Spinning method of super-strong absorbent high elastic shaggy chenille yarn

A technology of chenille yarn and high elasticity, which is applied in the spinning field of super-absorbent and high-elastic fluffy chenille yarn to achieve the effects of free stretching, good stretch recovery and good fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention provides a method for spinning superabsorbent and high-elastic fluffy chenille yarn.

[0015] Chenille yarn is composed of many short yarns and two complete, fine and strong yarns holding these short yarns. The short yarn is called velvet yarn, and the two yarns holding the velvet yarn are called core yarns. This kind of yarn looks like a rope from the outside, and it is covered with fluff, so chenille yarn is also called chenille yarn. The core yarn generally uses two yarns with better strength, and the commonly used raw materials are cotton, viscose, acrylic and polyester. The cashmere yarn can be made of the same raw material as the core yarn, or it can be different.

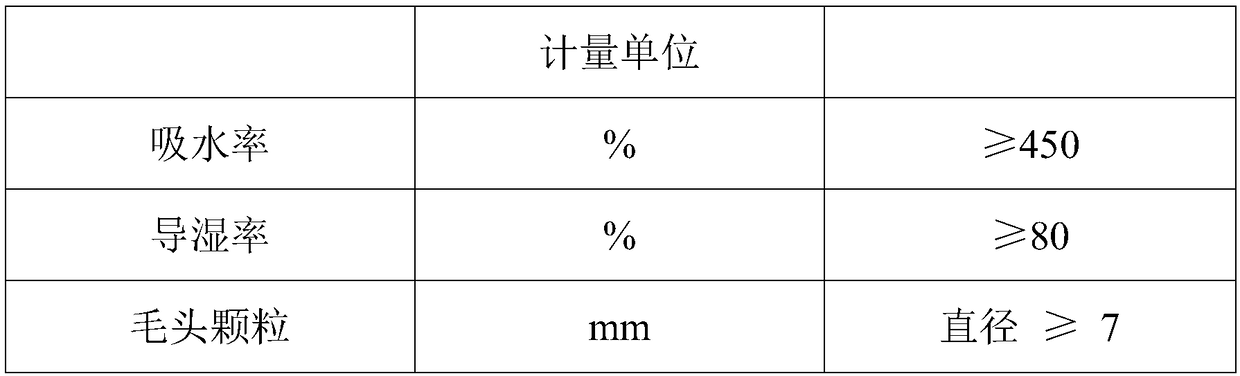

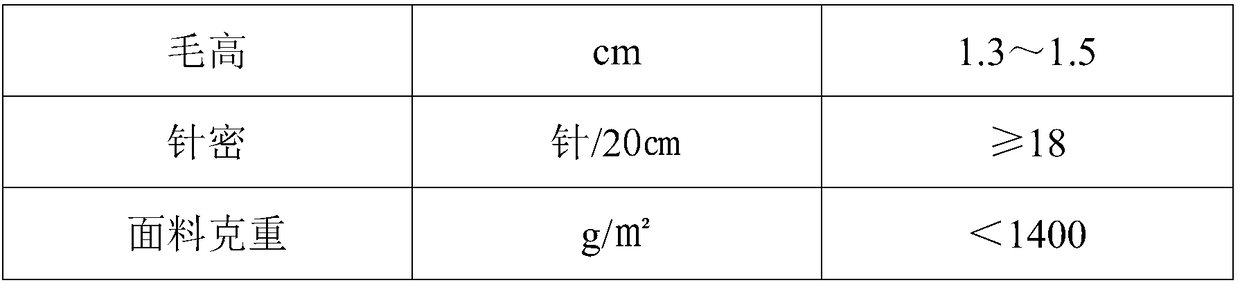

[0016] The core yarn of the invention adopts polyester filaments, and the fiber components in the velvet yarn account for 17-29% of PTT short filaments, 21-35% of polyester-nylon composite filaments, and 36-58% of polyester network filaments.

[0017] In terms of high water absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com