Cotton polyurethane light side-stretch high-end fabric preparation method

A four-way elastic and fabric technology, applied in the direction of dyeing, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of hard and astringent hand feeling, poor elastic recovery, etc., to reduce contact friction, release binding force, and improve Effects of vertical and lateral elasticity and stretch recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

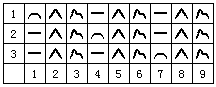

[0014] Example 1, such as figure 1 and figure 2 As shown, a method for preparing a cotton-spandex light four-way elastic high-grade fabric, the fabric includes terry yarn, intermediate yarn and ground yarn, and also includes the following steps, step A: select cotton yarn as the ground yarn raw material, and select spandex monofilament as Intermediate yarn raw material, select cotton yarn and cotton yarn as terry yarn raw material, and then weave ground yarn, intermediate yarn and terry yarn into fabric gray fabric through circular weft knitting machine, the ground yarn is S twist or Z twist in the weaving process, The loop yarn is fed with Z twist or S twist opposite to the ground yarn, and the intermediate yarn is directly fed into the loop formed by the ground yarn and the loop yarn in the form of monofilament. Among them, in the 9-way triangular structure, 1, 4 , The 7th road is loop yarn, the 1st road is tuck, float, float weaving structure cycle, the 4th road is float,...

Embodiment 2

[0016] Example 2, such as figure 1 and figure 2 As shown, a method for preparing a cotton-spandex light four-way elastic high-grade fabric, the fabric includes terry yarn, intermediate yarn and ground yarn, and also includes the following steps, step A: select cotton yarn as the ground yarn raw material, and select spandex monofilament as Intermediate yarn raw material, select cotton yarn and cotton yarn as terry yarn raw material, and then weave ground yarn, intermediate yarn and terry yarn into fabric gray fabric through circular weft knitting machine, the ground yarn is S twist or Z twist in the weaving process, The loop yarn is fed with Z twist or S twist opposite to the ground yarn, and the intermediate yarn is directly fed into the loop formed by the ground yarn and the loop yarn in the form of monofilament. Among them, in the 9-way triangular structure, 1, 4 , The 7th road is loop yarn, the 1st road is tuck, float, float weaving structure cycle, the 4th road is float,...

Embodiment 3

[0018] Example 3, such as figure 1 and figure 2 As shown, a method for preparing a cotton-spandex light four-way elastic high-grade fabric, the fabric includes terry yarn, intermediate yarn and ground yarn, and also includes the following steps, step A: select cotton yarn as the ground yarn raw material, and select spandex monofilament as Intermediate yarn raw material, select cotton yarn and cotton yarn as terry yarn raw material, and then weave ground yarn, intermediate yarn and terry yarn into fabric gray fabric through circular weft knitting machine, the ground yarn is S twist or Z twist in the weaving process, The loop yarn is fed with Z twist or S twist opposite to the ground yarn, and the intermediate yarn is directly fed into the loop formed by the ground yarn and the loop yarn in the form of monofilament. Among them, in the 9-way triangular structure, 1, 4 , The 7th road is loop yarn, the 1st road is tuck, float, float weaving structure cycle, the 4th road is float,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com