Sealing rubber strip for building curtain walls

A technology for sealing rubber strips and curtain walls, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of high cost, untidy appearance, poor water tightness and air tightness of silicone structural glue, etc., and achieves high production efficiency. Good compatibility of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment relates to a kind of sealant strip for building curtain wall and its preparation method, and this sealant strip is made up of following raw material by weight:

[0045] 58 parts of chlorosulfonated polyethylene rubber;

[0046] 25 parts of hydrogenated nitrile rubber;

[0047] 12 parts of crystalline 1,2 polybutadiene resin;

[0048] 3 parts of methylisothiazolinone;

[0049] 4 parts of tris (butoxyethyl) phosphate;

[0050] 5 parts of neopentyl glycol dimethacrylate;

[0051] 8 parts locust bean gum;

[0052] 2 parts meerschaum;

[0053] 10 parts of palygorskite powder;

[0054] 2.5 parts of crosslinking agent;

[0055] 0.6 parts of coupling agent;

[0056] Accelerator 1 part;

[0057] Anti-aging agent 1 part.

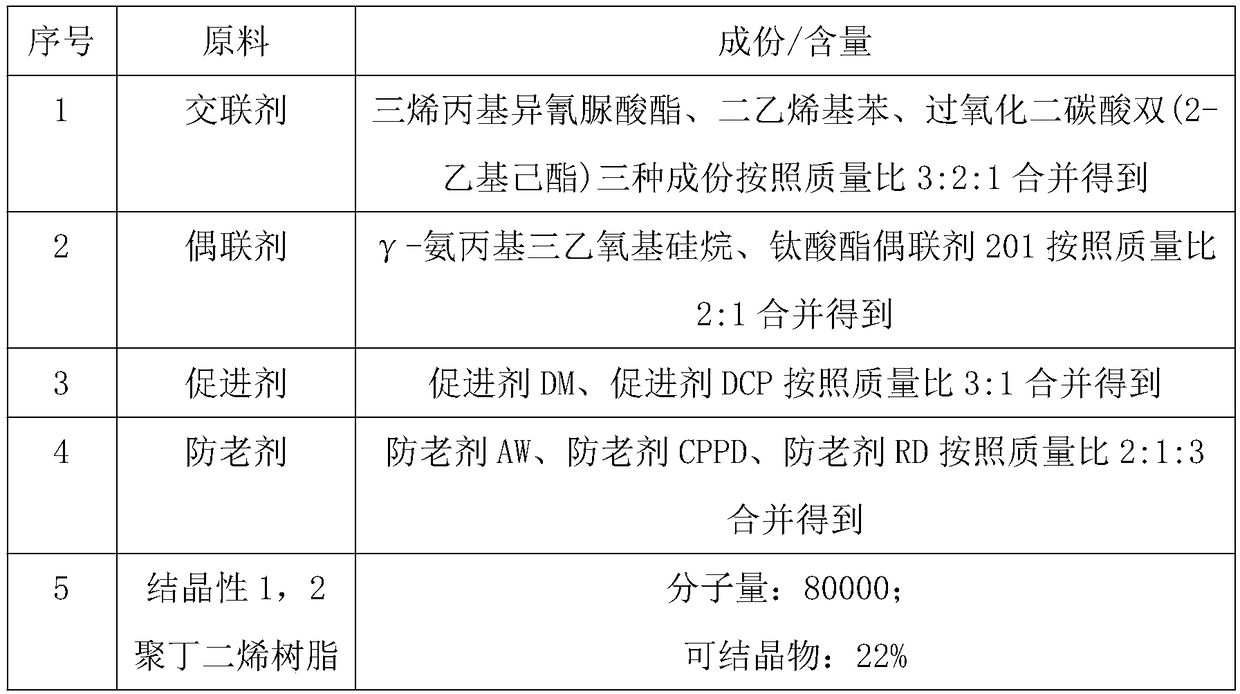

[0058] The selection of cross-linking agent, coupling agent, accelerator and anti-aging agent in the above raw materials is shown in Table 1 below:

[0059] Table 1

[0060]

[0061] The preparation method of the above-mentioned sea...

Embodiment 2

[0066] This embodiment relates to a kind of sealant strip for building curtain wall and its preparation method, and this sealant strip is made up of following raw material by weight:

[0067] 60 parts of chlorosulfonated polyethylene rubber;

[0068] 28 parts of hydrogenated nitrile rubber;

[0069] 14 parts of crystalline 1,2 polybutadiene resin;

[0070] 3.5 parts of methylisothiazolinone;

[0071] 5 parts of tris (butoxyethyl) phosphate;

[0072] 6 parts of neopentyl glycol dimethacrylate;

[0073] 9 parts of locust bean gum;

[0074] 2.4 parts of meerschaum;

[0075] 12 parts of palygorskite powder;

[0076] 3 parts of cross-linking agent;

[0077] 0.7 parts of coupling agent;

[0078] Accelerator 1.2 parts;

[0079] 1.4 parts of anti-aging agent;

