Patents

Literature

64results about How to "Good stretch recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

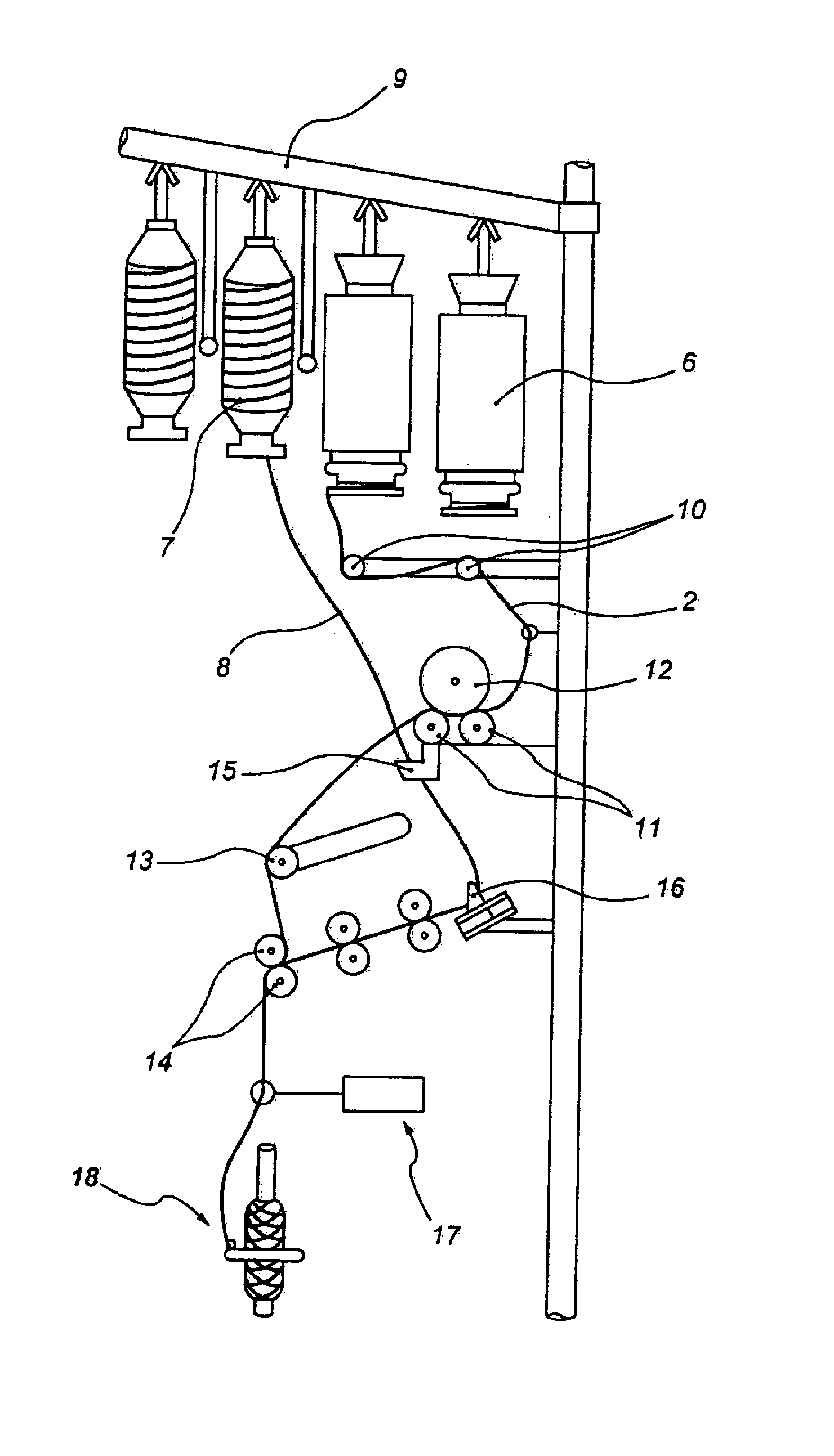

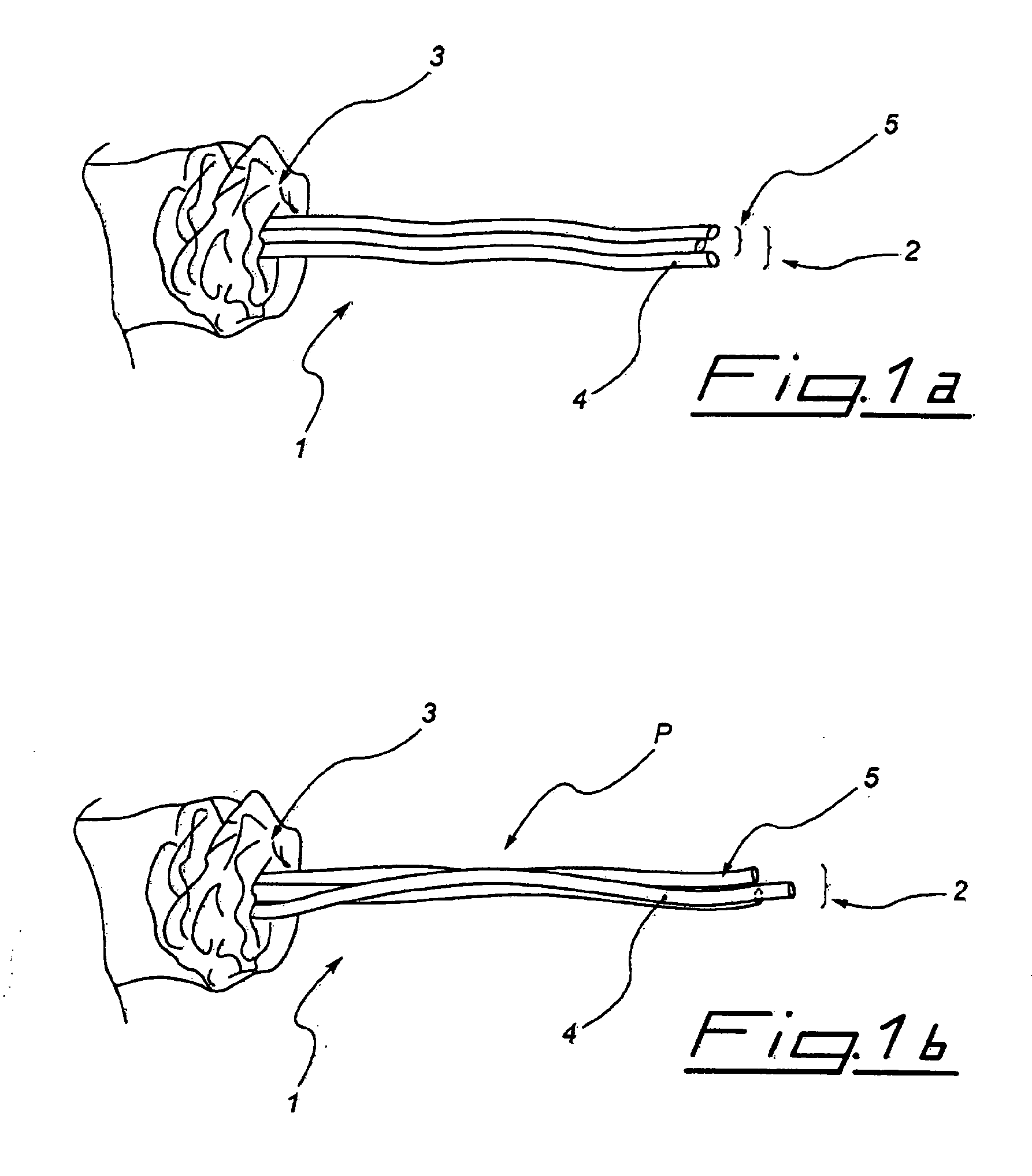

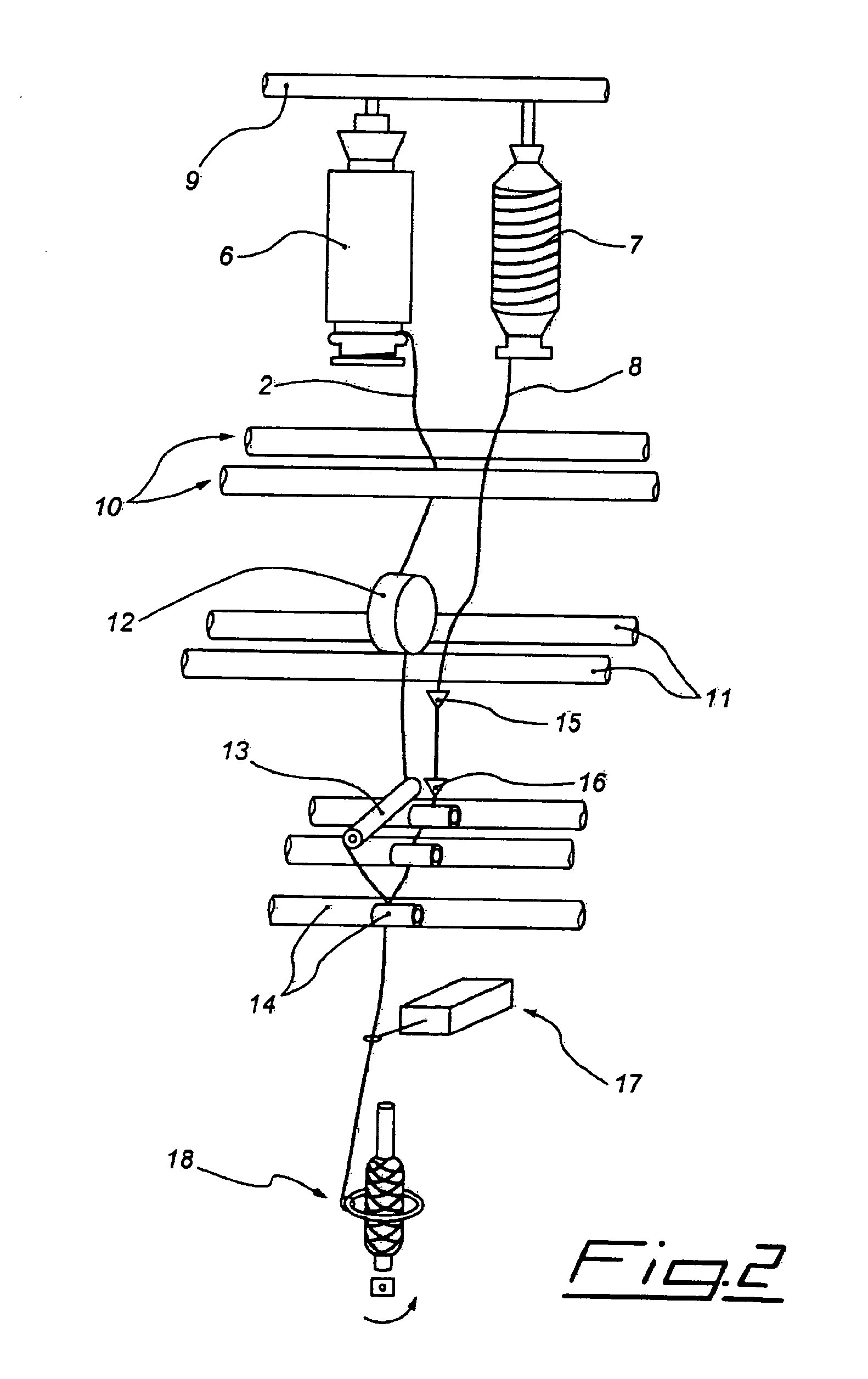

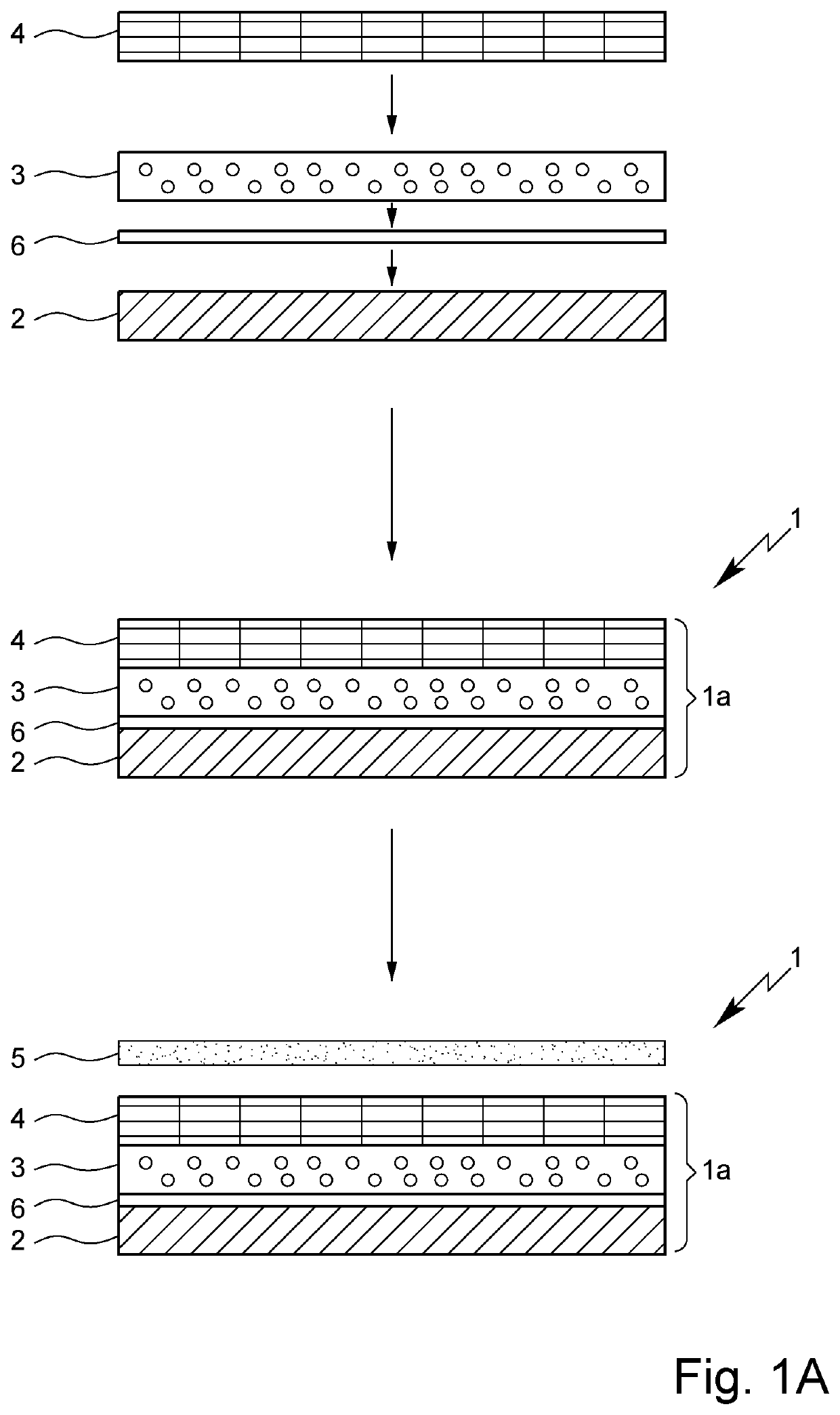

