Multifunctional super-hydrophobic conductive rubber composite material and preparation method thereof

A technology of conductive rubber and composite material, applied in the field of multifunctional super-hydrophobic conductive rubber composite material and its preparation, can solve the problem of weak electrostatic interaction force between conductive filler and polyurethane surface, damage to CPC conductive performance and sensing performance stability, stability resistance (low friction resistance and torsion resistance, etc.), to achieve the effect of broadening environmental applicability, excellent elongation at break and tensile recovery performance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

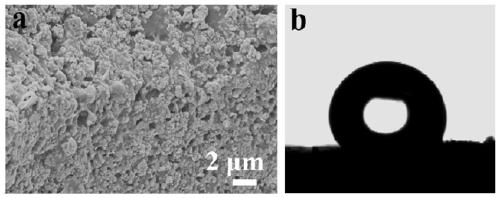

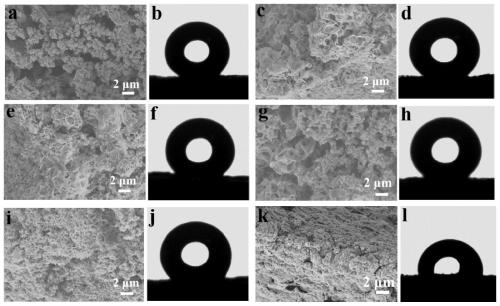

[0032] (1) Preparation of rubber foam / silver nanoparticle composite material: get 1g silver trifluoroacetate powder and be dissolved in 9g tetrahydrofuran, ultrasonic it is dissolved, obtain uniform silver trifluoroacetate solution; Will be made of 40% natural rubber and 60% butyl The rubber foam composed of styrene rubber is soaked in the silver trifluoroacetate solution for 1min. Then, put the silver precursor-adsorbed foam into 50wt% hydrazine hydrate reducing solution (water: absolute ethanol = 1:1) for reduction for 30 minutes, then take it out and rinse it with deionized water, and dry it under air conditions to obtain a composite material . The scanning electron microscope image of the prepared material is shown in image 3 As shown in a, the protruding silver nanoparticles form a multi-level structure. (2) Contact angle test, drop 5 μL of deionized water on the surface of the material to test the contact angle, the measurement results are as follows image 3 As shown ...

Embodiment 2

[0034] (1) Preparation of rubber foam / silver nanoparticle composite material: get 1g silver trifluoroacetate powder and be dissolved in 9g tetrahydrofuran, ultrasonic it is dissolved, obtain uniform silver trifluoroacetate solution; Will be made of 40% natural rubber and 60% butyl The rubber foam composed of styrene rubber is soaked in the silver trifluoroacetate solution for 5min. Then, put the silver precursor-adsorbed foam into 50wt% hydrazine hydrate reducing solution (water: absolute ethanol = 1:1) for reduction for 30 minutes, then take it out and rinse it with deionized water, and dry it under air conditions to obtain a composite material . The scanning electron microscope image of the obtained material is shown in image 3 As shown in c, the silver nanoparticles are covered by the polymer matrix precipitated during the phase separation process, which increases the interaction force between it and the polymer matrix. The small pores formed during the phase separation ...

Embodiment 3

[0036] (1) Get 1g silver trifluoroacetate powder and be dissolved in 9g tetrahydrofuran, ultrasonic dispersion makes it dissolve, obtains uniform silver trifluoroacetate solution; The rubber foam that will be made up of 40% natural rubber and 60% styrene-butadiene rubber in trifluoroacetic acid Soak in silver solution for 10 minutes. Then, put the rubber foam that has absorbed the silver precursor into 50wt% hydrazine hydrate reducing solution (water: absolute ethanol = 1:1) to reduce for 20min, then take it out and rinse it with deionized water, and dry it under air conditions to obtain Composite material, the surface scanning electron microscope picture of the obtained composite material is as follows image 3 As shown in e, the silver nanoparticles are covered by the polymer matrix precipitated during the phase separation process, which increases the interaction force between it and the polymer matrix. The small pores formed during the phase separation form a multi-level s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com