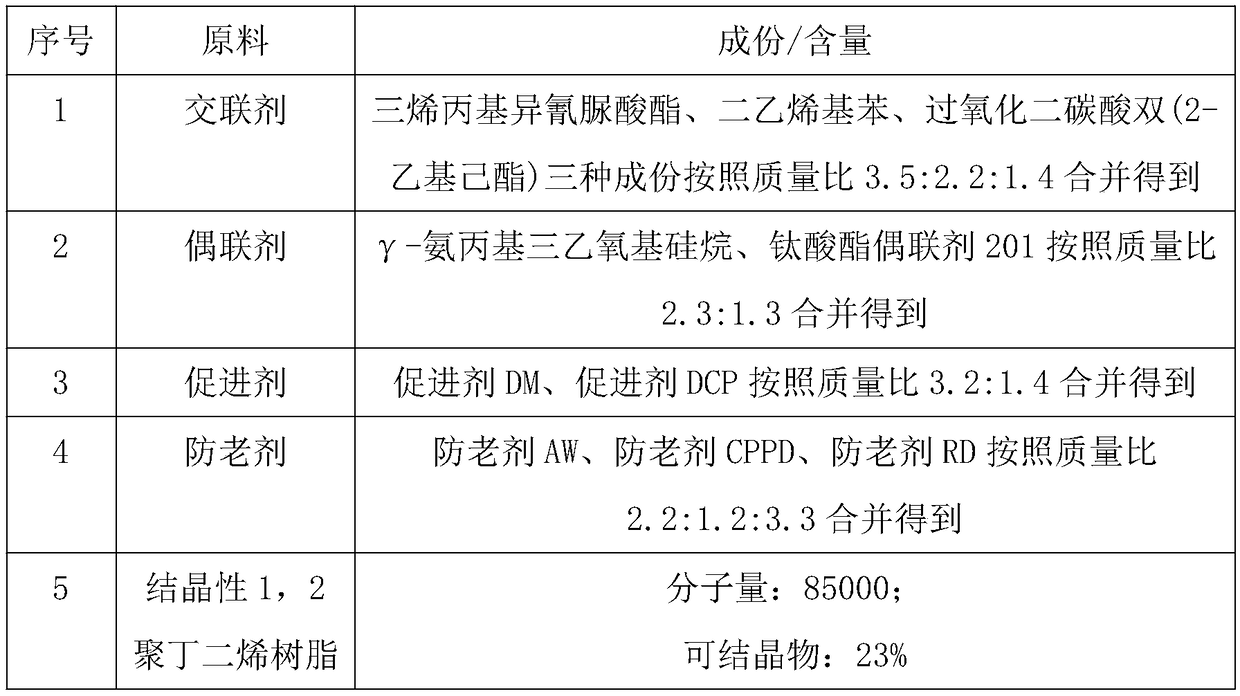

[0080] The selection of cross-linking agent, coupling agent, accelerator and anti-aging agent in the above raw materials is shown in Table 2 below:

[0081] Table 2

[0082]

[0083] The preparation method of the...

Embodiment 3

[0088] This embodiment relates to a kind of sealant strip for building curtain wall and its preparation method, and this sealant strip is made up of following raw material by weight:

[0089] 61 parts of chlorosulfonated polyethylene rubber;

[0090] 30 parts of hydrogenated nitrile rubber;

[0091] 15 parts of crystalline 1,2 polybutadiene resin;

[0092] 4 parts of methylisothiazolinone;

[0093] 6 parts of tris (butoxyethyl) phosphate;

[0094] 7 parts of neopentyl glycol dimethacrylate;

[0095] Locust bean gum 10 parts;

[0096] 2.7 parts of meerschaum;

[0097] 13 parts of palygorskite powder;

[0098] 3.3 parts of crosslinking agent;

[0099] 0.8 parts of coupling agent;

[0100] Accelerator 1.3 parts

[0101] Antiaging agent 1.5 parts.

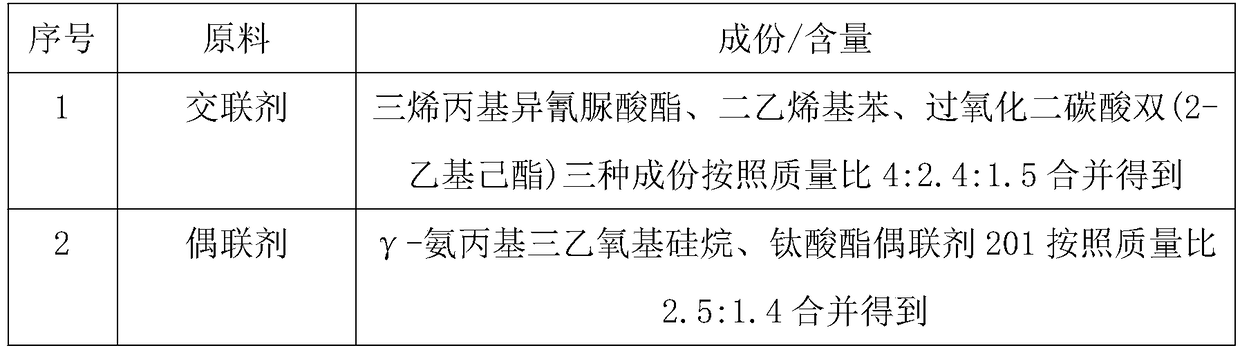

[0102] The selection of cross-linking agent, coupling agent, accelerator and anti-aging agent in the above raw materials is shown in Table 3 below:

[0103] table 3

[0104]

[0105]

[0106] The preparation method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com