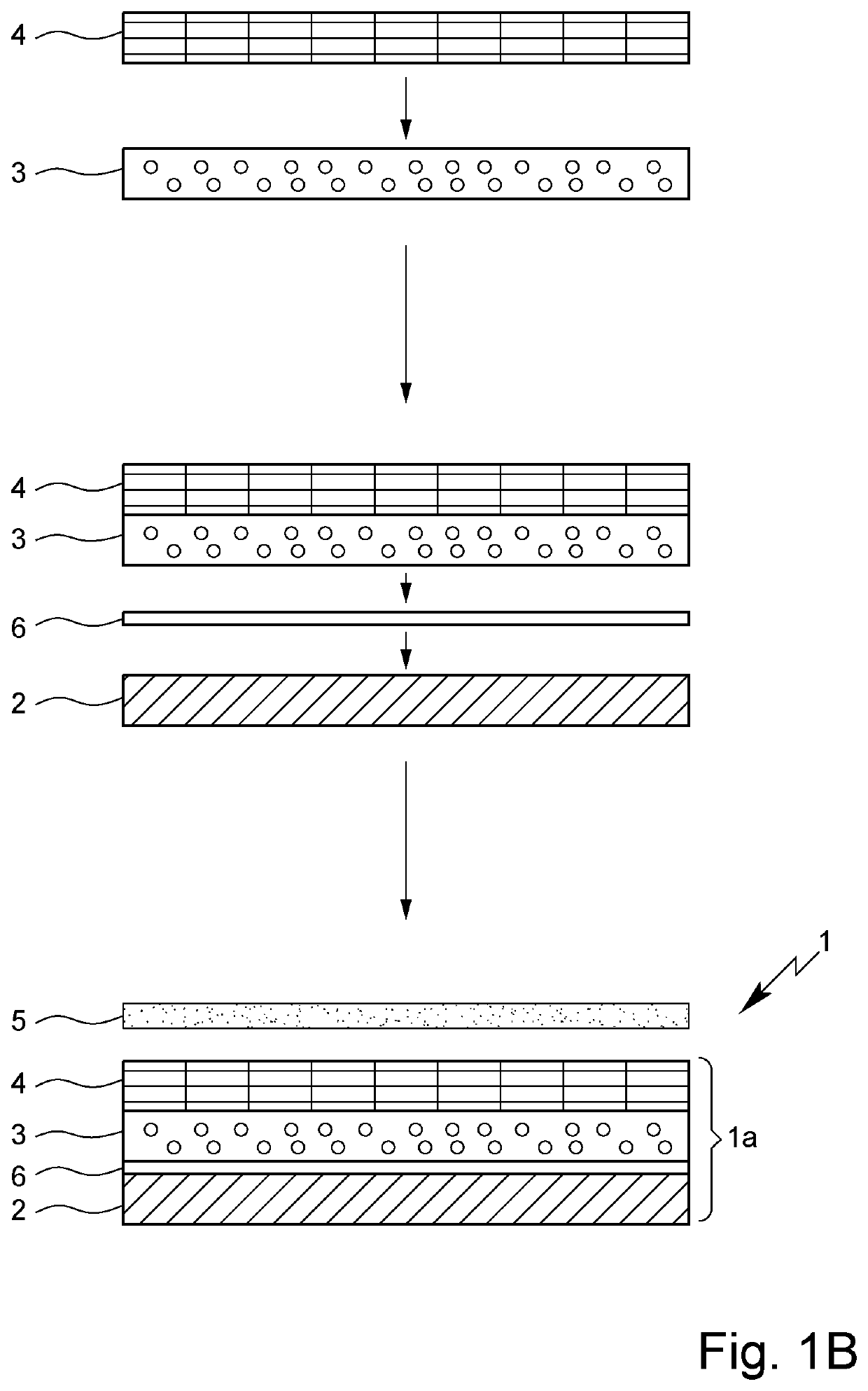

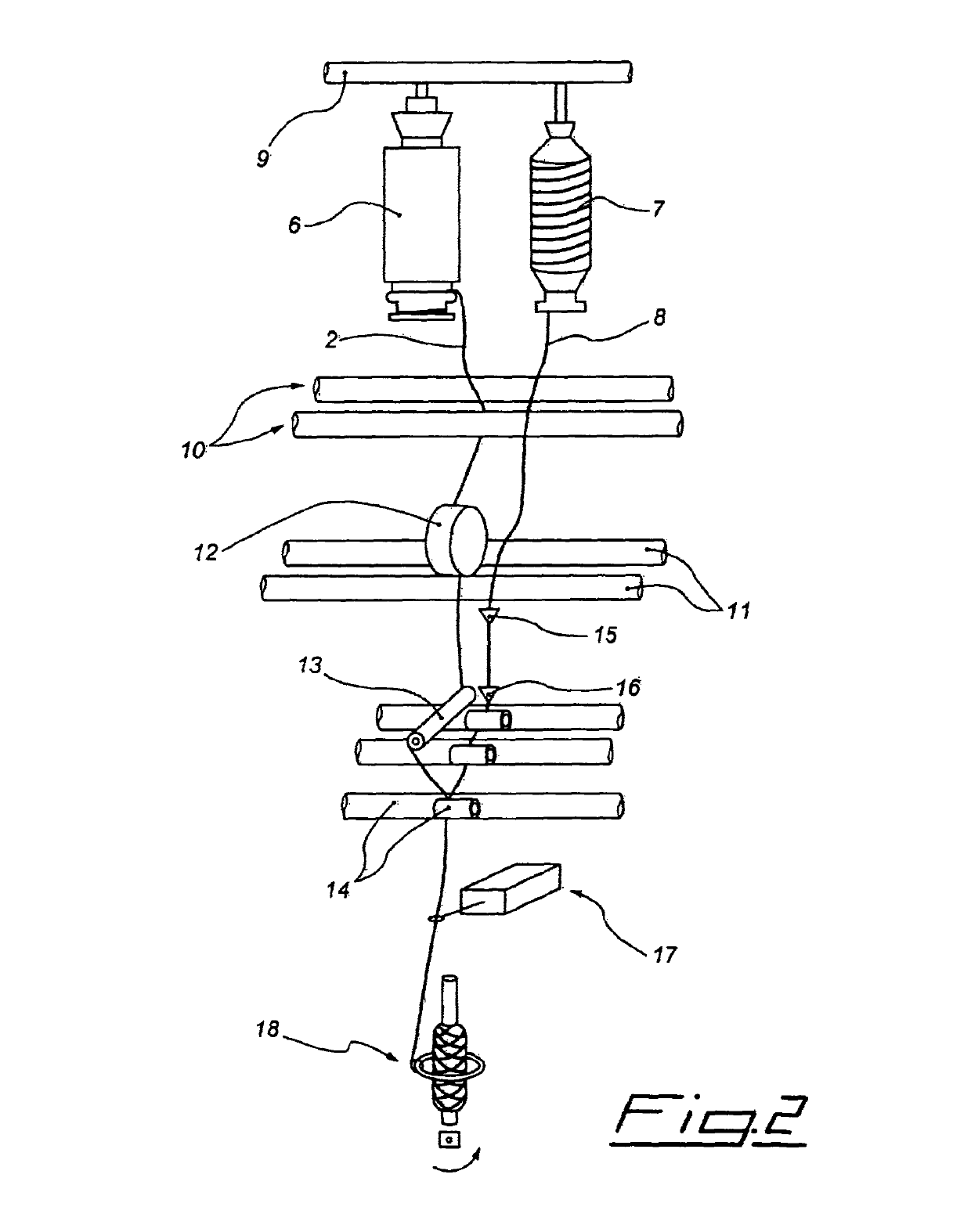

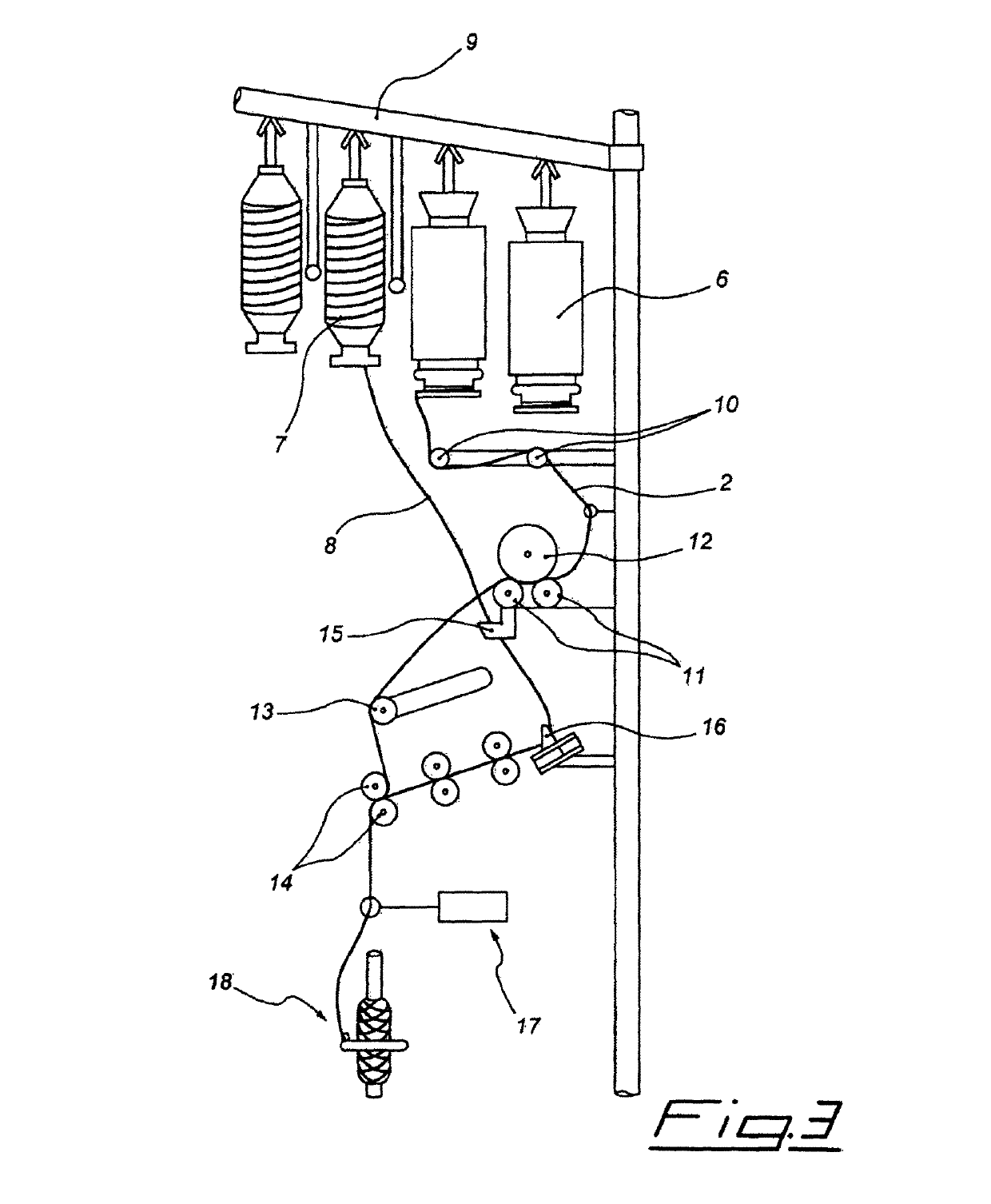

Composite stretch yarn, process and fabric

ActiveUS20130260129A1Increase elasticityGood stretch recoveryDrafting machinesAnimal housingElastomerYarn

