Support material and semipermeable membrane composite material

A technology of support materials and composite materials, applied in the field of membrane materials, can solve problems such as difficult performance and high filtration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

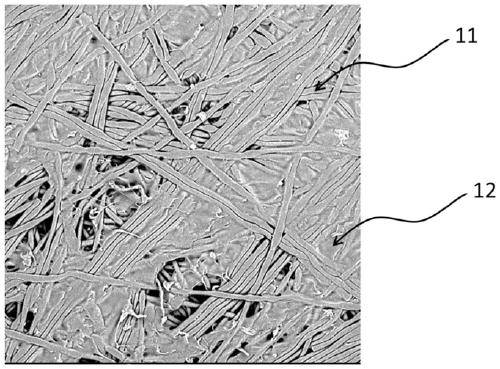

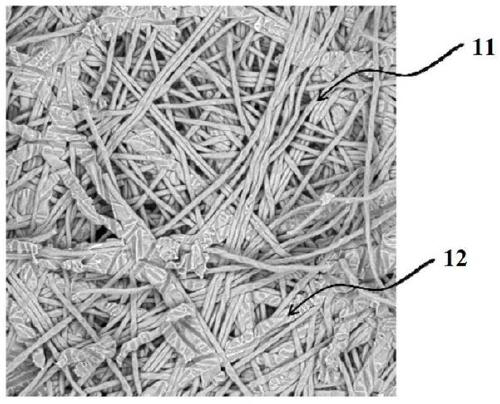

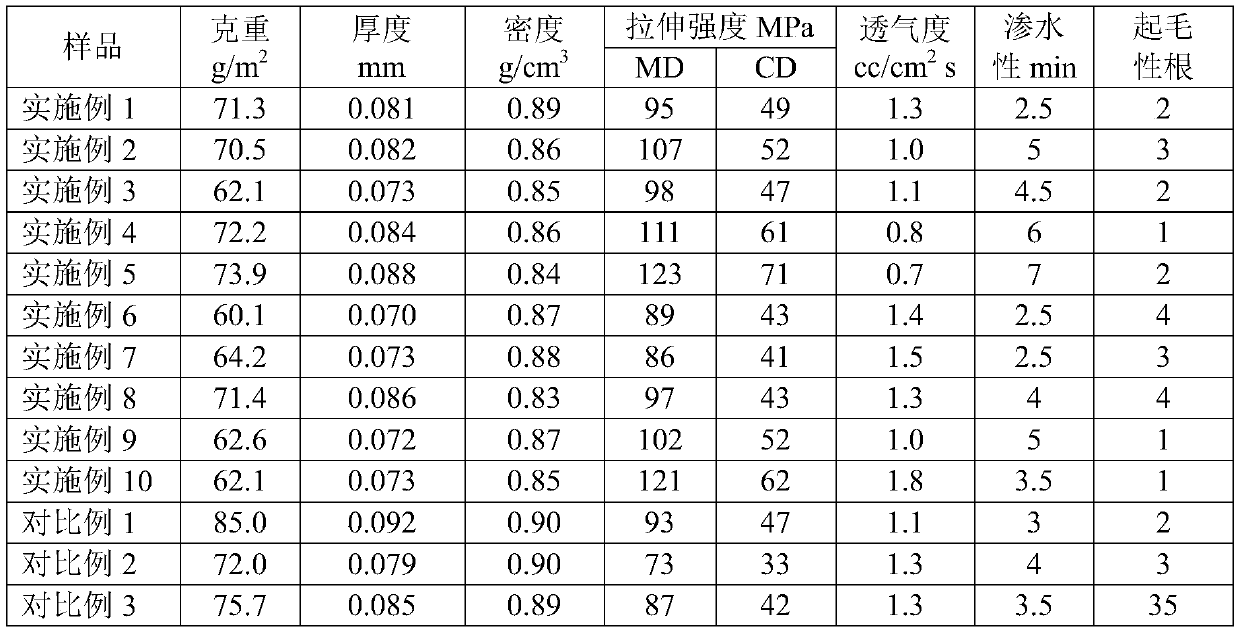

[0040] Raw materials for forming the support material: the mass fraction of the main fiber is 70%, and the mass fraction of the binder fiber is 30%, wherein the main fiber is PET, the length is 6mm, and the average diameter is 7 μm, and the binder fiber is PET with low melting point , where R 1 10μm, R 2 is 8 μm, and the length is 5 mm. (The diameter of the binder fiber stock used to form the surface area is R 1 , the diameter of the binder fiber stock used to form the inner region is R 2 ).

[0041] Because two kinds of binder fibers are used, in order to distinguish the fibers in the surface area and the inner area, the non-woven fabric is prepared by wet-laid papermaking with a three-layer inclined wire, and the middle layer is prepared to form the non-woven layer of the inner area. . The non-woven fabric layer is subjected to hot-pressing treatment by using a roller-type hot-pressing device to obtain a support material with a thickness of 0.081 mm, and a support mater...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that R 1 30μm, R 2 is 25 μm, a support material with a thickness of 0.082 mm is obtained, and the thickness of the two surface regions is each equal to 1 / 3 of the thickness of the support material. Its performance is tested, and the test results are listed in Table 1.

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is that R 1 2μm, R 2 is 1 μm, a support material with a thickness of 0.073 mm is obtained, and the thickness of the two surface regions is equal to 1 / 5 of the thickness of the support material. Its performance is tested, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com