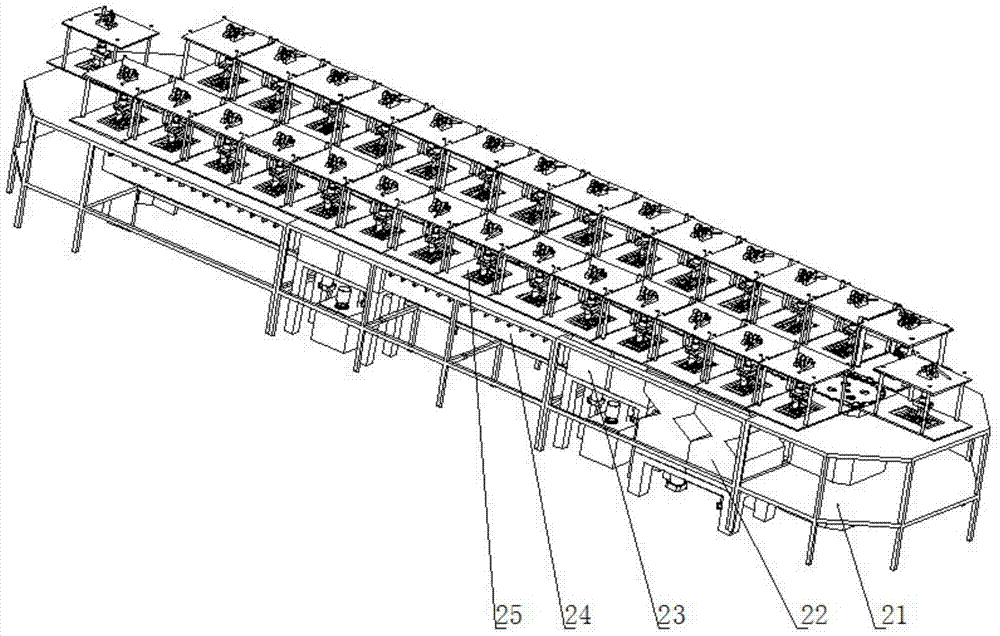

[0073] See attached figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com