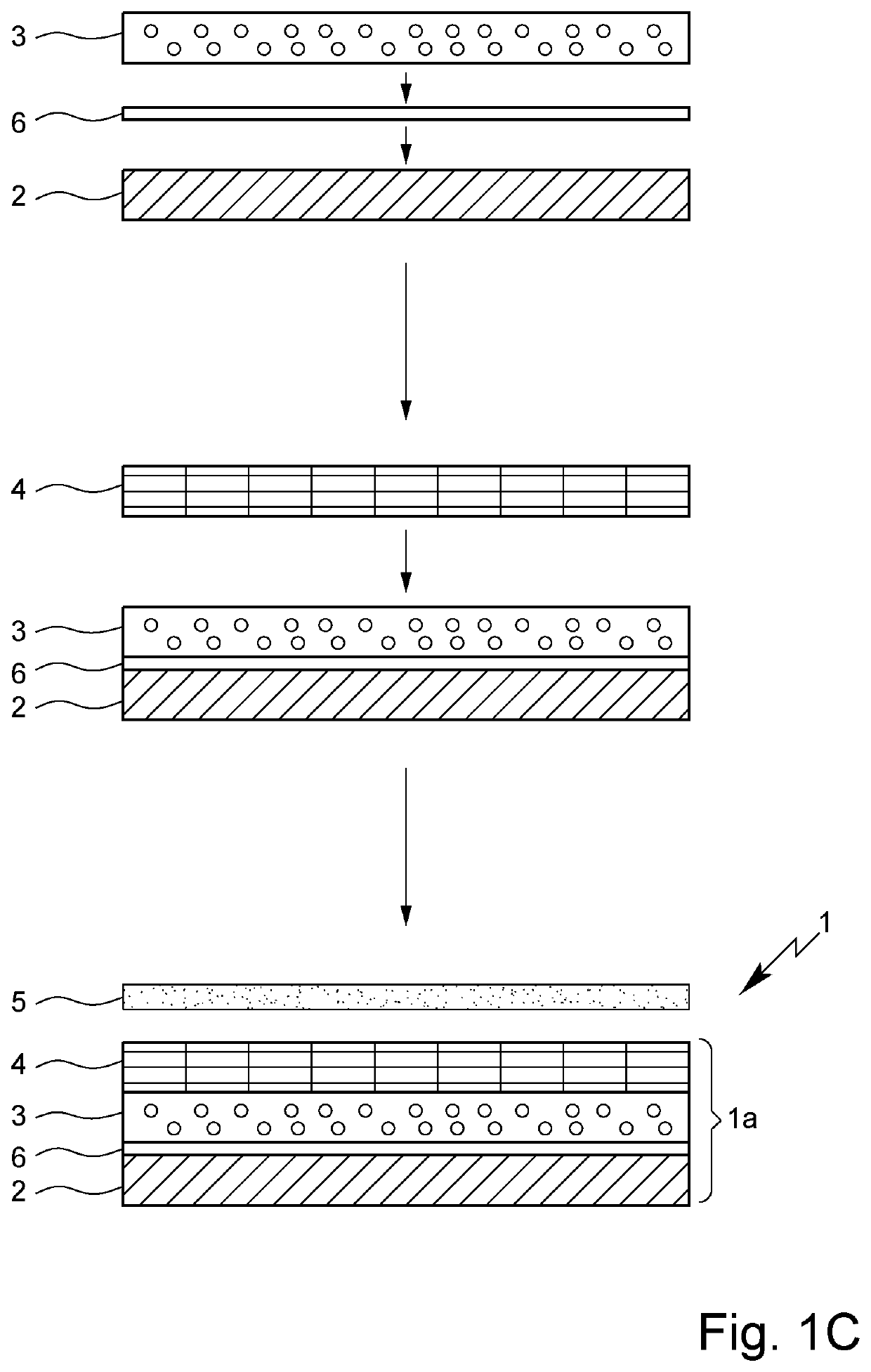

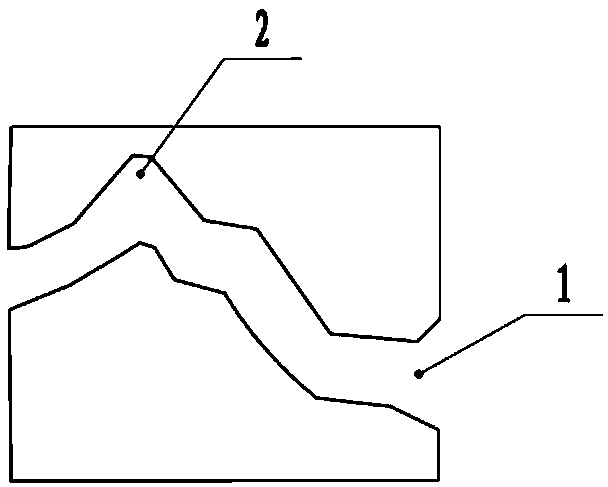

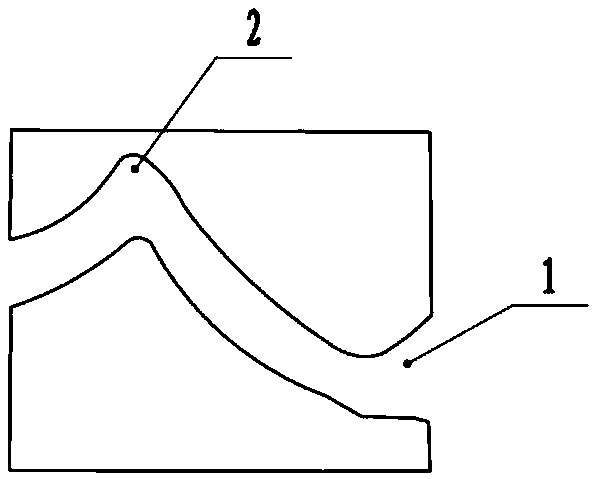

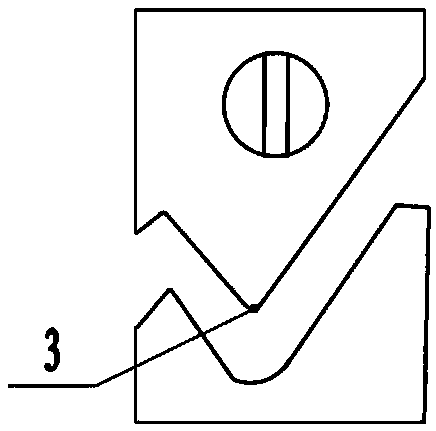

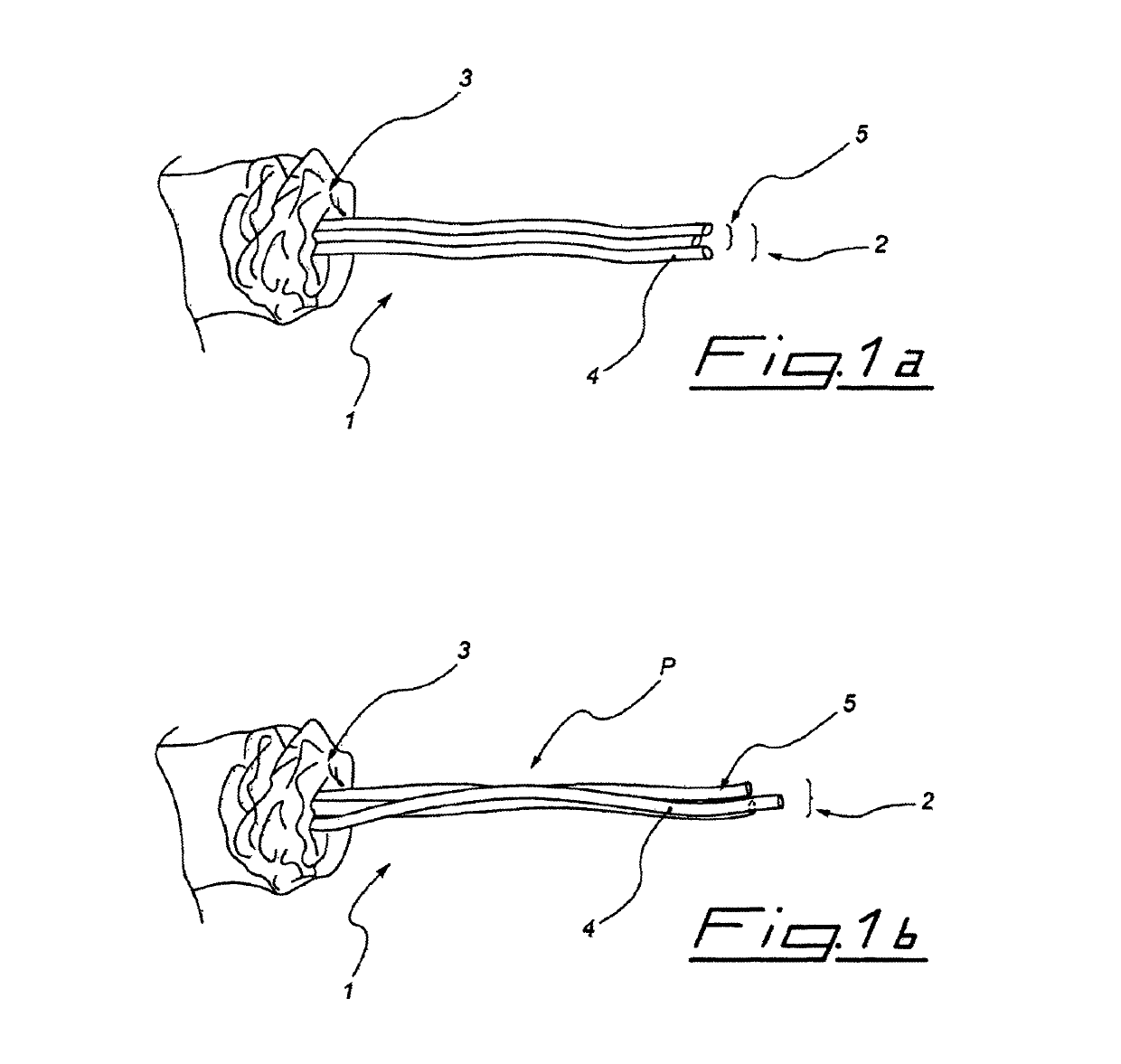

In a stretch yarn (1) comprising a stretchable core (2) covered by an inelastic fibers sheath (3) the stretchable core (2) comprises first and second fibers (4, 5) that have elastic properties, the first fiber (4) is an elastomer and the second fiber (5) is a polyester based (co)polymer, the amount of the second fiber being in the range of 60-90% (w / w) of the total weight of the fibers of the stretchable core (2); the first and second fibers are connected together at least at a plurality of points (P).

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Method for preparing high-intensity covalence/ion interpenetrating polymer network easily molded gel

InactiveCN104311841AImprove mechanical propertiesGood stretch recoveryPolymer scienceBiocompatibility Testing

The invention provides a method for preparing high-intensity covalence / ion interpenetrating polymer network easily molded gel, belonging to the field of functional polymers. The method comprises the following steps: mixing acrylamide with good biocompatibility and sodium alginate, uniformly stirring, reacting with a chemical cross-linking agent, polyvinylpyrrolidone and an initiator, under the action of the chemical cross-linking agent, forming a polyacrylamide gel network from acrylamide, forming semi-interpenetrating polymer network gel when sodium alginate penetrates through the polyacrylamide gel network, and performing aftertreatment by using a polyvalent metal salt solution, thereby forming the interpenetrating polymer network gel. The polyacrylamide / sodium alginate interpenetrating polymer network gel prepared by using the method is high in tensile strength, good in tension resilience, uniform in structure, good in molding property, and can be used in fields such as intelligent and self-repairing type functional textiles, medical textiles, printing wastewater dye collection, and the like.

