Rocker arm type fuzzing device

A rocker-type, wool needle technology, applied in textiles and papermaking, roughening, fabric surface trimming, etc., can solve the problems of time-consuming and laborious installation and disassembly, simple raising process, monotonous appearance of pile loops, etc. Good effect, good-looking effect of textile wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

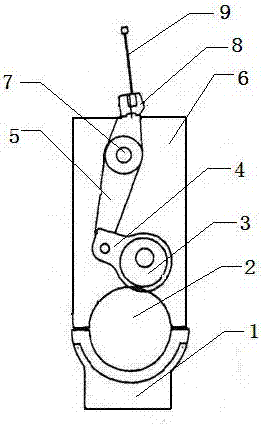

[0012] This embodiment provides a rocker arm type raising device, which is characterized in that: the rocker arm type raising device includes a rocker base (1), a rocker shaft (2), an eccentric wheel (3), a connecting rod (4 ), swing arm (5), mounting seat (6), swing shaft (7), raising needle seat (8), raising needle (9);

[0013] Among them: the rocking shaft (2) is installed on the rocking shaft base (1) in rotation, and the mounting base (6) is fixed on the rocking shaft base (1), and a swinging shaft (7) is installed in linkage on the mounting base (6). The shaft (7) is movably connected to the connecting rod (4) through the swing arm (5), and the other end of the connecting rod (4) is connected to the eccentric wheel (3). The eccentric wheel (3) circumscribes the rocking shaft (2), and the swinging shaft ( 7) A raising needle seat (8) is fixedly installed on the top.

[0014] One raising needle (9) is arranged on the raising needle seat (8).

Embodiment 2

[0016] A rocker arm type raising device, characterized in that: the rocker arm type raising device includes a rocker base (1), a rocker shaft (2), an eccentric wheel (3), a connecting rod (4), a swing arm ( 5), mounting seat (6), swing shaft (7), raising needle seat (8), raising needle (9);

[0017] Among them: the rocking shaft (2) is installed on the rocking shaft base (1) in rotation, and the mounting base (6) is fixed on the rocking shaft base (1), and a swinging shaft (7) is installed in linkage on the mounting base (6). The shaft (7) is movably connected to the connecting rod (4) through the swing arm (5), and the other end of the connecting rod (4) is connected to the eccentric wheel (3). The eccentric wheel (3) circumscribes the rocking shaft (2), and the swinging shaft ( 7) A raising needle seat (8) is fixedly installed on the top.

[0018] A plurality of raising needles (9) are arranged on the raising needle seat (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com