Full-automatic hemp fluffing machine

A fully automatic, hemp technology, applied in mechanical processing, textile and papermaking, fiber processing, etc., can solve the problems of no mechanical equipment, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

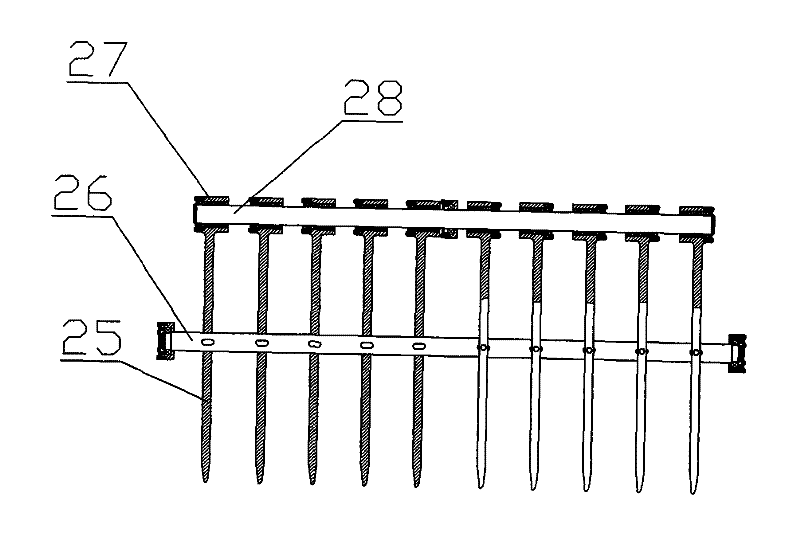

[0017] refer to figure 1 , a tooth shaking assembly device of a fully automatic cannabis shaker provided by the present invention includes a tooth shaking 25, a tooth shaking shaft 26, a swing shaft 27 and a rubber bushing 28, the tooth shaking shaft 26 is designed with small holes, and the tooth shaking 25 Through the small hole, the hole is provided with a screw to fix the shaking teeth 25, the rubber bushing 28 is sleeved on the shaking teeth 25, the swing shaft passes through the rubber bushing 28, and the rubber bushing 28 plays the role of shock absorption. The tooth 25 is fixedly connected with the swing shaft 27 with screws.

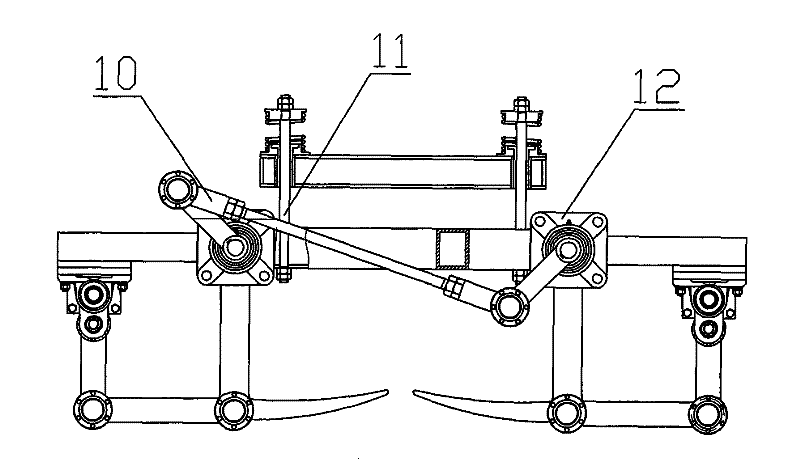

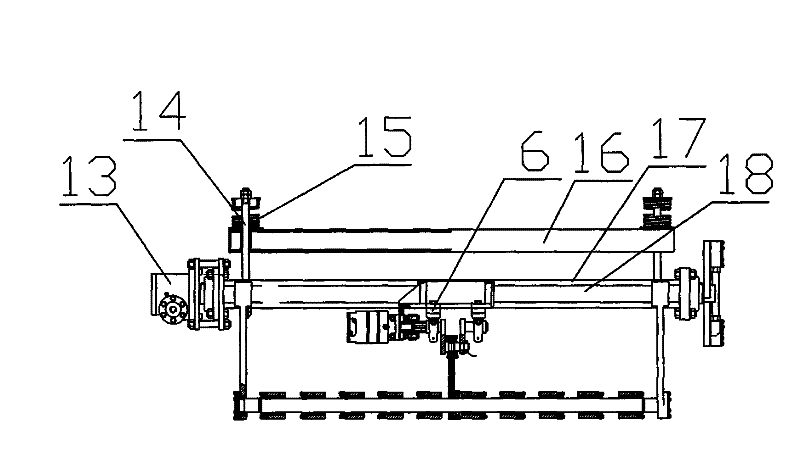

[0018] refer to figure 2 with image 3 , the loosening connecting rod device of the automatic cannabis shaking machine of the present invention comprises a self-lubricating rod end joint bearing 10, an adjusting connecting rod 11, a square seat outer spherical ball bearing 12, a hydraulic swing cylinder 13, a movable hanging rod 14, and a shoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com