Owner:JIANGNAN UNIV

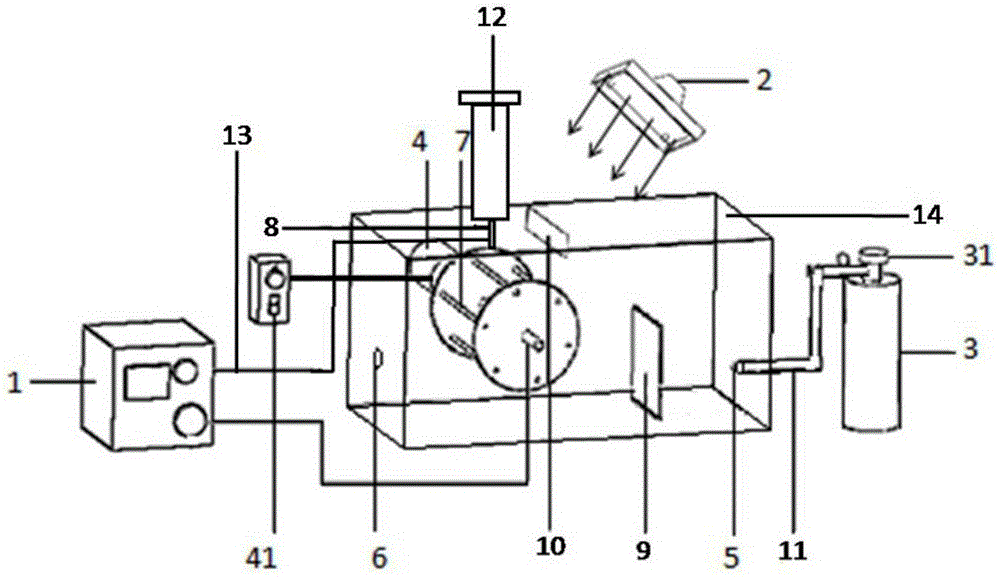

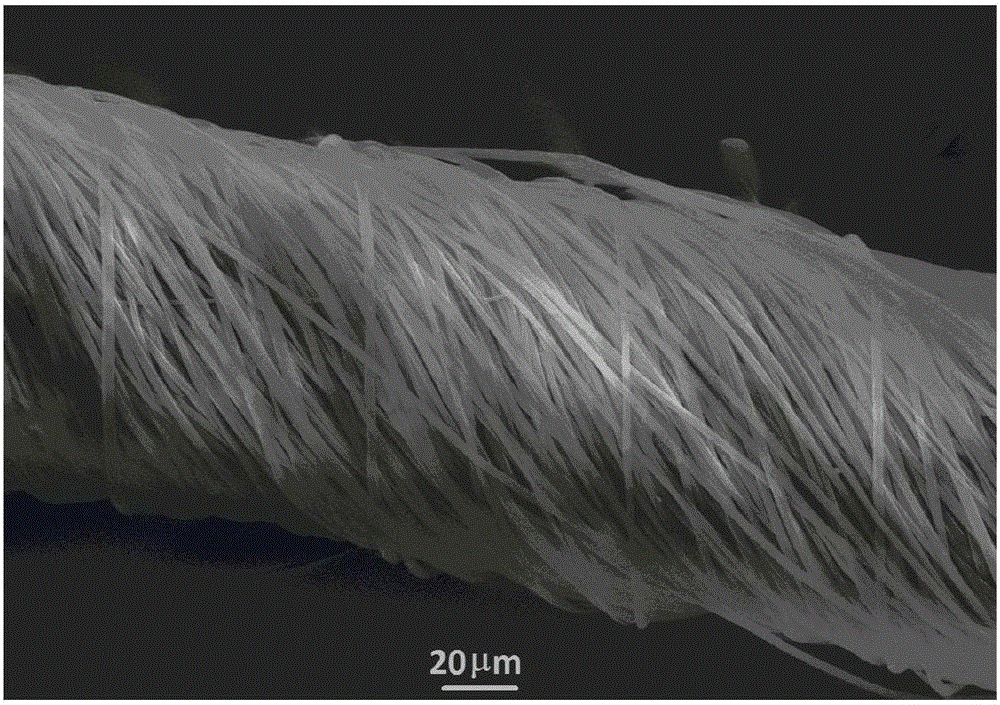

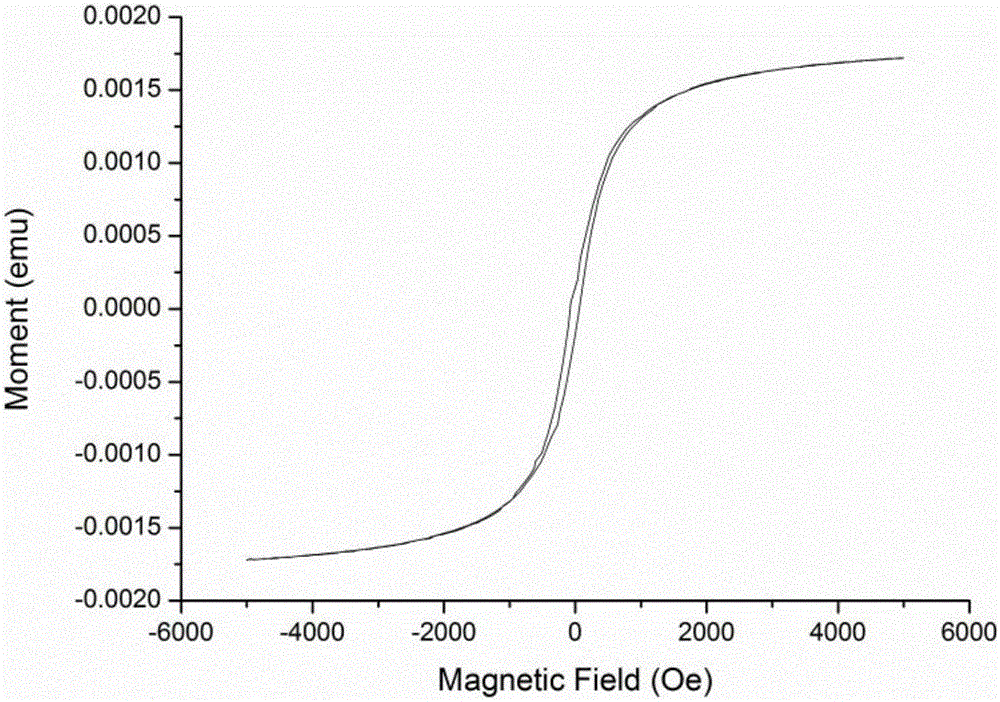

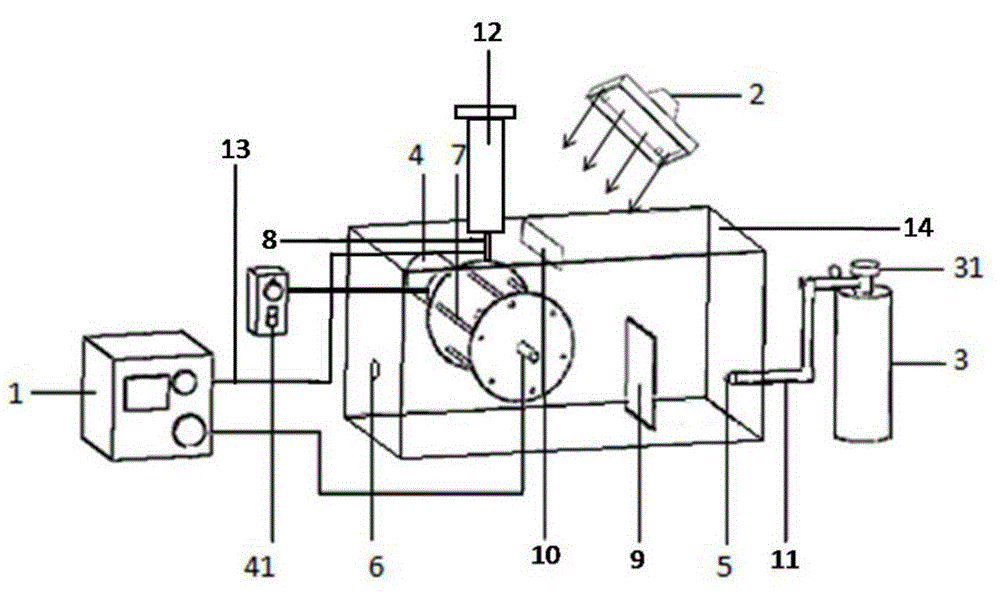

Flexible micro-nanofiber stranded wire with electromagnetic performance and preparation method thereof

ActiveCN105332092AImprove electromagnetic performanceImprove mechanical propertiesMonocomponent polyurethanes artificial filamentMaterial nanotechnologyFiberMagnetite Nanoparticles

The invention discloses a flexible micro-nanofiber stranded wire with electromagnetic performance and a preparation method of the flexible micro-nanofiber stranded wire. Micro-nanofiber which is used for forming the flexible micro-nanofiber stranded wire in a twining way contains a photo-curing polymer material, a conductive material and magnetic nano particles; the micro-nanofiber is prepared from a fiber spinning precursor solution during solvent-free electrospinning; an electrospinning process is carried out under a mionectic ultraviolet irradiation environment; the spinning precursor solution contains liquid prepolymer of a photo-curing material, a photoinitiator, the conductive material and the magnetic nano particles and does not contain an organic solvent. The flexible micro-nanofiber stranded wire disclosed by the invention has excellent mechanical property and good electromagnetic performance; meanwhile, during the electrospinning preparation process, the organic solvent needs not to be added, the preparation process is safer and more environmental-friendly, and the flexible micro-nanofiber stranded wire is suitable for large-scale production.

Owner:QINGDAO UNIV

Production method of worsted shell fabric containing polyolefin elastic fibers

InactiveCN103898645ALittle change in elasticityReduce disadvantagesBiochemical fibre treatmentYarnPolyesterPolymer science

The invention discloses a production method of worsted shell fabric containing polyolefin elastic fibers. The shell fabric is formed by spinning wool fibers, cashmere fibers, bamboo charcoal polyester fibers, superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers, and anti-pilling treatment, enzyme treatment and softening treatment are respectively conducted on the wool fibers and the cashmere fibers; the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers are spun into the shell fabric according to the weight ratio of 55-75 : 12-18 : 18-28 : 12-15 : 5-8, and eventually aftertreatment is conducted on the shell fabric through a water-soluble polyurethane wool anti-shrinking agent. The production method has the advantages that damage to wool fiber products can be greatly reduced, the pilling phenomenon is reduced, the shell fabric made of the wool fibers, the cashmere fibers, the bamboo charcoal polyester fibers, the superfine poly(butylene succinate) silk yarns and the polyolefin elastic fibers as major raw materials is softer, the felting shrinking percentage is greatly reduced, and the quality of the shell fabric is better.

Owner:汤丽娟

Novel comfortable elastic fabric and producing process thereof

Provided is a novel comfortable elastic fabric and a producing process thereof. The warp yarn of the fabric is made of LY / CJ of 11.7*2 tex at the blending ratio of 50 / 50, and the weft yarn of the fabric is made of STS / C of 36.7 tex at the blending ratio of 60 / 40; the density of the warp yarn of the fabric is 425 strands / 10cm, the density of the weft yarn of the fabric is 291 strands / 10cm, and the width is 175.5cm; the fabric is woven through 3 / 1 +1 / 3 and 2 / 2 +1 / 1 +1 / 1 derivative weave. Special technology is used in the processes such as sizing, weaving, dyeing and finishing in the producing process. The novel comfortable elastic fabric and the producing process thereof have the advantages that the fabric is easy to care, washable in a machine, stain resistant, soft in hand feeling and fluffy due to the innovative use of the novel comfortable elastic fabric, thereby meeting market demand and popular trend; the fabric is moderate in elasticity, comfortable to wear, and has the elasticity better than that of ordinary PTT products and the drawing recovery effect better than that of a spandex core elastic fabric.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

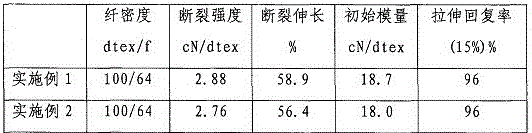

Method for preparing poly(trimethylene terephthalate) fibre having shape memory characteristic

InactiveCN101200821ANo residual stressStable unwindingMelt spinning methodsMonocomponent polyesters artificial filamentPolymer sciencePolyethylene terephthalate

The invention discloses a preparation method of polytrimethylene terephthalate fiber with shape memory characteristics, including: firstly, selected polyester polymer is provided with at least 0.8dL / g of intrinsic viscosity and contains at least 85mol percent of polytrimethylene terephthalate, wherein, at least 85mol percent of the repeating unit is composed of three-methylene; secondly, the polyester polymer is melted and transported through a screw melting extruder, the melting body is metered through a metering pump and is extruded out through a spinneret, and as-spun fibers are drafted successively through a pair of drafting hot rollers after being cooled through lateral blowing; thirdly, the drafted fibers are introduced into a group of grouping roller stereotype boxes with steam; fourthly, tow is introduced into a winding head to be winded into mold. The fiber made through the invention has the advantages of good packaging appearance forming, good structural stability and soft handle. And with lower modulus, the fiber is still provided with good elasticity and tensile recoverability. The textiles made of the fiber which are produced through the process are provided with good shape memory characteristics.

Owner:方圆化纤有限公司

Fusing alloying island fibre and production method thereof

ActiveCN101608351AOvercome deficienciesImprove performanceFilament/thread formingConjugated synthetic polymer artificial filamentsState of artFiber

The invention relates to a fusing alloying sea-island fibre and a production method thereof, wherein the components of island and sea are respectively PTT and PE. The production method comprises the following steps: slicing the PTT and drying, mixing the PTT slices with the PE by a certain proportion; fusing and mixing the PPT and PE into a screw extruder and then jetting the mixture, finally drawing, curling and cutting the mixture to make the product. The invention overcomes the shortage of the prior art, has excellent performance and low production cost, and has favorable economic and social benefits.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Sea-island polyester drawn yarn and preparation method thereof

ActiveCN101982575AImprove deformation recovery performanceHigh coloring rateFilament/thread formingArtificial filament heat treatmentPolyesterYarn

The invention discloses a sea-island polyester drawn yarn, of which a sea component is a COPET and an island component is a PTT, and mass percent of the PTT is 65%-75%, and mass percent of the COPET is 25%-35%. A production method of the sea-island polyester drawn yarn comprises the following steps: drying sections of the PTT, and then mixing the PPT with the COPET according to a certain proportion, mixing them in a screw extruder in fusion form, and jetting yarns via a jetting plate, finally, drawing and coiling the yarns to form products. The invention provides a sea-island polyester drawn yarn with high degree of dyeing and a preparation method thereof.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

Fabric interweaving with polyolefin elastic fiber and polyester fiber, and its machining process

InactiveCN1800470AIncrease elasticityGood chemical resistanceShrinkingWarp knittingPolyesterPolyolefin

The invention discloses a face fabric of intercrossed polyolefin flexible fiber and polyester fiber, and relative processing technique. The face fabric is formed by DOW XLA polyolefin flexible fiber in 15-35% weight and the PTT polyester fiber in 65-85% weight; the woven structure can be warp velveteen, double velveteen or double fabric. The processing technique comprises: knitting, pre-treating before colorizing, pre-shaping before colorizing, colorizing and shaping. The surface fabric has better flexibility and anti-chemical property, which has small flexible change even it is dipped in water / seawater for long time. It has better extension recover property, which is higher 2-3 times than nylon, with soft feeling, eliminated rough feeling, and high anti-ultraviolet property.

Owner:上海彩艳实业有限公司

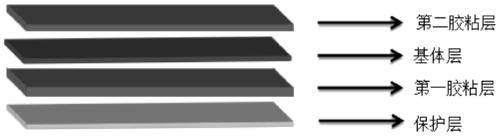

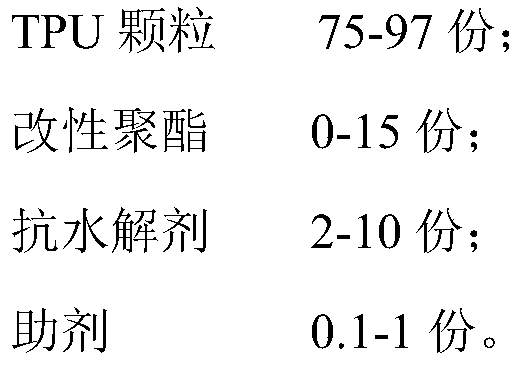

TPU adhesive, hot melt adhesive film and application

ActiveCN111040711AHigh strengthReduce deformation rateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention relates to the field of polymer adhesives, in particular to a TPU adhesive, a hot melt adhesive film and an application. The TPU adhesive is prepared from the following components in parts by weight: 75 to 97 parts of TPU particles, 0 to 15 parts of modified polyester, 2 to 10 parts of an anti-hydrolysis agent and 0.1 to 1 part of an auxiliary agent. The hot melt adhesive film sequentially comprises a first adhesive layer, a matrix layer and a second adhesive layer, the first adhesive layer is made of the TPU adhesive, and the second adhesive layer is made of the TPU adhesive. The base layer is a screen cloth or a thin film. The hot melt adhesive film with the three-layer composite structure is soft in hand feeling, high in tensile strength, excellent in tensile resilience, good in adhesion and washing resistance and capable of being widely applied to seamless adhesion of elastic clothes such as underwear, underpants, bras, mold cups, shoulder straps, shapewear and sportswear.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

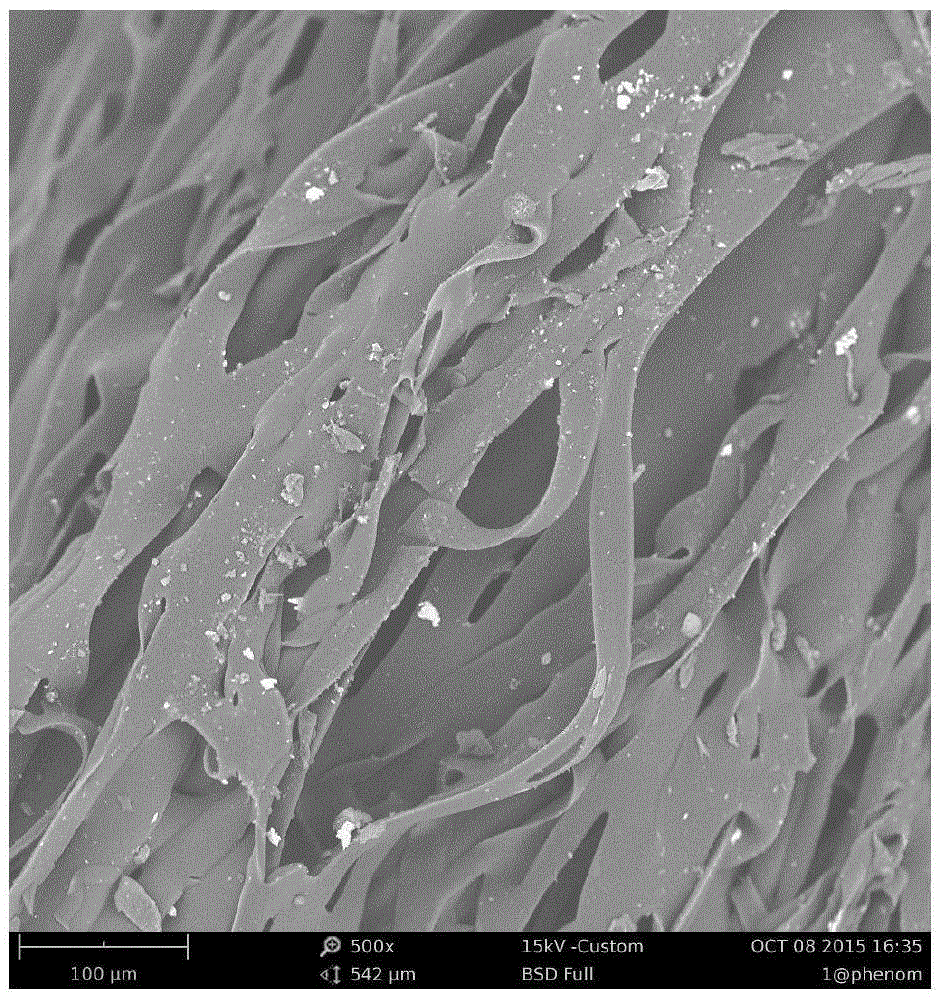

Conductive micro-nanometer fiber stranded wire based on solvent-free electrospinning and preparing method thereof

The invention discloses a conductive micro-nanometer fiber stranded wire based on solvent-free electrospinning and a preparing method thereof. The conductive micro-nanometer fiber stranded wire comprises a photocuring material template stranded wire and a conductive macromolecule layer. The photocuring material template stranded wire is formed by winding micro-nanometer fiber cured by solvent-free electrospinning ultraviolet light. The conductive macromolecule layer is manufactured through an in-situ polymerization method and comprises conductive macromolecule layer bodies permeating into the template stranded wire and wrapping the template stranded wire. According to the conductive micro-nanometer fiber stranded wire, conductivity of the fiber stranded wire is further improved while excellent stretchability is kept, organic solvent does not need to be added in the electrostatic spun yarn preparing process, the preparing process is safer and more environmentally friendly, and the stranded wire is suitable for large-scale production.

Owner:QINGDAO UNIV

Novel biomass elastic short fiber blended sports knitted fabric

The invention relates to a novel biomass elastic short fiber blended sports knitted fabric. The knitted fabric comprises yarns which are formed by fibers and blended by biomass elastic short fibers (namely comfortable and elastic yarns) and bleached hemp fibers. The fabric structurally adopts weft-knitting interlock stitch. The novel blended sports knitted fabric is comfortable and elastic, is excellent in hand feeling and good in stretching resilience, can be still elastic, durable and stable after being stretched for multiple times, suffering from solarization and being subjected to after-treatment process, is not easy to wrinkle, is easy to manage and free in extension, can beautify stature and fit a wearer well, is free from compression and tension when being worn, is hydroscopic and fast-dry, has the functions and characteristics of preventing mold, bacteria, ultraviolet, static electricity and the like, and is a green, low-carbon and environment-friendly novel blended sports knitted fabric leading the trend of the times.

Owner:SHAOXING SHULILE TEXTILE PROD

Sea-island composite fiber mixed fabric

The invention discloses a sea-island composite fiber mixed fabric, which comprises warps and wefts. The warps are formed by blending cotton fibers and sea-island composite fibers, and the wefts consist of cotton fibers, sea-island composite fiber blended fibers and polyolefin elastic fibers by means of core spinning. All fibers in the fabric include, by weight, 50% to 70% cotton fibers, 20% to 35% sea-island composite fibers and 10% to 15% polyolefin elastic fibers. According to the above structure, the sea-island composite fiber mixed fabric has the advantages of softness, high elasticity, fine breathability and high hygroscopicity, can be used for various clothes, such as sportswear, tennis apparels, golf jackets, shirts, swimsuits, close fittings, coats and the like.

Owner:SUZHOU CHUANGYU WEAVING

Mixed-color core-spun yarn and production device and production method thereof

The invention relates to mixed-color core-spun yarn and a production device and a production method thereof. The production method includes following steps: subjecting sliver A prepared through a drawing process and thick yarn B prepared through a roving process to roving to obtain thick yarn C, wherein the thick yarn C is core-spun yarn, the sliver A is skin yarn, and the thick yarn B is core yarn; subjecting the thick yarn C and filament D to a spinning core-spun yarn process to produce the mixed-color core-spun yarn. The mixed-color core-spun yarn produced by the method is of a three-layeroverlapped structure, has the advantages of high shape maintaining performance, elasticity and obvious functional feature, can form special color effect according to color selecting, matching and adjusting, can be widely used for knitting, weaving and knitwear and is prime yarn for making fashionable fabric for high-grade underwear, sports T shirts and casual wear.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Method for producing a textile composite material and textile composite material produced according to said method

InactiveUS20200165122A1High force load-bearing capacityHigh and improved compatibilityUpholstery manufactureDomestic upholsteryPolymer sciencePolymer chemistry

The invention relates to a method for producing a textile composite material with shrink properties, in particular heat shrink properties, preferably in the form of a shrinkable, in particular heat-shrinkable textile upholstery and / or covering material, preferably for seating furniture, to the textile composite material obtained therefrom and to the uses thereof.

Owner:K&R TEXTIL

Technology for worsted spinning of high-elasticity thermal wool fabric

The invention relates to a technology for worsted spinning of a high-elasticity thermal wool fabric. According to the technology for worsted spinning of the high-elasticity thermal wool fabric, a phosphate ester and antimonous oxide mixture serves as an anti-pilling agent for anti-pilling treatment, the anti-pilling effect of fibers and textiles is further improved, and the anti-pilling effect can reach the 4th-5th grade. A water-soluble organic silicon softening agent is used for softening treatment, so a wool and cashmere fiber textile has smoother and fuller hand feeling. Polyolefin elastic fibers have good characteristics of small elastic change and high tensile resilience, so advantage complementation and disadvantage reduction of various fibers are well achieved, and the fabric made from the fibers is better in strength, higher in water-absorbing and thermal performance, stiffer and beneficial to human body health and environment protection.

Owner:JIANGSU SUNSHINE

Semi-aqueous silicone, costume and preparation method of costume

InactiveCN107637896AGood stretch recoveryStrengthen local supportGarmentsClothes making applicancesPolymer scienceVulcanization

The invention provides semi-aqueous silicone, a costume and a preparation method of the costume. The semi-aqueous silicone is prepared by mixing first rubber cement and second rubber cement, wherein the first rubber cement comprises silicic acid gel, zinc oxide, a vulcanization accelerator and an anti-aging agent, and the silicic acid gel accounts for 74-84% of the semi-aqueous silicone; the second rubber cement comprises polyurethane paste which accounts for 2-7% of the semi-aqueous silicone. The costume with established silicon-printing patterns can be prepared by using the semi-aqueous silicone and the preparation method, and the silicon-printing patterns are formed in the steps of first printing, drying to a semi-dry state, second printing and then drying and setting. The silicon-printing patterns of the costume have beautifying and decorating effects, moreover, the local support of limbs can be strengthened, the stretching recovery performance of the costume can be improved, and the application potential in sports and medical correction products is great.

Owner:KUNSHAN TENGFEI UNDERWEAR TECH

Spinning method of super-strong absorbent high elastic shaggy chenille yarn

The invention relates to a spinning method of a super-strong absorbent high elastic shaggy chenille yarn, and belongs to the technical field of spinning. Core yarns are made of polyester filament, woolen yarns are prepared from, by weight, 17-19% of PTT staple fiber, 21-35% of polyester-nylon composite filament, 36-58% of terylene interlaced yarn; two 16S / 2 or four 16S core yarns are taken as corewires, the core yarns and the woolen yarns are fed synchronously through same group yarn taking 6-10 yarns as a group, high-speed rotation and twisting are carried out through a swiveling head, the woolen yarns are wound synchronously to form a yarn ring on a cutting distance piece, slides down with the rotation of a roller piece, the woolen yarns are cut into short fibers, and the cut short fibers and cross-twist core yarns enter a control roller and a twisting area, the yarn is spun from Z-Z-S direction of twist, fluff convolutes in a spiral rod-shaped shaggy yarn. The spinning method of the super-strong absorbent high elastic shaggy chenille yarn has the advantages of good stretch resilience, free stretch, no compression, no tension, high elasticity, high fleeciness and high water absorption capacity.

Owner:JINHUA JIELING HOUSE WARES CO LTD

Cotton polyurethane light side-stretch high-end fabric preparation method

ActiveCN109097900ARelease the bondageIncrease elasticityWeft knittingHeating/cooling textile fabricsRecovery performanceEngineering

The invention relates to a knitted fabric preparation method, in particular to a cotton polyurethane light side-stretch high-end fabric preparation method. A fabric comprises loop yarns, middle yarnsand ground yarns. The method includes: step A, weaving a gray fabric; step B, subjecting the surface of the gray fabric to pilling; step C, dyeing the gray fabric; step D, dewatering the gray fabric;step E, drying the gray fabric; step F, subjecting the gray fabric to re-shaping. Compared with the prior art, the method has advantages that the fabric woven according to the method is high in elasticity and excellent in elastic recovery performance, and by adoption of the novel weaving mode, fabric skewness is effectively improved, and great handfeel and anti-pilling performances of the fabric are kept.

Owner:NINGBO DAQIAN TEXTILE

Method for producing worsted wool fabrics with polyolefin elastic fibers

InactiveCN106480564ALittle change in elasticityStrong stretch recoveryBiochemical fibre treatmentWoven fabricsFiberPolyolefin

The invention relates to a method for producing worsted wool fabrics with polyolefin elastic fibers. The method for producing the worsted wool fabrics with the polyolefin elastic fibers has the advantages that anti-pilling treatment is carried out by the aid of organophosphate and antimony trioxide mixtures which are used as anti-pilling agents, and accordingly anti-pilling effects of the fibers and textile fabrics further can be improved and can reach 4-5 levels; softening treatment is carried out by the aid of water-soluble organosilicone softening agents, and accordingly the wool and cashmere fiber textile fabrics can have smooth and plump hand feel; the polyolefin elastic fibers have excellent characteristics of extremely low elasticity change and high elastic recovery of elongation, accordingly, merits of the various fibers can complement one another, weakness of the various fibers can be reduced, and the fabrics made of the fibers are good in strength and high in water absorption and thermal property, are stiff and smooth and are beneficial to human health and environmental protection.

Owner:JIANGSU SUNSHINE

UV-curable electrospun colored micro-nanofiber stranded wire and preparation method thereof

ActiveCN105506768AOxygen inhibition is not obviousGood flexibilityMaterial nanotechnologyMonocomponent polyurethanes artificial filamentSolventPrepolymer

The invention discloses a UV-curable electrospun colored micro-nanofiber stranded wire and its preparation method. Micro-nanofiber for being twisted into the stranded wire is colored. The micro-nanofiber contains a photo-curing polymer material and color phototherapy gel. The micro-nanofiber is prepared from a solvent-free electrospinning precursor solution. The electrospinning process is carried out in a mionectic UV-irradiation environment. The electrospinning precursor solution contains a liquid prepolymer of a photo-curing material, a photoinitiator and phototherapy gel, and contains no organic solvent. The stranded wire has rich and full colors, has good color fastness, is not easy to fade and has good tensile mechanical property. Meanwhile, there is no need to add an organic solvent during the electrospinning preparation process. The preparation process is safer and more environmentally-friendly. The preparation method is suitable for large-scale production.

Owner:QINGDAO UNIV

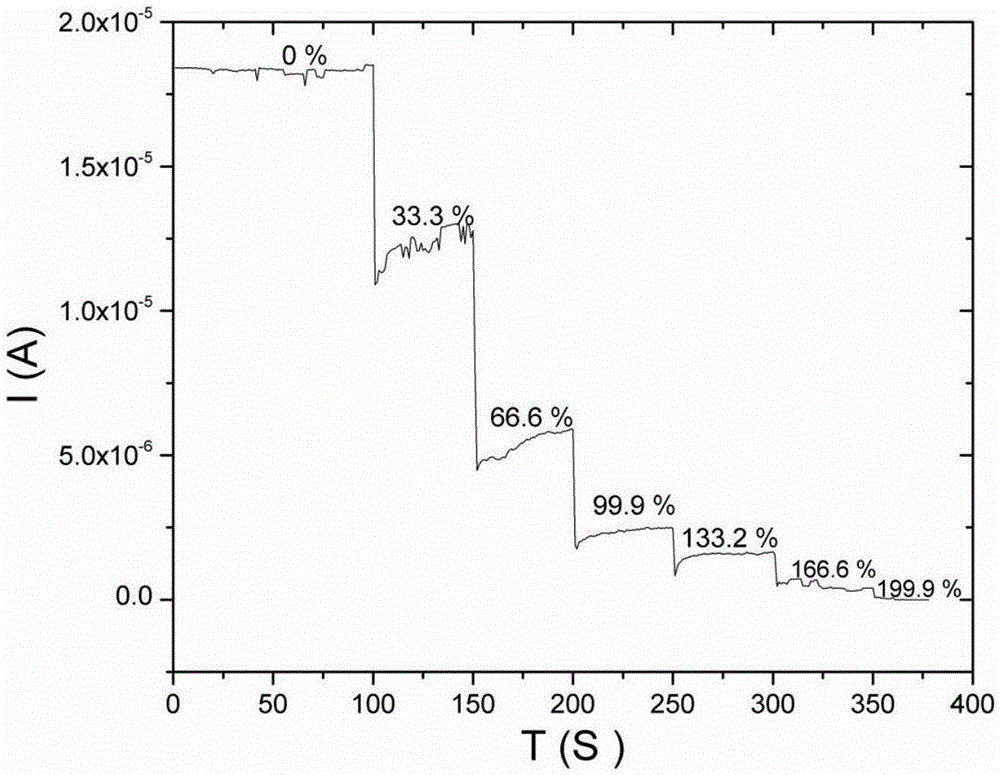

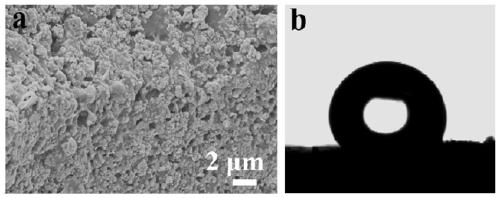

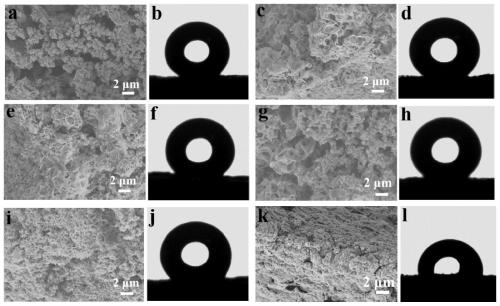

Multifunctional super-hydrophobic conductive rubber composite material and preparation method thereof

The invention discloses a multifunctional super-hydrophobic conductive rubber composite material and a preparation method thereof. The method comprises the following steps: soaking rubber foam consisting of 40% of natural rubber and 60% of butadiene styrene rubber into a tetrahydrofuran solution of silver trifluoroacetate; and reducing the silver precursor, and carrying out phase separation on thepartially dissolved polymer matrix in a non-solvent in the reducing solution to obtain the super-hydrophobic conductive rubber foam / silver nanoparticle composite material. The composite material disclosed by the invention has tensile and compression response properties, can be used for detecting human motion by wearable electronic equipment, and is good in stability, excellent in cycle performance and wide in application range; and the material has super-hydrophobic, electric-heating and photo-thermal effects, so that the application of the material in severe environments is broadened.

Owner:YANGZHOU UNIV

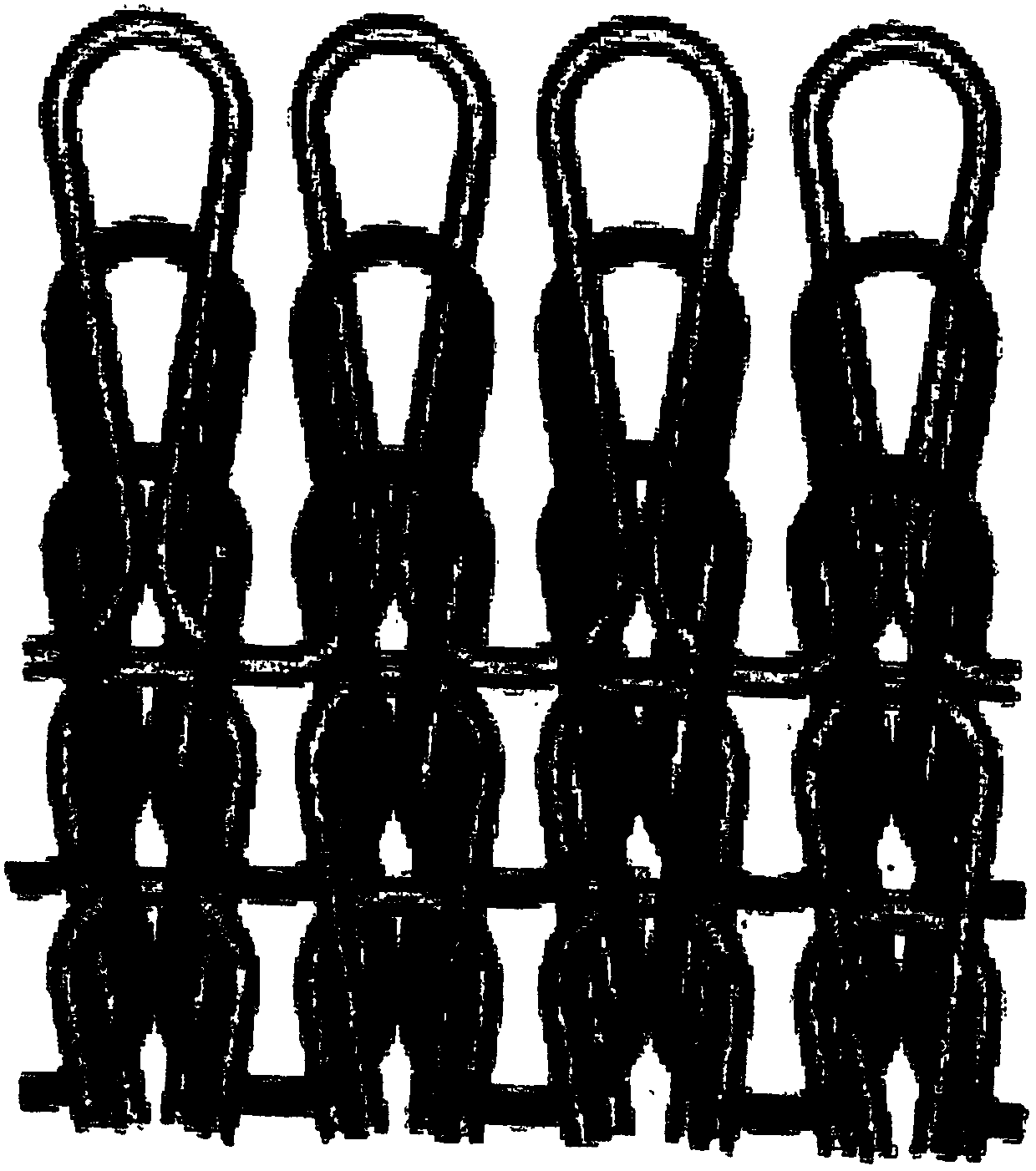

Interlaced wave elastic knitted fabric and preparation method thereof

PendingCN110629374AStrong textureObvious textureWeft knittingOrnamental textile articlesYarnPolyester

The invention relates to an interlaced wave elastic knitted fabric and a preparation method thereof. The fabric is of a special double-face structure prepared by interweaving of recycled polyester, elastic spandex, and blended yarn of regenerated polyester staple fiber and cotton fiber; one face of the double-face structure refers to an interlaced wave stereoscopic structure and the other face refers to a smooth flat linear strip structure; particularly, the plating stitch of the recycled polyester and the elastic spandex and the blended yarn blended by the regenerated polyester staple fiber and the cotton fiber are interwoven. According to the interlaced wave elastic knitted fabric, natural fiber and regenerated synthetic fiber are matched, so that the fabric is environmentally friendly and comfortable, and the performance of the cotton fiber is improved; with reasonable application of the elastic spandex, the fabric is compact after being dyed and finished, and accordingly has good recovery of elongation; further, as one face of the double-face fabric has an interlaced wave stereoscopic effect while the other face has the smooth flat linear strip effect, the fabric has strong anddistinctive texture.

Owner:NINGBO DAQIAN TEXTILE

Production method of spinning solution having memory function

InactiveCN105862170AStable unwindingStable structure and performanceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberThermoforming

The invention relates to a production method of a spinning solution having a memory function. The production method comprises the steps of 1, preparing a fiber-forming polymer solution; 2, preparing slurry with the memory function; 3, uniformly dispersing the fiber-forming polymer solution prepared in step 1 and the slurry with the memory function prepared in step 2 in stirring equipment, and storing the materials for 24-36 hours till the materials are cured completely, so that a shell spinning solution is obtained, wherein the shell spinning solution can be used for spinning shells. According to production method, the modified spinning solution is prepared, it can be guaranteed that after silk flocks are subjected to drafting and thermoforming, basically no residual stress exists, and the silk flocks are unwound smoothly; what is more important, a fiber product which is stable in structural performance, good in mechanical performance and low in fiber modulus and has the shape memory characteristic is obtained.

Owner:NANTONG SUZHONG TEXTILE

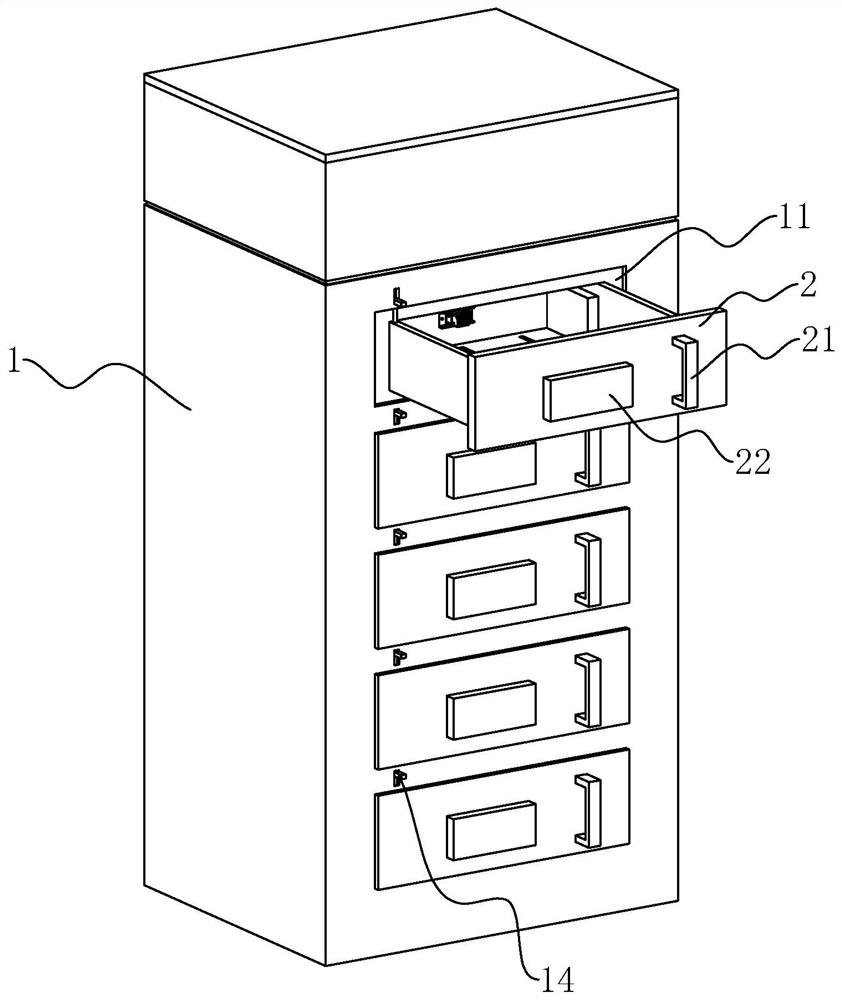

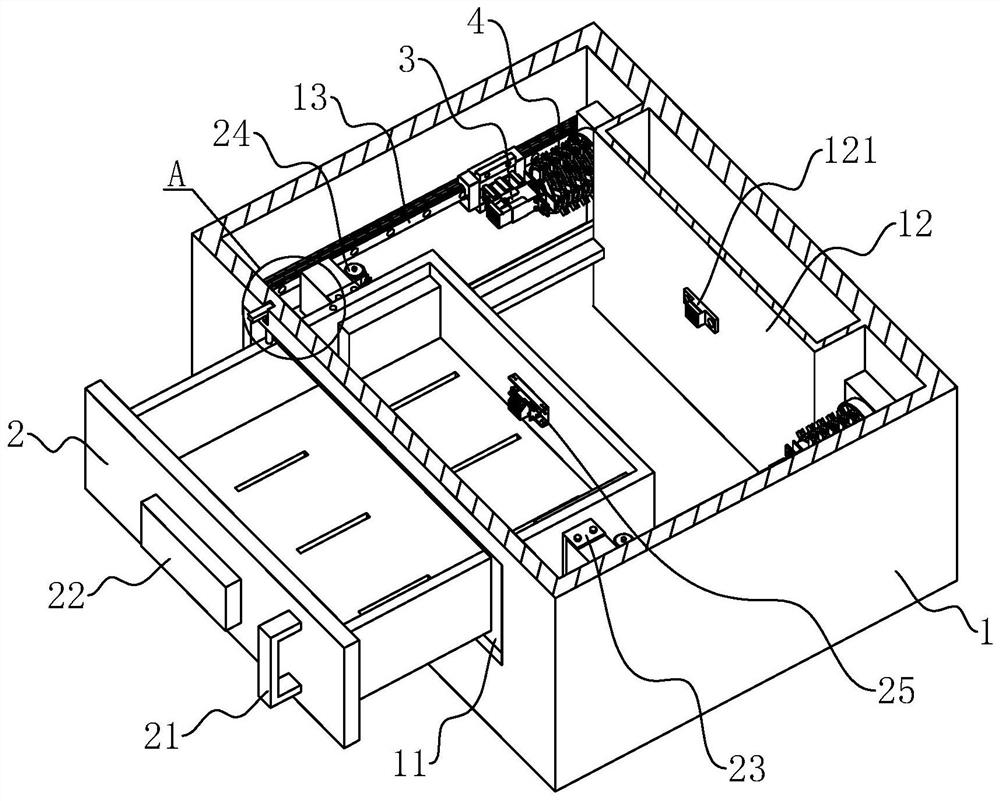

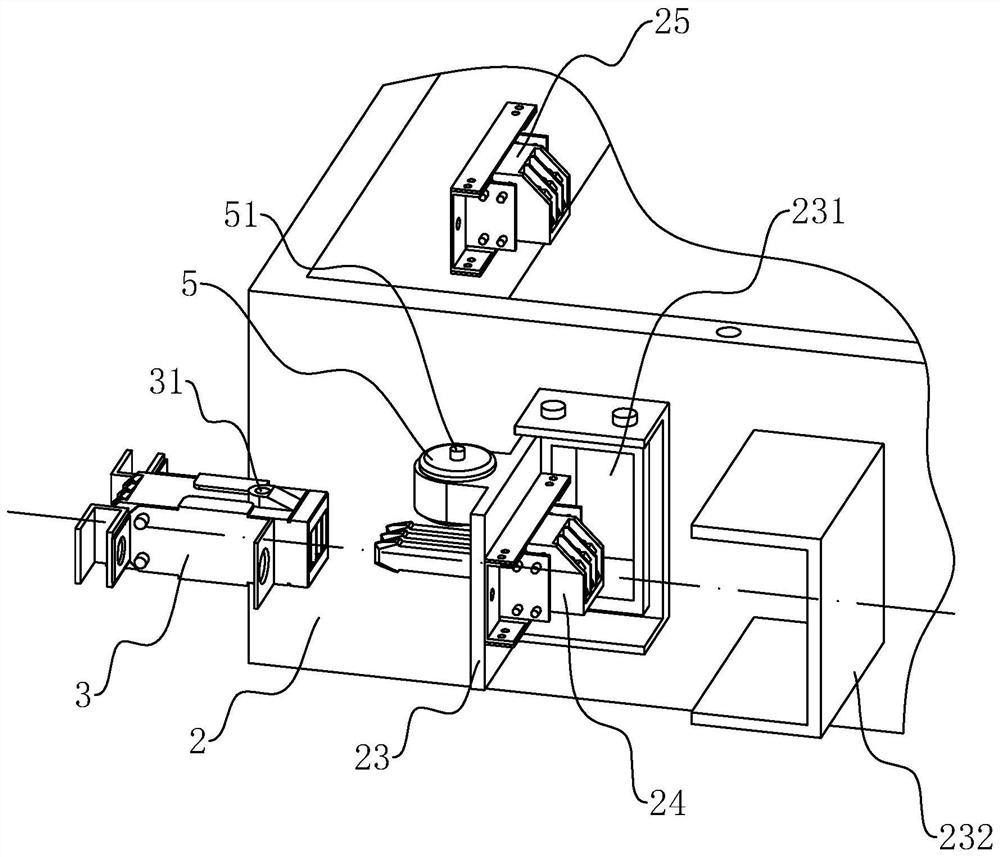

Drawer type capacitance compensation cabinet

ActiveCN111917043AImprove securityHas the ability to extendBus-bar/wiring layoutsSwitchgear with withdrawable carriageCapacitanceStructural engineering

The invention relates to a drawer type capacitance compensation cabinet, and the cabinet comprises a cabinet body; a plurality of drawing openings are formed in the cabinet body, and drawer assembliesare arranged in the drawing openings in a sliding mode; the male plug-in unit is arranged on the drawer assembly, and a female socket is arranged in the drawing opening in a sliding mode; a movable connecting mechanism is arranged between the female socket and the cabinet body; and a locking device is arranged between the male plug-in and the female socket. When the drawer assembly is pulled outwards, the female socket is driven to move outwards synchronously, so components and electronic equipment in the drawer assembly are still in a running state, and faults in the drawer assembly can be observed clearly; when the drawer assembly needs to be overhauled, the male plug-in and the female socket are unlocked through the locking device, and the male plug-in and the female socket are separated from each other, so the drawer assembly is powered off, and the safety during overhauling is improved.

Owner:XIANGXING ELECTRIC EQUIP

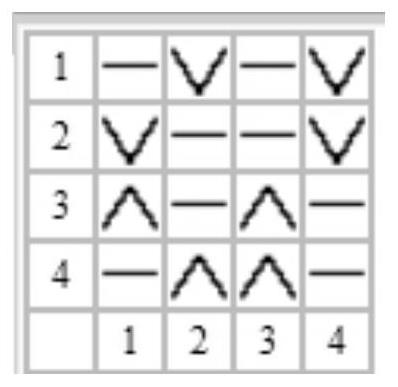

Production technology of high-elasticity water absorption and quick-dry smooth fabric

ActiveCN109652912AReduce the difficulty of debuggingSave introduction costWeft knittingPolyesterYarn

The invention provides a production technology of a high-elasticity water absorption and quick-dry smooth fabric to solve the problems that high-elasticity water absorption and quick-dry smooth fabricproduction equipment is high in cost, and produced fabrics are easily defected, and belongs to the field of textile. An improved double-sided circular knitting machine is adopted, a first route includes that a cylinder needle is withdrawn to knit cotton yarns along with a knitting cam, pads spandex and then knocks over to form fabric surface yarns; a second route includes that A-needle butt frameneedles of the cylinder needle and a dial needle knit polyester yarns along with a tucking cam to form an interlayer for connecting a fabric surface layer with an inner layer; a third route includesthat all dial needles are withdrawn to knit the polyester yarns along with the knitting cam, pad the spandex and then knock over to form fabric inner yarns; a fourth route includes that all cylinder needles are withdrawn to knit the cotton yarns along with the knitting cam, pad the spandex and then knock over to form fabric surface yarns; a fifth route includes that B-needle butt frame needles ofthe cylinder needles and the dial needles knit the polyester yarns along with the tucking cam to form interlayers for connecting surface layers with inner layers; a sixth route includes that the dialneedles are withdrawn to knit the polyester yarns along with the knitting cam, pad the spandex and then knock over to form fabric inner yarns. The fabric produced by the production technology has fewer defects and is smooth and good in extension recovery and water absorption and quick-dry performances.

Owner:青岛颐和针织有限公司 +1

Composite stretch yarn, process and fabric

In a stretch yarn (1) comprising a stretchable core (2) covered by an inelastic fibers sheath (3) the stretchable core (2) comprises first and second fibers (4, 5) that have elastic properties, the first fiber (4) is an elastomer and the second fiber (5) is a polyester based (co)polymer, the amount of the second fiber being in the range of 60-90% (w / w) of the total weight of the fibers of the stretchable core (2); the first and second fibers are connected together at least at a plurality of points (P).

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

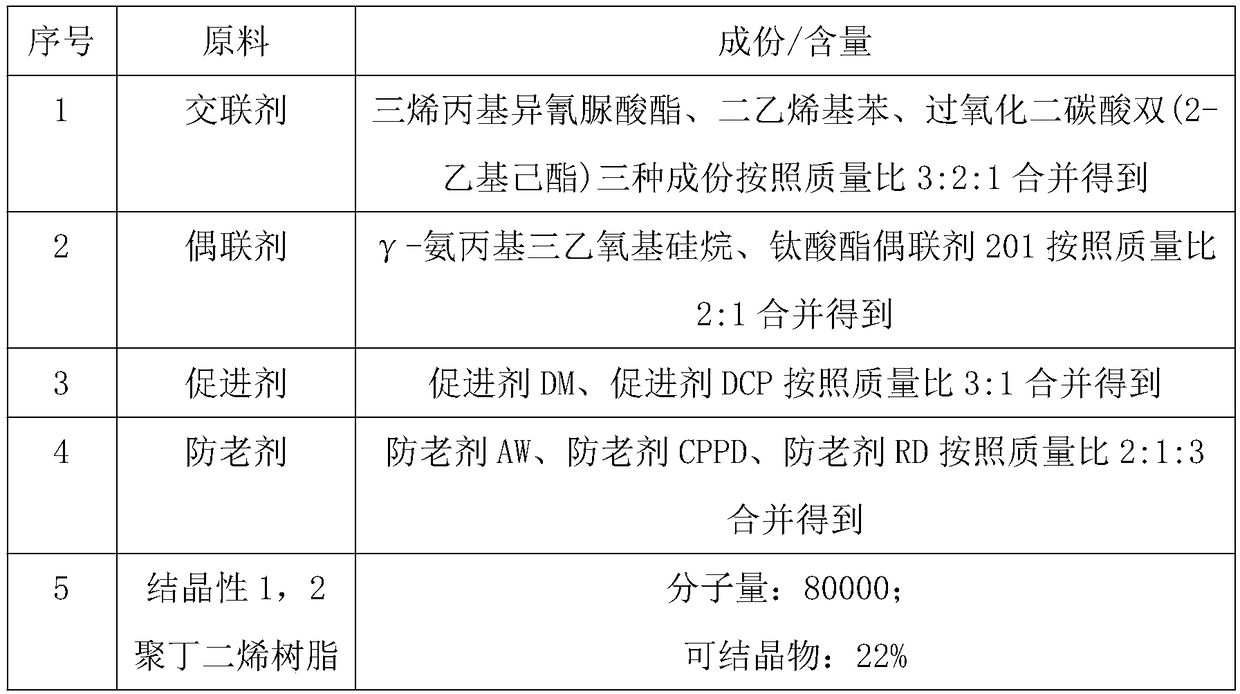

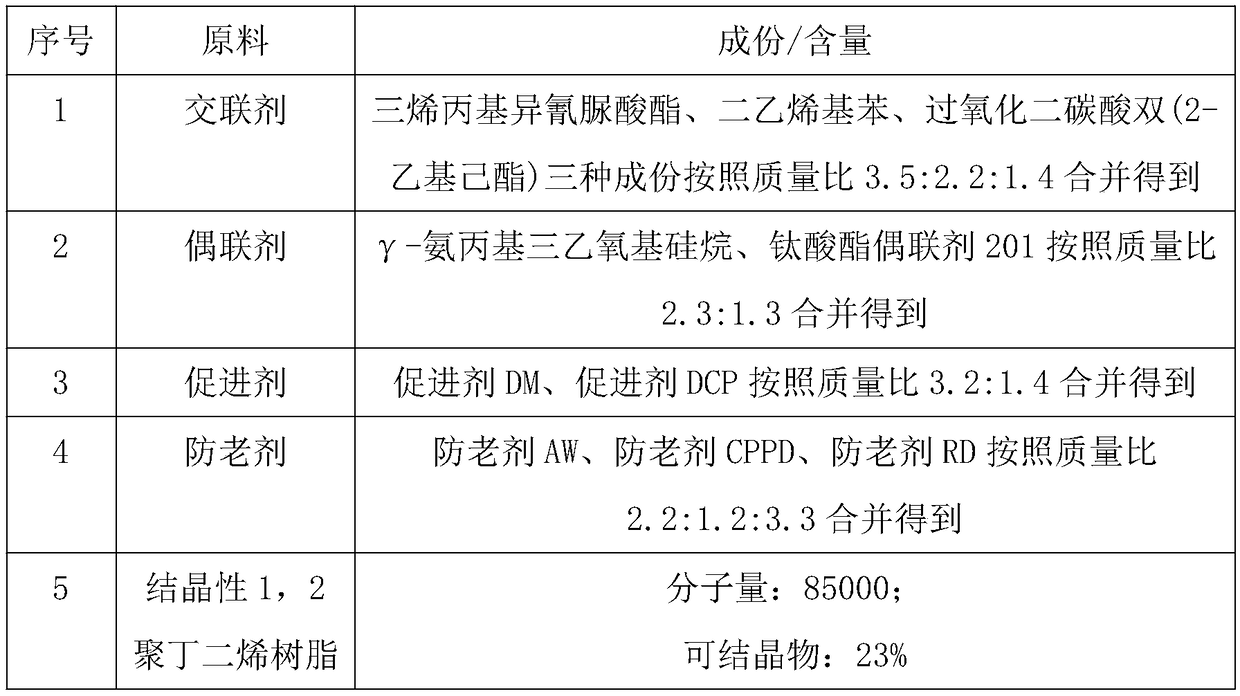

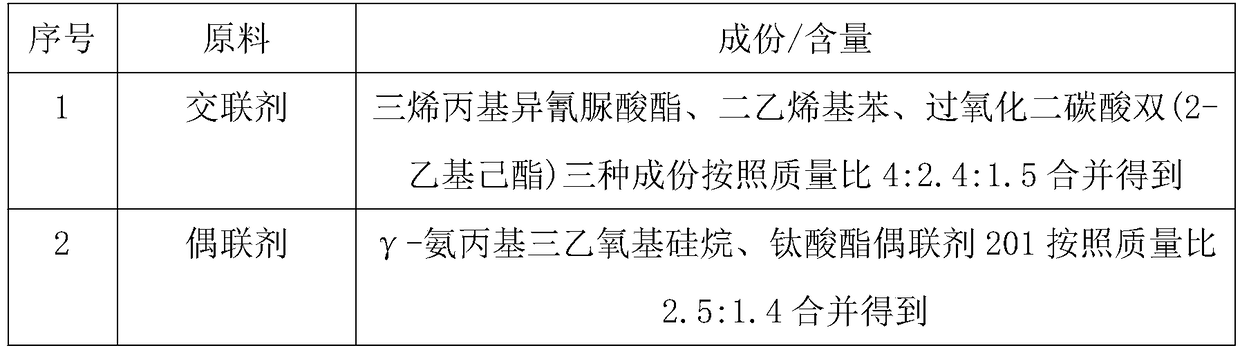

Sealing rubber strip for building curtain walls

ActiveCN108794909AGood compatibilityIncrease productivityOther chemical processesMethacrylateLocust bean gum

The invention discloses a sealing rubber strip for building curtain walls and relates to the technical field of building sealing rubber strips. The sealing rubber strip for building curtain walls is made from chlorosulfonated polyethylene rubber, hydrogenated nitrile butadiene rubber, crystalline 1,2-polybutadiene resin, methylisothiazolinone, tris(butoxyethyl)phosphate, neopentanediol dimethacrylate, locust bean gum, sepiolite fabric, palygorskite powder, a crosslinking agent, a coupling agent, an accelerant, and an anti-aging agent. The sealing rubber strip is convenient and simple to prepare; the sealing rubber strip has compact and stable structure, good sealing performance, flame retardance, tolerance to high and low temperatures, good mechanical performance, heat insulation, sound insulation, insect-dispelling property, mildew resistance, good energy efficiency and environmental friendliness, wide applicable range, and long service life.

Owner:佛山周信密封条制品有限公司

Skin-ice smooth high-elasticity knitted fabric and weaving method thereof

PendingCN113981598AReasonable structureWith stiffnessWeft knittingHeating/cooling textile fabricsYarnPolymer science

The invention relates to a skin-ice smooth high-elasticity knitted fabric. The knitted fabric comprises surface layer yarns and bottom layer yarns; in a four-way triangular structure of the knitted fabric, a first way and a second way are the surface layer yarns, a third way and a fourth way are the bottom layer yarns, the first way is a floating thread, looping, looping and floating thread weaving structure cycle, the second way is a looping, floating thread, floating thread and looping weaving structure cycle, the third way is a floating thread, floating thread, looping and looping weaving structure cycle, and the fourth wasy is looping, looping, floating thread and floating thread weaving structure cycle. By means of the high-stitch-length double-face structure, the fabric has certain stiffness and smoothness and is not thick and heavy; according to the invention, environment-friendly superfine regenerated fibers and chinlon / spandex wrapped filament fibers with good rebound resilience are selected; the superfine regenerated fibers are smooth in hand feeling, good in moisture absorption and moisture permeability and good in dyeing performance, so that the fabric has elegant luster like real silk; the polyamide fiber is excellent in wear resistance and durability, good in hygroscopicity and very good in stretching restorability.

Owner:NINGBO DAQIAN TEXTILE

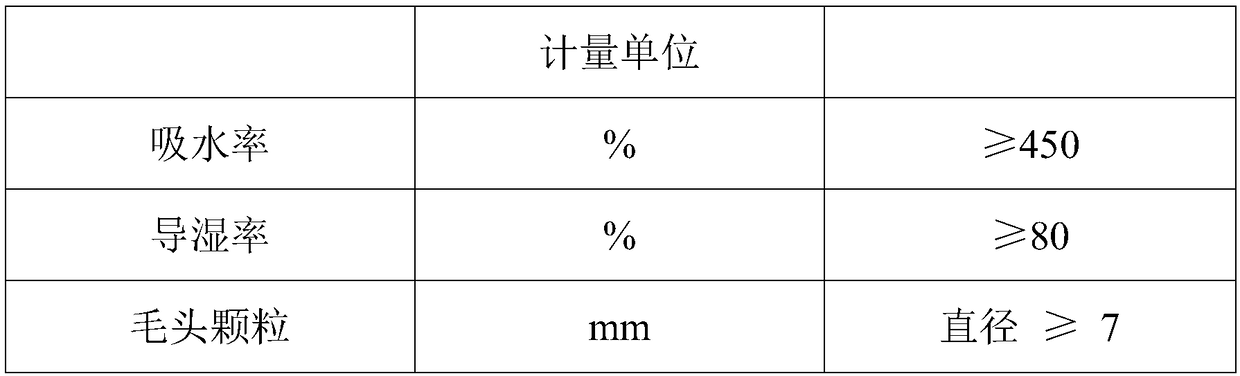

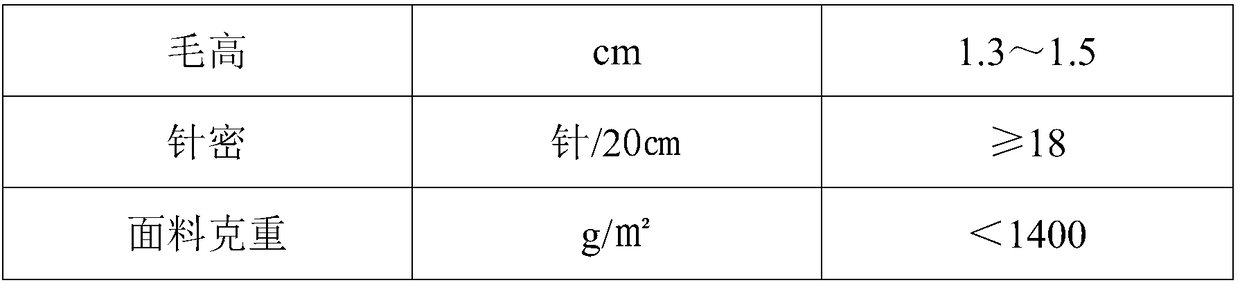

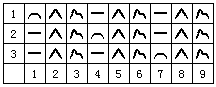

Preparation method of super-water-absorption and high-elasticity fluffy chenille fabric

InactiveCN108103690AGood fastnessGood stretch recoveryYarnEmbroidering machines apparatusPolyesterYarn

The invention relates to a preparation method of a super-water-absorption and high-elasticity fluffy chenille fabric and belongs to the technical field of spinning. Core yarns adopting polyester filaments and velvet yarns are prepared from the following fiber components in percentage by weight: 17 to 29 percent of PTT (Poly(trimethylene terephthalate)) staple filaments, 21 to 35 percent of polyester and nylon composite filaments and 36 to 58 percent of polyester network filaments; two 16S / 2 or four 16S core yarns are used as core threads. The prepared fluffy yarns are dyed at 120 to 140 DEG Cfor 1 to 2.5h; polyester is selected as a grey fabric spinning material and the dyed fluffy yarns are yarns of a velvet layer and are tufted on a bottom fabric; a tufting machine has the needle distance of 10 to 14 needles / 10cm, the needle height of 1.5 to 1.7cm, the needle width of 0.95 to 1cm, the needle speed of 1.2 to 1.8m / min and the width of 100 to 120cm. By adopting the preparation method,the chenille textile fabric has the advantages of good stretching recovery, free extending, no compression and no tension and has the effects of high elasticity, high fluffiness and high water absorption performance.

Owner:JINHUA JIELING HOUSE WARES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com